In the world of precision engineering, the cold forged type-II anodized machined aluminum spool represents the pinnacle of metallurgical excellence. These specialized components combine advanced forging techniques with precise machining and protective anodizing to deliver exceptional performance in demanding applications. MAIKONG brings decades of expertise to the manufacturing of these critical components, offering unmatched quality, durability, and cost-effectiveness for industries worldwide.

The Science Behind Cold Forged Type-II Anodized Machined Aluminum Spools

At MAIKONG, we’ve perfected the art and science of creating superior aluminum spools through a meticulous multi-stage process. Our manufacturing expertise ensures each component meets the highest standards of structural integrity and performance.

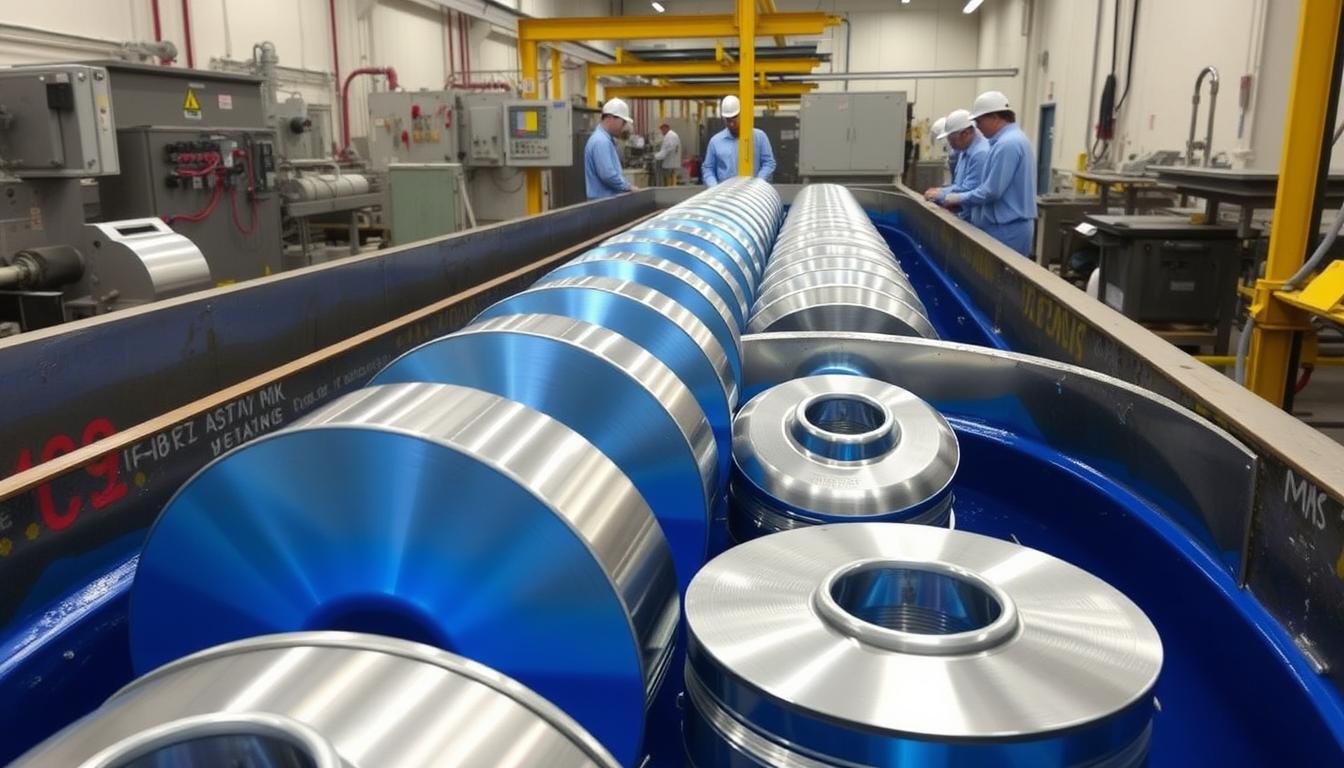

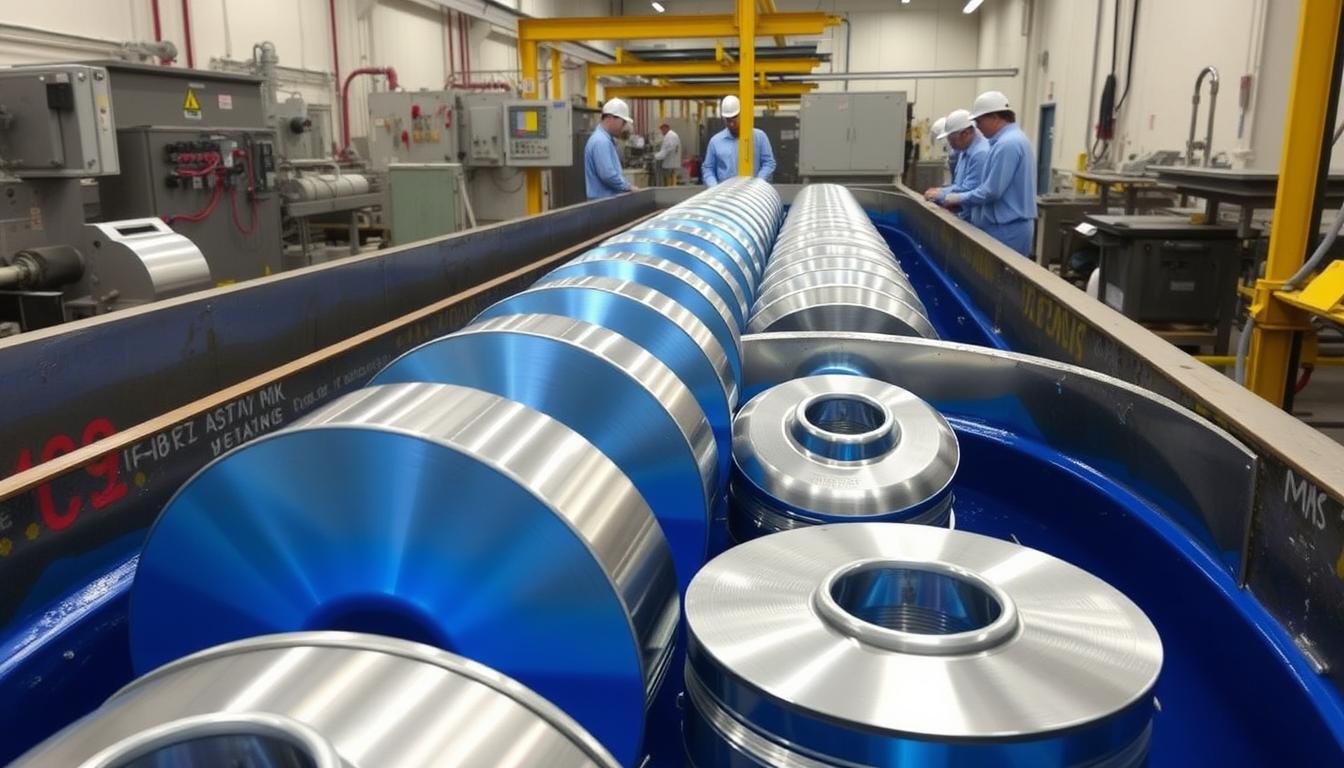

MAIKONG’s state-of-the-art cold forging facility in GD, SZ

MAIKONG’s state-of-the-art cold forging facility in GD, SZ

The Cold Forging Advantage for Type-II Anodized Machined Aluminum Spools

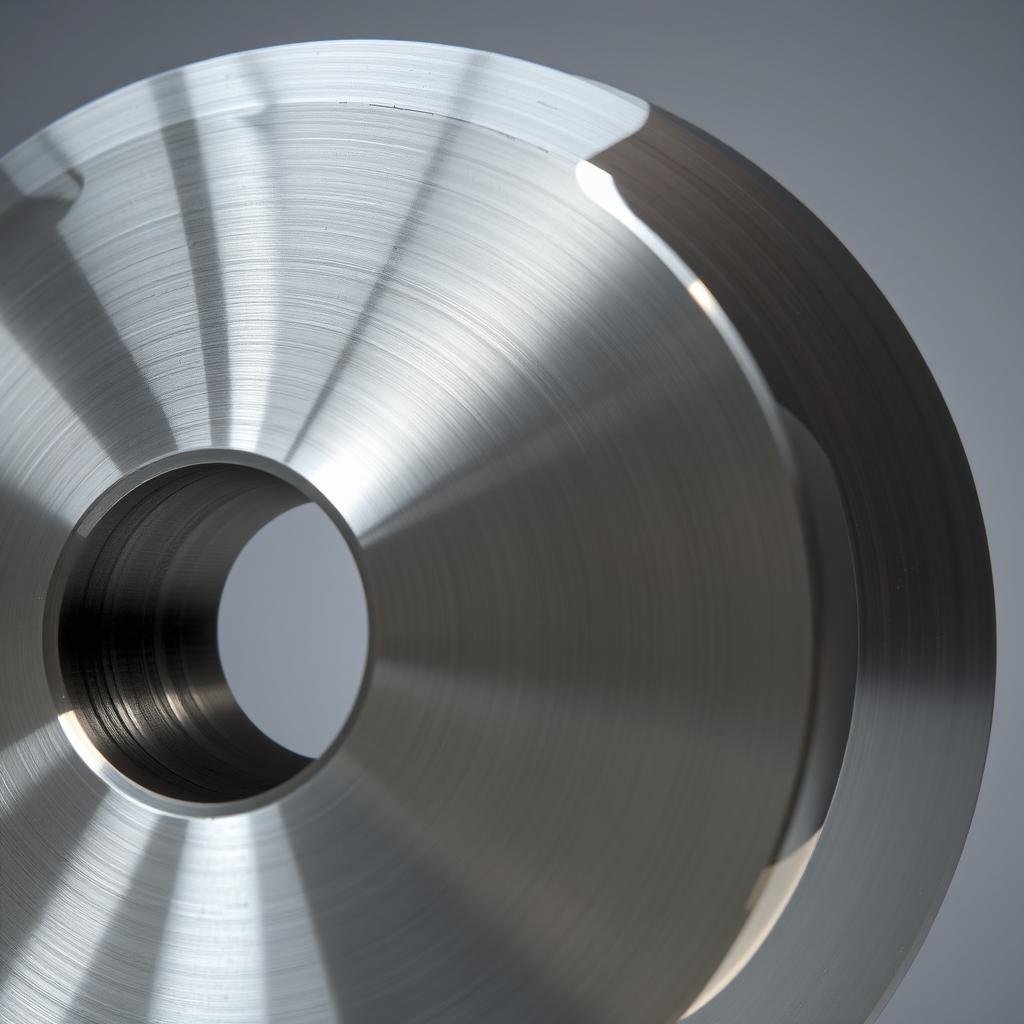

