The Versatility of Billet Machining: Crafting Diverse Custom Parts

»

Billet Machining » The Versatility of Billet Machining: Crafting Diverse Custom Parts

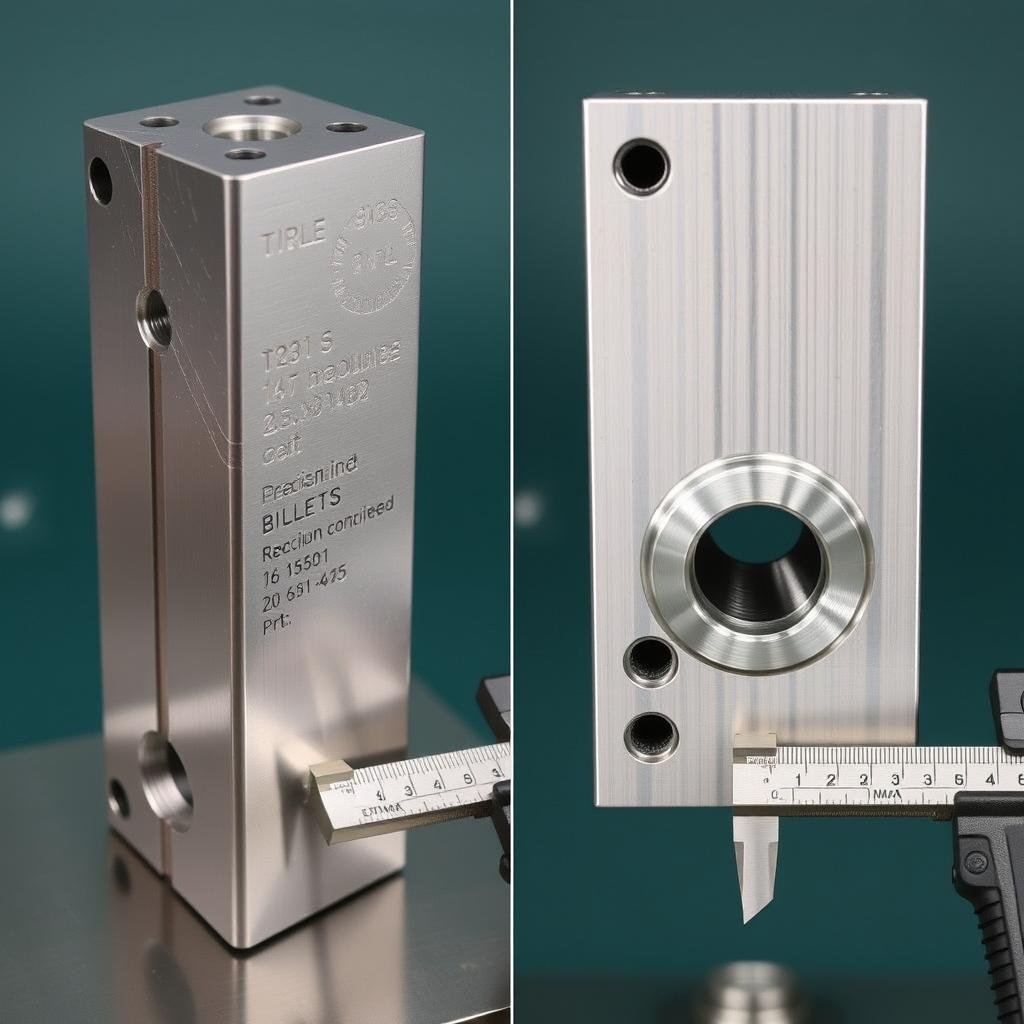

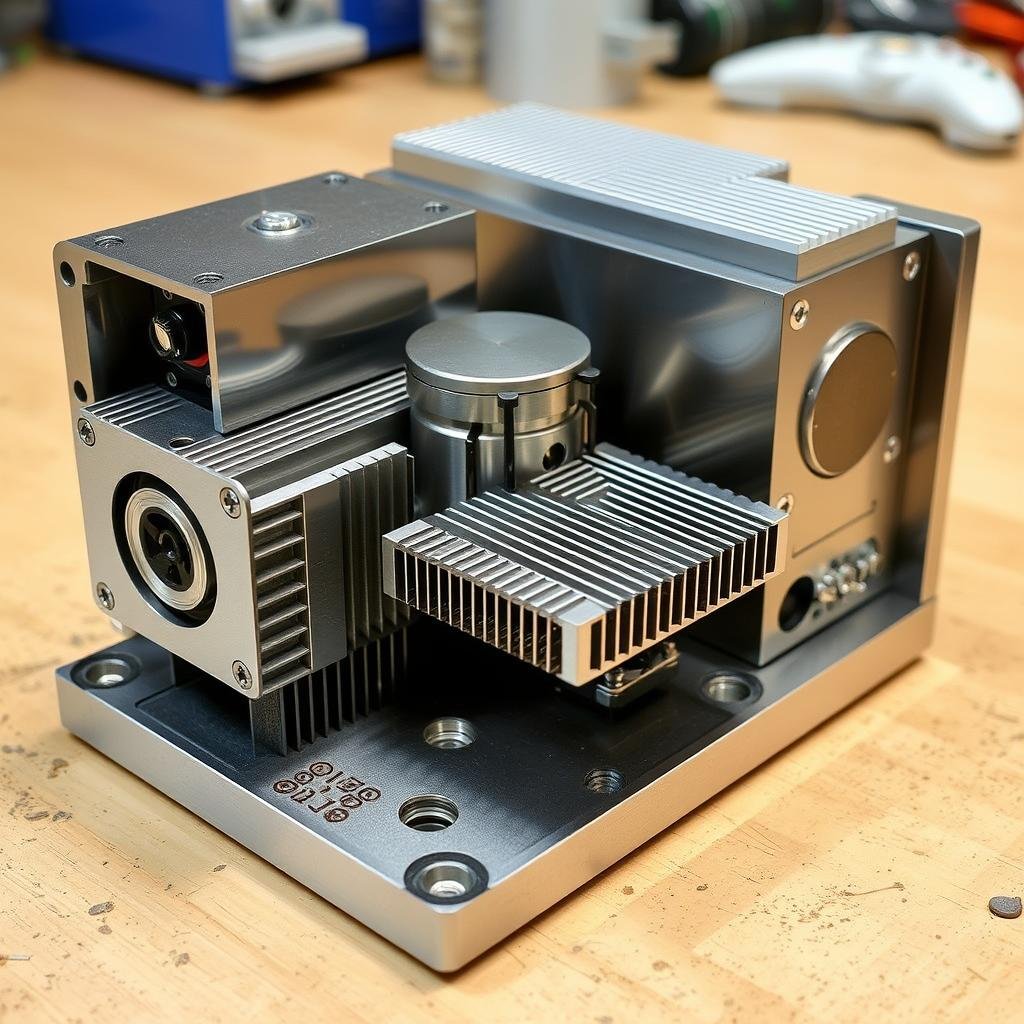

In the world of precision manufacturing, billet machining stands as a cornerstone technique for creating high-quality custom components. At MAIKONG, we’ve mastered this versatile process to deliver exceptional custom parts that meet the most demanding specifications. Whether you need prototype development or high-precision production components, our advanced billet machining capabilities ensure superior quality, dimensional accuracy, and material integrity for your most critical applications.

What Is Billet Machining?

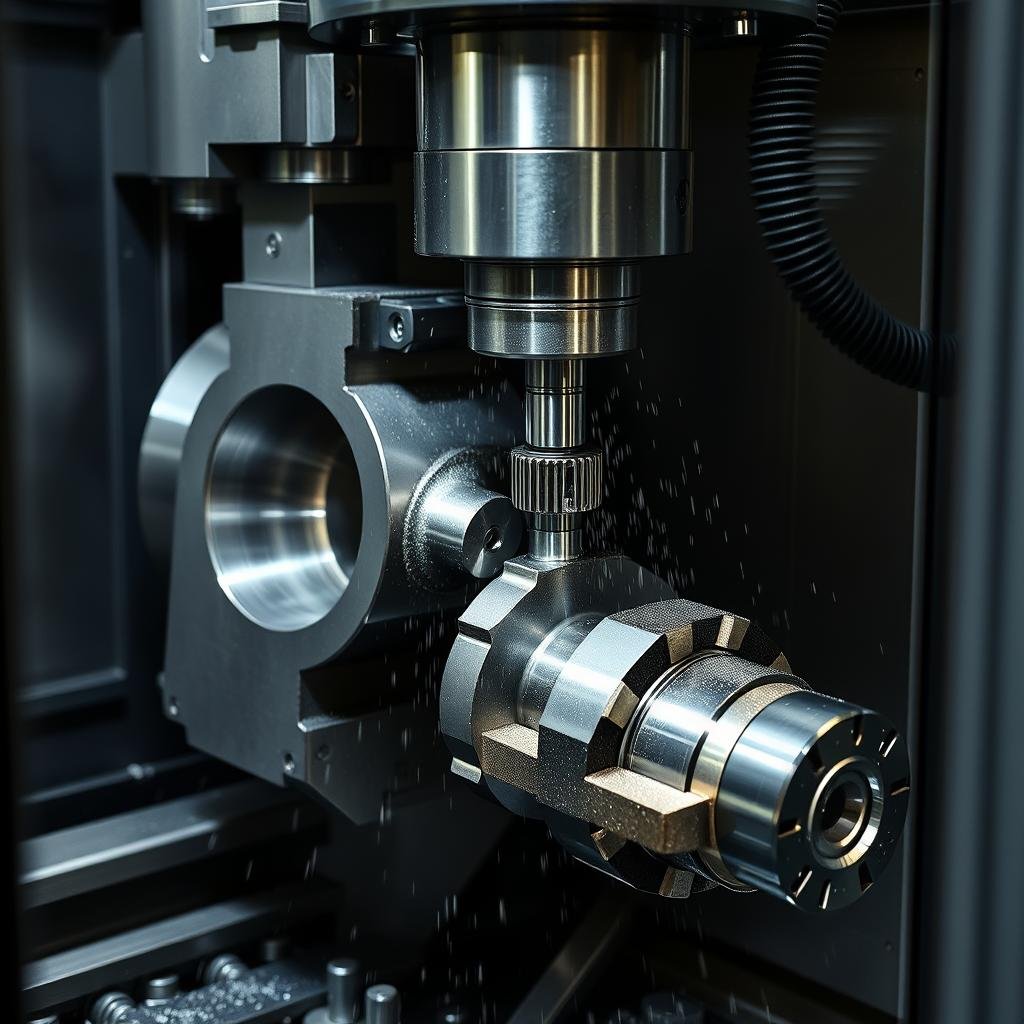

Billet machining is a subtractive manufacturing process that creates components by removing material from a solid block of metal, known as a billet. Unlike casting or forging, which form parts by pouring molten metal or applying pressure to heated material, billet machining utilizes precision CNC (Computer Numerical Control) equipment to cut away excess material until only the desired shape remains.

Billet machining is a subtractive manufacturing process that creates components by removing material from a solid block of metal, known as a billet. Unlike casting or forging, which form parts by pouring molten metal or applying pressure to heated material, billet machining utilizes precision CNC (Computer Numerical Control) equipment to cut away excess material until only the desired shape remains.

The process begins with a solid metal block, typically made from aluminum, steel, brass, or other alloys. Using multi-axis CNC machines, material is systematically removed according to precise digital specifications. This approach allows for extremely tight tolerances and exceptional surface finishes that other manufacturing methods often cannot achieve.

At MAIKONG, our state-of-the-art CNC machining centers can produce components with tolerances as tight as ±0.005mm, ensuring your parts meet exact specifications every time.

The Billet Machining Process

Material Selection

The process begins with selecting the appropriate material for your application. MAIKONG works with a wide range of metals including aluminum, steel, brass, and specialty alloys to match your specific requirements for strength, weight, and performance.

