The landscape of Billet Machining is rapidly evolving, reshaping manufacturing capabilities across American industries. As precision demands increase and technology advances, staying ahead of these developments is crucial for companies seeking competitive advantages. This comprehensive guide explores the cutting-edge trends, technological innovations, and strategic applications that are defining the future of billet manufacturing in the United States.

Understanding Billet Machining: The Foundation of Precision Manufacturing

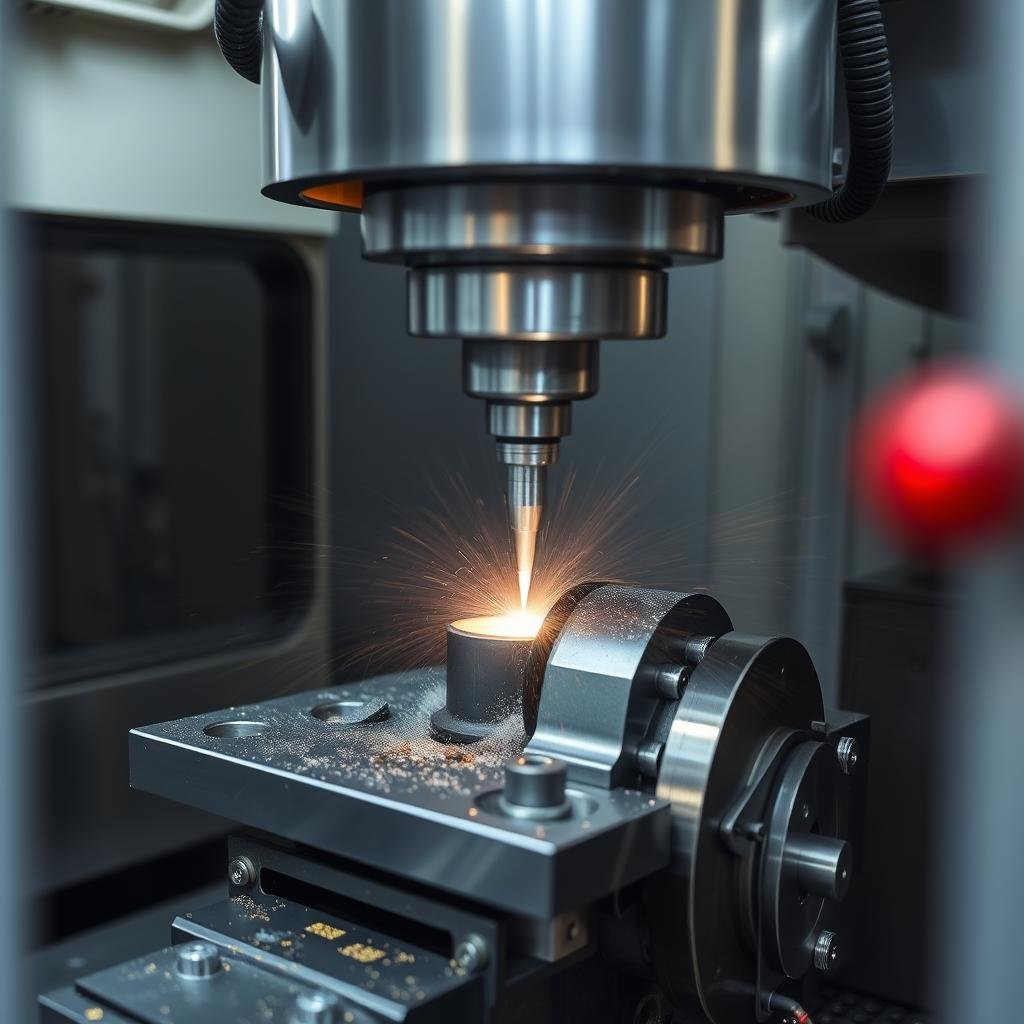

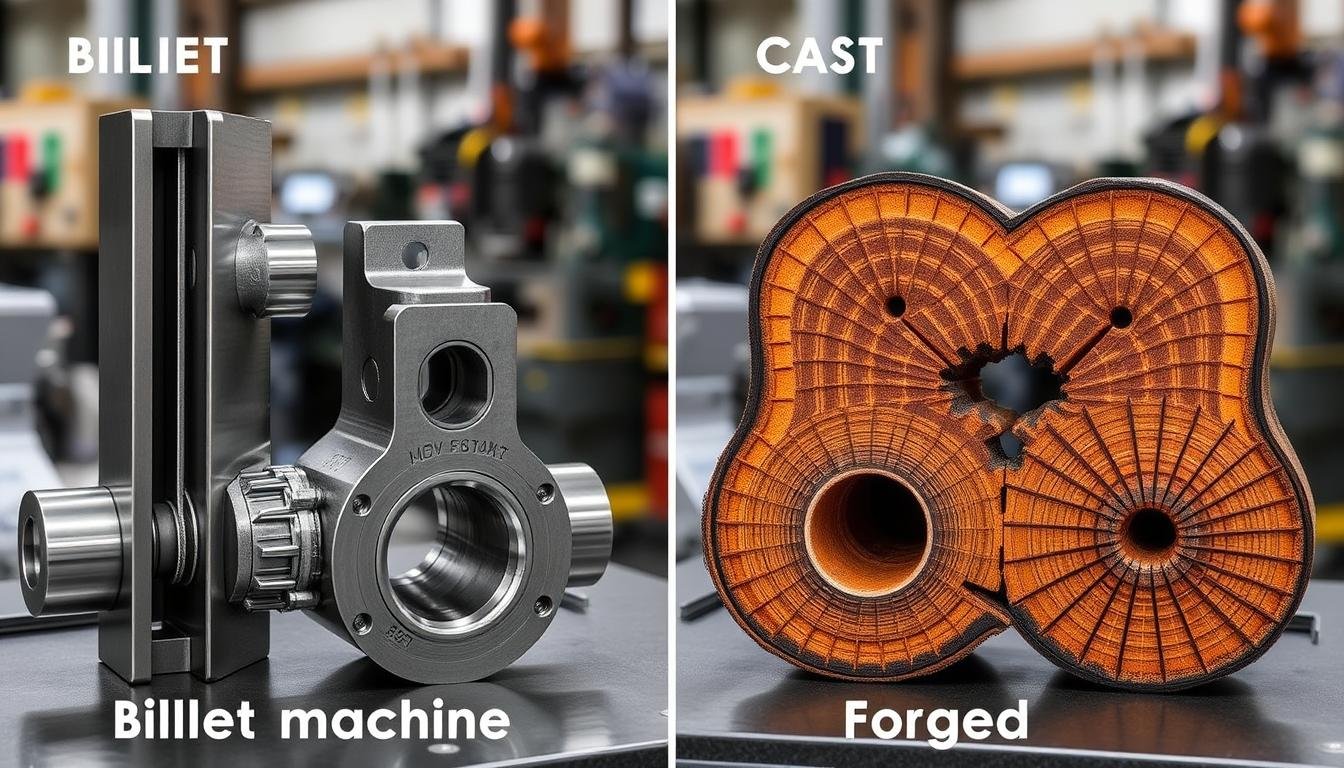

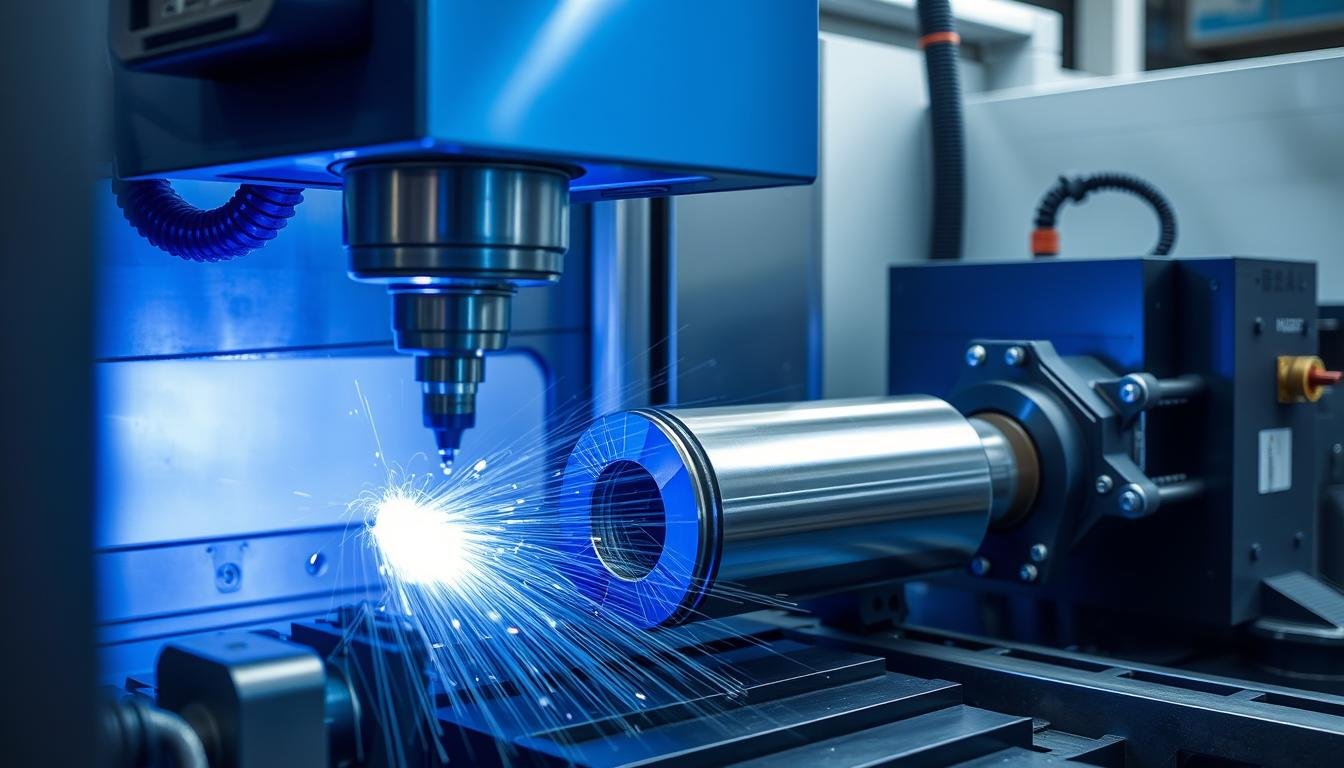

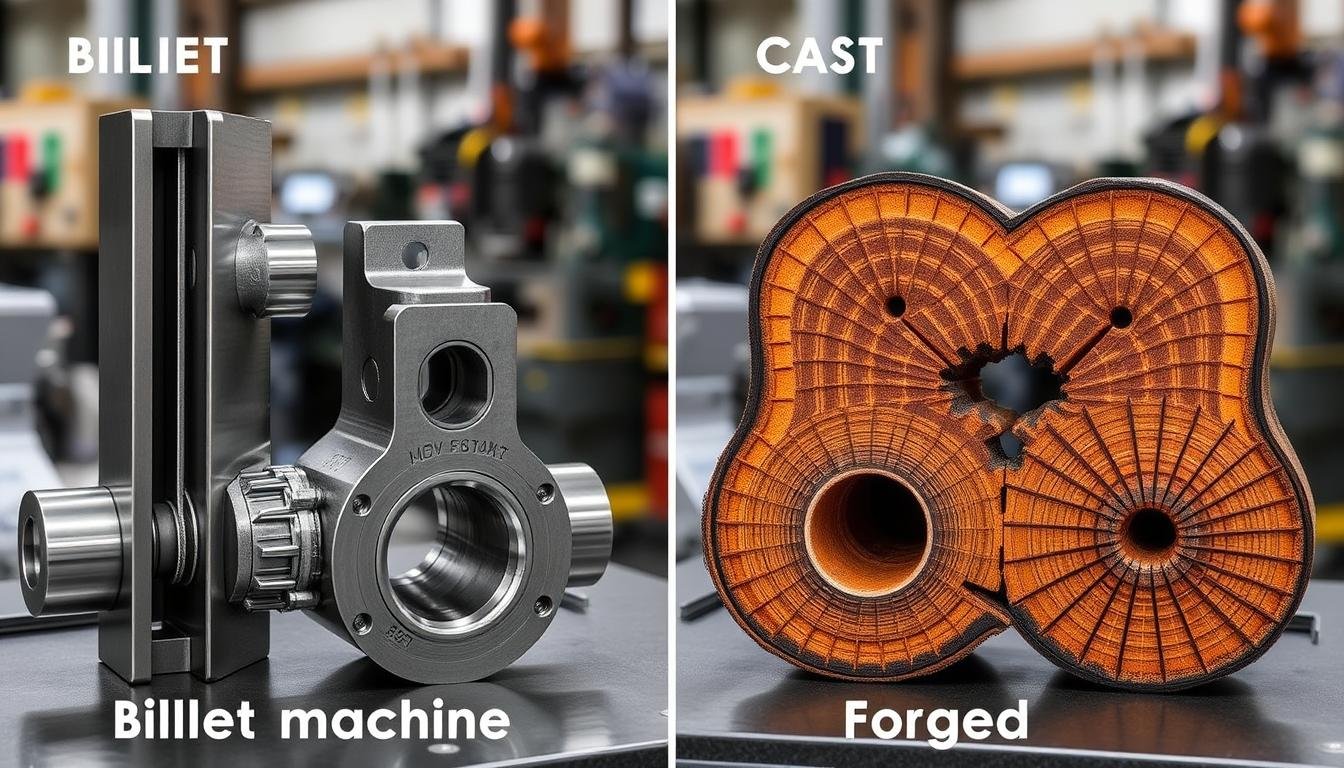

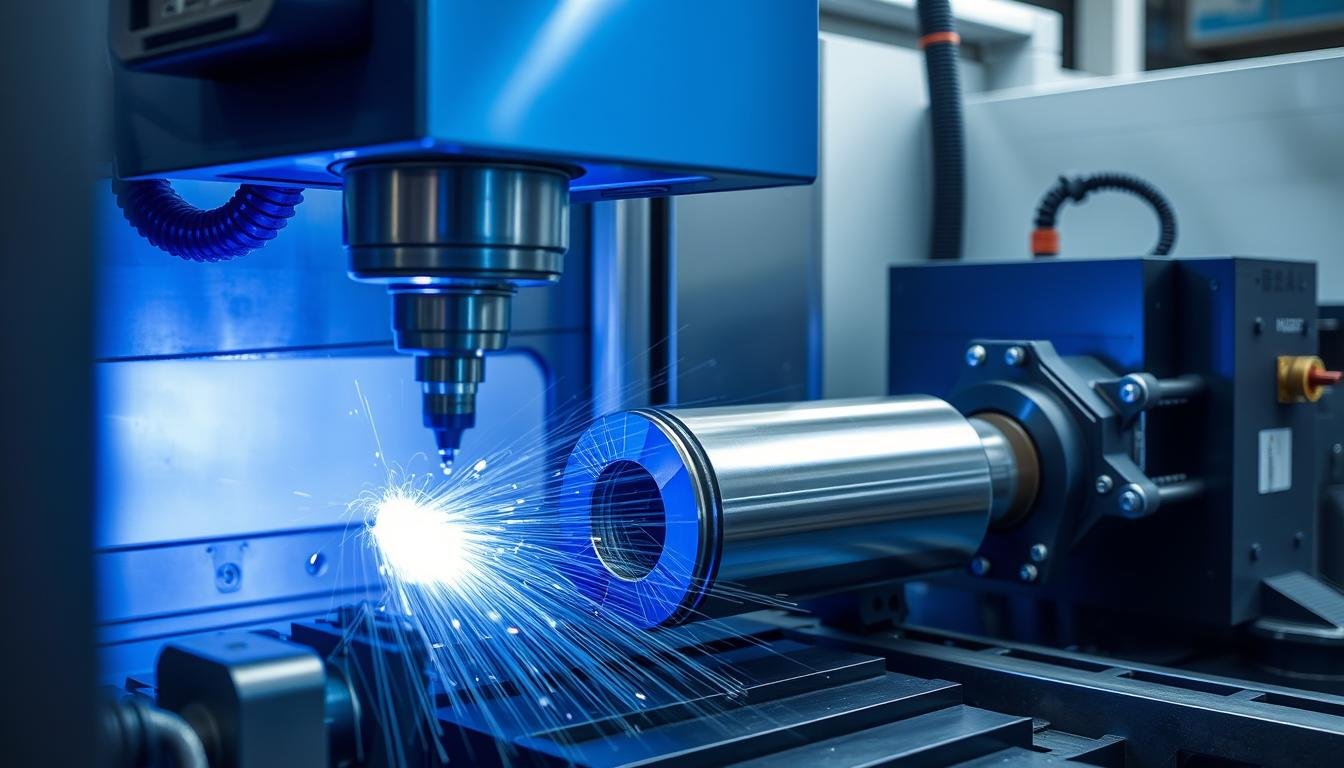

At its core, billet machining involves the precise removal of material from solid metal stock to create components with exact specifications. Unlike casting or forging, which form metal through melting or compression, billet manufacturing starts with solid metal blocks (billets) that are systematically machined to achieve the desired form.

