Various aluminum billets ready for processing at MAIKONG’s manufacturing facility

Various aluminum billets ready for processing at MAIKONG’s manufacturing facility

What is Aluminum Billet: Definition and Basic Characteristics

An aluminum billet is a solid semi-finished aluminum product, typically cylindrical in shape, produced through casting processes. It represents the initial stage of aluminum deep processing and serves as the raw material for extrusion, forging, and machining operations. Billets are characterized by their uniform internal structure, consistent dimensions, and specific alloy composition tailored to their intended applications.

At MAIKONG, we work with premium-quality aluminum billets in various sizes and alloy compositions to create precision components for industries ranging from automotive to aerospace. The consistent internal structure of billets makes them ideal for applications requiring high strength, excellent machinability, and superior surface finish.

Need Custom Aluminum Components?

MAIKONG offers expert aluminum processing services with industry-leading quality and competitive pricing.

How Aluminum Billets Are Manufactured

The production of aluminum billets involves several critical stages that determine their quality and performance characteristics. Understanding this process helps appreciate why billets are preferred for high-precision applications.

Aluminum billet casting process at a modern foundry facility

Key Processes in Aluminum Billet Manufacturing

- Raw Material Selection: High-quality aluminum ingots or recycled aluminum is selected based on the desired alloy composition and application requirements.

- Melting and Alloying: The aluminum is melted in furnaces at temperatures exceeding 660°C (1220°F), and specific alloying elements are added to achieve the desired properties.

- Degassing and Filtration: The molten aluminum undergoes degassing to remove hydrogen and other gases, followed by filtration to eliminate impurities.

- Casting: The molten aluminum is poured into molds and cooled under controlled conditions to form billets with consistent dimensions and uniform density.

- Homogenization: The cast billets undergo heat treatment to eliminate microsegregation and ensure uniform distribution of alloying elements.

- Cooling and Quality Control: The billets are cooled and subjected to rigorous quality checks, including ultrasonic testing and chemical analysis.

At MAIKONG, we source only premium-quality aluminum billets that meet stringent specifications, ensuring that our finished components deliver exceptional performance and reliability.

Properties and Characteristics of Aluminum Billets

Understanding the properties of aluminum billets is essential for selecting the right material for specific applications. These properties vary depending on the alloy composition and manufacturing process.

Close-up view of aluminum billet surface showing characteristic metallic texture

Key Physical and Mechanical Properties

Physical Properties

- Density: Typically 2.7 g/cm³, making aluminum billets lightweight compared to steel (7.85 g/cm³)

- Melting Point: Around 660°C (1220°F), varying slightly with alloy composition

- Thermal Conductivity: Excellent (205 W/mK), facilitating heat dissipation

- Electrical Conductivity: High (36 mega-siemens/m), suitable for electrical applications

- Corrosion Resistance: Forms a protective oxide layer that prevents further oxidation

Mechanical Properties

- Tensile Strength: Ranges from 30,000 to 45,000 psi depending on alloy

- Yield Strength: Varies by alloy, typically 25,000-40,000 psi

- Hardness: Moderate, allowing for excellent machinability

- Fatigue Resistance: Good, especially in forged components

- Formability: Excellent, suitable for complex shaping operations

MAIKONG leverages these properties to create high-performance aluminum components that meet the most demanding specifications across various industries.

Common Aluminum Billet Alloys and Their Applications

Different aluminum alloys offer varying properties that make them suitable for specific applications. Here’s an overview of the most common aluminum billet alloys and their typical uses:

| Alloy Series | Key Characteristics | Typical Applications | Strength Level |

| 1000 Series (Pure Aluminum) | High electrical conductivity, excellent corrosion resistance, high ductility | Electrical components, chemical equipment, heat exchangers | Low |

| 2000 Series (Al-Cu) | High strength, good heat resistance, lower corrosion resistance | Aerospace components, military equipment, high-stress structural parts | Very High |

| 3000 Series (Al-Mn) | Moderate strength, good workability, excellent corrosion resistance | Heat exchangers, cooking utensils, roofing materials | Moderate |

| 5000 Series (Al-Mg) | Good strength, excellent corrosion resistance in marine environments | Marine components, storage tanks, pressure vessels | Moderate to High |

| 6000 Series (Al-Mg-Si) | Good strength-to-weight ratio, excellent extrudability, good corrosion resistance | Architectural extrusions, automotive components, structural profiles | Moderate to High |

| 7000 Series (Al-Zn) | Highest strength among aluminum alloys, good machinability | Aerospace structures, high-performance automotive parts, sports equipment | Extremely High |

At MAIKONG, we work with all major aluminum alloy series to provide the optimal material solution for each application. Our metallurgical expertise ensures that we select the right alloy for your specific requirements.

