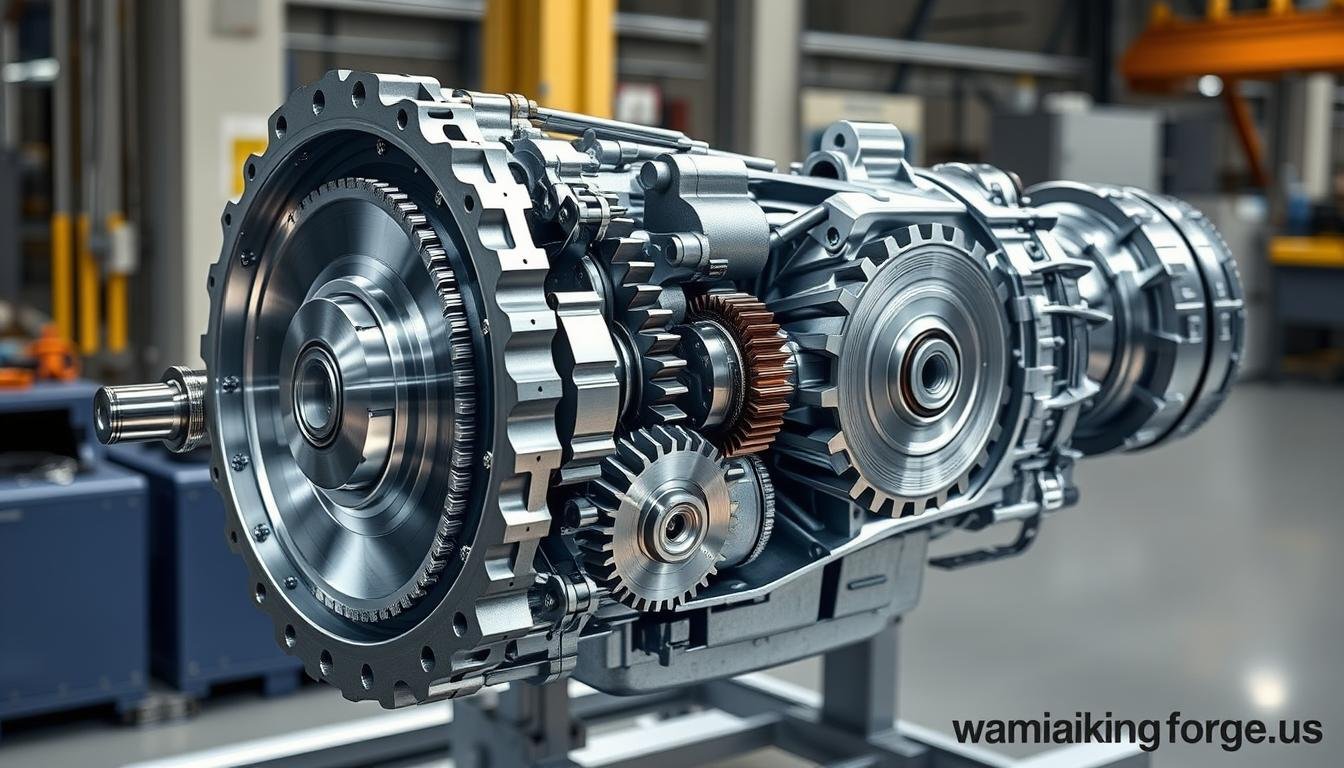

When it comes to manufacturing high-performance gears, the choice between gear forged aluminum vs machined steel can significantly impact your product’s performance, durability, and cost-effectiveness. Both materials offer distinct advantages in specific applications, making the selection process crucial for engineers and manufacturers alike. At MAIKONG, we specialize in both aluminum forging and steel machining processes, providing you with comprehensive insights to make the optimal material choice for your specific requirements.

Material Properties: Gear Forged Aluminum vs Machined Steel

Strength and Durability Comparison

When evaluating gear forged aluminum vs machined steel for gear applications, strength characteristics are paramount. Forged aluminum gears typically offer yield strengths between 35,000-45,000 psi, depending on the specific alloy and forging process. The forging process aligns the grain structure of aluminum, significantly enhancing its strength compared to cast aluminum.

Machined steel gears, by comparison, demonstrate superior strength properties with yield strengths often exceeding 100,000 psi for alloy steels. This makes machined steel the preferred choice for high-torque applications where maximum strength is essential.

The forging process aligns aluminum’s grain structure with the part geometry, creating a stronger component than would be possible with other manufacturing methods. This grain alignment is particularly beneficial for gear applications where directional forces are applied.