At its core, billet machining involves the precise removal of material from solid metal stock to create components with exact specifications. Unlike casting or forging, which form metal through melting or compression, billet manufacturing starts with solid metal blocks (billets) that are systematically machined to achieve the desired form.

What Defines Modern Billet Machining?

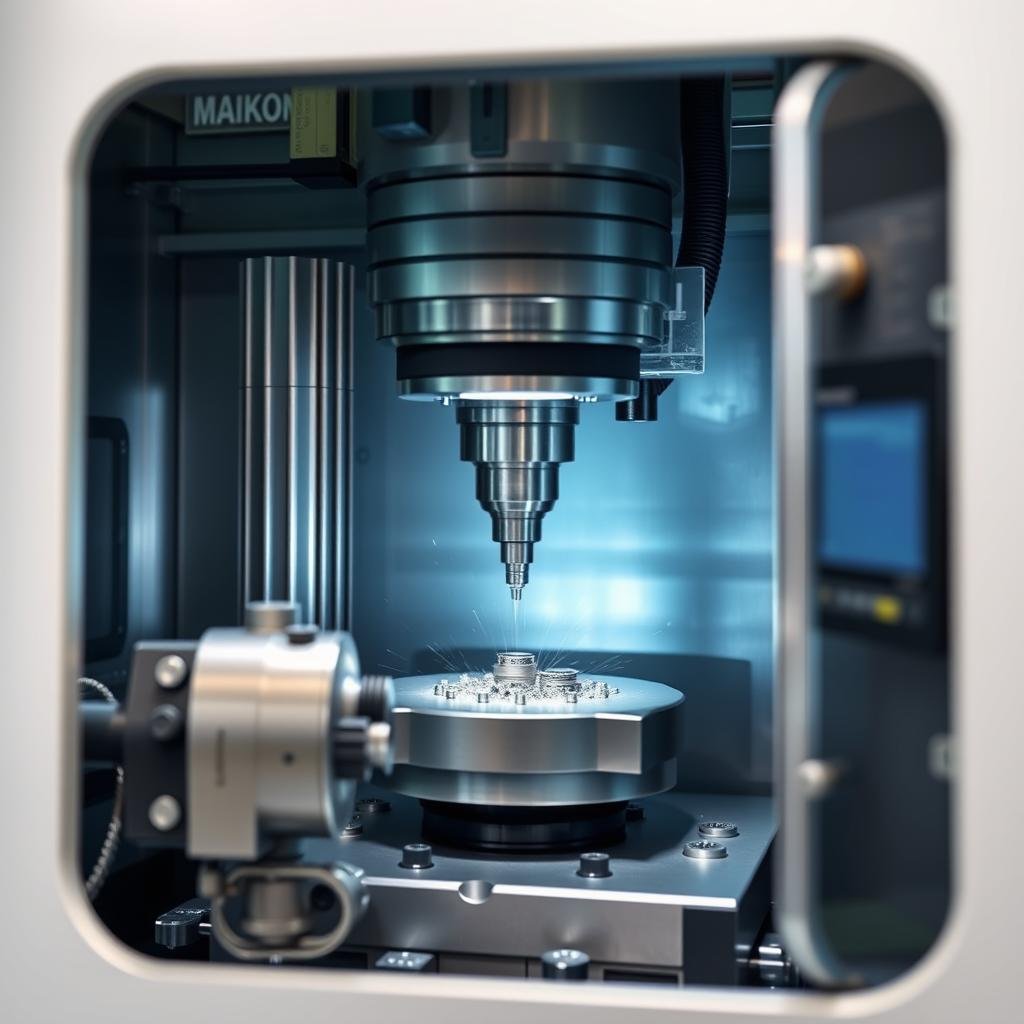

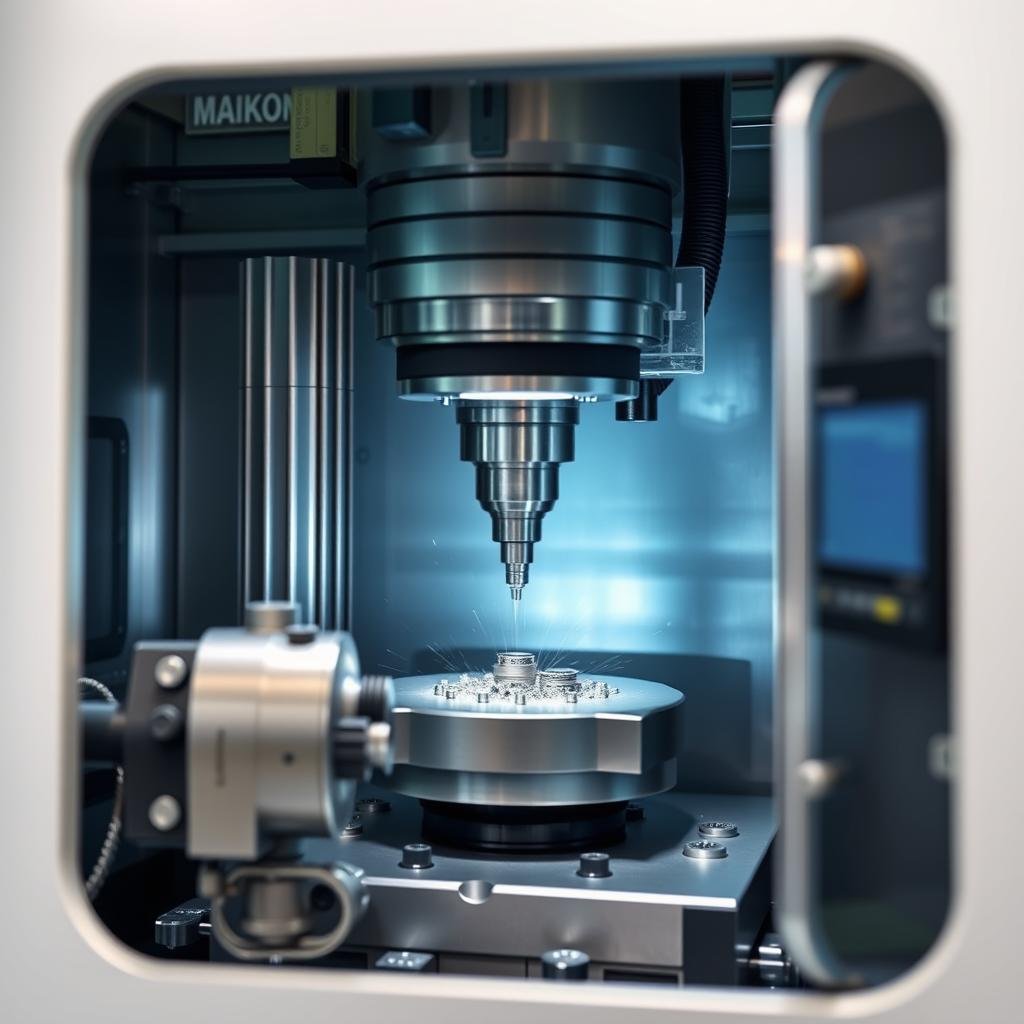

Today’s billet machining processes leverage advanced CNC technology to transform raw metal into precision components. This subtractive manufacturing method offers exceptional accuracy, structural integrity, and flexibility across diverse applications.

