MAIKONG, we specialize in crafting premium machined forged aluminum center wheels that combine exceptional strength, reduced weight, and superior performance. Our state-of-the-art manufacturing facility in GD, SZ delivers custom-engineered wheel solutions that meet the most demanding specifications for automotive applications worldwide. With decades of expertise in aluminum forging and precision CNC machining, we provide cost-effective manufacturing solutions without compromising on quality or performance.

Superior Advantages of Machined Forged Aluminum Center Wheels

The machined forged aluminum center wheel represents the pinnacle of wheel engineering, offering significant advantages over cast alternatives. Our manufacturing process ensures optimal grain structure alignment, resulting in wheels that deliver exceptional performance under the most demanding conditions.

Strength-to-Weight Excellence

Our machined forged aluminum center wheels deliver an optimal balance between structural integrity and weight reduction. Through our advanced forging techniques, we achieve up to 35% weight reduction compared to cast wheels while maintaining superior strength characteristics.

Enhanced Performance Characteristics

The directional grain structure created during our forging process significantly improves fatigue resistance, impact strength, and overall durability. This makes our machined forged aluminum center wheels ideal for high-performance applications where reliability is paramount.

Ready to Upgrade Your Wheel Manufacturing?

Discover how MAIKONG’s machined forged aluminum center wheel technology can enhance your product offerings with superior performance and competitive pricing.