Weight and Density Benefits

One of the most significant advantages of forged aluminum gears is their weight. With a density of approximately 2.7 g/cm³ compared to steel’s 7.85 g/cm³, aluminum gears are nearly 65% lighter than their steel counterparts. This weight reduction translates to:

- Reduced inertia in rotating assemblies

- Lower energy consumption in operation

- Decreased overall system weight

- Improved fuel efficiency in automotive applications

- Enhanced acceleration and deceleration characteristics

Need Expert Guidance on Material Selection?

Our engineering team can help you determine whether forged aluminum or machined steel is optimal for your specific gear application.

Get Expert Advice

Manufacturing Processes and Their Impact

Forging Process for Aluminum Gears

The forging process for aluminum gears involves heating aluminum billets to temperatures between 300°C and 500°C, then applying controlled pressure to shape the material. This process offers several advantages:

Forging Benefits:

- Enhanced grain structure alignment

- Improved mechanical properties

- Greater strength-to-weight ratio

- Reduced internal defects

- Superior fatigue resistance

Forging Limitations:

- Higher initial tooling costs

- Limitations on complex geometries

- Reduced ductility after forging

- Limited alloy selection

- More complex process control requirements

Machining Process for Steel Gears

Steel gear machining typically involves CNC milling or turning operations to create precise gear profiles from steel stock. MAIKONG utilizes advanced CNC technology with over 60 machines providing 100+ tons of metal processing capacity monthly.

Machining Benefits:

- Exceptional dimensional accuracy

- Ability to create complex geometries

- Excellent surface finish

- Flexibility in design modifications

- Lower initial tooling costs

Machining Limitations:

- Material waste from cutting

- Longer production times for complex parts

- Higher energy consumption

- No grain structure improvement

- Higher material costs for specialty steels

Cost Analysis and Manufacturing Considerations

Initial Production Costs

The initial production costs for gear forged aluminum vs machined steel vary significantly based on several factors:

Forged Aluminum Cost Factors:

- Higher tooling setup costs

- More expensive raw material

- Lower machining costs post-forging

- Reduced energy consumption during machining

- Faster production cycles for large volumes

Machined Steel Cost Factors:

- Lower initial tooling costs

- Less expensive raw material

- Higher machining costs

- Increased energy consumption

- Longer production cycles

Lifecycle Cost Considerations

When evaluating the total cost of ownership, several factors beyond initial production costs should be considered:

- Energy savings from lighter aluminum components

- Maintenance requirements and frequency

- Replacement intervals based on wear characteristics

- System efficiency improvements from reduced weight

- Environmental impact and recycling value

At MAIKONG, we help our clients analyze both initial and lifecycle costs to determine the most cost-effective material choice for their specific application requirements.

Request a Custom Quote

Get a detailed cost analysis for your gear manufacturing project comparing forged aluminum and machined steel options.

Request Quote

Industry Applications and Case Studies

Automotive Industry Applications

In automotive applications, the choice between gear forged aluminum vs machined steel depends largely on the specific requirements of the component:

Forged Aluminum Applications:

- Differential carrier gears

- Timing gears

- Accessory drive gears

- Electric vehicle reduction gears

- Performance racing transmission components

Machined Steel Applications:

- High-torque transmission gears

- Heavy-duty differential gears

- Camshaft drive gears

- Commercial vehicle powertrain components

- High-stress planetary gear systems

Aerospace and Defense Applications

The aerospace industry has unique requirements where both materials find specialized applications:

Forged aluminum gears are particularly valuable in aerospace applications where weight reduction is critical. These components can reduce system weight by up to 65% compared to steel alternatives, directly improving fuel efficiency and payload capacity. MAIKONG supplies precision forged aluminum gears for various aerospace systems, including actuators, flap mechanisms, and auxiliary power units.

Machined steel gears remain essential for high-stress aerospace applications such as main transmission systems, landing gear mechanisms, and engine accessories where maximum strength and durability are non-negotiable requirements.

MAIKONG’s aerospace-grade manufacturing processes meet stringent industry standards for both forged aluminum and machined steel components, ensuring reliability in critical applications.