The process begins with high-quality metal billets—typically aluminum, steel, or specialty alloys—which are then shaped through controlled material removal. This approach delivers components with superior mechanical properties and precise dimensional tolerances.

Key Advantages of Billet Machining

- Exceptional dimensional precision and repeatability

- Superior structural integrity throughout the component

- Flexibility to create complex geometries and features

- Excellent surface finish quality with minimal post-processing

- Ability to work with virtually any machinable metal

- Ideal for both prototyping and production applications

- No tooling investments required for design changes

Emerging Trends Reshaping Billet Machining in 2023

The billet machining landscape is experiencing significant transformation driven by technological innovation, sustainability concerns, and evolving market demands. Understanding these trends is essential for manufacturers looking to maintain competitive advantages.

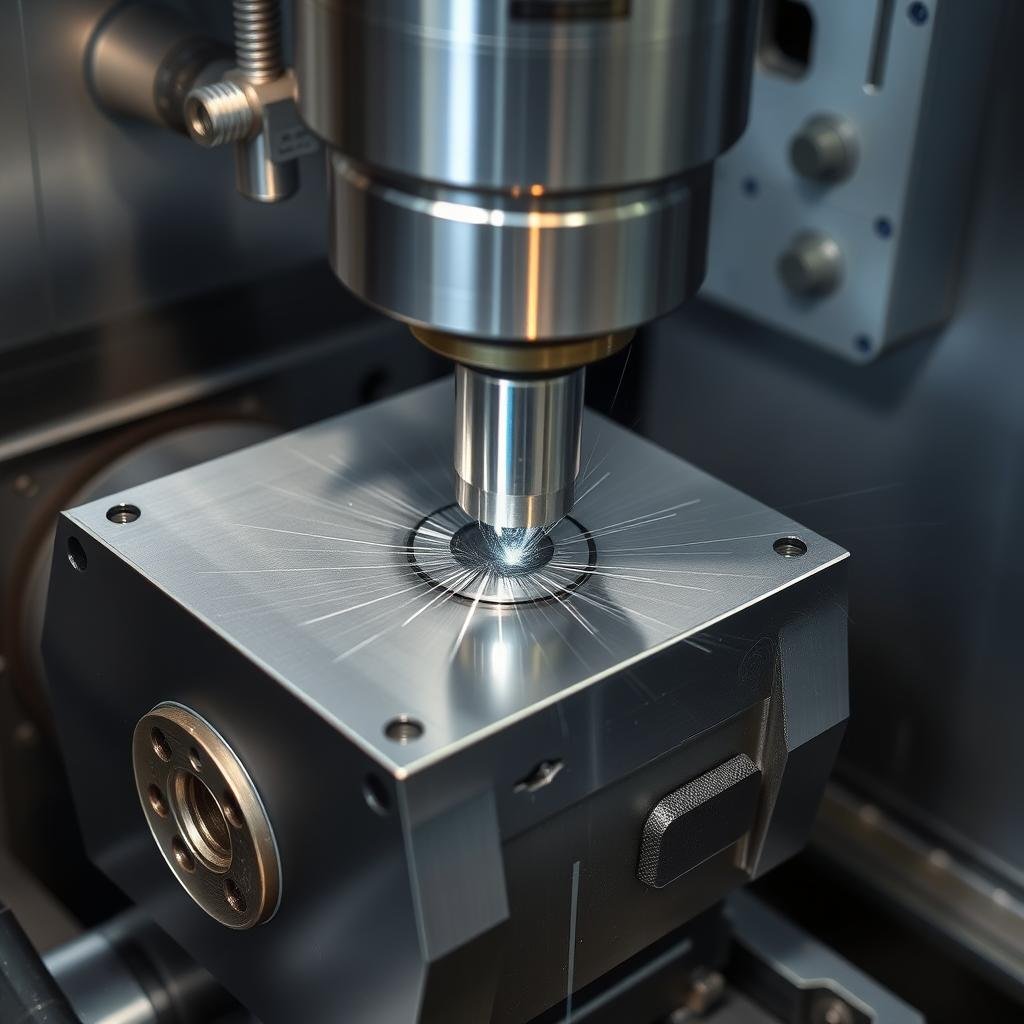

Multi-Axis Machining Evolution

The shift from traditional 3-axis to 5-axis and even 7-axis CNC machining systems has revolutionized billet machining capabilities. These advanced systems enable single-setup manufacturing of complex components, dramatically reducing production time while improving accuracy and surface finish quality.

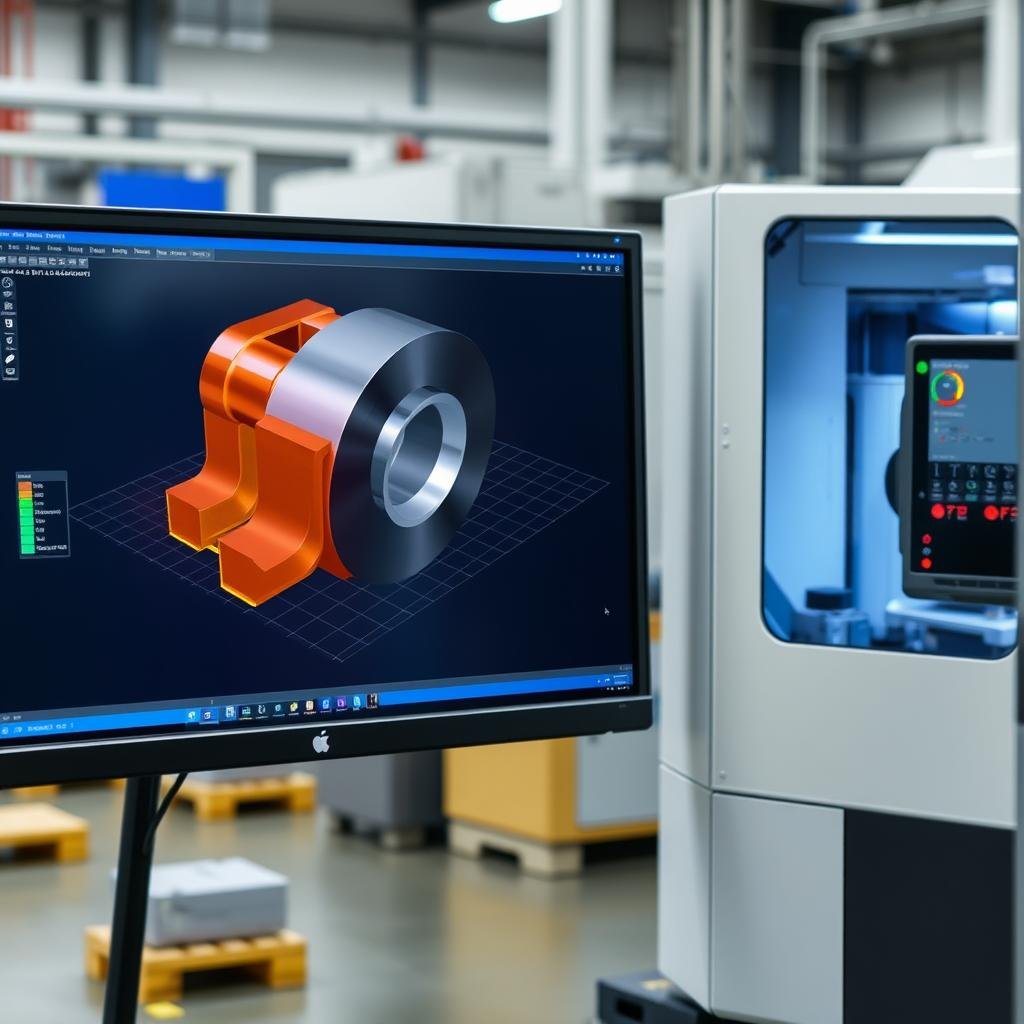

Digital Twin Technology

Digital twin implementations create virtual replicas of physical machining processes, enabling real-time monitoring, predictive maintenance, and process optimization. This technology allows manufacturers to simulate and refine billet machining operations before cutting actual material.