Different aluminum alloy billets used in MAIKONG’s manufacturing processes

Call us at: +86 13510907401Expert advice on selecting the right aluminum alloy for your application

How Aluminum Billets Are Processed

Aluminum billets serve as the starting point for various manufacturing processes. Understanding these processes helps in appreciating the versatility of aluminum billets and their applications.

Precision CNC machining of aluminum billets at MAIKONG’s state-of-the-art facility

Major Processing Methods for Aluminum Billets

Extrusion

Extrusion involves forcing heated aluminum billets through a die to create profiles with consistent cross-sections. This process is ideal for producing long components with complex cross-sectional shapes, such as frames, rails, and structural components.

Forging

Forging applies compressive force to shape aluminum billets, resulting in components with enhanced grain structure and mechanical properties. This process is preferred for high-strength applications in aerospace, automotive, and industrial sectors.

CNC Machining

CNC machining removes material from aluminum billets to create precise components with complex geometries. This versatile process is suitable for producing parts with tight tolerances and excellent surface finishes.

MAIKONG specializes in all these processing methods, offering comprehensive solutions for transforming aluminum billets into high-quality finished components. Our advanced equipment and skilled technicians ensure precision and consistency in every project.

Expert Aluminum Processing Services

From forging to CNC machining, MAIKONG delivers precision aluminum components that meet your exact specifications.

Aluminum Billets vs. Other Manufacturing Materials

When choosing materials for manufacturing, it’s important to understand how aluminum billets compare to alternatives like steel, cast aluminum, and plastic. This comparison helps in making informed decisions based on specific application requirements.

| Characteristic | Aluminum Billets | Steel | Cast Aluminum | Plastic |

| Density | Low (2.7 g/cm³) | High (7.85 g/cm³) | Low (2.7 g/cm³) | Very Low (0.9-1.5 g/cm³) |

| Strength-to-Weight Ratio | Excellent | Good | Moderate | Poor to Moderate |

| Corrosion Resistance | Excellent | Poor (unless treated) | Good | Excellent |

| Machinability | Excellent | Moderate | Good | Excellent |

| Thermal Conductivity | Excellent | Moderate | Good | Poor |

| Cost | Moderate | Low to Moderate | Low | Very Low |

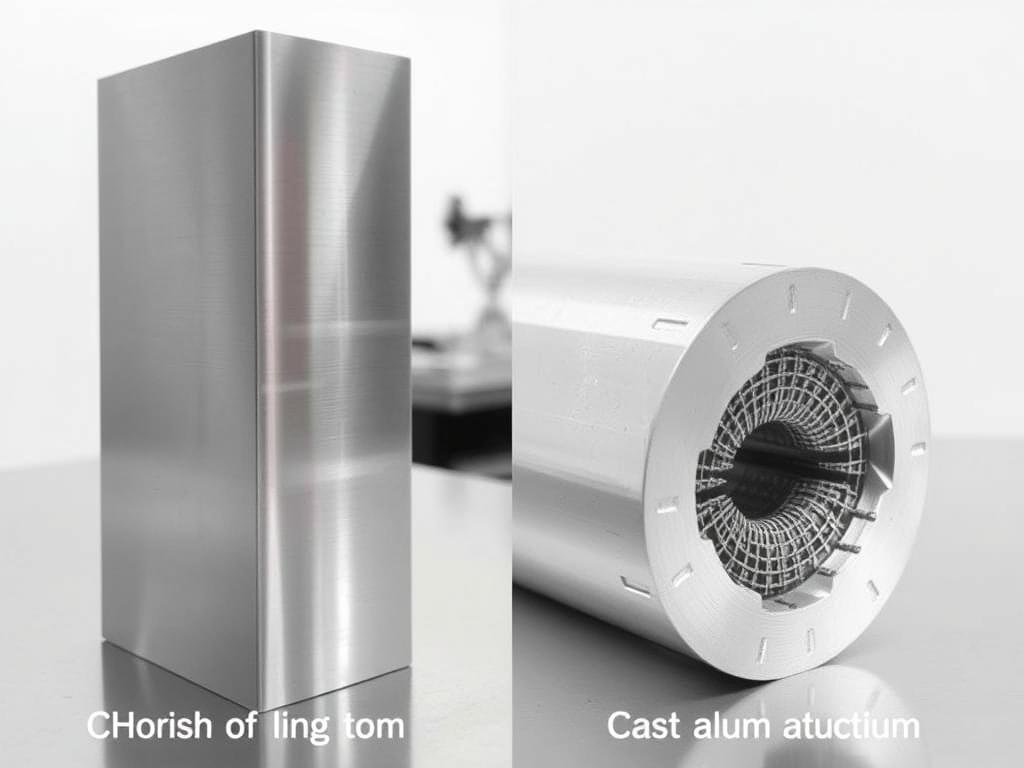

Aluminum Billets vs. Cast Aluminum: A Detailed Comparison

Structural comparison between forged aluminum billet (left) and cast aluminum (right)