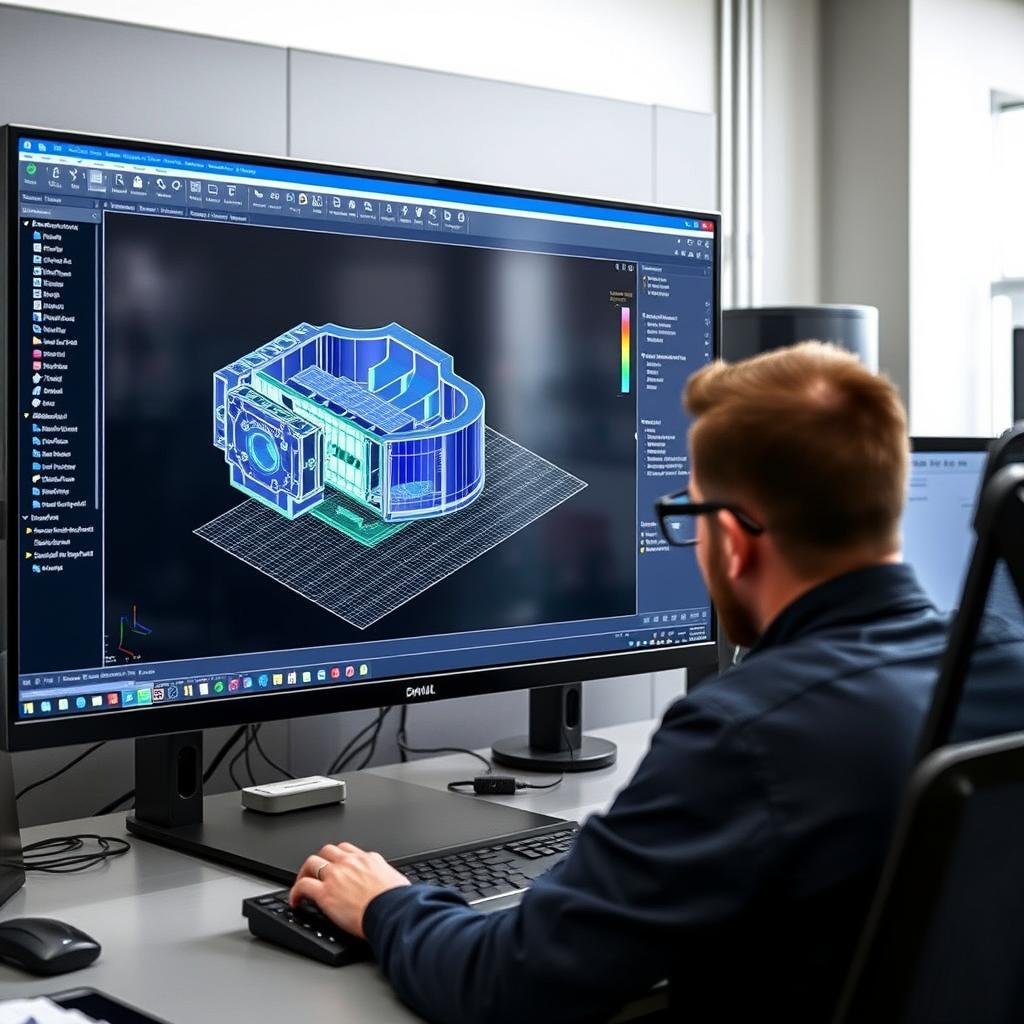

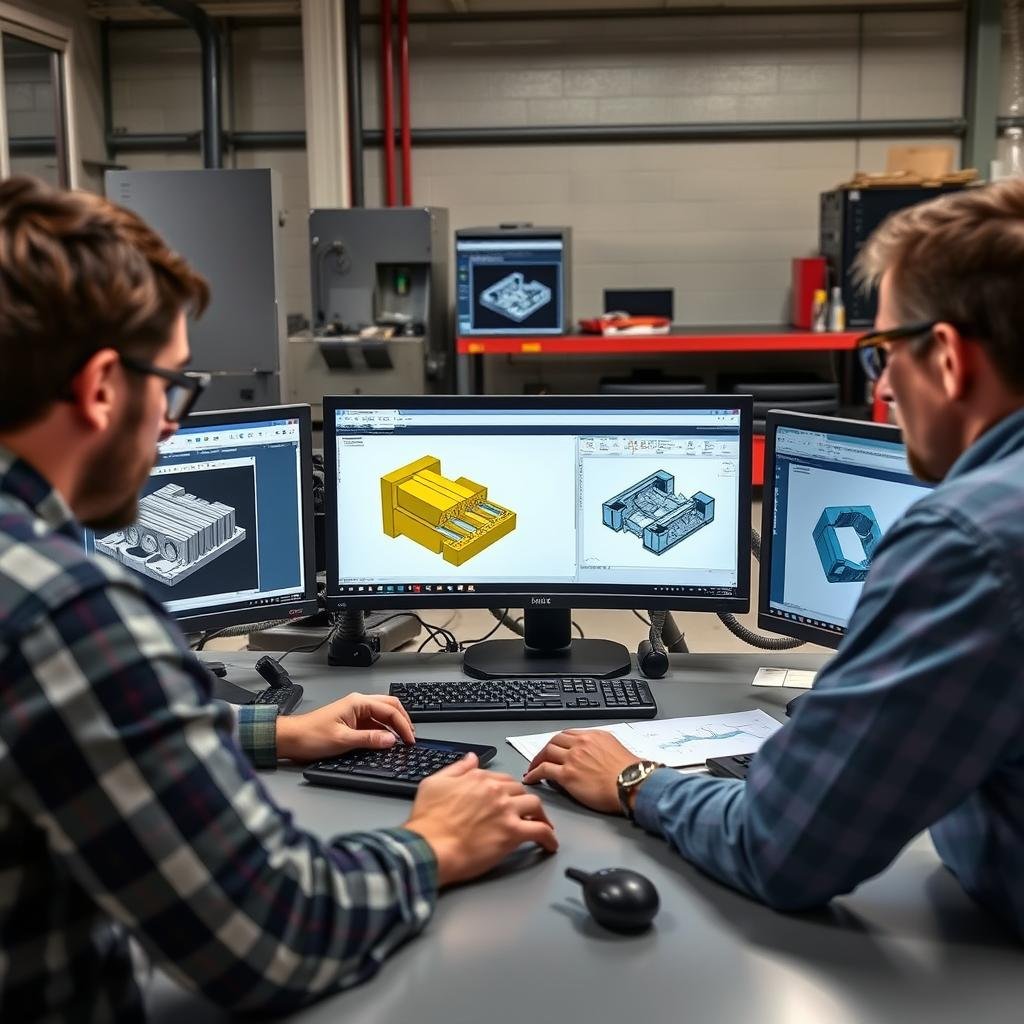

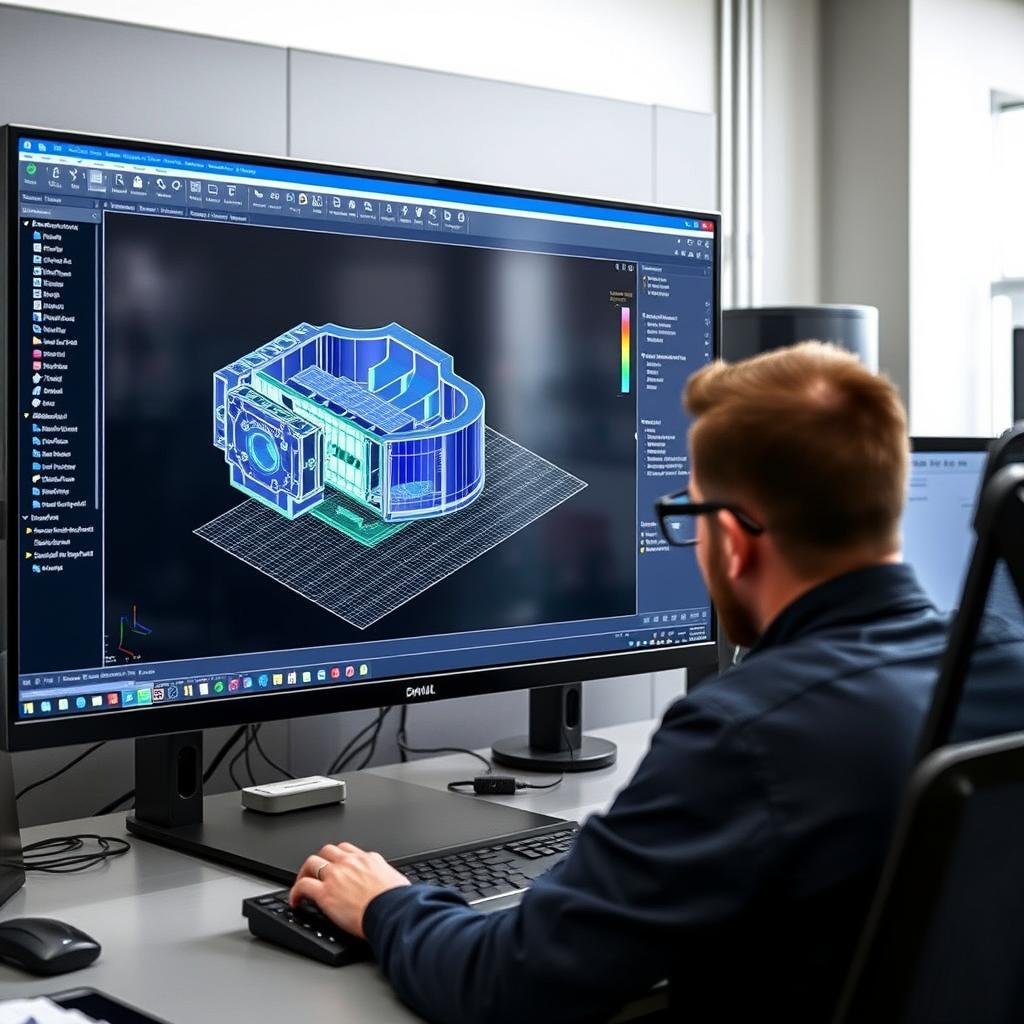

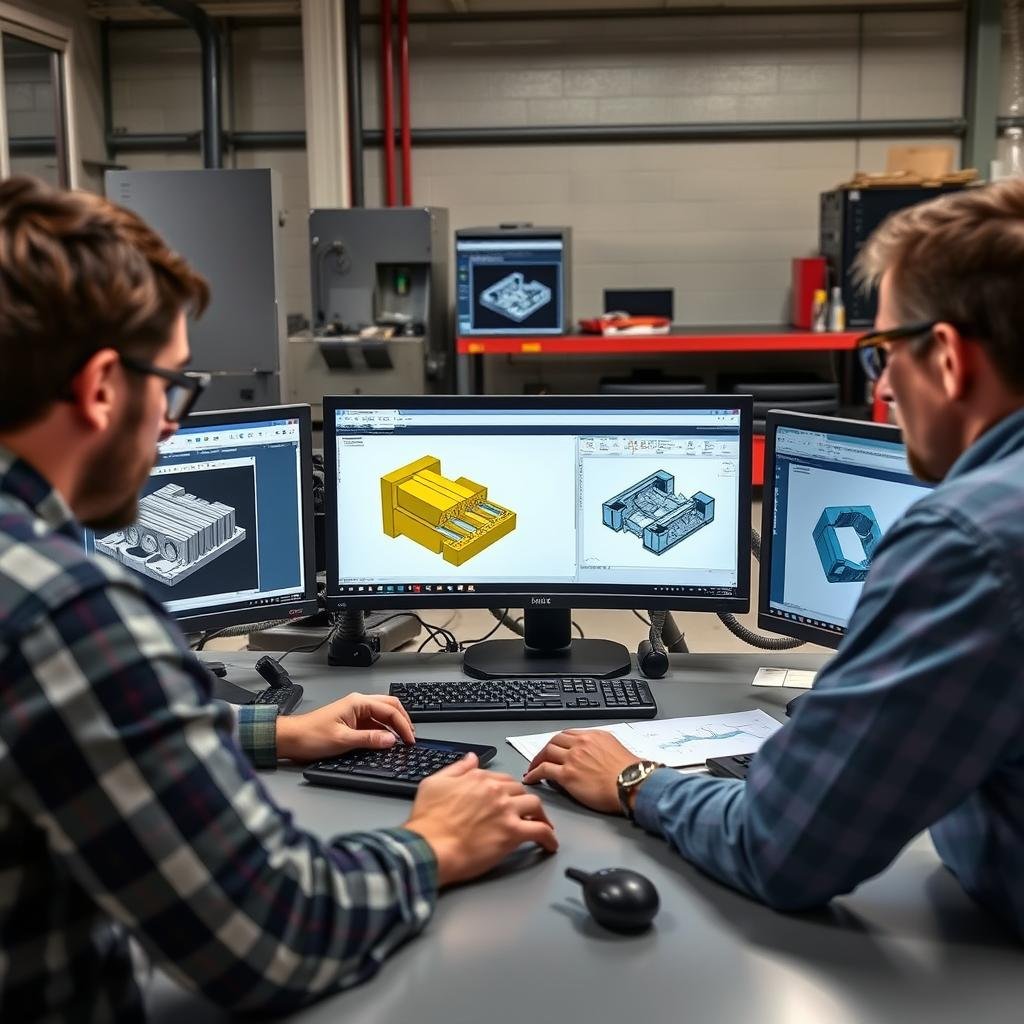

Digital Design

Our engineering team uses advanced CAD/CAM software to create precise digital models of your part. These models define every dimension and feature, allowing us to simulate the machining process before cutting begins, ensuring optimal results.