Sustainable Manufacturing

Environmental considerations are driving innovations in billet machining, including closed-loop coolant systems, energy-efficient machinery, and comprehensive metal recycling programs that recover and reprocess nearly 100% of machining waste.

Automation & Robotics Integration

Robotic material handling, automated tool changing, and integrated quality inspection systems are transforming billet machining operations. These systems enable 24/7 production capabilities while maintaining consistent quality standards.

High-Speed Machining (HSM)

Advancements in HSM technology allow for faster material removal rates without sacrificing surface quality or dimensional accuracy. These techniques are particularly valuable for billet machining of aluminum components for aerospace and automotive applications.

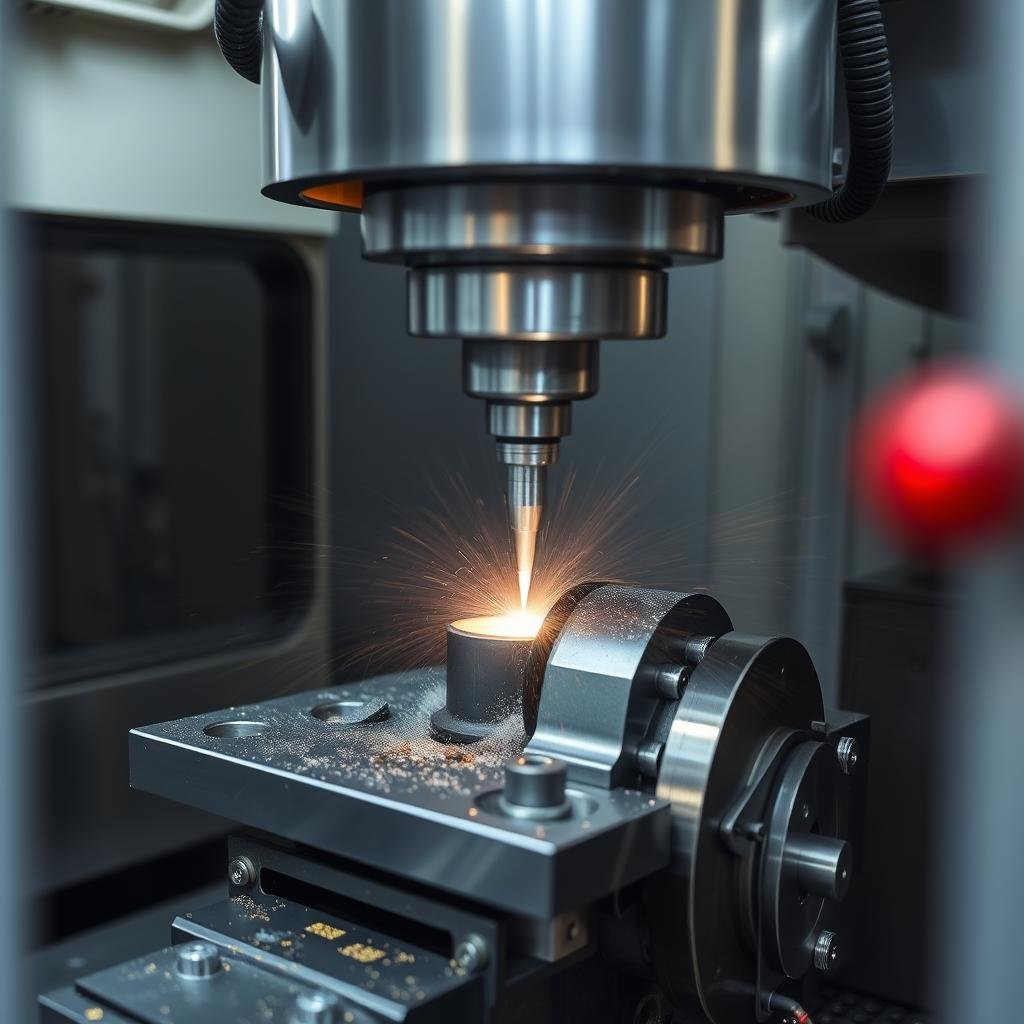

Hybrid Manufacturing

Emerging hybrid systems combine traditional billet machining with additive manufacturing capabilities, enabling the creation of components with features that would be impossible to produce through either process alone.

Elevate Your Manufacturing Capabilities with MAIKONG

Discover how our advanced billet machining solutions can transform your production processes. Our team of experts is ready to analyze your requirements and develop custom manufacturing strategies that deliver exceptional quality at competitive prices.

