Premium Brass Extrusion Services: Custom Solutions for Industry Leaders

At MAIKONG, we specialize in high-precision brass extrusion services that meet the most demanding industry requirements. With our advanced manufacturing capabilities and premium Chinese supply chain, we deliver superior quality custom brass extrusions with exceptional cost-effectiveness. Whether you need architectural profiles, industrial components, or specialized shapes, our expert team ensures precision, consistency, and timely delivery for every project.

What is Brass Extrusion?

Brass extrusion is a metalworking process that creates objects with fixed cross-sectional profiles by forcing heated brass through a die of the desired shape. This manufacturing technique produces long, straight metal pieces with excellent surface finish and consistent dimensions throughout their length.

As a specialized brass aluminum forge operation, MAIKONG leverages advanced equipment and technical expertise to produce complex profiles with tight tolerances. Our brass extrusion capabilities extend to a wide range of alloys, dimensions, and custom specifications to meet diverse industrial applications.

Advantages of Brass Extrusion Manufacturing

Benefits of Brass Extrusions

- Superior cost-effectiveness compared to other manufacturing methods

- Excellent machinability and surface finish quality

- High dimensional accuracy and consistency

- Outstanding corrosion resistance and durability

- Exceptional electrical and thermal conductivity

- Versatility in creating complex custom profiles

- Reduced material waste through efficient processing

- Excellent strength-to-weight ratio

Challenges to Consider

- Initial tooling costs for custom profiles

- Minimum order quantities for specialized shapes

- Limited to constant cross-sectional profiles

- Potential for supplier quality inconsistencies

- Overseas shipping considerations

- Communication barriers with some manufacturers

- Variable lead times depending on complexity

- Quality verification requirements

Applications of Brass Extrusions

The versatility of brass extrusions makes them ideal for numerous applications across diverse industries. Our custom brass extrusion services cater to a wide range of sectors where precision, durability, and aesthetic appeal are paramount.

Architectural Applications

- Decorative trim and moldings

- Door and window frames

- Handrails and balustrades

- Wall cladding systems

- Ornamental fixtures

Industrial Applications

- Electrical components

- Heat exchangers

- Plumbing fixtures

- Mechanical components

- Pneumatic systems

Specialized Applications

- Automotive components

- Marine hardware

- Medical equipment

- Electronics housings

- Aerospace parts

MAIKONG’s Brass Extrusion Capabilities

As a leading brass aluminum forging enterprises LLC equivalent in China, MAIKONG offers comprehensive brass extrusion services with state-of-the-art equipment and technical expertise. Our manufacturing capabilities ensure precision, consistency, and exceptional quality for every project.

Technical Specifications

- Extrusion size range: 5mm to 200mm cross-sectional dimension

- Tolerance capabilities: ±0.05mm for precision requirements

- Surface finishes: Natural, polished, brushed, and custom treatments

- Available alloys: C2680, C2800, C3850, C3800, CuZn39Pb3, and custom formulations

- Production capacity: High-volume capabilities with consistent quality

- Custom profile development: From concept to production

Ready to Discuss Your Project?

Our engineering team can help optimize your design for manufacturability and cost-effectiveness.

Contact Our Engineers

Brass Alloys for Extrusion

The performance characteristics of brass extrusions largely depend on the specific alloy composition. At MAIKONG, we work with a variety of brass alloys to meet diverse application requirements, including specialized forging aluminum bronze compositions for enhanced properties.