Cold forging fundamentally transforms the aluminum’s molecular structure, creating a denser, stronger material with superior grain alignment. Unlike casting, which can introduce porosity and inconsistencies, our cold forging process ensures exceptional structural integrity throughout the entire spool.

With our 60+ CNC machines and monthly capacity exceeding 100 tons, MAIKONG delivers precision-engineered components with remarkable consistency. The cold forging process aligns the metal’s grain structure along stress lines, significantly enhancing tensile strength and fatigue resistance – critical factors for components subjected to repeated stress cycles.

Key Benefits of Cold Forging

- Enhanced material density and structural integrity

- Superior tensile strength and fatigue resistance

- Optimized grain flow for improved mechanical properties

- Excellent dimensional stability and consistency

- Reduced material waste compared to machining from solid stock

Type-II Anodizing: Superior Protection for Aluminum Spools

After the cold forging and precision machining processes, our aluminum spools undergo Type-II anodizing – a critical surface treatment that dramatically enhances corrosion resistance, wear protection, and aesthetic appeal.

MAIKONG’s advanced Type-II anodizing facility ensures superior surface protection

The Science of Type-II Anodizing for Cold Forged Machined Aluminum Spools

Type-II anodizing is an electrochemical process that creates a protective oxide layer on the aluminum surface. At MAIKONG, we’ve optimized this process to deliver a coating thickness of 0.7-25 microns, providing the ideal balance of protection and dimensional precision.

Type-II anodizing forms a corrosion-resistant and durable oxide layer with a thickness ranging from 0.7 to 25 microns, depending on the intended application. The coating’s color varies based on the metal type and voltage of the current.

Advantages of Type-II Anodizing

- Exceptional corrosion resistance in diverse environments

- Enhanced surface hardness and wear resistance

- Excellent electrical insulation properties

- Ability to accept dyes for customized appearance

- Environmentally friendly surface treatment

Precision CNC Machining for Perfect Aluminum Spools

The final stage in creating our premium cold forged type-ii anodized machined aluminum spools involves sophisticated CNC machining. This process ensures perfect dimensional accuracy, smooth operation, and flawless performance in the most demanding applications.

