Extruded brass combines exceptional durability, conductivity, and aesthetic appeal, making it an ideal material for countless industrial and commercial applications. This versatile manufacturing process creates precise, uniform brass profiles with superior mechanical properties compared to cast alternatives. At MAIKONG, we specialize in custom extruded brass components that deliver exceptional performance across plumbing systems, electrical components, and architectural elements.

What is Extruded Brass and How is it Manufactured?

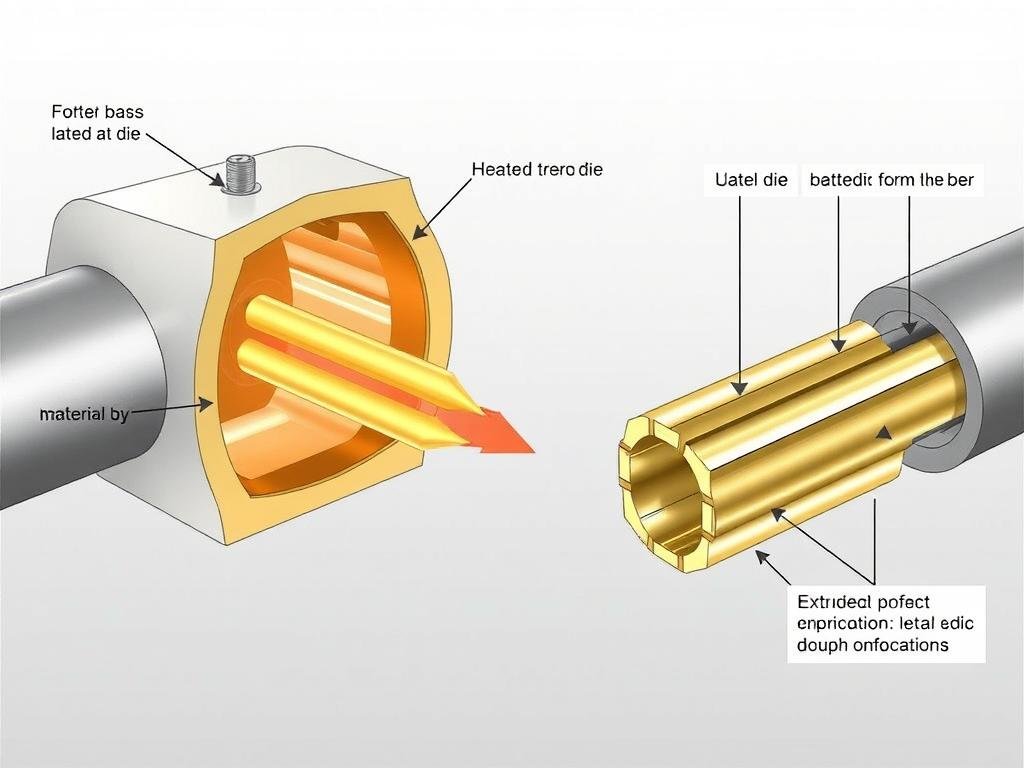

Extruded brass is created through a metal working process where brass alloy is heated and forced through a die to create a specific cross-sectional profile. This manufacturing technique produces components with consistent dimensions, excellent surface finish, and enhanced mechanical properties compared to casting or other forming methods.

The Extruded Brass Manufacturing Process

The extrusion process begins with selecting the appropriate brass alloy based on the desired properties and application requirements. The brass is then heated to increase ductility before being forced through a precision-engineered die under high pressure. This creates a continuous length of material with a uniform cross-section that can be cut to the required dimensions.

At MAIKONG, our advanced extrusion equipment allows us to produce complex profiles with tight tolerances, ensuring consistent quality across production runs. Our process engineers optimize each parameter to achieve the ideal balance of mechanical properties and surface finish.