| Alloy Designation |

Composition |

Properties |

Typical Applications |

| C2680 (Cartridge Brass) |

70% Copper, 30% Zinc |

Excellent formability, good strength |

Decorative hardware, architectural trim |

| C3600 (Free-Cutting Brass) |

61.5% Copper, 35.5% Zinc, 3% Lead |

Superior machinability, moderate strength |

Precision components, gears, valves |

| C3800 (Architectural Bronze) |

57% Copper, 40% Zinc, 3% Lead |

Good corrosion resistance, excellent finish |

Architectural elements, decorative fixtures |

| C38500 (Architectural Bronze) |

57% Copper, 40% Zinc, 3% Lead |

Excellent machinability, good corrosion resistance |

Plumbing fixtures, hardware, marine components |

| CuZn39Pb3 (European Designation) |

58% Copper, 39% Zinc, 3% Lead |

Good strength, excellent machinability |

Industrial components, fasteners |

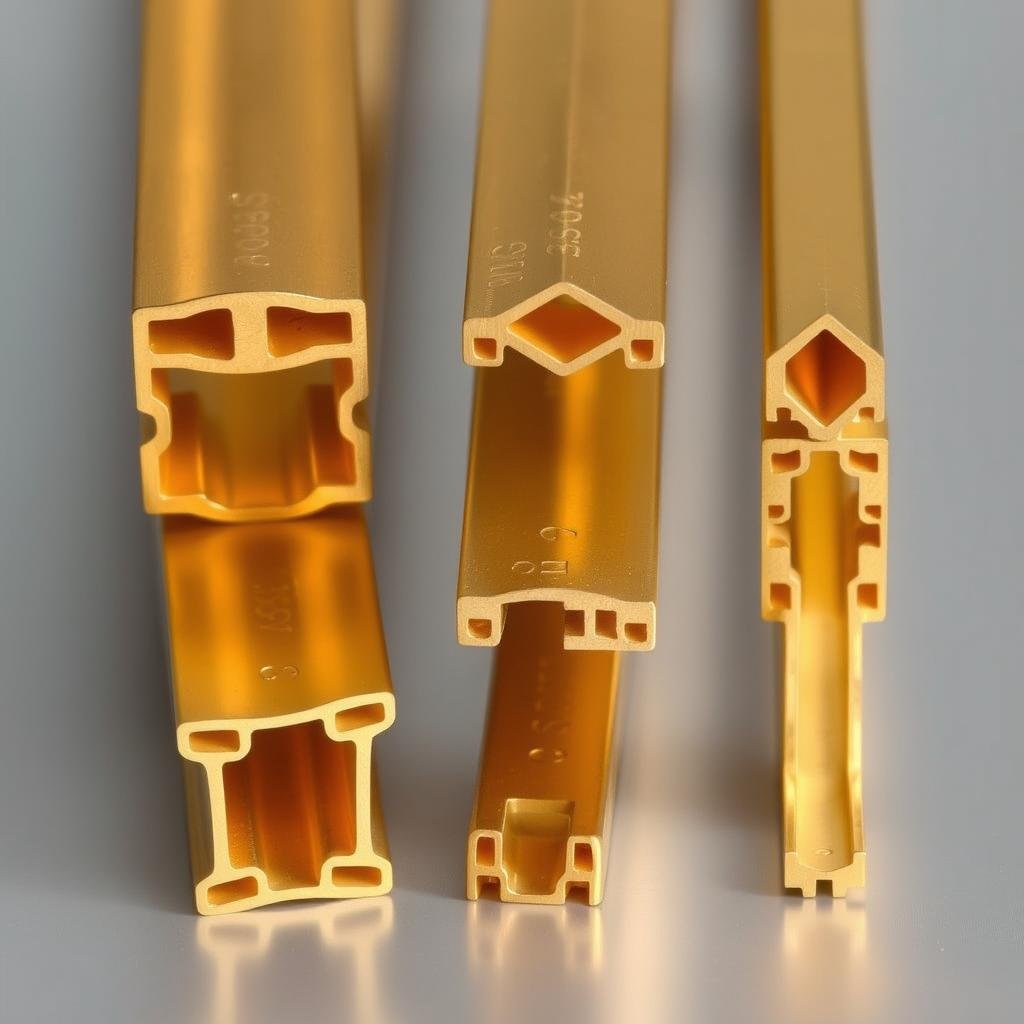

Custom Brass Extrusion Shapes

MAIKONG specializes in producing a wide variety of brass extrusion profiles to meet specific application requirements. Our advanced manufacturing capabilities allow us to create both standard and highly complex custom shapes with precision and consistency.