Advantages of Aluminum Billets over Casting

- Higher strength due to dense, uniform grain structure

- Superior tensile properties and fatigue resistance

- Better dimensional accuracy and tighter tolerances

- Smoother surfaces with reduced post-processing requirements

- More predictable and controlled material properties

- Enhanced corrosion resistance due to denser structure

- Higher strength-to-weight ratio for critical applications

Limitations of Aluminum Billets

- Higher initial cost compared to casting

- More complex manufacturing process

- Limitations in creating certain complex geometries

- Requires multiple processing steps for complex shapes

- Higher energy consumption during production

- Less suitable for very large components

- Longer lead times for specialized alloys

MAIKONG specializes in both billet processing and casting, allowing us to recommend the optimal manufacturing approach based on your specific requirements, budget, and performance expectations.

Applications of Aluminum Billets Across Industries

What is aluminum billet used for? The versatility, strength, and lightweight properties of aluminum billets make them suitable for a wide range of applications across various industries. Here’s how different sectors leverage the advantages of aluminum billets:

Diverse applications of aluminum billet components across multiple industries

Automotive Industry

- Engine components (pistons, cylinder heads)

- Transmission housings and parts

- Suspension components

- Structural frames and chassis parts

- Wheels and brake components

Aerospace Sector

- Aircraft structural components

- Wing and fuselage parts

- Landing gear components

- Engine mounts and housings

- Interior fittings and brackets

Construction Industry

- Window and door frames

- Curtain wall systems

- Structural supports and beams

- Railings and balustrades

- Decorative architectural elements

Electronics Industry

- Heat sinks and thermal management

- Electronic enclosures and housings

- Mounting brackets and frames

- Computer and server components

- Mobile device chassis and frames

Medical Equipment

- Surgical instruments and tools

- Medical device housings

- Hospital equipment frames

- Prosthetic components

- Imaging equipment structures

Consumer Goods

- Sports equipment (bicycle frames, golf clubs)

- Furniture components and fixtures

- Appliance housings and parts

- Decorative items and accessories

- Cookware and kitchen utensils

MAIKONG serves all these industries with precision-manufactured aluminum components that meet the highest standards of quality and performance. Our expertise in aluminum processing enables us to deliver solutions tailored to the specific requirements of each application.

Advantages of Using Aluminum Billets in Manufacturing

Aluminum billets offer numerous advantages that make them a preferred choice for many manufacturing applications. Understanding these benefits helps in appreciating why aluminum billets are widely used across industries.

Precision aluminum components manufactured from billets at MAIKONG’s facility

- Excellent Strength-to-Weight Ratio: Aluminum billets provide high strength while keeping components lightweight, crucial for transportation and aerospace applications.

- Superior Machinability: Aluminum billets are easily machined to tight tolerances and complex geometries, reducing manufacturing time and costs.

- Excellent Corrosion Resistance: The natural oxide layer that forms on aluminum provides protection against corrosion, extending component lifespan.

- Good Thermal and Electrical Conductivity: Aluminum billets are ideal for applications requiring heat dissipation or electrical conductivity.

- Recyclability: Aluminum is 100% recyclable with no loss of properties, making it an environmentally sustainable choice.

- Versatility: Aluminum billets can be processed through various methods including machining, forging, and extrusion.

- Aesthetic Appeal: Aluminum components can be finished in various ways to achieve attractive appearances, from polished to anodized surfaces.

- Cost-Effectiveness: While initial costs may be higher than some alternatives, the long-term benefits often result in lower total cost of ownership.

At MAIKONG, we leverage the exceptional properties of aluminum billets to create components that exceed our customers’ expectations in terms of performance, durability, and aesthetics. Our expertise in aluminum processing ensures that each component fully capitalizes on the material’s inherent advantages.

Discover MAIKONG’s Aluminum Expertise

Let our team help you leverage the advantages of aluminum billets for your next project.

MAIKONG’s Aluminum Processing Capabilities

As a leading manufacturer specializing in aluminum processing, MAIKONG offers comprehensive services to transform aluminum billets into high-quality components that meet the most demanding specifications.

MAIKONG’s state-of-the-art aluminum processing facility in GD, SZ

Our Comprehensive Service Offerings

Aluminum Forging

Our advanced forging capabilities allow us to create components with enhanced grain structure and superior mechanical properties. We specialize in both hot and cold forging processes, delivering components with exceptional strength and durability.