Technological Innovations Driving Billet Machining Excellence

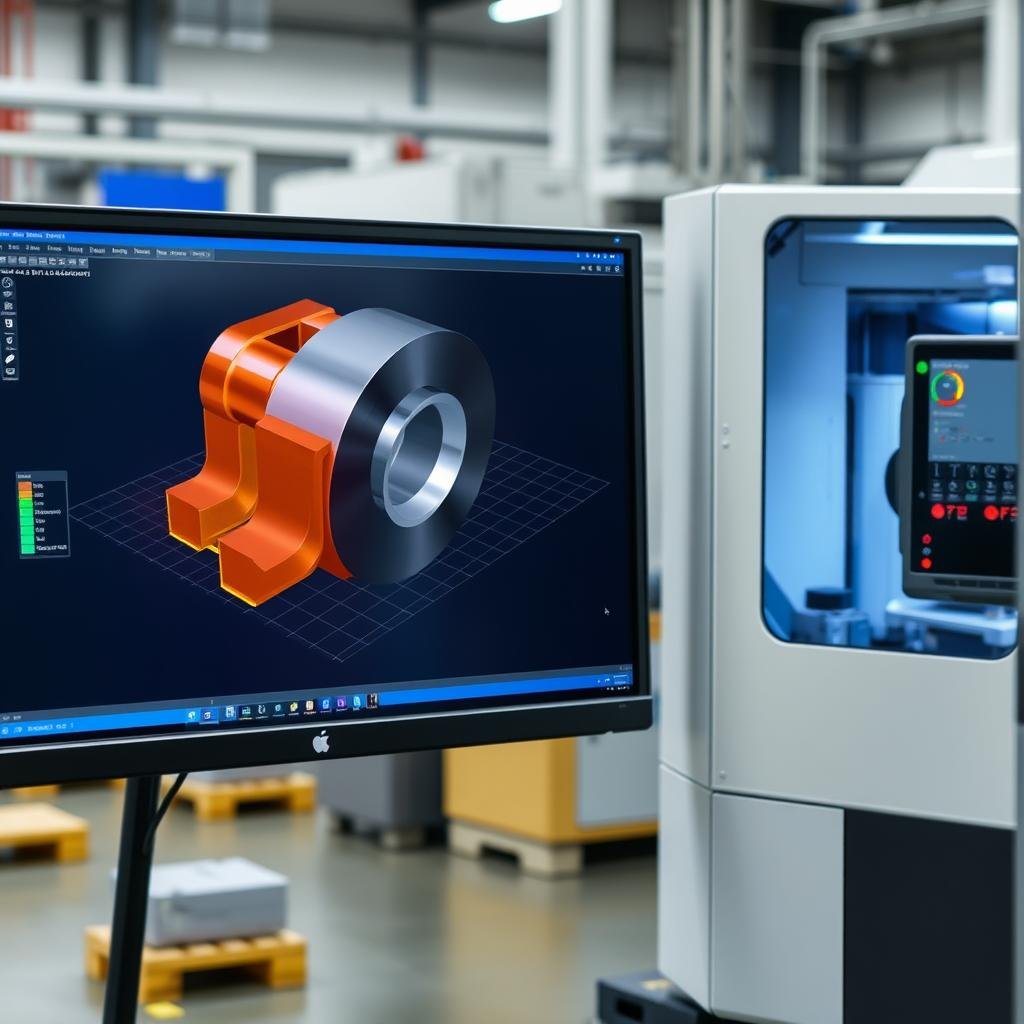

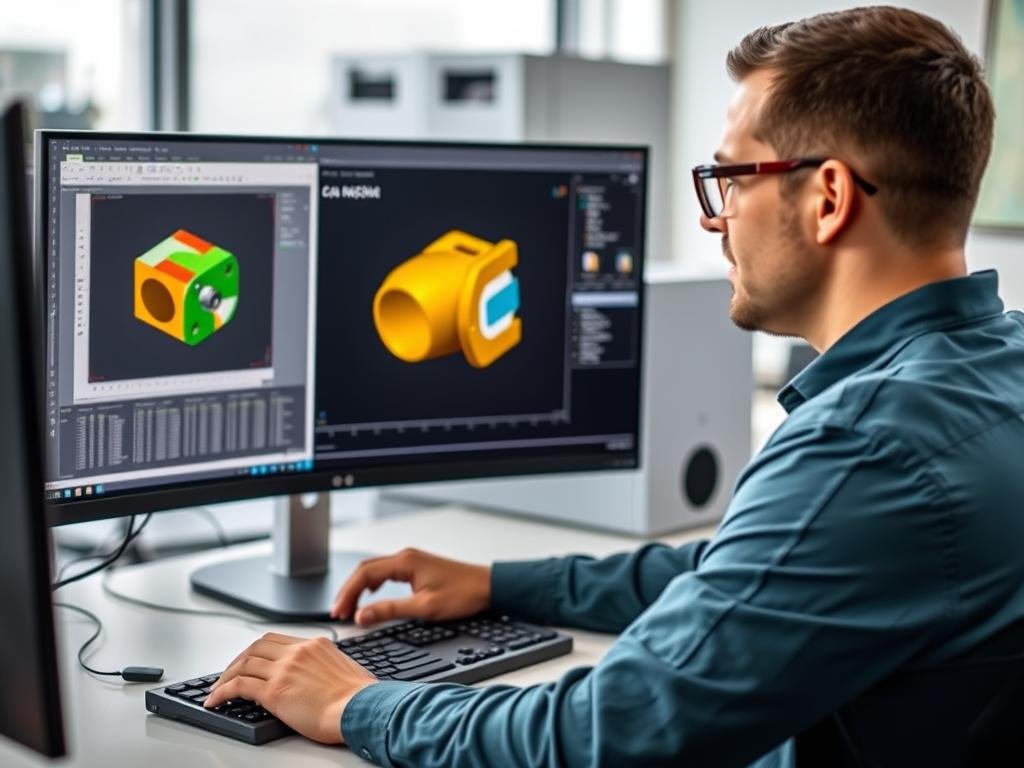

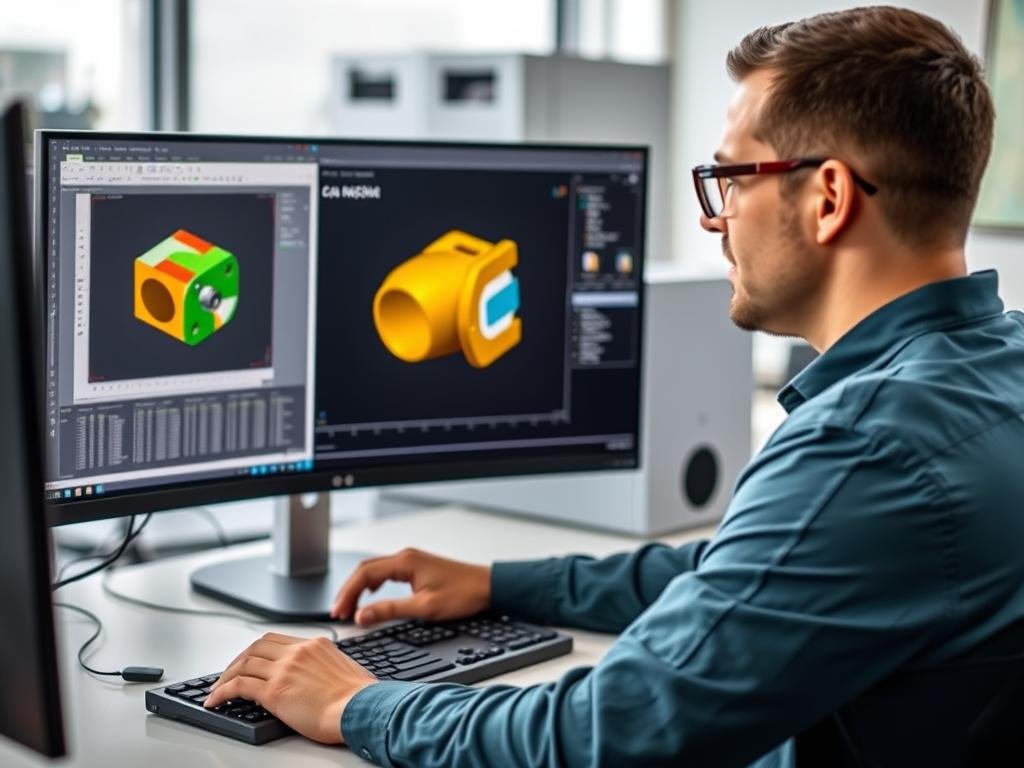

Advanced CAD/CAM Integration

Modern billet machining relies heavily on sophisticated CAD/CAM systems that streamline the transition from design to production. These systems enable:

- Automated tool path generation with collision detection

- Physics-based machining simulation for process validation

- Adaptive machining strategies that optimize tool engagement

- Seamless integration with quality inspection systems

Cutting Tool Technology Advancements

Innovations in cutting tool materials, geometries, and coatings have dramatically improved billet machining performance:

- PVD and CVD coatings that extend tool life by up to 300%

- Advanced carbide formulations optimized for specific materials

- Specialized geometries for high-speed and high-feed applications

- Modular tooling systems that reduce setup and changeover times

Machine Learning and AI in Billet Machining

Artificial intelligence and machine learning algorithms are revolutionizing billet machining through:

Predictive Maintenance

AI systems monitor machine performance metrics to predict potential failures before they occur, minimizing unplanned downtime and extending equipment life.

Adaptive Process Control

Real-time monitoring systems adjust machining parameters based on actual cutting conditions, ensuring optimal performance regardless of material variations.

Quality Prediction

Machine learning algorithms analyze process data to predict quality outcomes, enabling proactive adjustments that maintain tight tolerances and surface finish requirements.

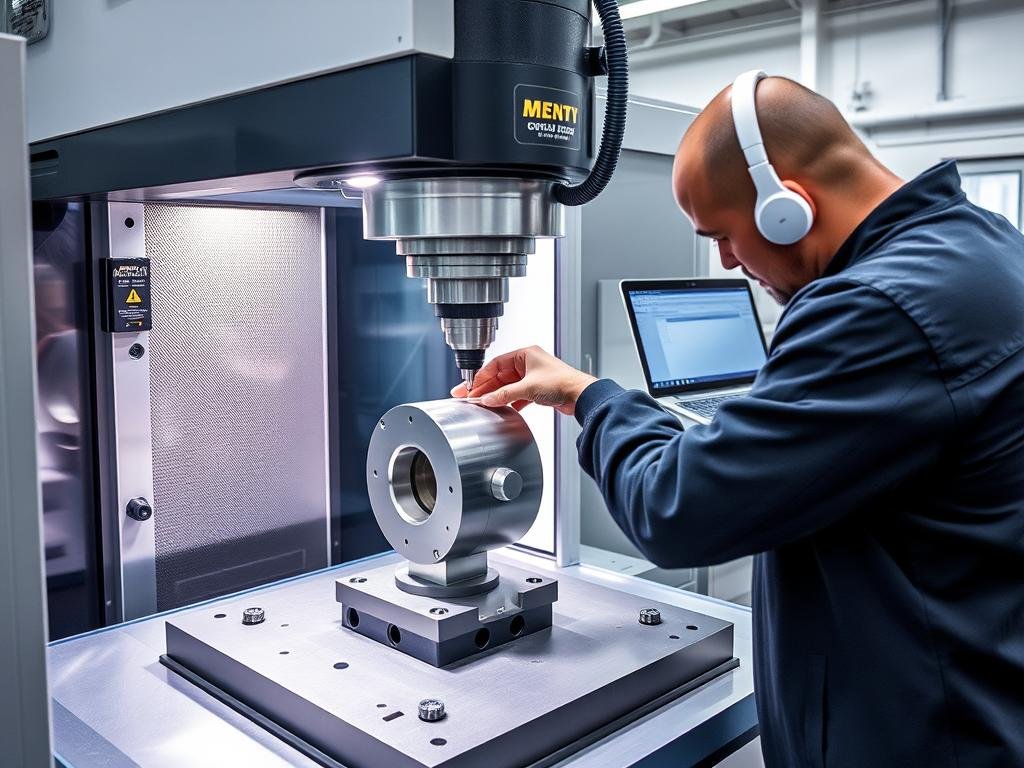

MAIKONG’s Advanced Billet Machining Capabilities

At MAIKONG, we’ve invested in state-of-the-art technology and expertise to deliver exceptional billet machining services. Our comprehensive capabilities ensure we can meet the most demanding manufacturing requirements across diverse industries.