MAIKONG’s advanced CNC machining ensures perfect dimensional accuracy

Our Comprehensive CNC Machining Capabilities

MAIKONG offers a complete range of machining services to transform cold forged aluminum components into precision-engineered spools. Our technical expertise spans multiple machining disciplines:

CNC Turning

Perfect for creating cylindrical profiles, deep holes, and machined threads with superior surface finishes. Our CNC turning capabilities deliver exceptional precision for all spool dimensions.

CNC Milling

Ideal for complex prismatic shapes and flat surfaces. Our multi-axis CNC milling machines require no fixed tooling, offering flexibility and extreme accuracy for intricate spool features.

Swiss-Type Machining

Specialized precision for small parts and long shaft components. Our equipment features dual spindles and multi-axis capabilities for one-stop manufacturing solutions.

Need Custom Machined Aluminum Components?

Our engineering team can help design and manufacture custom aluminum spools and components to your exact specifications.

Get A Quick Quote

Aluminum Forging vs. Casting: Why Choose Forged Spools?

When selecting manufacturing methods for aluminum spools, the choice between forging and casting significantly impacts performance, durability, and reliability. MAIKONG specializes in cold forging because it delivers superior results for critical components.

Visual comparison between forged (left) and cast (right) aluminum spools

| Comparison Categories |

Cold Forged Aluminum Spools |

Cast Aluminum Spools |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Lower due to potential air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Excellent resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Grain Structure |

Directional grain flow for improved properties |

No directional grain structure |

| Weight-to-Strength Ratio |

High strength-to-weight ratio |

Bulkier parts may be needed for equivalent strength |

Optimized Strength-to-Weight Ratio in Cold Forged Type-II Anodized Machined Aluminum Spools

The exceptional strength-to-weight ratio of our aluminum spools makes them ideal for applications where performance and efficiency are paramount. Through our specialized cold forging process, we enhance the aluminum’s natural properties to deliver components that are both lightweight and incredibly strong.