Standard Profiles

- Round rods and tubes

- Square and rectangular bars

- Hexagonal and octagonal profiles

- Flat bars and strips

- L-shaped angles

Architectural Profiles

- T-shaped profiles

- Decorative moldings

- Handrail components

- Window and door frames

- Skirting and trim pieces

Complex Custom Profiles

- Multi-channel designs

- Interlocking components

- Heat sink profiles

- Custom connector shapes

- Application-specific geometries

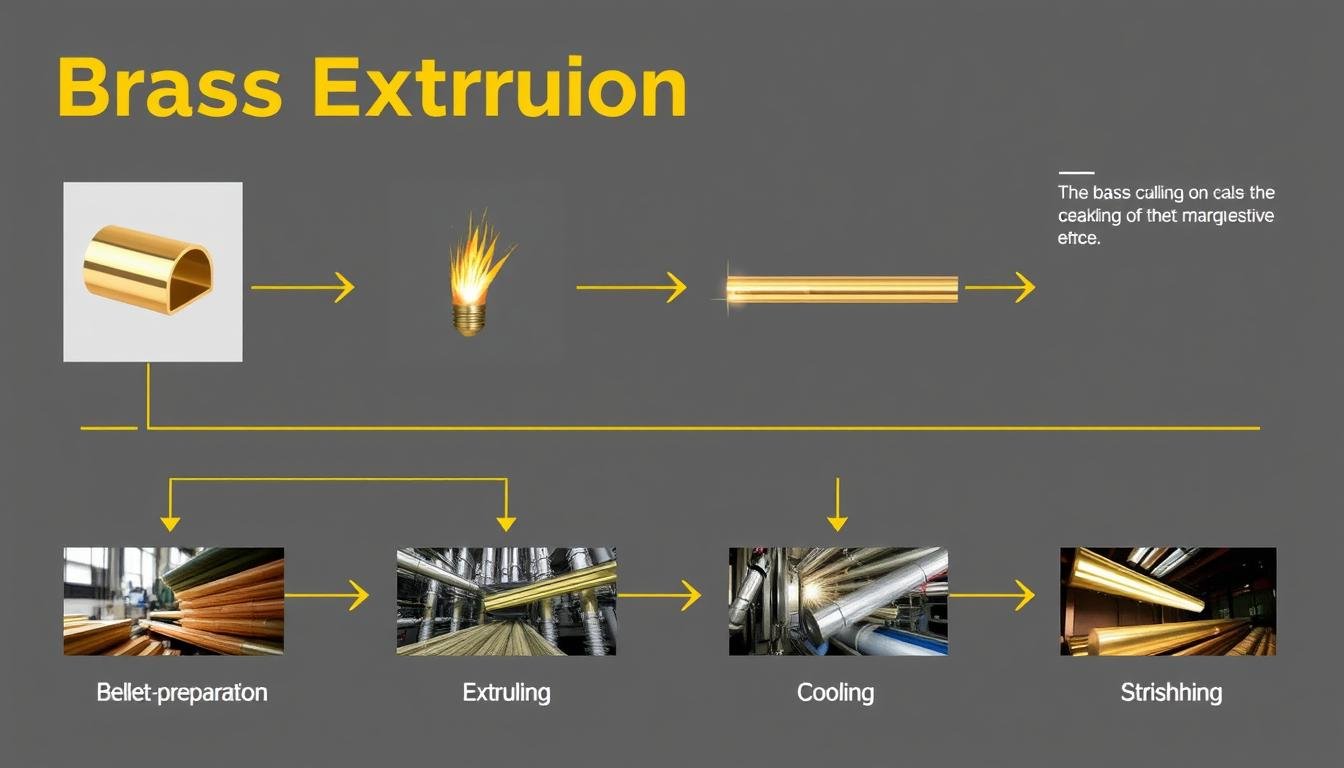

Our Brass Extrusion Manufacturing Process

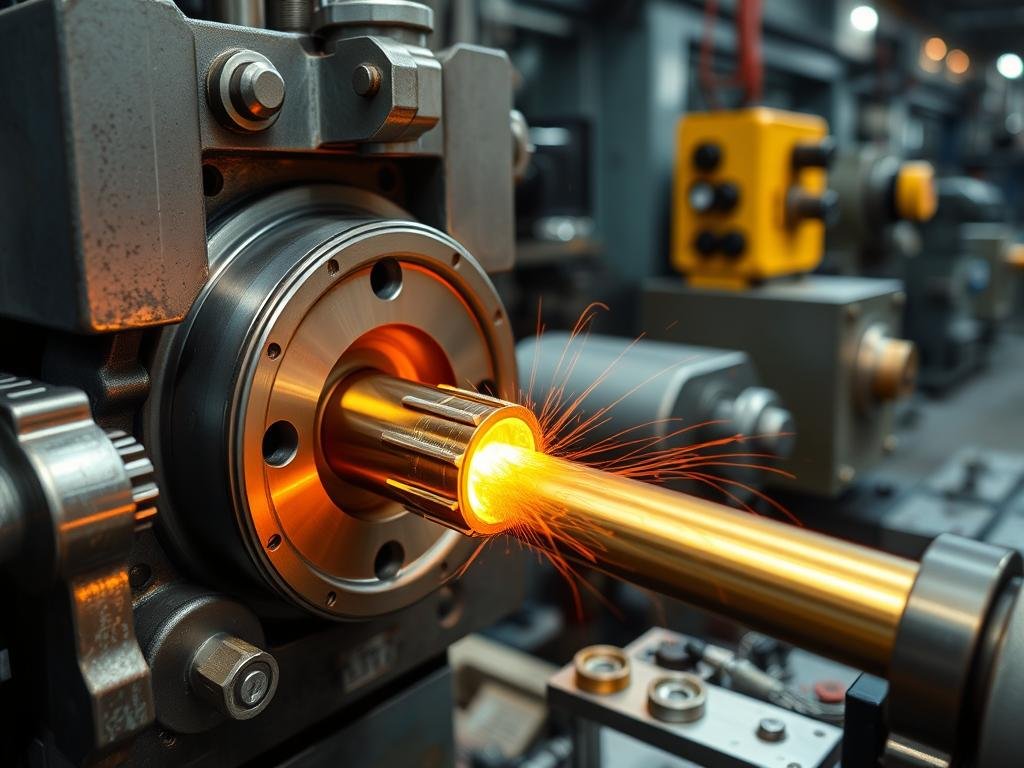

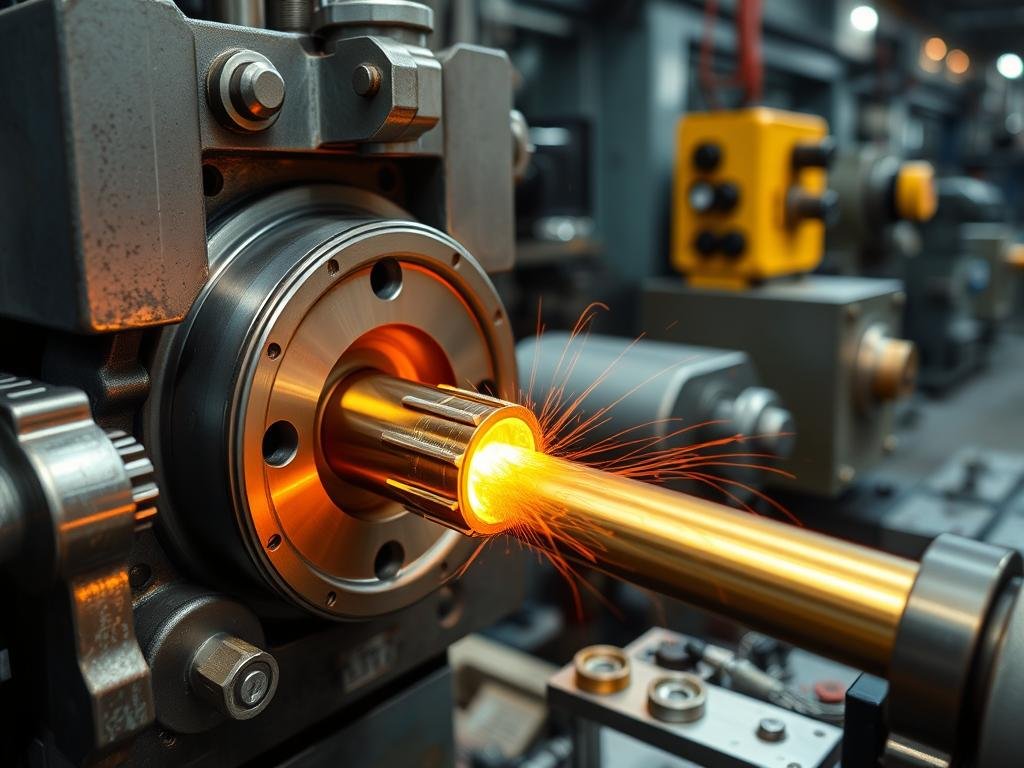

At MAIKONG, we employ a comprehensive brass extrusion process that ensures consistent quality and precision. Our brass aluminum forge operations integrate advanced technologies with traditional metalworking expertise to deliver superior results.

1. Design & Engineering

Our engineering team works closely with clients to optimize designs for manufacturability while maintaining critical specifications.

2. Tooling & Die Preparation

Precision dies are manufactured to exact specifications, ensuring consistent profile dimensions throughout production.

3. Extrusion Process

Heated brass billets are forced through custom dies under controlled pressure to create the desired profiles with precise dimensions.

4. Quality Control

Rigorous inspection ensures all brass extrusions meet dimensional tolerances and surface quality requirements.

Quality Assurance