Types of Extruded Brass Processes

| Extrusion Type |

Process Description |

Advantages |

Best Applications |

| Direct Extrusion |

Billet and ram move in the same direction, creating friction between billet and container |

Simple process, low cost per component, good for high volumes |

Simple shapes, longer components, plumbing fittings |

| Indirect Extrusion |

Punch and billet move in opposite directions with minimal friction |

Requires less force, minimal friction, durable container |

Complex profiles, electrical connectors |

| Impact Extrusion |

Suitable for creating hollow brass items like cups |

Ideal for thin-walled tubes, simple process, low tooling cost |

Thin-walled components, decorative elements |

| Hydrostatic Extrusion |

Uses fluid as pressure medium with no billet-container contact |

No friction, suitable for brittle materials, room temperature operation |

Precision components, architectural details |

Key Advantages of Extruded Brass Components

Advantages of Extruded Brass

- Efficient mass production with short cycle times

- Wide range of possible cross-sectional profiles

- Superior corrosion resistance compared to cast brass

- Enhanced machinability for secondary operations

- Dense grain structure with excellent mechanical properties

- High dimensional accuracy for complex parts

- Excellent thermal and electrical conductivity

- Attractive appearance with minimal finishing required

Limitations to Consider

- Higher initial setup costs for tooling and dies

- Requires significant force for the extrusion process

- Not economical for very small production runs

- Cross-section remains uniform throughout the length

- Some complex geometries may require secondary operations

Need Custom Extruded Brass Components?

MAIKONG specializes in high-quality brass extrusions with competitive pricing and quick turnaround times. Our engineering team can help optimize your design for manufacturability and cost-efficiency.

Contact Us on WhatsApp

Email for Quote

Extruded Brass in Plumbing Applications

The exceptional corrosion resistance, durability, and machinability of extruded brass make it an ideal material for plumbing components. Its natural antimicrobial properties also help inhibit bacterial growth, making it a hygienic choice for water systems.

Common Plumbing Applications for Extruded Brass

Fittings & Connectors

Pipe fittings, connectors, adapters, and unions benefit from the excellent machinability and thread-forming capabilities of extruded brass.

Valves & Controls

Ball valves, gate valves, and control components rely on the durability and precision of extruded brass for reliable operation.

Specialty Components

Pressure regulators, backflow preventers, and custom components benefit from the versatility and performance of extruded brass.

Why Choose Extruded Brass for Plumbing Applications?

- Corrosion Resistance: Exceptional resistance to water corrosion, ensuring long service life

- Lead-Free Options: Available in lead-free formulations for potable water applications

- Antimicrobial Properties: Natural ability to inhibit bacterial growth on surfaces