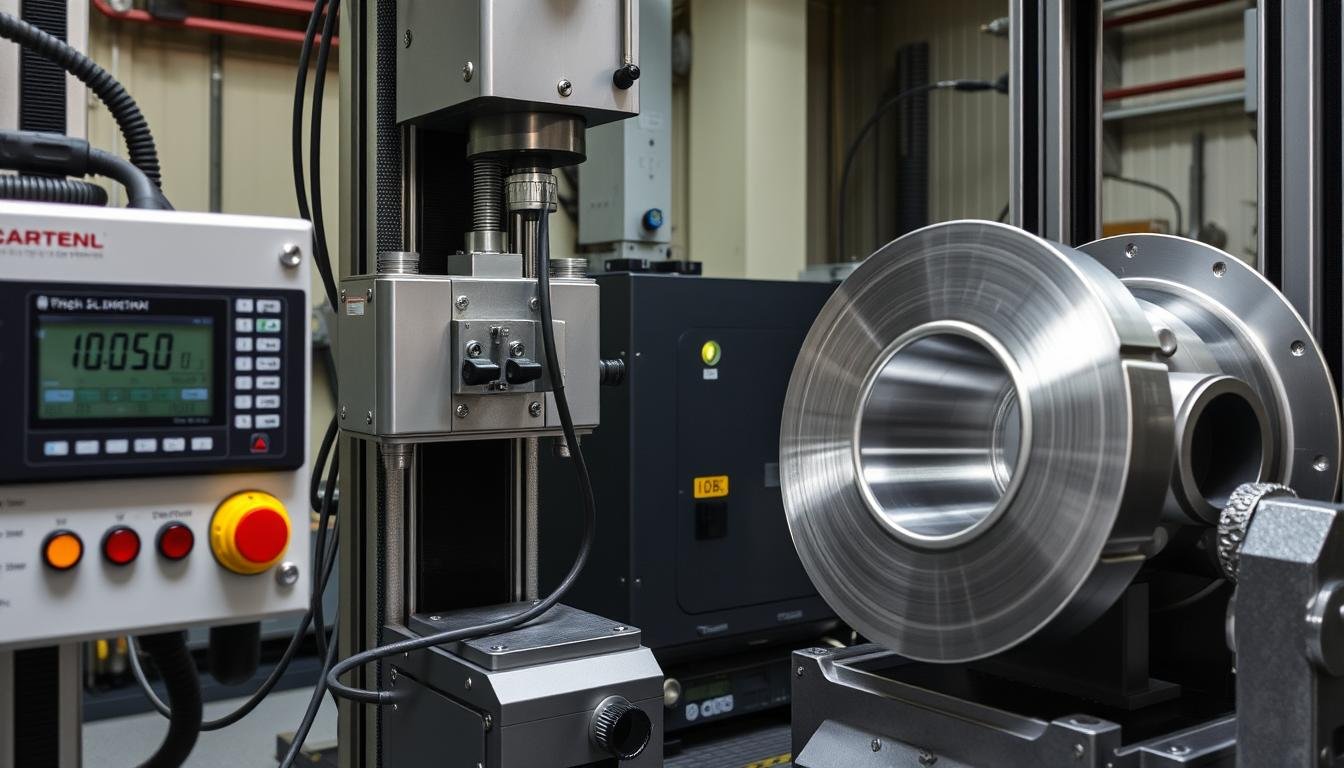

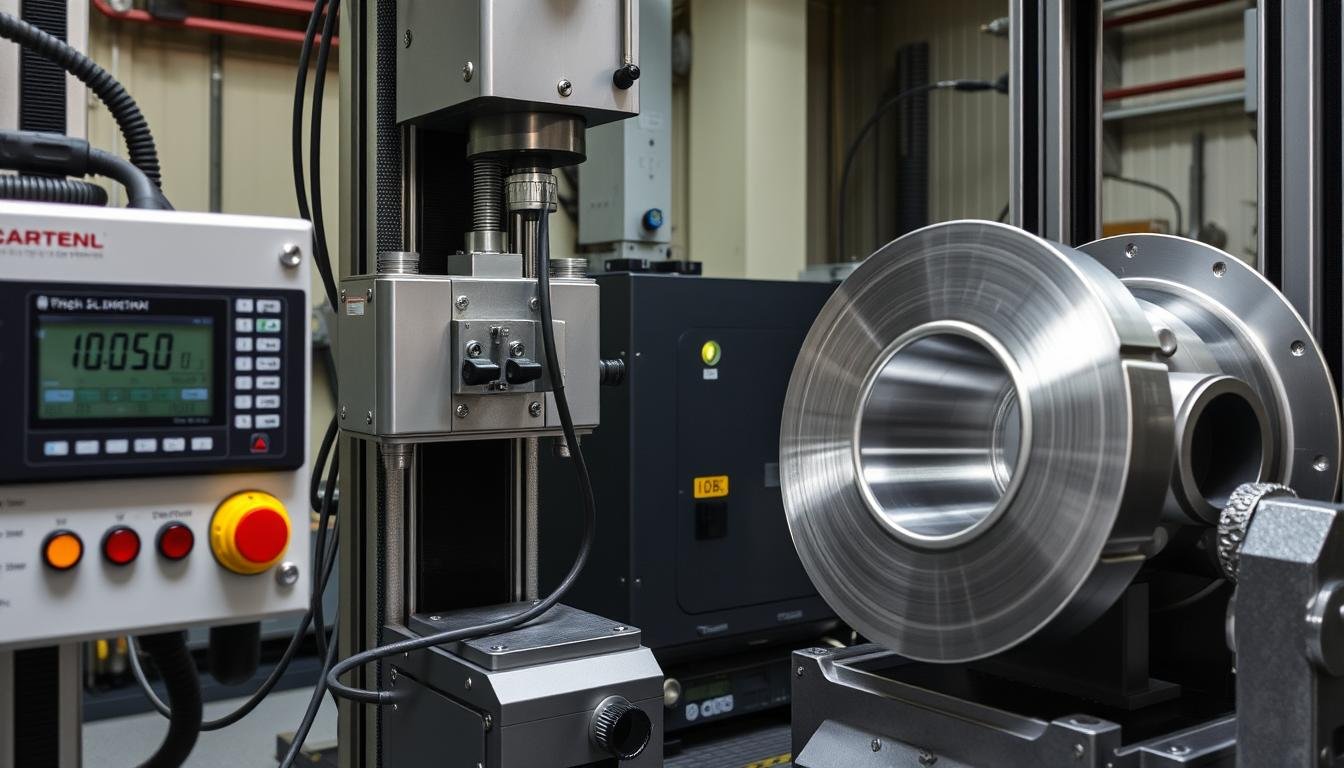

MAIKONG’s quality control lab conducting strength testing on finished spools

Engineering Excellence in Cold Forged Type-II Anodized Machined Aluminum Spools

Our engineering team leverages decades of metallurgical expertise to optimize the grain structure of aluminum through controlled deformation. This process, combined with precise heat treatment and Type-II anodizing, creates components with exceptional mechanical properties.