Get a Custom Quote

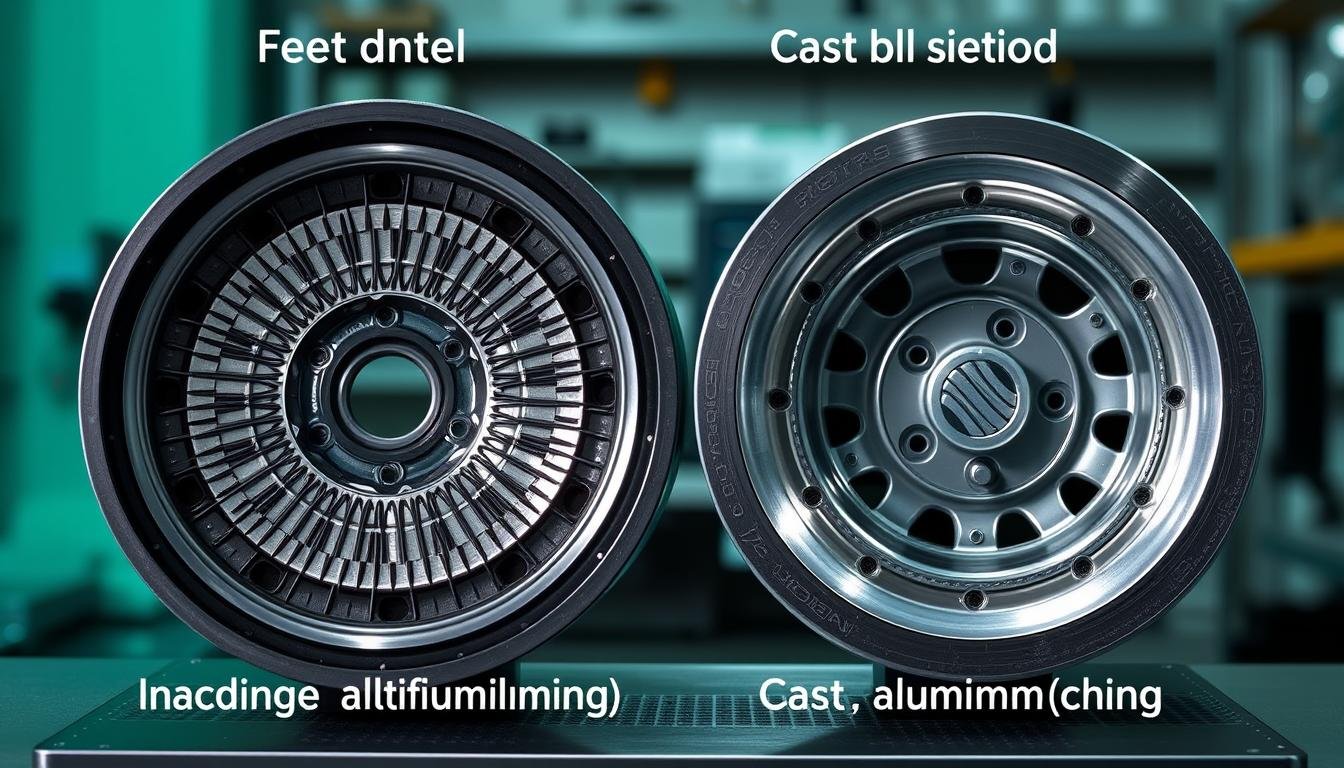

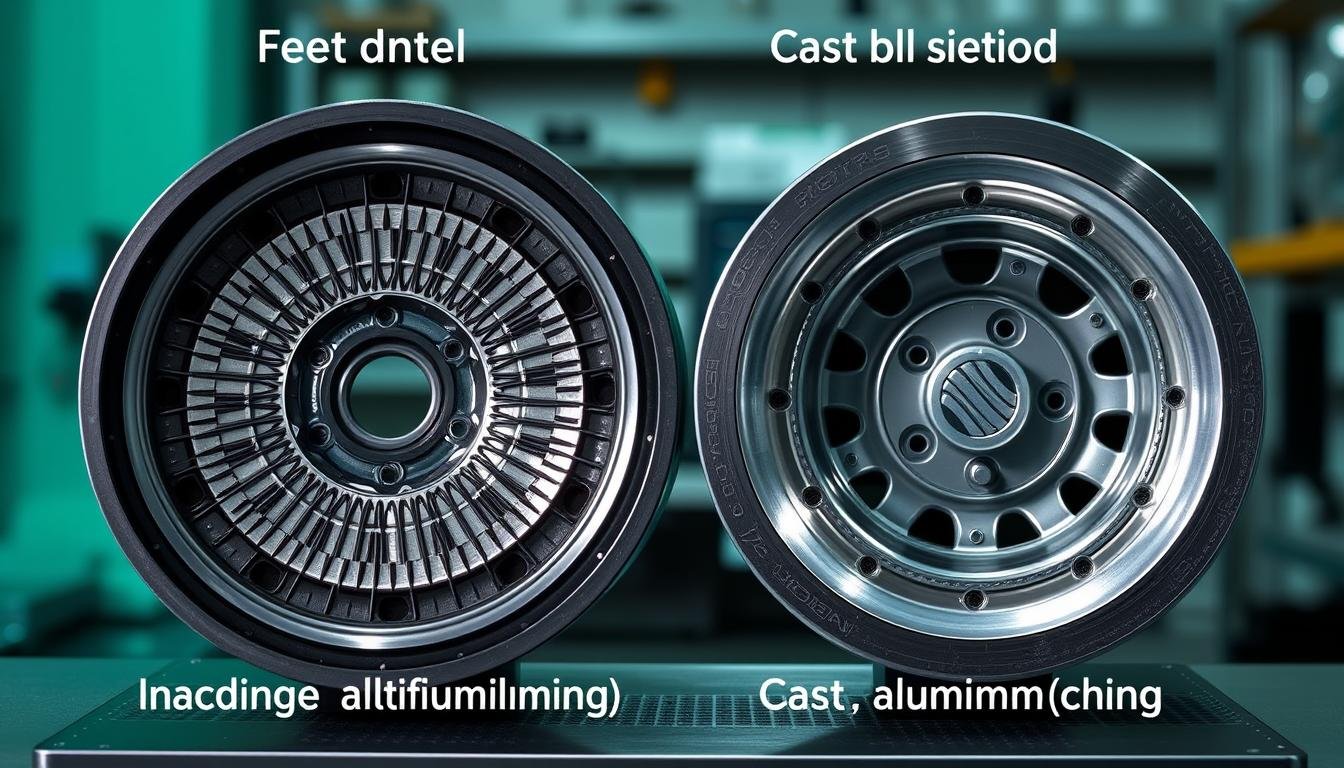

Machined Forged Aluminum Center Wheel vs. Cast Aluminum

Understanding the fundamental differences between forged and cast aluminum wheels helps illustrate why machined forged aluminum center wheels are the preferred choice for performance applications. Our manufacturing process ensures superior mechanical properties through controlled deformation and precision machining.