- Thermal Stability: Maintains integrity across a wide temperature range

- Excellent Machinability: Easily machined for precise threads and connections

Corrosion Resistance

4.8/5

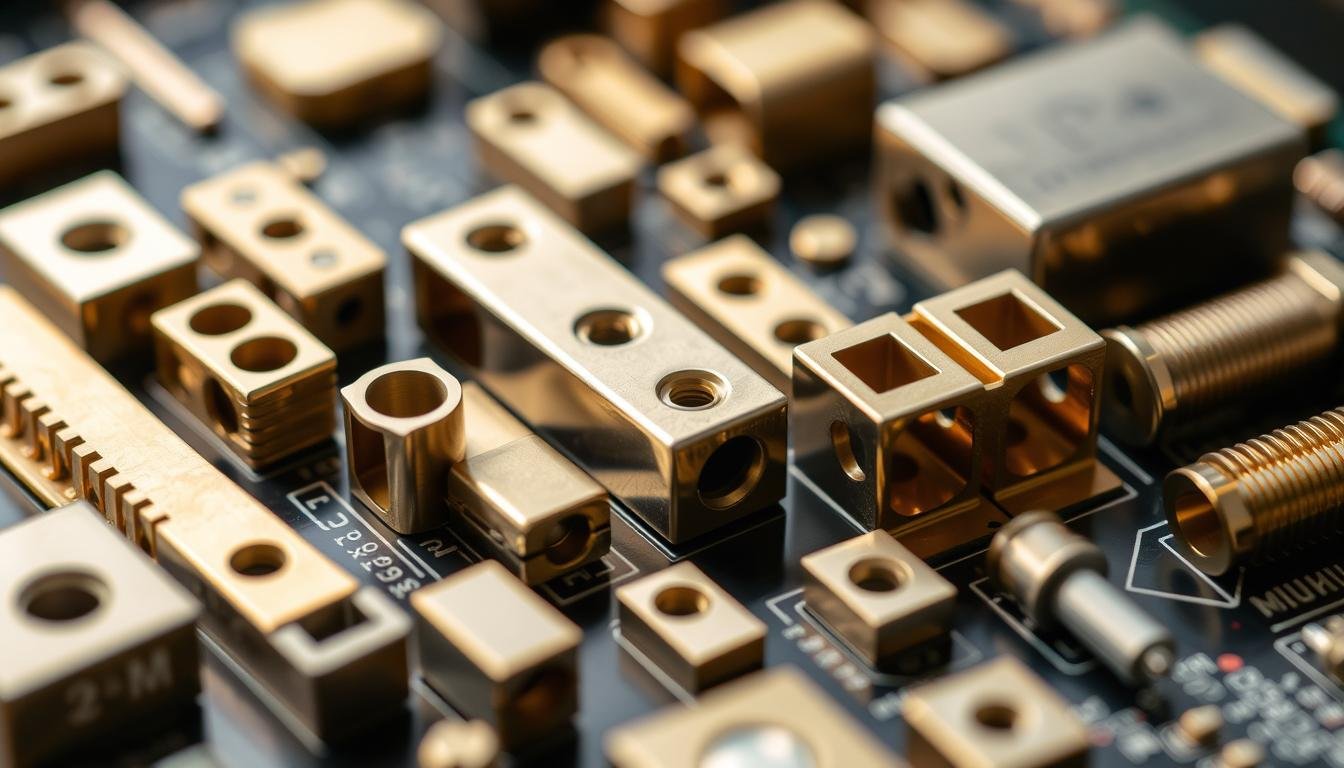

Extruded Brass in Electrical Applications

The exceptional electrical conductivity of extruded brass makes it an excellent choice for various electrical components. With approximately 28% of the conductivity of pure copper but with enhanced strength and machinability, brass extrusions provide an ideal balance of performance and manufacturability.

Key Electrical Applications for Extruded Brass

Terminals & Connectors

Terminal blocks, battery terminals, and electrical connectors benefit from the conductivity and corrosion resistance of extruded brass.

Switch Components

Contact points, switch housings, and mechanical elements in switches rely on the durability and conductivity of extruded brass.

Conductive Hardware

Bus bars, grounding components, and conductive fasteners leverage the excellent conductivity and machinability of extruded brass.

Comparing Extruded Brass to Alternative Materials for Electrical Applications

| Property |

Extruded Brass |

Copper |

Aluminum |

Steel |

| Electrical Conductivity |

Excellent (28% of copper) |

Superior (100%) |

Good (61% of copper) |

Poor (3-15% of copper) |

| Machinability |

Excellent |

Good |

Very Good |

Fair |

| Corrosion Resistance |

Very Good |

Good |

Good (with oxide layer) |

Poor (requires coating) |

| Strength |

High |

Moderate |

Moderate |

Very High |

| Cost |

Moderate |

High |

Low |

Low |

Need Custom Electrical Components?

MAIKONG specializes in precision extruded brass components for electrical applications. Our engineering team can help optimize your design for conductivity, durability, and cost-efficiency.