CNC Programming

Skilled programmers convert the digital design into detailed instructions for our CNC machines. These programs define toolpaths, cutting speeds, and tool selections to achieve the desired geometry with maximum efficiency and precision.

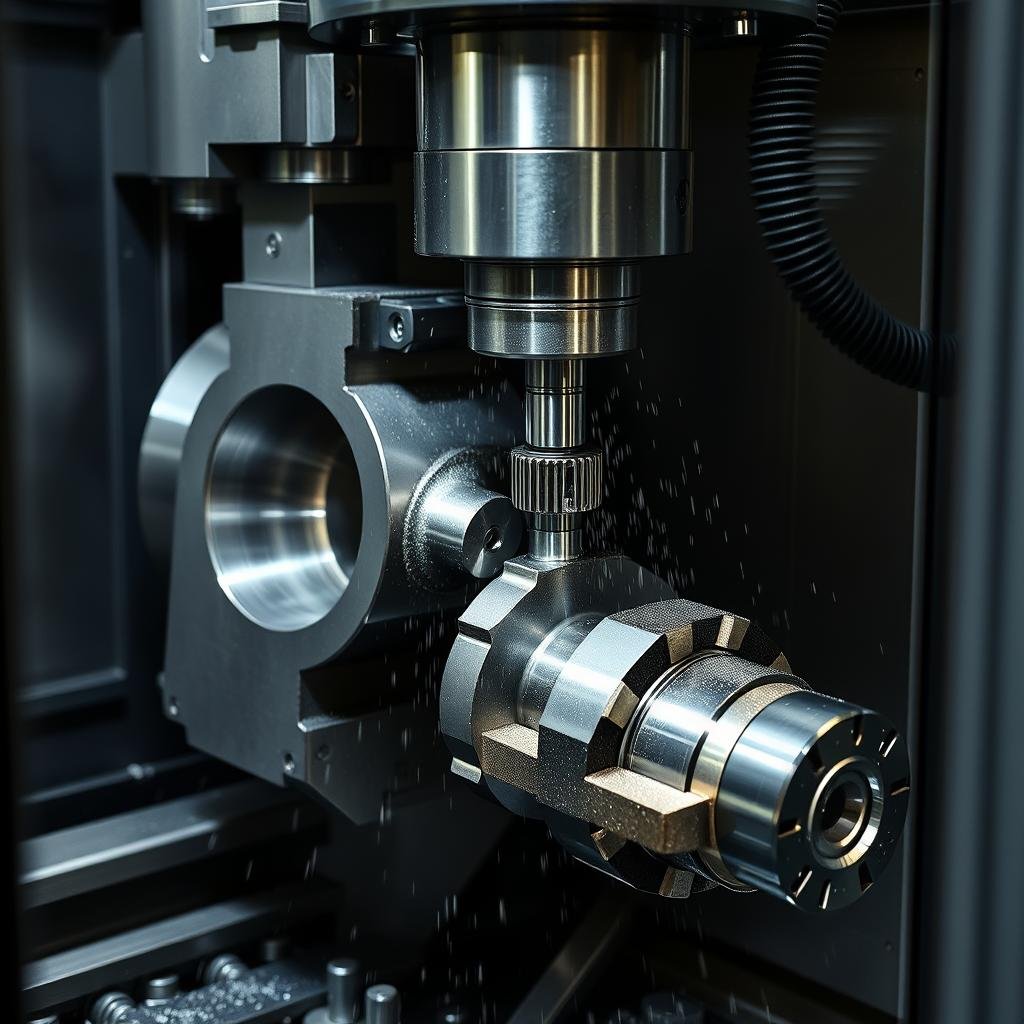

Machining Operations

Our advanced multi-axis CNC machines execute the programmed instructions, removing material through operations like milling, turning, drilling, and threading. Multiple setups may be required for complex geometries, with each stage carefully controlled for accuracy.

Quality Inspection

Throughout and after machining, parts undergo rigorous inspection using precision measuring equipment. Our quality control team verifies that all dimensions meet specifications, ensuring consistent quality across production runs.

