Premium aluminum billets manufactured by MAIKONG

Premium aluminum billets manufactured by MAIKONG

What is Aluminum Billet?

An aluminum billet is a solid cylindrical or rectangular semi-finished aluminum product created through casting processes. These metal forms serve as the raw material for various manufacturing processes, particularly extrusion, where they’re transformed into profiles, tubes, and other shapes. Aluminum billets represent the initial stage of aluminum deep processing, offering excellent machinability, strength, and versatility.

At MAIKONG, we produce aluminum billets through carefully controlled casting processes where molten aluminum is shaped into solid forms with consistent dimensions and uniform density. Our billets feature precise metallurgical structures, making them ideal for applications requiring high performance and reliability.

Need Custom Aluminum Billets?

Contact our experts today to discuss your specific requirements and get a competitive quote.

Aluminum Billet Manufacturing Process

The production of high-quality aluminum billets involves several critical steps that directly impact the final product’s performance. At MAIKONG, we’ve perfected this process to deliver superior results:

MAIKONG’s advanced aluminum billet casting process

Raw Material Selection

We carefully select aluminum scrap or virgin aluminum based on application requirements, considering factors like cost, supply conditions, and required alloy composition to ensure optimal material performance.

Melting and Alloying

Virgin aluminum is melted in our high-temperature furnaces at over 660°C (1220°F), with precise additions of alloying elements like magnesium and zinc to enhance strength, corrosion resistance, and other critical properties.

Casting and Cooling

Molten aluminum is poured into steel molds and cooled under precise control, resulting in billets with consistent dimensions and uniform density. Advanced cooling techniques prevent internal stresses and ensure excellent metallurgical properties.

Quality Control in Aluminum Billet Production

Every aluminum billet we produce undergoes rigorous quality control testing to ensure it meets our exacting standards. Our comprehensive testing includes:

- Chemical composition analysis to verify alloy specifications

- Ultrasonic testing to detect internal defects

- Dimensional inspection for precise sizing

- Mechanical property testing for strength verification

- Microstructure analysis for grain structure evaluation

Common Types of Aluminum Billets

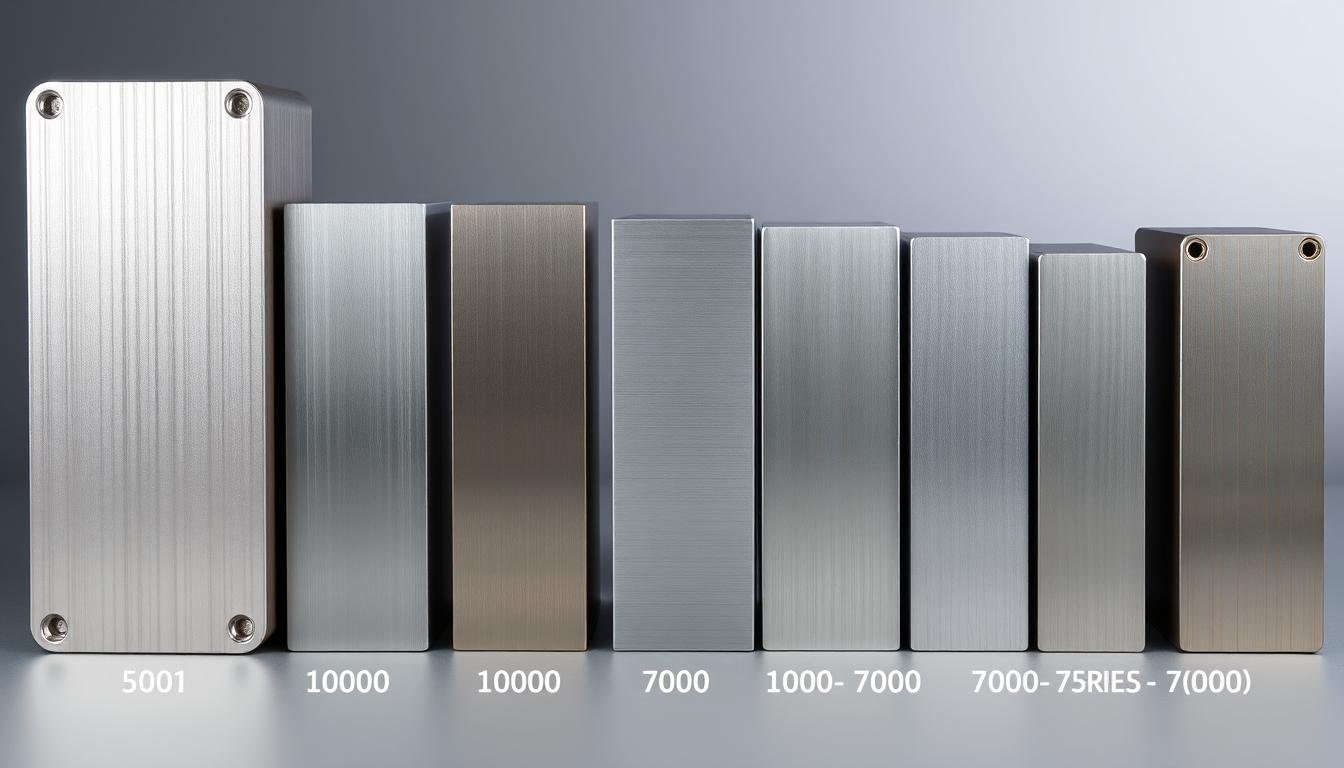

Aluminum billets are available in several alloy series, each offering specific properties and benefits for different applications. At MAIKONG, we specialize in producing various alloy types to meet diverse industry needs:

Various aluminum billet alloy series produced by MAIKONG

| Aluminum Alloy Series | Primary Alloying Elements | Key Characteristics | Ideal Applications |

| 1000 Series | Pure Aluminum (99%+) | Excellent corrosion resistance, high electrical conductivity, limited strength | Electrical components, chemical equipment, heat exchangers |

| 2000 Series | Copper | High strength, good heat resistance, lower corrosion resistance | Aerospace components, military equipment, high-strength structural parts |

| 3000 Series | Manganese | Moderate strength, good formability, excellent corrosion resistance | Food and chemical storage, roofing materials, heat exchangers |

| 5000 Series | Magnesium | Good corrosion resistance, moderate strength, excellent weldability | Marine applications, transportation, storage tanks |

| 6000 Series | Magnesium and Silicon | Good strength-to-weight ratio, excellent extrudability, good corrosion resistance | Architectural extrusions, automotive parts, structural components |

| 7000 Series | Zinc | Highest strength, good fatigue resistance, moderate corrosion resistance | Aerospace structures, high-performance automotive parts, sports equipment |

Our most popular aluminum billet alloy is the 6061 series, which offers an excellent balance of strength, weldability, and corrosion resistance. We also specialize in high-strength 7075 aluminum for aerospace and defense applications.