Explore Our Capabilities

Call Us: 8613-51090-74-01

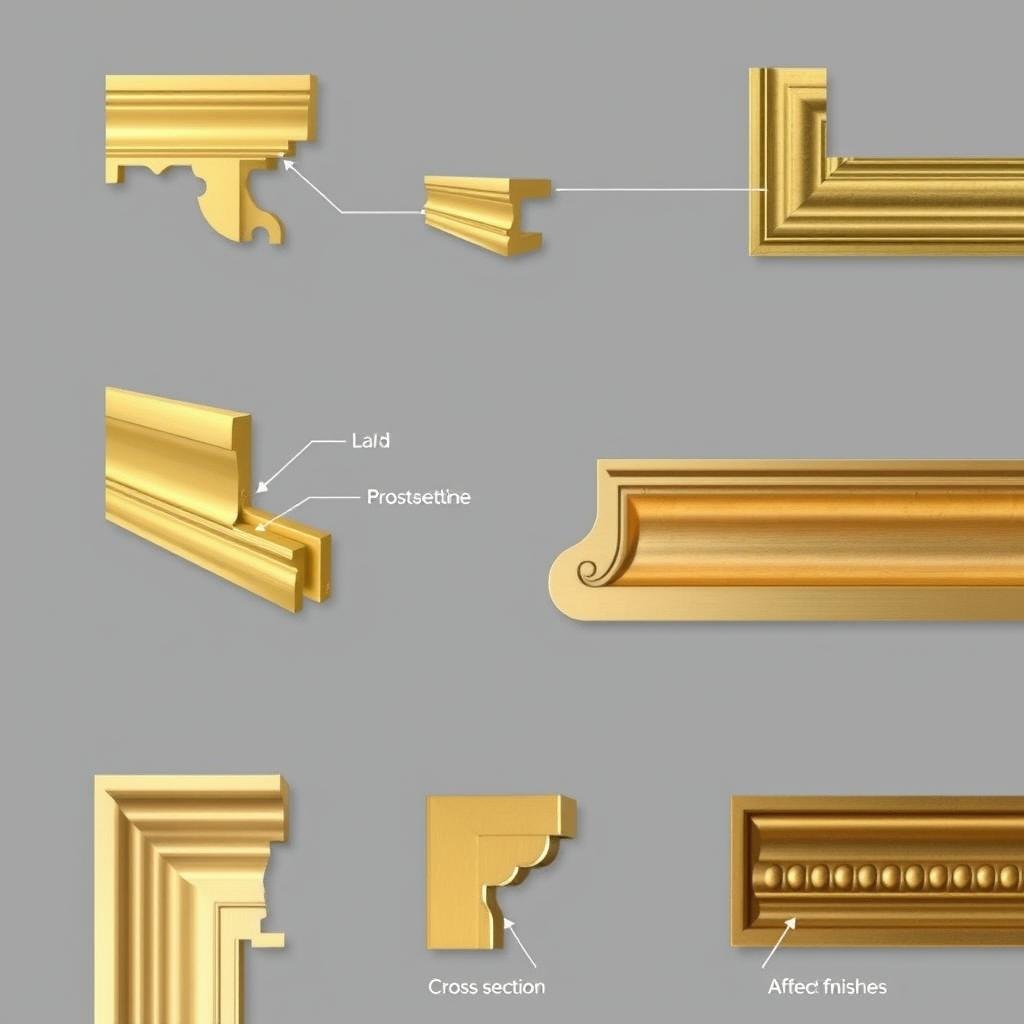

Extruded Brass in Architectural Applications

The timeless aesthetic appeal, durability, and versatility of extruded brass make it a preferred material for architectural applications. From decorative elements to functional hardware, brass extrusions combine beauty with performance.

Popular Architectural Applications for Extruded Brass

Railings & Fixtures

Handrails, balustrades, and stair fixtures benefit from the strength and aesthetic appeal of extruded brass profiles.

Trim & Moldings

Decorative trim, corner moldings, and accent pieces showcase the versatility and beauty of extruded brass profiles.

Hardware & Fittings

Door handles, hinges, locks, and decorative hardware components combine functionality with elegance through extruded brass.

Surface Finishes for Architectural Extruded Brass

The appearance and performance of architectural brass can be enhanced through various surface treatments. At MAIKONG, we offer a comprehensive range of finishing options to achieve your desired aesthetic and functional requirements.

| Finish Type |

Description |

Appearance |

Best Applications |

| Polished |

Highly reflective mirror-like surface |

Bright, shiny golden appearance |

Decorative elements, luxury fixtures |

| Brushed/Satin |

Unidirectional satin texture |

Subdued luster with visible grain |

Modern interiors, high-touch surfaces |

| Antiqued/Patinated |

Chemical treatment to create aged appearance |

Darkened with highlights on raised areas |

Historic restorations, vintage aesthetics |

| Lacquered |

Clear protective coating |

Preserves underlying finish, adds slight gloss |

Preserving appearance, reducing maintenance |

| Oil-Rubbed |

Dark coating with bronze undertones |

Deep brown-black with brass highlights |

Traditional designs, contrast elements |

MAIKONG’s Extruded Brass Manufacturing Capabilities

At MAIKONG, we offer comprehensive manufacturing solutions for custom extruded brass components. Our state-of-the-art facility in GD, SZ combines advanced extrusion technology with precision CNC machining capabilities to deliver high-quality brass components that meet your exact specifications.