Finishing Operations

Depending on your requirements, machined parts may undergo additional finishing processes such as deburring, polishing, anodizing, or painting to enhance appearance, corrosion resistance, or other functional properties.

Advantages of Billet Machining

Benefits of Billet Machined Parts

- Superior precision with tolerances as tight as ±0.005mm

- Excellent structural integrity with uniform grain structure

- High-quality surface finishes without additional processing

- Complex geometries and intricate details achievable

- Cost-effective for low to medium volume production

- Rapid prototyping capabilities with quick turnaround

- Consistent material properties throughout the part

- No tooling investment required for new designs

Limitations to Consider

- Higher material waste compared to additive methods

- May be less economical for very high volume production

- Some internal geometries may be difficult to achieve

- Heavier than cast parts due to solid material density

- Higher unit cost for complex parts with extensive machining

Billet Machining vs. Alternative Manufacturing Methods

Understanding the differences between manufacturing methods helps in selecting the right process for your specific application. Here’s how billet machining compares to other common manufacturing techniques:

| Feature |

Billet Machining |

Casting |

Forging |

| Process Type |

Subtractive (material removal) |

Additive (pouring molten metal) |

Deformation (reshaping solid metal) |

| Precision |

Excellent (±0.005mm possible) |

Moderate (±0.2mm typical) |

Good after secondary machining |

| Grain Structure |

Uniform, non-directional |

Random with potential voids |

Directional, follows part contour |

| Strength |

Very good, consistent |

Lower, potential porosity |

Excellent, especially under load |

| Surface Finish |

Excellent |

Requires post-processing |

Requires secondary machining |

| Design Flexibility |

High for external features |

Excellent for complex shapes |

Limited by die design |

| Production Volume |

Low to medium |

Medium to high |

Medium to high |

| Material Waste |

Higher |

Low |

Low |

| Tooling Cost |

Low (no special tooling) |

Moderate (molds required) |

High (dies required) |

When to Choose Billet Machining

- When precision and tight tolerances are critical

- For prototyping and low to medium volume production

- When design changes may be needed during development

- For parts requiring excellent surface finish

- When consistent material properties are essential

- For complex external geometries and features

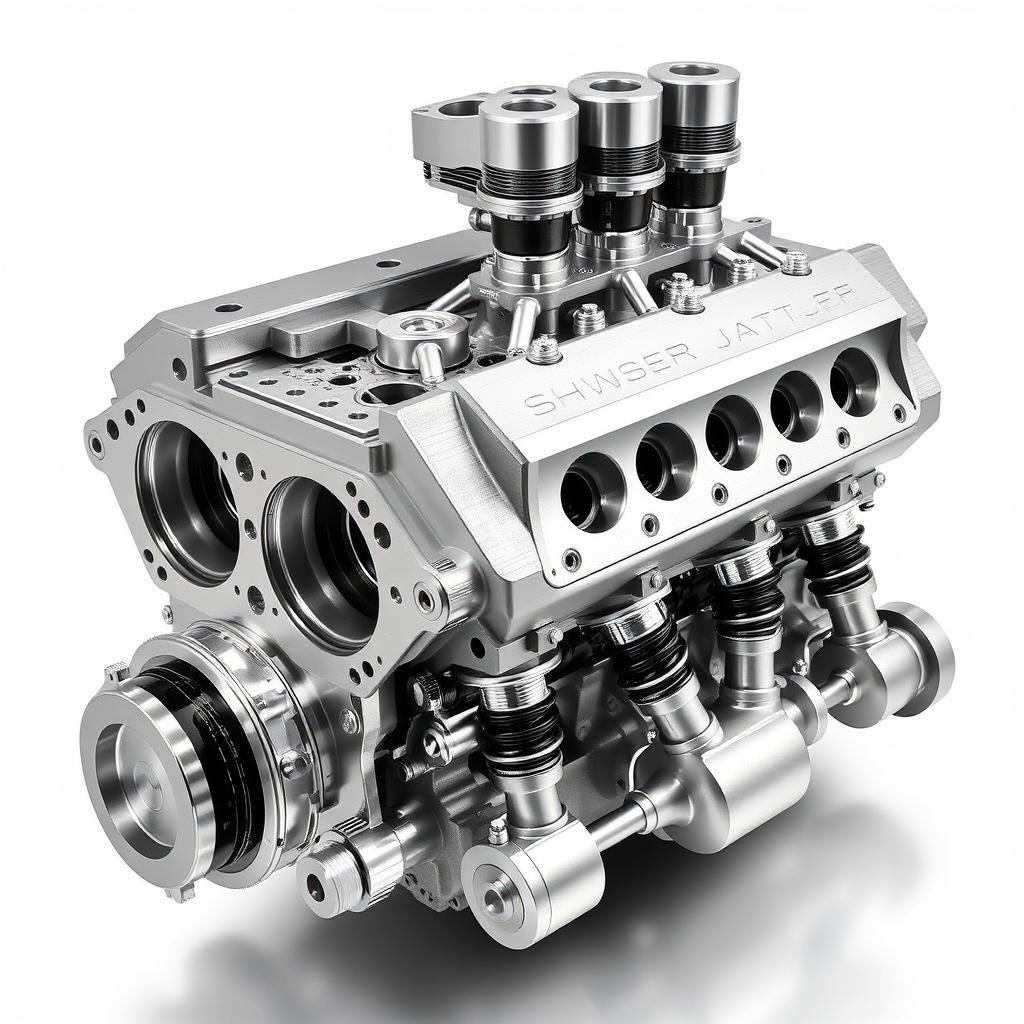

Industries and Applications for Billet Machining

The versatility of billet machining makes it suitable for a wide range of industries and applications where precision, strength, and quality are paramount:

Aerospace

- Structural components

- Hydraulic manifolds

- Landing gear components

- Control system parts

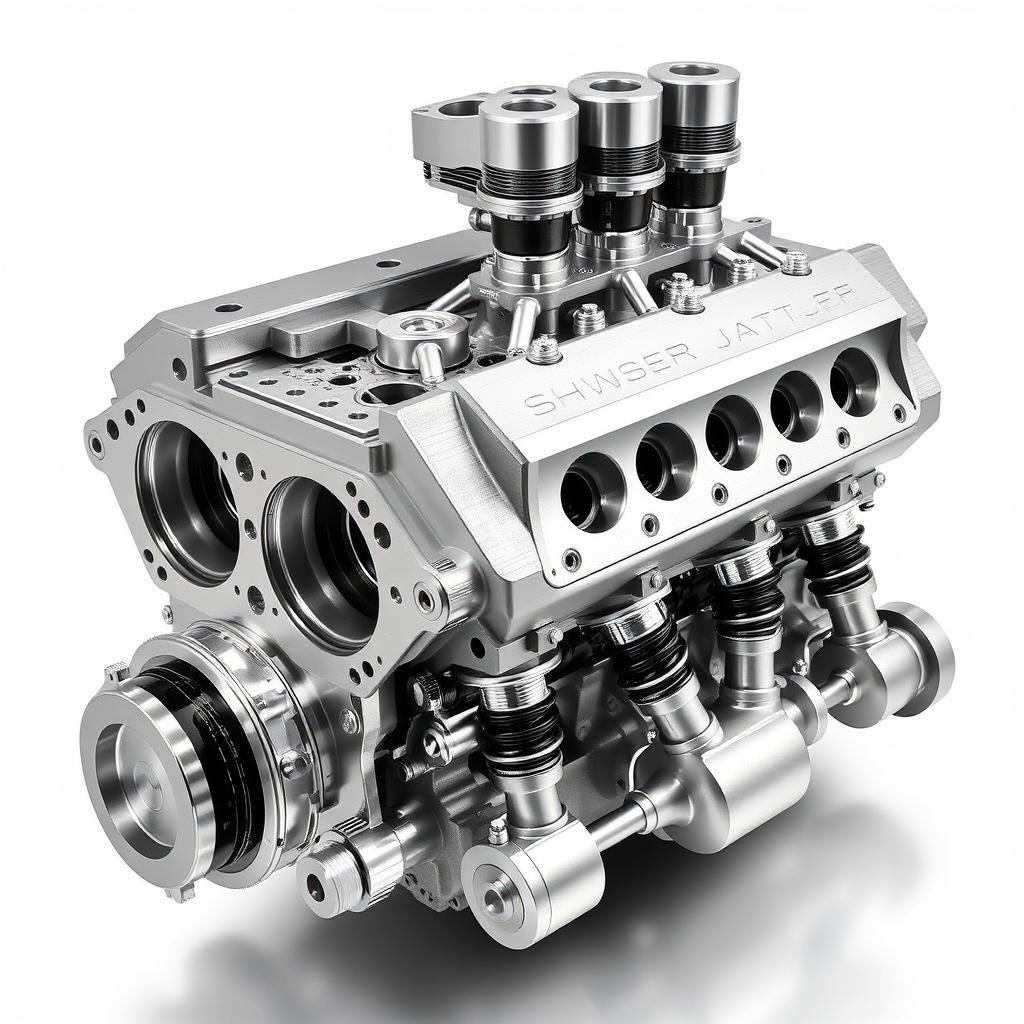

Automotive

- Engine components

- Transmission parts

- Performance upgrades

- Prototype development

Medical

- Surgical instruments

- Implant components

- Diagnostic equipment

- Laboratory devices

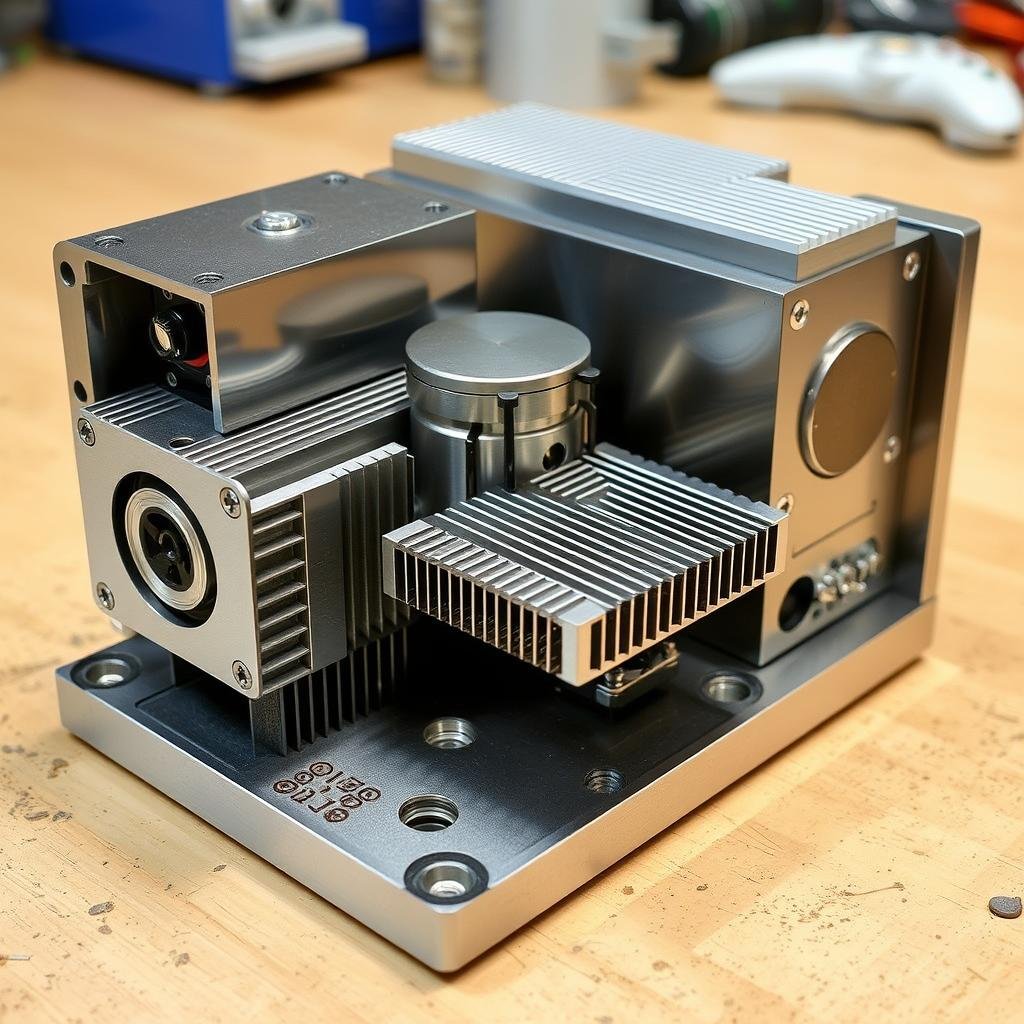

Electronics

- Heat sinks

- Enclosures

- Connector housings

- Test fixtures

Defense

- Weapon components

- Communication equipment

- Vehicle parts

- Optical mounts

Industrial

- Hydraulic components

- Pneumatic fittings

- Custom machinery parts

- Robotic components

Ready to Start Your Billet Machining Project?

MAIKONG offers comprehensive billet machining services with competitive pricing and exceptional quality. Contact our team to discuss your specific requirements.

Request a Quote

Email: Lucy@maikongforge.us

MAIKONG’s Billet Machining Capabilities

At MAIKONG, we offer comprehensive billet machining services backed by state-of-the-art equipment and decades of manufacturing expertise. Our facilities in GD, SZ are equipped with the latest CNC technology to deliver exceptional quality and precision for your most demanding projects.

Our Equipment

- 60+ advanced CNC machines with multi-axis capabilities

- High-precision turning centers for cylindrical components

- Vertical and horizontal machining centers

- Swiss-type machines for small, complex parts

- Advanced metrology and quality control equipment

Materials We Work With

Aluminum Alloys

- 6061, 7075, 2024

- 5052, 6063, 7050

- Custom alloys available

Steel & Stainless

- Carbon steel

- Tool steel

- 304, 316, 17-4 stainless

Other Metals

- Brass and bronze

- Titanium alloys

- Special alloys

Additional Services

Design Support

Our engineering team can help optimize your designs for manufacturability, cost-effectiveness, and performance. We offer complete CAD/CAM support to bring your concepts to reality.

Surface Treatments

Enhance the appearance and performance of your parts with our comprehensive finishing services, including anodizing, plating, painting, powder coating, and more.

Quality Assurance

Our rigorous quality control processes ensure that every part meets your exact specifications. We offer full inspection reporting and material certifications upon request.

Why Choose MAIKONG for Your Billet Machining Needs

- Exceptional Quality: ISO 9001:2015 certified processes ensure consistent, high-quality results

- Competitive Pricing: Cost-effective manufacturing without compromising on quality

- Technical Expertise: Experienced engineers and machinists with decades of industry knowledge

- Production Capacity: 100+ tons monthly metal processing capacity for projects of any size

- Comprehensive Services: One-stop solution from design to finished product

- Global Capabilities: Serving customers worldwide with efficient logistics

- Responsive Communication: Dedicated project managers for clear, timely communication

“At MAIKONG, we don’t just machine parts – we deliver precision solutions that help our customers succeed. Our commitment to quality, innovation, and customer satisfaction drives everything we do.”

– MAIKONG Engineering Team

Become a MAIKONG Distributor in the US