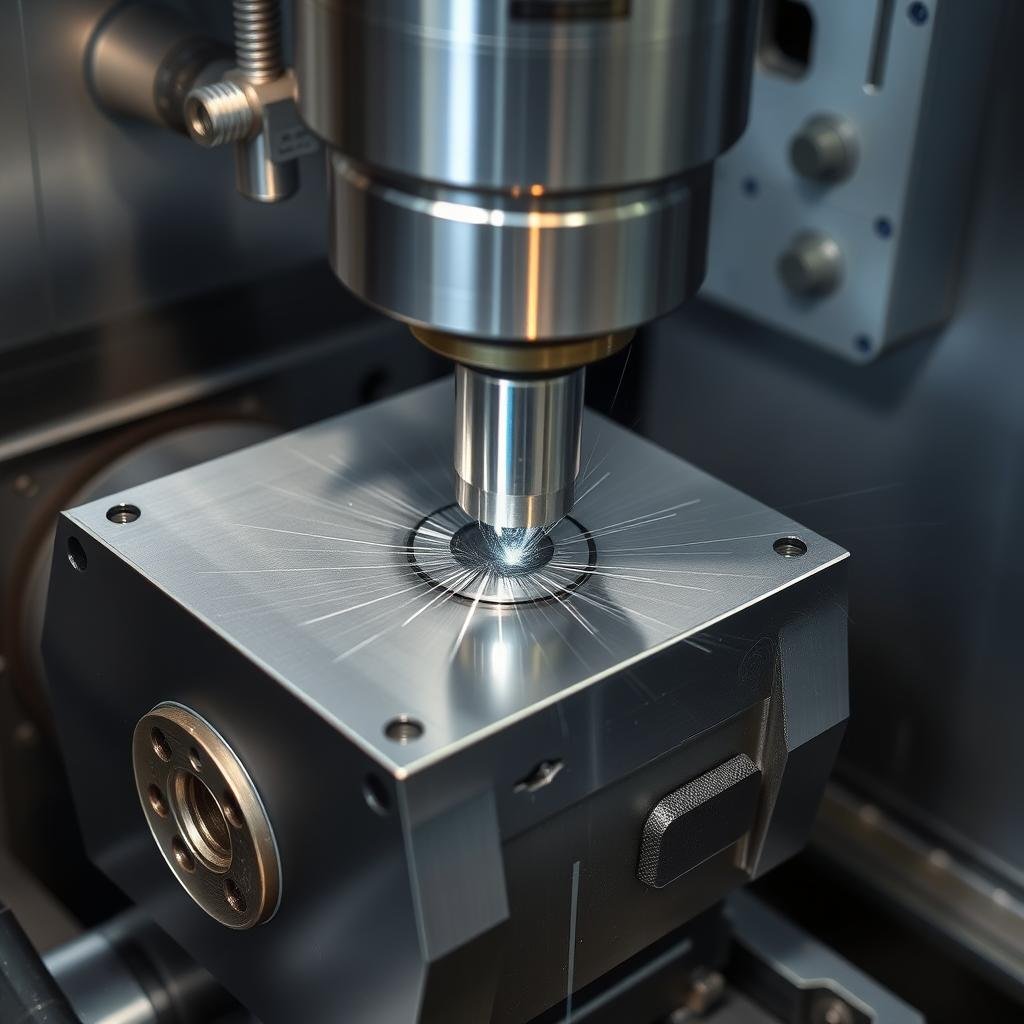

CNC Turning Services

Our advanced CNC turning capabilities deliver precision cylindrical components with exceptional surface finishes. Ideal for deep holes, machined threads, and complex profiles, our turning operations maintain tolerances as tight as ±0.0005″.

Learn More

CNC Milling Services

Our multi-axis milling systems create complex prismatic shapes and precision flat surfaces without fixed tooling requirements. This flexibility enables rapid production of both prototypes and production components.

Learn More

Swiss-Type Machining

Our Swiss-type machining specializes in precision small parts and long shaft components. With dual spindles and multi-axis capabilities, we deliver complete solutions without requiring additional equipment.

Learn More

Comprehensive Material Expertise

MAIKONG’s material science capabilities ensure optimal results across a wide range of metals and alloys:

| Material Category |

Specific Alloys |

Typical Applications |

MAIKONG Capabilities |

| Aluminum Alloys |

6061, 7075, 2024, 5052 |

Aerospace, automotive, consumer products |

High-speed machining, thin-wall structures, complex geometries |

| Steel Alloys |

4140, 4340, 1018, 1045, stainless 303/304/316 |

Industrial equipment, tooling, structural components |

Precision turning, milling, heat treatment coordination |

| Brass & Copper |

C360, C260, C110, C145 |

Electrical components, fluid systems, decorative hardware |

High-polish finishing, intricate features, tight tolerances |

| Specialty Alloys |

Titanium, Inconel, Hastelloy |

Medical, aerospace, chemical processing |

Specialized tooling strategies, controlled parameters |

Comparing Billet Machining with Alternative Manufacturing Methods

Understanding the relative advantages of billet machining compared to casting and forging helps in selecting the optimal manufacturing approach for specific applications.

| Comparison Criteria |

Billet Machining |

Metal Casting |

Metal Forging |

| Structural Integrity |

Excellent – uniform grain structure |

Good – potential for porosity |

Excellent – aligned grain flow |

| Dimensional Accuracy |

Superior (±0.0005″) |

Moderate (±0.010″) |

Good (±0.005″) |

| Surface Finish |

Excellent |

Requires post-processing |

Requires finishing operations |

| Complex Geometries |

Good for external features |

Excellent for internal features |

Limited by die design |

| Production Volume |

Low to medium |

Medium to high |

Medium to high |

| Material Utilization |

Lower (30-40% typical) |

High (85-95%) |

High (80-90%) |

| Design Flexibility |

High – easy modifications |

Moderate – requires new molds |

Low – requires new dies |

MAIKONG’s Integrated Manufacturing Approach

At MAIKONG, we leverage the strengths of multiple manufacturing methods to deliver optimal solutions. Our integrated approach combines billet machining with forging and other processes to achieve the perfect balance of quality, cost, and performance.

When to Choose Billet Machining

- Low to medium production volumes

- Complex external geometries required

- Highest precision and surface finish needed

- Rapid prototyping applications

- Frequent design iterations anticipated

When to Consider Alternatives

- Very high production volumes

- Complex internal features needed

- Material cost is primary concern

- Maximum structural strength required

- Design is finalized with no expected changes

Industry Applications and Case Studies

MAIKONG’s billet machining expertise delivers exceptional results across diverse industries. The following case studies highlight our capabilities and the tangible benefits we provide to our clients.

Aerospace

Our precision billet machining services produce critical aerospace components with exceptional dimensional accuracy and surface quality. From structural elements to fluid system components, we maintain the highest standards of quality and traceability.

Automotive

MAIKONG’s billet machining capabilities deliver high-performance automotive components that meet stringent requirements for strength, weight, and durability. Our services support both OEM production and aftermarket performance applications.

Medical

Our advanced billet machining processes create precision medical components with exceptional surface finish and biocompatibility. From surgical instruments to implantable devices, we maintain the highest standards of quality and consistency.