Our Comprehensive Manufacturing Services

CNC Machining Services

- CNC Turning for cylindrical components

- CNC Milling for complex geometries

- Swiss-type machining for precision small parts

- Multi-axis machining capabilities

- Surface grinding and finishing

- Laser engraving for markings

Metal Forging Expertise

- Brass forging for enhanced strength

- Aluminum forging services

- Steel forging capabilities

- Custom metal parts production

- Precision forging techniques

- Heat treatment services

Quality Assurance

- Comprehensive material testing

- Dimensional inspection

- Surface finish verification

- Mechanical property testing

- ISO quality management system

- 100% quality inspection

Best Brass Alloys for Extrusion

We work with a variety of brass alloys to meet your specific application requirements. Our metallurgists can help select the optimal alloy based on your performance needs and cost considerations.

| Alloy |

Composition |

Key Properties |

Recommended Applications |

| C26000 (Cartridge Brass) |

70% Cu, 30% Zn |

Excellent ductility, good strength |

Plumbing components, hardware |

| C27000 (Yellow Brass) |

65% Cu, 35% Zn |

Good formability, moderate strength |

Decorative hardware, trim |

| C35300 (Low-Lead Brass) |

62% Cu, 37% Zn, 0.25% Pb |

Good machinability, low lead content |

Potable water applications |

| C38000 (Architectural Bronze) |

57% Cu, 40% Zn, 3% Pb |

Excellent machinability, good strength |

Architectural components |

| C48500 (Naval Brass) |

60% Cu, 39% Zn, 1% Sn |

Superior corrosion resistance |

Marine hardware, outdoor fixtures |

Become a MAIKONG Distributor in the US

We’re seeking distributors across the United States for our high-quality metal components. Partner with MAIKONG to offer your customers superior extruded brass products at competitive prices.

Contact Our Distribution Team

Quality Factors in Custom Extruded Brass Components

The quality of extruded brass components depends on several critical factors throughout the manufacturing process. At MAIKONG, we carefully control each of these parameters to ensure consistent, high-quality results.

Material Quality

The composition and purity of the brass alloy significantly impact the extrusion process and final product performance. We source only premium-grade materials with verified chemical composition to ensure consistent results.

Temperature Control

Precise temperature management during the extrusion process is essential for achieving optimal grain structure and mechanical properties. Our advanced temperature monitoring systems maintain tight control throughout production.

Extrusion Speed

The rate at which brass is extruded affects surface finish, grain size, and dimensional stability. Our process engineers optimize extrusion speeds for each profile to achieve the ideal balance of productivity and quality.

Die Design

The precision and design of the extrusion die directly impact the quality of the final product. Our tooling specialists create optimized die designs that ensure smooth material flow and precise dimensions.

Cooling Process

Controlled cooling after extrusion prevents distortion and ensures consistent mechanical properties. Our cooling systems are calibrated to the specific requirements of each brass alloy and profile geometry.

Surface Treatment

Post-extrusion finishing operations enhance appearance and performance. From polishing to anodizing, our comprehensive surface treatment capabilities deliver the exact finish your application requires.

Recommended Tolerances for Extruded Brass Parts

Achieving precise dimensional control is critical for functional components. MAIKONG’s advanced extrusion and machining capabilities allow us to maintain tight tolerances across a range of brass profiles.

| Dimension Type |

Standard Tolerance |

Precision Tolerance |

Factors Affecting Tolerance |

| Cross-sectional dimensions |

±0.005″ (±0.127mm) |

±0.002″ (±0.051mm) |

Profile complexity, die wear |

| Length |

±0.030″ (±0.762mm) |

±0.010″ (±0.254mm) |

Cutting method, material temperature |

| Straightness |

0.015″ per foot (1.25mm per meter) |

0.005″ per foot (0.42mm per meter) |

Cooling process, profile symmetry |

| Angularity |

±1° |

±0.5° |

Die design, material flow |

| Surface Finish |

125 μin Ra (3.2 μm) |

63 μin Ra (1.6 μm) |

Die finish, extrusion speed, lubricant |

Conclusion: The Versatility and Value of Extruded Brass

Extruded brass components offer an exceptional combination of performance, aesthetics, and value across plumbing, electrical, and architectural applications. The extrusion process creates products with superior mechanical properties, consistent dimensions, and excellent surface finish, making brass extrusions ideal for demanding applications.

At MAIKONG, we leverage our advanced manufacturing capabilities and metallurgical expertise to deliver custom extruded brass components that meet your exact specifications. From initial design consultation through production and quality control, our team is committed to providing exceptional service and superior products.

Contact us today to discuss your extruded brass requirements or explore opportunities to become a MAIKONG distributor in the United States. Experience the MAIKONG difference in quality, service, and value for all your custom metal component needs.