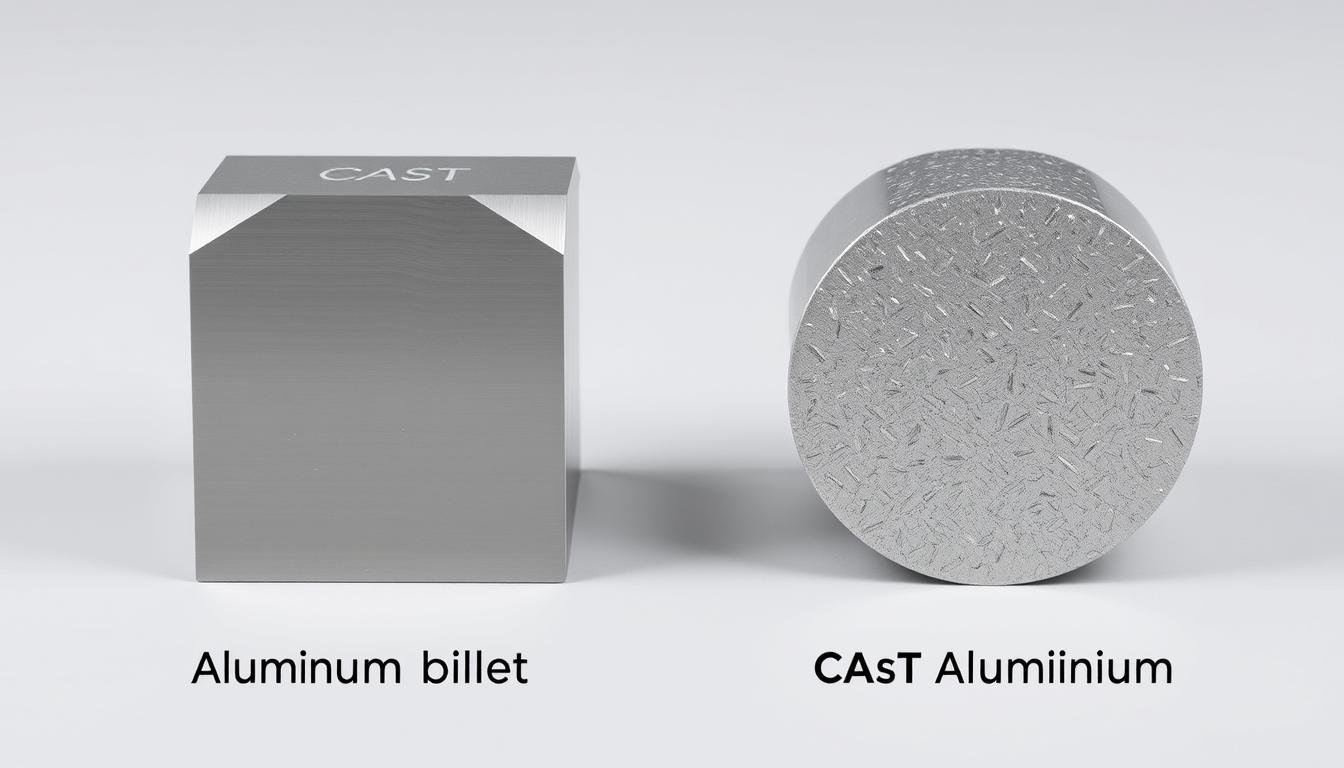

Aluminum Billet vs. Alternative Materials

When choosing materials for your manufacturing needs, it’s important to understand how aluminum billets compare to alternatives like cast aluminum, steel, and other materials:

Structural comparison: Aluminum billet vs. cast aluminum

Aluminum Billet vs. Cast Aluminum

Advantages of Aluminum Billet

- Higher strength due to dense, uniform grain structure

- Superior tensile properties and fatigue resistance

- Better dimensional accuracy and tighter tolerances

- Smoother surfaces requiring less post-processing

- More predictable heat treatment response

- Improved corrosion resistance from denser structure

Limitations of Aluminum Billet

- Requires multiple steps to achieve complex shapes

- Generally higher initial cost than casting

- Limited to certain shape possibilities

- Requires more energy in the production process

- Less material-efficient for complex geometries

Aluminum Billet vs. Steel Billet

| Property | Aluminum Billet | Steel Billet |

| Weight | Lightweight (density ~2.7 g/cm³) | Heavy (density ~7.85 g/cm³) |

| Strength-to-Weight Ratio | Excellent | Good |

| Corrosion Resistance | Naturally resistant | Requires protective coatings |

| Thermal Conductivity | High | Low |

| Electrical Conductivity | Excellent | Poor |

| Machinability | Excellent | Good but requires more energy |

| Cost | Moderate | Lower |

Need Help Selecting the Right Aluminum Billet?

Our materials experts can help you choose the perfect aluminum alloy for your specific application.

Applications of Aluminum Billets

Aluminum billets serve as the foundation for countless products across diverse industries. Their versatility, strength-to-weight ratio, and excellent machinability make them ideal for applications where performance and reliability are critical:

Diverse applications of MAIKONG aluminum billets across industries

Aerospace

- Structural components

- Aircraft frames

- Wing components

- Interior fittings

Automotive

- Engine blocks

- Transmission cases

- Suspension components

- Wheels and rims

Construction

- Window frames

- Door systems

- Structural profiles

- Curtain walls

Electronics

- Heat sinks

- Enclosures

- LED housings

- Mounting brackets

At MAIKONG, we work closely with clients across these industries to provide aluminum billets that meet their specific requirements for performance, durability, and cost-effectiveness.

MAIKONG’s Aluminum Billet Capabilities

As a leading manufacturer of aluminum billets, MAIKONG offers comprehensive solutions from raw material selection to finished products. Our state-of-the-art facilities in GD, SZ are equipped with advanced technology to deliver superior quality and consistent performance:

MAIKONG’s state-of-the-art aluminum billet production facility in GD, SZ

Manufacturing Capacity

Our facility features 60+ CNC machines with 100+ tons of metal processing capacity per month, ensuring we can meet high-volume demands with consistent quality and on-time delivery.

Alloy Expertise

We specialize in producing a wide range of aluminum alloys, including 1000, 2000, 3000, 5000, 6000, and 7000 series, each tailored to specific application requirements.

Quality Assurance

Our comprehensive testing laboratory ensures all raw materials and finished products meet exact specifications through chemical analysis, mechanical testing, and dimensional verification.

Our Full-Service Approach

MAIKONG offers a complete solution for your aluminum billet needs:

Design & Engineering

-

-

- CAD/CAM capabilities

- Material selection expertise

- Finite element analysis

- Process optimization

- Tooling design

-

Manufacturing

-

-

- Aluminum forging

- Heat treatment

- CNC machining

- Surface finishing

- Quality control

-

Additional Services

-

- Custom packaging

- Logistics management

- Inventory solutions

- Technical support

- Material certification

Precision CNC machining of aluminum billets at MAIKONG

Our CNC Machining Services

We offer comprehensive CNC machining services for aluminum billets, including:

CNC Turning Services

Our CNC turning capabilities are ideal for creating deep holes, machined threads, and cylindrical shapes with superior surface finishes from aluminum billets. When you need precisely manufactured parts with fast turnaround, our CNC turning solutions deliver exceptional results.