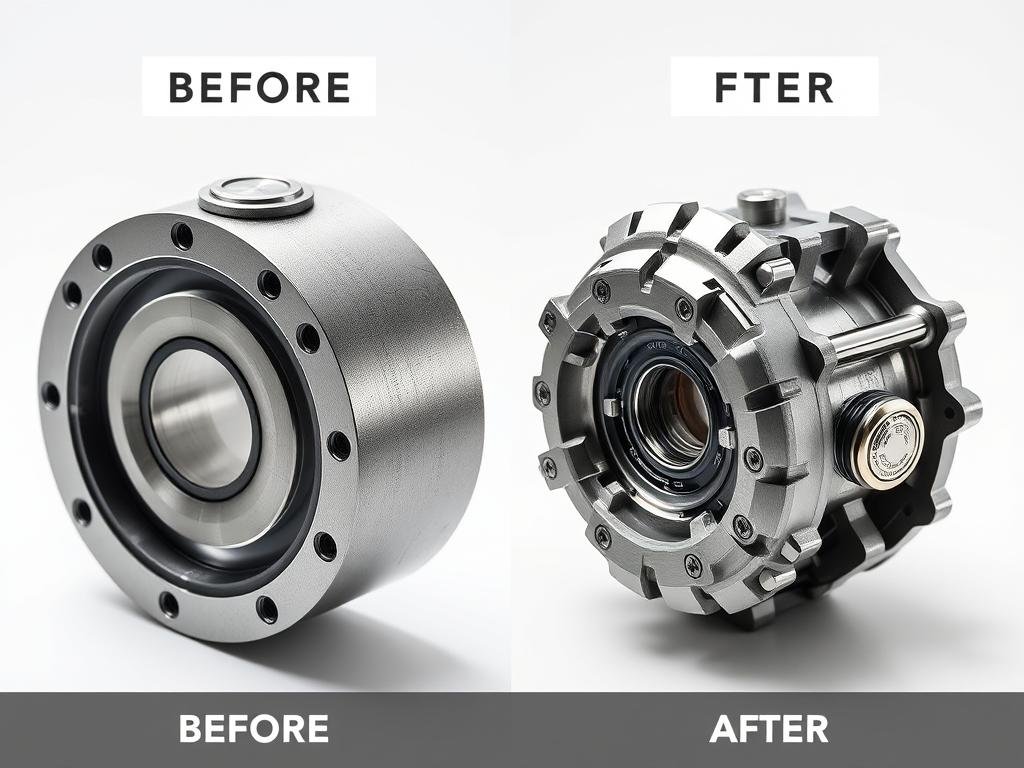

Case Study: Aerospace Structural Component

A leading aerospace manufacturer approached MAIKONG to produce a complex structural component with challenging thin-wall features and tight tolerances. Through our advanced billet machining capabilities, we delivered:

- 35% weight reduction compared to previous design

- Maintained dimensional tolerances within ±0.001″

- Achieved 16 Ra surface finish without secondary operations

- Reduced lead time from 6 weeks to 3 weeks

- 100% first-article inspection pass rate

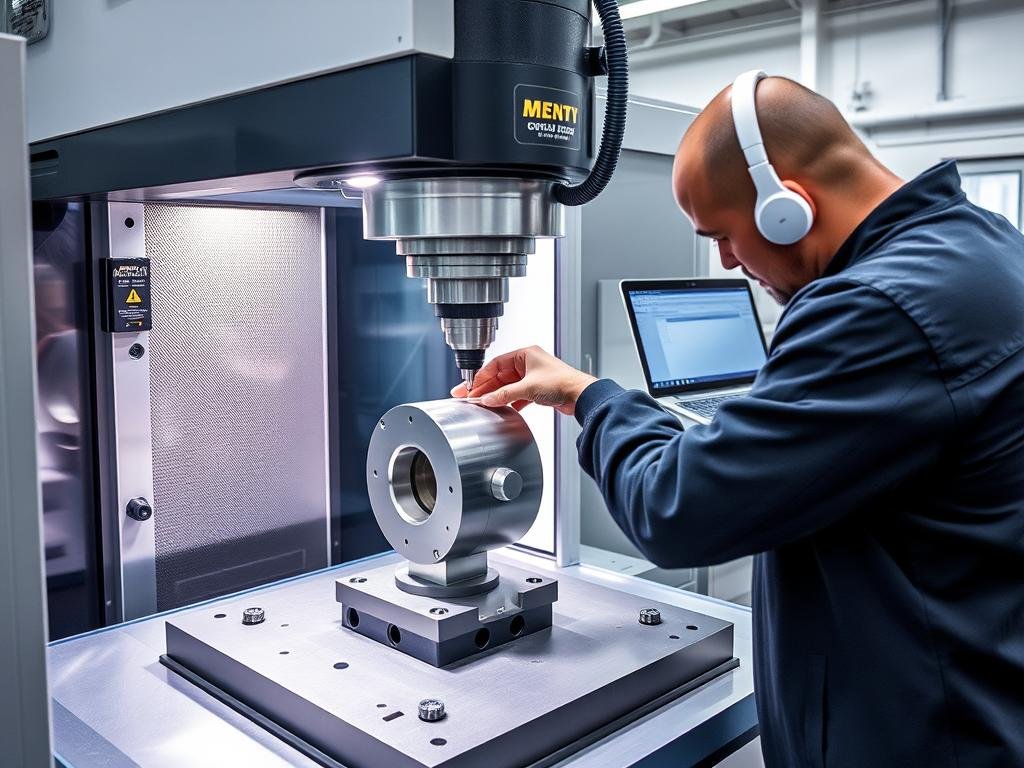

Quality Assurance in Billet Machining

MAIKONG maintains rigorous quality control processes throughout our billet machining operations. Our comprehensive approach ensures consistent excellence in every component we produce.

Advanced Inspection Technologies

Our quality assurance program leverages state-of-the-art inspection technologies:

- Coordinate Measuring Machines (CMM) with accuracy to 0.0001″

- Optical measurement systems for non-contact inspection

- Surface roughness analyzers for finish verification

- Material composition verification through XRF analysis

- First article inspection documentation to AS9102 standards

Certifications and Standards

MAIKONG maintains ISO 9001:2015 certification and adheres to industry-specific standards including:

- AS9100 aerospace quality management system

- IATF 16949 automotive quality standards

- ISO 13485 medical device quality management

- NADCAP special process certifications

Our commitment to quality extends beyond certification requirements. We implement continuous improvement methodologies including Six Sigma and lean manufacturing principles throughout our operations.

ISO 9001:2015

AS9100

IATF 16949

ISO 13485

Partnership Opportunities with MAIKONG

US Agent Recruitment Program

MAIKONG is actively seeking representatives throughout the United States to expand our market presence. Our agent program offers exceptional opportunities for professionals with established networks in manufacturing industries.

- Competitive commission structure on all referred business

- Comprehensive training on our capabilities and processes

- Marketing and technical support for client development

- Exclusive territory protection for qualified agents

Why Partner with MAIKONG?

Our unique value proposition makes MAIKONG an ideal manufacturing partner for US companies:

- Exceptional cost-performance ratio compared to domestic options

- Comprehensive capabilities from design support through finished components

- Advanced technology and equipment for superior quality

- Experienced engineering team with industry-specific expertise

- Reliable logistics and communication systems

Become a MAIKONG Agent

Join our growing network of US representatives and leverage our manufacturing excellence to build your business.

Apply Today

The Future of Billet Machining: Embracing Innovation

As we look toward the future, billet machining will continue to evolve through technological advancement and process innovation. MAIKONG remains committed to staying at the forefront of these developments, investing in new capabilities and expertise to deliver exceptional value to our clients.

The integration of artificial intelligence, advanced materials, and sustainable manufacturing practices will drive the next generation of billet machining excellence. By partnering with MAIKONG, you gain access to these cutting-edge capabilities and our unwavering commitment to quality and customer satisfaction.

Transform Your Manufacturing with MAIKONG

Ready to experience the MAIKONG difference? Contact our team today to discuss your billet machining requirements and discover how our comprehensive capabilities can deliver exceptional results for your business.

At its core, billet machining involves the precise removal of material from solid metal stock to create components with exact specifications. Unlike casting or forging, which form metal through melting or compression, billet manufacturing starts with solid metal blocks (billets) that are systematically machined to achieve the desired form.

At its core, billet machining involves the precise removal of material from solid metal stock to create components with exact specifications. Unlike casting or forging, which form metal through melting or compression, billet manufacturing starts with solid metal blocks (billets) that are systematically machined to achieve the desired form.