| Comparison Criteria |

MAIKONG Machined Forged Aluminum Center Wheel |

Cast Aluminum Wheel |

| Strength and Durability |

Superior strength due to dense, uniform grain structure |

Lower strength with potential air pockets and inclusions |

| Weight Reduction |

Up to 35% lighter than equivalent cast wheels |

Heavier construction required for comparable strength |

| Fatigue Resistance |

Exceptional resistance to cyclic loading and fatigue failure |

More susceptible to fatigue-related failures |

| Dimensional Accuracy |

Precision CNC machining ensures tight tolerances (±0.02mm) |

Wider tolerance ranges and potential inconsistencies |

| Surface Finish |

Superior surface quality requiring minimal post-processing |

Often requires extensive machining to remove surface defects |

| Ideal Applications |

Performance vehicles, racing, premium automotive |

Standard consumer vehicles, non-critical applications |

Our Machined Forged Aluminum Center Wheel Manufacturing Process

At MAIKONG, we’ve perfected the art and science of creating premium machined forged aluminum center wheels through our comprehensive manufacturing process. Each step is carefully controlled to ensure exceptional quality and consistency.

1. Design & Engineering

Our engineering team utilizes advanced CAD/CAM software to design wheels that meet specific performance requirements. We employ finite element analysis (FEA) to optimize structural integrity while minimizing weight.

2. Material Selection

We carefully select premium aluminum alloys (typically 6061-T6 or 7075) based on the specific application requirements, ensuring optimal mechanical properties for each machined forged aluminum center wheel.

3. Forging Process

Our forging process applies controlled pressure to align the aluminum’s grain structure, significantly enhancing strength and durability compared to cast alternatives.

4. Heat Treatment

Precision heat treatment optimizes the mechanical properties of each machined forged aluminum center wheel, ensuring consistent performance characteristics.