CNC Machining

With our fleet of state-of-the-art CNC machines, we provide precision machining services for aluminum components with complex geometries and tight tolerances. Our capabilities include multi-axis milling, turning, and grinding.

Heat Treatment

We offer comprehensive heat treatment services to enhance the mechanical properties of aluminum components, including solution heat treatment, aging, annealing, and stress relieving.

Surface Finishing

Our surface treatment capabilities include anodizing, powder coating, painting, polishing, and sandblasting, allowing us to provide components with the desired aesthetic and functional surface properties.

Quality Assurance

Our comprehensive quality control procedures, including dimensional inspection, material testing, and performance validation, ensure that every component meets the highest standards of quality and reliability.

Design Support

Our engineering team provides expert design assistance, helping customers optimize their components for manufacturability, performance, and cost-effectiveness.

Why Choose MAIKONG for Your Aluminum Processing Needs?

- ISO 9001:2015 Certified: Our quality management system ensures consistent, high-quality results.

- Comprehensive In-House Capabilities: From raw material to finished product, we handle every step of the process.

- Advanced Equipment: Our state-of-the-art machinery ensures precision and efficiency.

- Experienced Team: Our skilled engineers and technicians bring decades of industry expertise.

- Competitive Pricing: We offer exceptional value without compromising on quality.

- Global Logistics: We efficiently serve customers worldwide from our facility in GD, SZ.

WhatsApp: +86 13510907401Contact us today to discuss your aluminum processing requirements

Frequently Asked Questions About Aluminum Billets

Here are answers to some common questions about what is aluminum billet and its applications in manufacturing:

What is the difference between aluminum billets and ingots?

While both are forms of semi-finished aluminum, billets are typically cylindrical in shape and designed for extrusion or forging processes, while ingots are larger rectangular blocks primarily used for remelting. Billets generally have more controlled dimensions, better surface quality, and more uniform internal structure compared to ingots.

What are the most common aluminum alloys used for billets?

The most common aluminum alloys used for billets include 6061 and 6063 (Al-Mg-Si alloys) for general-purpose applications, 7075 (Al-Zn alloy) for high-strength applications, and 5052 (Al-Mg alloy) for applications requiring good corrosion resistance. The choice of alloy depends on the specific requirements of the application, including strength, corrosion resistance, and machinability.

How does forging affect the properties of aluminum billets?

Forging significantly enhances the mechanical properties of aluminum billets by refining the grain structure and eliminating porosity. This results in components with higher strength, improved fatigue resistance, and better toughness compared to cast aluminum. The directional grain flow created during forging also contributes to enhanced mechanical properties in specific directions.

What surface treatments can be applied to aluminum billet components?

Aluminum components manufactured from billets can undergo various surface treatments, including anodizing (for corrosion resistance and decorative purposes), powder coating, painting, polishing, sandblasting, and chemical treatments. These treatments enhance the appearance, corrosion resistance, wear resistance, and other functional properties of the components.

How does MAIKONG ensure the quality of aluminum billet components?

MAIKONG implements a comprehensive quality management system that includes rigorous material inspection, in-process quality checks, and final inspection of finished components. We utilize advanced measurement equipment, including coordinate measuring machines (CMMs), optical comparators, and material testing instruments, to verify that all components meet the specified dimensional, mechanical, and surface quality requirements.

Conclusion: The Value of Aluminum Billets in Modern Manufacturing

Understanding what is aluminum billet and its capabilities is essential for making informed decisions in manufacturing. As we’ve explored in this comprehensive guide, aluminum billets offer exceptional versatility, strength-to-weight ratio, and processability, making them ideal for a wide range of applications across industries.

At MAIKONG, we combine advanced equipment, skilled craftsmanship, and metallurgical expertise to transform aluminum billets into precision components that meet the most demanding specifications. Our comprehensive capabilities—from forging and CNC machining to heat treatment and surface finishing—enable us to provide complete solutions for your aluminum component needs.

Whether you require high-strength aerospace components, lightweight automotive parts, or precision electronic housings, MAIKONG has the expertise and capabilities to deliver exceptional results. We invite you to partner with us for your next project and experience the MAIKONG difference—superior quality, competitive pricing, and exceptional service.

The MAIKONG team: Your partners in aluminum excellence

Ready to Start Your Next Aluminum Project?

Contact MAIKONG today to discuss your requirements and discover how our aluminum processing expertise can benefit your business.

Email: Lucy@maikongforge.us | Website: https://maikongforge.us

US Distributors and Agents Wanted! Contact us to discuss partnership opportunities.