We’re actively seeking US distributors for our high-quality machined and forged components. Join our team and offer your customers exceptional manufacturing solutions at competitive prices.

Distributor Inquiry

Call: 8613-51090-74-01

Frequently Asked Questions About Billet Machining

What is the difference between billet machining and casting?

Billet machining is a subtractive process that removes material from a solid block to create the final part, while casting involves pouring molten metal into a mold. Billet machined parts typically offer better precision, surface finish, and structural integrity, while casting can be more cost-effective for high-volume production and complex internal geometries.

What tolerances can be achieved with billet machining?

At MAIKONG, our advanced CNC equipment can achieve tolerances as tight as ±0.005mm (0.0002″) depending on the part geometry and material. This precision makes billet machining ideal for components that require exact dimensions and fit.

What materials can be used for billet machining?

Billet machining can be performed on virtually any machinable material. Common choices include aluminum alloys (6061, 7075), stainless steel, carbon steel, brass, bronze, titanium, and various specialty alloys. The choice of material depends on your specific requirements for strength, weight, corrosion resistance, and cost.

Is billet machining cost-effective for large production runs?

Billet machining is most cost-effective for low to medium volume production. For very high volumes, methods like casting or forging may be more economical due to lower material waste and faster production times. However, for parts requiring exceptional precision or frequent design changes, billet machining may still be the preferred option regardless of volume.

What is the typical lead time for billet machined parts?

Lead times vary depending on part complexity, quantity, and current production schedule. Simple parts can often be produced in 1-2 weeks, while more complex components may require 3-4 weeks. At MAIKONG, we offer expedited services for time-sensitive projects and can provide specific timeline estimates based on your requirements.

Partner with MAIKONG for Superior Billet Machining Solutions

When precision, quality, and reliability matter for your custom parts, MAIKONG delivers exceptional billet machining services that meet your most demanding requirements. Our comprehensive capabilities, technical expertise, and commitment to customer satisfaction make us the ideal manufacturing partner for your next project.

From prototype development to production runs, our team is ready to help you achieve success with cost-effective, high-quality machined components. Contact us today to discuss your specific needs and discover how MAIKONG can support your manufacturing goals.

Billet machining is a subtractive manufacturing process that creates components by removing material from a solid block of metal, known as a billet. Unlike casting or forging, which form parts by pouring molten metal or applying pressure to heated material,

Billet machining is a subtractive manufacturing process that creates components by removing material from a solid block of metal, known as a billet. Unlike casting or forging, which form parts by pouring molten metal or applying pressure to heated material,