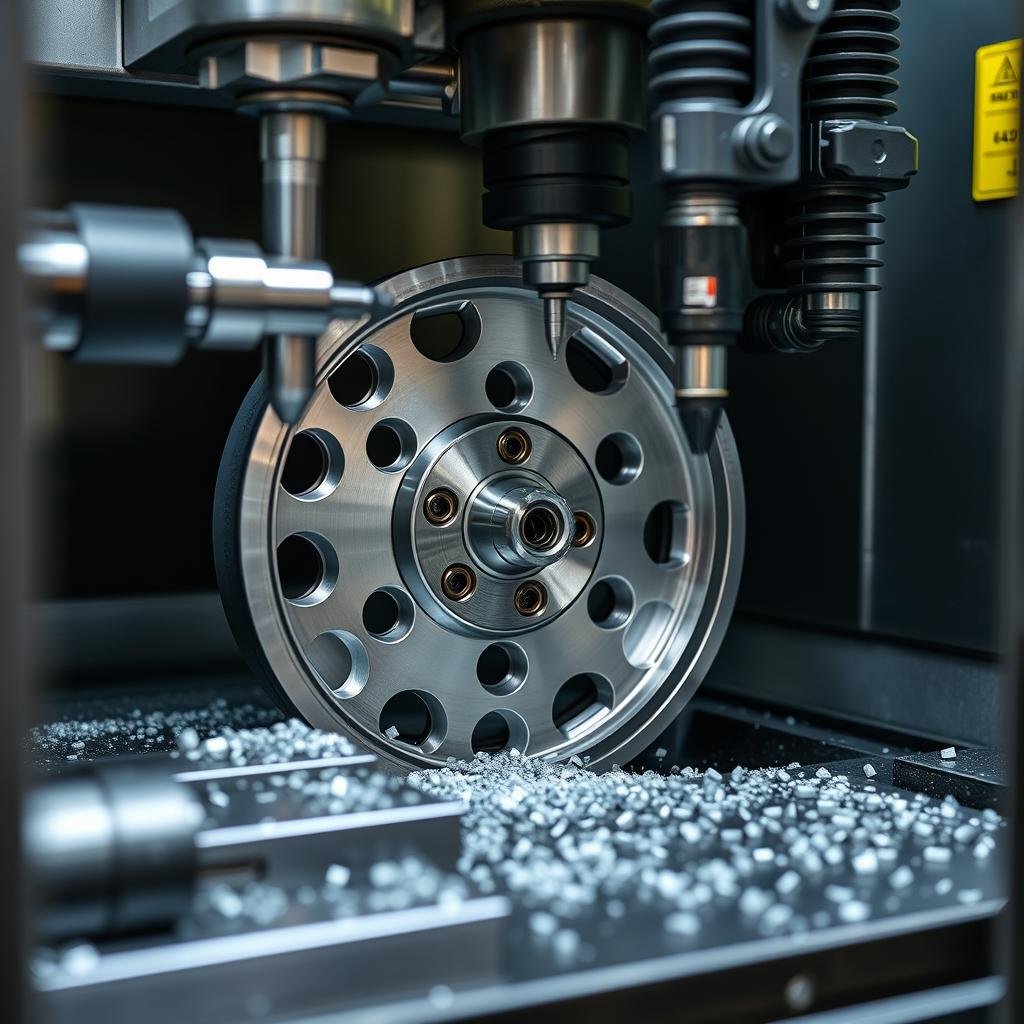

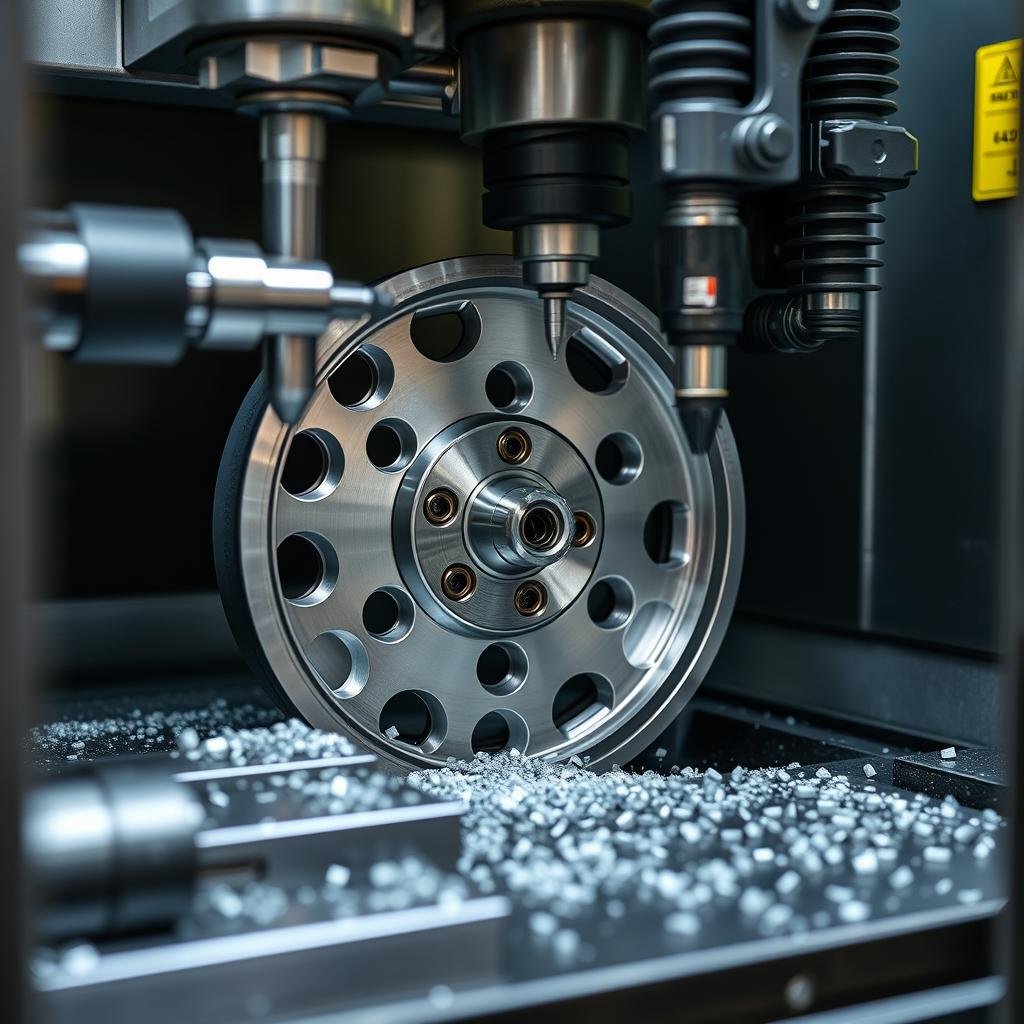

5. CNC Machining

Our state-of-the-art CNC machining centers provide precise dimensional control, creating the final contours and features of each wheel with tolerances as tight as ±0.02mm.