Every MAIKONG brass extrusion undergoes comprehensive quality control procedures, including dimensional verification, material composition testing, and surface inspection. Our quality management system ensures consistent adherence to specifications and international standards.

Aluminum Bronze Forgings: Enhanced Performance

In addition to traditional brass alloys, MAIKONG specializes in aluminum bronze forgings that offer enhanced performance characteristics for demanding applications. These specialized alloys combine the excellent properties of brass with the additional benefits of aluminum content.

Our expertise in forging aluminum bronze allows us to produce components with superior strength, wear resistance, and corrosion protection, particularly in marine and high-stress environments. The brass aluminum forging upper process creates components with exceptional mechanical properties that outperform standard brass in many applications.

Why Choose MAIKONG for Your Brass Extrusion Needs

Superior Quality

Our state-of-the-art equipment and rigorous quality control procedures ensure consistent, high-quality brass extrusions that meet or exceed industry standards.

Technical Expertise

Our engineering team provides comprehensive technical support, from design optimization to material selection and manufacturing process development.

Cost-Effectiveness

Our premium Chinese supply chain and advanced manufacturing capabilities deliver exceptional value without compromising quality or performance.

“MAIKONG consistently delivers high-quality brass extrusions that meet our exact specifications. Their technical support and customization capabilities have made them an invaluable partner for our manufacturing operations.”

– Manufacturing Director, Industrial Equipment Company

Frequently Asked Questions About Brass Extrusion

What are the minimum order quantities for custom brass extrusions?

Minimum order quantities vary based on profile complexity and dimensions. For standard profiles, we can accommodate smaller orders, while custom profiles may require higher minimums to offset tooling costs. Contact us with your specific requirements for detailed information.

What tolerances can be achieved with brass extrusion?

Our advanced brass extrusion processes can achieve tolerances as tight as ±0.05mm for critical dimensions, depending on the profile complexity and size. Standard tolerances typically range from ±0.1mm to ±0.2mm.

How does the brass extrusion process compare to other manufacturing methods?

Brass extrusion offers several advantages over other manufacturing methods, including cost-effectiveness for long runs, excellent surface finish, consistent cross-sectional dimensions, and minimal material waste. It’s particularly advantageous for producing long, straight components with complex cross-sections.

What surface finishes are available for brass extrusions?

We offer various surface finishes for brass extrusions, including natural (as-extruded), polished, brushed, and custom treatments. Additional finishing options include plating, anodizing, and protective coatings to enhance appearance and performance.