Quality Control and Manufacturing Excellence

MAIKONG’s Manufacturing Capabilities

At MAIKONG, we maintain exceptional quality standards across both our forging and machining operations:

- 60+ CNC machines with 100+ tons monthly metal processing capacity

- Advanced forging presses for precision aluminum components

- State-of-the-art material testing laboratory

- ISO 9001:2015 certified quality management system

- Comprehensive inspection capabilities including CMM, ultrasonic testing, and metallurgical analysis

Material Verification and Testing

Our rigorous quality control process ensures that both forged aluminum and machined steel gears meet exact specifications:

Aluminum Testing Protocols:

- Chemical composition analysis

- Grain structure verification

- Hardness testing

- Dimensional inspection

- Non-destructive testing

Steel Testing Protocols:

- Alloy verification

- Hardness and microhardness testing

- Surface finish measurement

- Precision dimensional inspection

- Heat treatment verification

Making the Right Choice: Gear Forged Aluminum vs Machined Steel

Decision Factors for Material Selection

When deciding between gear forged aluminum vs machined steel for your gear applications, consider these key factors:

When to Choose Forged Aluminum

- Weight reduction is a primary concern

- Moderate load requirements

- Corrosion resistance is needed

- Noise and vibration dampening are important

- Heat dissipation is critical

- High production volumes can offset tooling costs

When to Choose Machined Steel

- Maximum strength and durability are required

- High-torque applications

- Extreme operating conditions

- Dimensional stability across temperature ranges

- Extended service life is critical

- Lower initial tooling costs for small production runs

Hybrid Solutions and Custom Approaches

In many applications, the optimal solution may involve a combination of both materials. MAIKONG specializes in designing hybrid gear systems that leverage the strengths of both forged aluminum and machined steel components working together.

Our engineering team can develop custom solutions that incorporate:

- Forged aluminum housings with machined steel gear inserts

- Composite gear designs with aluminum cores and steel tooth surfaces

- Selective material application based on load analysis

- Specialized surface treatments to enhance performance characteristics

- Advanced alloy selection for optimized properties

The optimal material choice depends on your specific application requirements. MAIKONG’s engineering team provides comprehensive analysis to help you make the best decision for your unique needs.

Conclusion: Partner with MAIKONG for Your Gear Manufacturing Needs

The debate between gear forged aluminum vs machined steel doesn’t have a one-size-fits-all answer. Each material offers distinct advantages that make it suitable for specific applications. At MAIKONG, we excel in manufacturing both forged aluminum and machined steel gears, providing you with the flexibility to choose the optimal material for your requirements.

Our comprehensive services include:

- Expert material selection consultation

- Precision CNC machining services

- Advanced aluminum forging capabilities

- Custom metal parts manufacturing

- Comprehensive quality control and testing

- Full-service supply chain solutions

With over 60 CNC machines and 100+ tons of monthly metal processing capacity, MAIKONG is your trusted partner for high-quality gear manufacturing, whether you choose forged aluminum, machined steel, or a custom hybrid solution.

Contact MAIKONG Today

Ready to discuss your gear manufacturing project? Our team of experts is standing by to help you select the optimal material and manufacturing process for your specific requirements.

MAIKONG is actively seeking US distributors and agents for our high-quality, cost-effective forging and machining services. Contact us today to explore partnership opportunities!

Frequently Asked Questions

What are the main advantages of forged aluminum gears over machined steel?

Forged aluminum gears offer significant weight reduction (approximately 65% lighter than steel), excellent corrosion resistance, better heat dissipation, and improved noise/vibration dampening. These properties make them ideal for applications where weight reduction and efficiency are priorities.

When should I choose machined steel gears instead of forged aluminum?

Machined steel gears are preferable for high-torque applications, environments with extreme operating conditions, situations requiring maximum durability and wear resistance, and applications where dimensional stability across temperature ranges is critical. Steel gears typically offer 2-3 times longer service life in high-wear applications.

How does the forging process improve aluminum’s properties for gear applications?

The forging process aligns aluminum’s grain structure with the part geometry, significantly enhancing its strength, fatigue resistance, and impact toughness compared to cast or machined aluminum. This grain alignment is particularly beneficial for gear applications where directional forces are applied, resulting in stronger, more durable components.

What industries benefit most from forged aluminum gears?

Industries that prioritize weight reduction and efficiency gain the most benefit from forged aluminum gears, including aerospace, automotive (especially electric vehicles), marine applications, and high-performance racing. These sectors leverage aluminum’s lightweight properties to improve fuel efficiency, range, and overall system performance.

Can MAIKONG produce custom gear designs in both materials?

Yes, MAIKONG specializes in custom gear manufacturing in both forged aluminum and machined steel. Our comprehensive capabilities include design consultation, material selection, precision manufacturing, and quality testing. We can produce custom gears to your exact specifications or help optimize your design for the selected material.