6. Quality Control

Rigorous quality control procedures, including dimensional inspection and material testing, ensure each machined forged aluminum center wheel meets our exacting standards.

Partner with MAIKONG for Superior Wheel Manufacturing

Our comprehensive manufacturing process ensures exceptional quality and performance for every machined forged aluminum center wheel.

Contact Our Engineers on WhatsApp

Custom Machined Forged Aluminum Center Wheel Solutions

At MAIKONG, we specialize in creating bespoke machined forged aluminum center wheels tailored to your specific requirements. Our engineering team works closely with clients to develop custom solutions that meet precise performance specifications and aesthetic requirements.

Design Customization Options

- Custom spoke patterns and designs

- Varied center bore configurations

- Custom bolt patterns and PCD specifications

- Specialized center cap integration

- Unique surface finishes and treatments

- Weight optimization for specific applications

- Custom offsets and backspacing

Surface Finish Options

Polished Finish

Mirror-like reflective surface highlighting the premium quality of our machined forged aluminum center wheels.

Brushed Finish

Sophisticated satin appearance with directional grain pattern for a contemporary aesthetic.

Anodized Finish

Durable colored surface treatment available in various hues to match brand aesthetics.

Need Custom Machined Forged Aluminum Center Wheel Solutions?

Our engineering team is ready to develop bespoke wheel solutions tailored to your specific requirements.

Email Our Design Team

Technical Specifications of Our Machined Forged Aluminum Center Wheels

MAIKONG’s machined forged aluminum center wheels are engineered to meet the most demanding performance requirements. Our manufacturing capabilities allow for a wide range of specifications to accommodate diverse applications.

| Specification |

Available Range |

Notes |

| Diameter |

15″ to 24″ |

Custom sizes available upon request |

| Width |

6″ to 14″ |

Precision machined to exact specifications |

| Bolt Patterns |

4×100 to 6×139.7 |

Custom patterns available for specialized applications |

| Center Bore |

56.1mm to 87.1mm |

Precision machined for hub-centric fitment |

| Offset Range |

-45mm to +60mm |

Custom offsets available for specific applications |

| Load Rating |

Up to 1,200kg per wheel |

Engineered for optimal safety margins |

| Weight Reduction |

25-35% vs. cast equivalents |

Application-specific optimization available |

Material Specifications

Our machined forged aluminum center wheels are manufactured using premium aluminum alloys selected for their optimal mechanical properties:

- 6061-T6 Aluminum: Excellent strength-to-weight ratio with good corrosion resistance

- 7075-T6 Aluminum: Superior strength for high-performance applications

- 2024-T3 Aluminum: Exceptional fatigue resistance for demanding conditions

Need Specific Technical Requirements?

Our engineering team can develop custom machined forged aluminum center wheels to meet your exact specifications.

Request Technical Consultation

Quality Assurance for Machined Forged Aluminum Center Wheels

At MAIKONG, we implement rigorous quality control procedures throughout our manufacturing process to ensure each machined forged aluminum center wheel meets the highest standards of performance and reliability.

Material Verification

We conduct comprehensive material testing to verify chemical composition and mechanical properties of all aluminum alloys used in our manufacturing process.

Dimensional Inspection

Advanced coordinate measuring machines (CMM) ensure precise dimensional accuracy for every machined forged aluminum center wheel.

Structural Testing

Rigorous structural testing, including impact and fatigue testing, validates the performance and durability of our wheels under extreme conditions.