Applications Benefiting from Optimized Strength-to-Weight Ratio

- Aerospace components requiring minimal weight and maximum reliability

- High-performance fishing reels and outdoor equipment

- Automotive systems where weight reduction improves efficiency

- Industrial machinery requiring durable, lightweight components

- Medical devices demanding strength and precision

MAIKONG’s Full-Service Manufacturing Process

As a comprehensive manufacturing partner, MAIKONG handles every aspect of producing cold forged type-ii anodized machined aluminum spools. Our integrated approach ensures quality control at every stage, from initial design to final delivery.

MAIKONG’s comprehensive manufacturing facility in GD, SZ

Our End-to-End Manufacturing Capabilities

Design & Engineering

Our engineering team utilizes advanced CAD/CAM software to optimize designs for manufacturability. We conduct finite element analysis to identify and address potential issues before production begins.

Material Selection

We carefully select aluminum alloys based on mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness to ensure optimal performance.

Tooling Design

Our precision tooling ensures initial quality, while regular maintenance preserves consistency – both critical factors for producing high-quality forgings.

Forging Process

Our forging workshop accommodates diverse aluminum forging specifications, with specialized equipment for cold forging that enhances material properties.

Heat Treatment

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment, ensuring optimal mechanical properties.

Precision Machining

Our state-of-the-art CNC machines perform precise and intricate operations to transform forgings into finished components with exact specifications.

Surface Treatment

Our Type-II anodizing process enhances appearance, performance, and durability, with strict quality controls to ensure consistent results.

Quality Control

Rigorous inspection procedures ensure every component meets stringent standards for dimensional accuracy, surface finish, and mechanical properties.

Global Logistics

We manage the entire supply chain from raw materials to final delivery, ensuring timely shipment to customers worldwide.

Partner with MAIKONG for Complete Manufacturing Solutions

Experience the benefits of working with a full-service aluminum forging and machining specialist.

Become a Distributor

Industry Applications for Cold Forged Type-II Anodized Machined Aluminum Spools

The exceptional properties of our aluminum spools make them ideal for numerous applications across diverse industries. From high-performance fishing equipment to critical aerospace components, MAIKONG’s precision-engineered spools deliver reliability in demanding environments.

MAIKONG’s aluminum spools serve diverse industries with demanding requirements

Fishing & Marine

Our aluminum spools are ideal for high-performance fishing reels, offering exceptional corrosion resistance in saltwater environments while maintaining lightweight handling and smooth operation.

Aerospace & Defense

The superior strength-to-weight ratio and reliability of our aluminum spools make them perfect for aerospace applications where performance and safety are critical.

Automotive

From performance vehicles to commercial transport, our aluminum spools provide lightweight, durable solutions for various automotive systems and components.

Industrial Machinery

Our robust aluminum spools withstand demanding industrial environments, offering long service life and reliable performance in critical applications.

Medical Equipment

The precision and reliability of our aluminum components make them suitable for sophisticated medical devices and equipment.

Consumer Products

From high-end audio equipment to premium tools, our aluminum spools add value to consumer products where quality and performance matter.

Quality Assurance and Certifications

At MAIKONG, quality is built into every step of our manufacturing process. Our commitment to excellence is backed by rigorous testing, comprehensive quality management systems, and international certifications.

MAIKONG’s quality control laboratory ensures every component meets strict specifications

Our Quality Management System

MAIKONG maintains comprehensive quality management systems that monitor every aspect of production. From raw material verification to final inspection, we ensure consistent quality in every component we manufacture.

Quality Certifications

- ISO 9001:2015 Quality Management System

- IATF 16949 Automotive Quality Management

- Environmental Management System certification

- Material testing and verification capabilities

- Comprehensive statistical process control

Quality expresses a component’s capacity for fully satisfying the customer’s needs and expectations. At MAIKONG, we let the numbers speak for themselves through rigorous testing and verification.

MAIKONG’s state-of-the-art cold forging facility in GD, SZ

MAIKONG’s state-of-the-art cold forging facility in GD, SZ