CNC Milling Services

Our multi-axis CNC milling machines transform aluminum billets into complex prismatic shapes and flat surfaces for a limitless variety of commercial and industrial products. These advanced systems require no fixed tooling, offering high flexibility and extreme accuracy.

Ready to Order Custom Aluminum Billets?

Contact us today to discuss your requirements and get a competitive quote.

Quality Assurance for Aluminum Billets

At MAIKONG, quality is at the core of everything we do. Our comprehensive quality management system ensures that every aluminum billet we produce meets the highest standards for performance, reliability, and consistency:

Rigorous quality testing of aluminum billets at MAIKONG’s laboratory

Our Quality Control Process

Every aluminum billet undergoes a rigorous quality control process:

- Raw material verification through chemical analysis

- Process monitoring during melting and casting

- Dimensional inspection for precise sizing

- Ultrasonic testing to detect internal defects

- Mechanical property testing for strength verification

- Surface quality inspection

- Final certification and documentation

“At MAIKONG, we don’t just meet industry standards – we exceed them. Our commitment to quality ensures that every aluminum billet we produce delivers exceptional performance and reliability.”

Why Choose MAIKONG for Your Aluminum Billet Needs

When you partner with MAIKONG for your aluminum billet requirements, you gain access to industry-leading expertise, advanced manufacturing capabilities, and exceptional customer service:

MAIKONG’s expert team ensuring premium quality aluminum billets

Superior Quality

Our state-of-the-art facilities and rigorous quality control processes ensure that every aluminum billet meets the highest standards for performance and reliability.

Competitive Pricing

Our efficient manufacturing processes and strategic location in GD, SZ allow us to offer competitive pricing without compromising on quality.

Technical Expertise

Our team of metallurgists and engineers provides expert guidance on alloy selection, process optimization, and application-specific requirements.

Customer Testimonials

“MAIKONG has consistently delivered high-quality aluminum billets that meet our exact specifications. Their technical expertise and responsive service have made them our preferred supplier.”

“We’ve been impressed with the consistency and reliability of MAIKONG’s aluminum billets. Their competitive pricing and on-time delivery have helped us improve our own production efficiency.”

Finished products manufactured from MAIKONG aluminum billets

What sizes of aluminum billets does MAIKONG offer?

MAIKONG offers aluminum billets in a wide range of diameters from 3″ to 16″ and in various lengths according to customer specifications. We can customize sizes to meet your exact requirements.

What aluminum alloys are available for your billets?

We produce aluminum billets in various alloy series including 1000, 2000, 3000, 5000, 6000, and 7000 series. Our most popular alloys include 6061, 6063, and 7075, but we can produce custom alloys to meet specific requirements.

What is the minimum order quantity for aluminum billets?

Our minimum order quantity varies depending on the alloy and size requirements. Please contact us directly to discuss your specific needs, and we’ll work with you to accommodate your order volume.

Contact MAIKONG for Premium Aluminum Billets

Ready to experience the MAIKONG difference? Contact us today to discuss your aluminum billet requirements and discover how we can help you achieve your manufacturing goals.

Our dedicated team is ready to assist with your aluminum billet needs

Contact Information

- Phone/WhatsApp: 8613-5109-0701

- Email: Lucy@maikongforge.us

- Website: https://maikongforge.us

US Agent Opportunities

MAIKONG is currently recruiting agents throughout the United States. If you’re interested in representing our high-quality aluminum billets and other metal products, please contact us for more information.

Ready to Order Premium Aluminum Billets?

Contact us today to discuss your requirements and get a competitive quote.

Conclusion

Aluminum billets are the foundation of countless products across diverse industries, offering an exceptional combination of strength, lightweight properties, and versatility. At MAIKONG, we’re committed to providing premium-quality aluminum billets that meet your exact specifications and help you achieve your manufacturing goals.

With our advanced manufacturing capabilities, technical expertise, and commitment to customer satisfaction, MAIKONG is your ideal partner for all your aluminum billet needs. Contact us today to experience the MAIKONG difference.

Looking for high-quality aluminum billets at competitive prices? MAIKONG offers premium manufacturing and supply solutions tailored to your specific requirements. Contact us today to discuss your needs and get a quick quote.