Certification Standards

Our machined forged aluminum center wheels meet or exceed international quality and safety standards:

- ISO 9001:2015 Quality Management System

- IATF 16949 Automotive Quality Management

- JWL/VIA Certification Standards

- TÜV Certification Requirements

- SAE J2530 Aftermarket Wheel Performance Requirements

Quality You Can Trust

Experience the MAIKONG difference with our rigorously tested and certified machined forged aluminum center wheels.

Request Quality Documentation

Applications for Machined Forged Aluminum Center Wheels

MAIKONG’s premium machined forged aluminum center wheels are engineered for a wide range of applications where performance, weight reduction, and reliability are critical factors.

High-Performance Automotive

Our machined forged aluminum center wheels deliver the optimal balance of strength and weight reduction for sports cars and performance vehicles.

Motorsport & Racing

Engineered for the extreme demands of competitive motorsport, our wheels provide the durability and performance required for racing applications.

Luxury Vehicles

Premium aesthetics combined with superior performance make our machined forged aluminum center wheels ideal for luxury vehicle applications.

Off-Road & SUV

Robust construction and impact resistance make our wheels suitable for demanding off-road applications where durability is paramount.

Aftermarket Customization

Our custom machined forged aluminum center wheels provide endless possibilities for vehicle personalization and performance enhancement.

Commercial Vehicles

Weight reduction and durability benefits make our wheels an excellent choice for commercial applications where efficiency is critical.

Find the Perfect Wheel Solution for Your Application

Our engineering team can help you select or develop the ideal machined forged aluminum center wheel for your specific requirements.

Discuss Your Application Needs

MAIKONG’s Machined Forged Aluminum Center Wheel Manufacturing Capabilities

Our state-of-the-art manufacturing facility in GD, SZ is equipped with advanced machinery and staffed by skilled technicians to deliver exceptional machined forged aluminum center wheels with precision and efficiency.

Production Capacity

- Monthly production capacity of 100+ tons of metal processing

- 60+ CNC machines for precision machining

- Hydraulic forging presses ranging from 800 to 3,000 tons

- Heat treatment facilities with precise temperature control

- Advanced surface treatment capabilities

- Comprehensive quality control laboratory

Additional Manufacturing Services

CNC Machining Services

Precision CNC turning, milling, and multi-axis machining for complex wheel geometries and tight tolerances.

Surface Treatment

Comprehensive surface finishing options including anodizing, painting, polishing, and custom finishes for machined forged aluminum center wheels.

Custom Engineering

Full-service engineering support from concept development through production for bespoke wheel solutions.

Partner with MAIKONG for Your Wheel Manufacturing Needs

Experience our comprehensive manufacturing capabilities for premium machined forged aluminum center wheels.

Contact Our Manufacturing Team

Become a MAIKONG Machined Forged Aluminum Center Wheel Distributor

We’re actively seeking distribution partners across the United States for our premium machined forged aluminum center wheels. Partner with MAIKONG to offer your customers exceptional quality, performance, and value.

Distributor Benefits

- Competitive pricing structure for excellent margins

- Custom branding opportunities

- Technical support and training

- Marketing materials and product documentation

- Flexible minimum order quantities

- Reliable lead times and delivery schedules

- Comprehensive warranty support

Become a MAIKONG Distribution Partner

Join our network of distributors and offer your customers premium machined forged aluminum center wheels at competitive prices.

Apply for Distributorship

Why Choose MAIKONG for Your Machined Forged Aluminum Center Wheel Needs

MAIKONG combines technical expertise, manufacturing excellence, and competitive pricing to deliver superior machined forged aluminum center wheels for diverse applications. Our commitment to quality, innovation, and customer satisfaction makes us the ideal manufacturing partner for your wheel requirements.

Technical Excellence

Our engineering team brings decades of experience in aluminum forging and precision machining to every project, ensuring optimal performance and reliability.

Manufacturing Capability

Our state-of-the-art facility equipped with advanced machinery enables us to deliver exceptional quality machined forged aluminum center wheels with efficiency and precision.

Customer Focus

We work closely with each client to understand their specific requirements and develop customized solutions that meet their exact needs and expectations.

Ready to Elevate Your Wheel Performance?

Contact MAIKONG today to discuss your machined forged aluminum center wheel requirements and discover the difference our expertise can make for your business.

Get Started Today