When selecting materials for critical components, the choice between forged aluminum vs machined steel can significantly impact your project’s success. Both materials offer distinct advantages in strength, weight, cost, and performance characteristics. This comprehensive guide explores the key differences to help you make an informed decision for your specific application.

Material Properties: Forged Aluminum vs Machined Steel

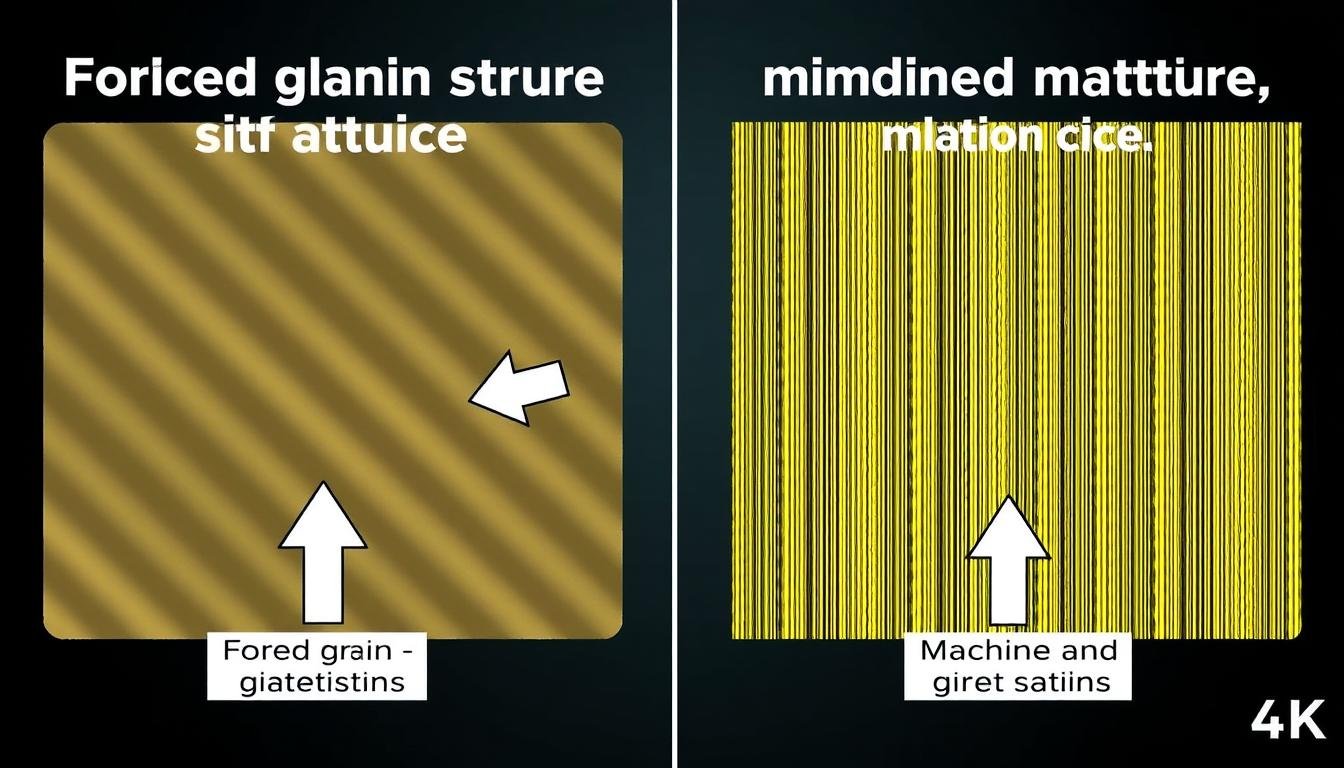

Material samples showing the distinctive properties of forged aluminum (left) and machined steel (right)

Material samples showing the distinctive properties of forged aluminum (left) and machined steel (right)

Understanding the fundamental properties of each material is essential for making the right choice for your application. Let’s examine how forged aluminum vs machined steel compare in key performance metrics.

Strength and Durability Comparison

When comparing strength profiles, machined steel generally offers superior tensile strength and hardness. Steel components can withstand higher loads and stresses before deformation, making them ideal for high-stress applications.

| Property |

Forged Aluminum |

Machined Steel |

| Tensile Strength |

83-607 MPa (depending on alloy) |

400-1100 MPa |

| Yield Strength |

35-570 MPa |

250-950 MPa |

| Hardness |

30-150 HB |

120-300 HB |

| Fatigue Resistance |

Good (improved through forging) |

Excellent |

| Impact Resistance |

Moderate |

High |

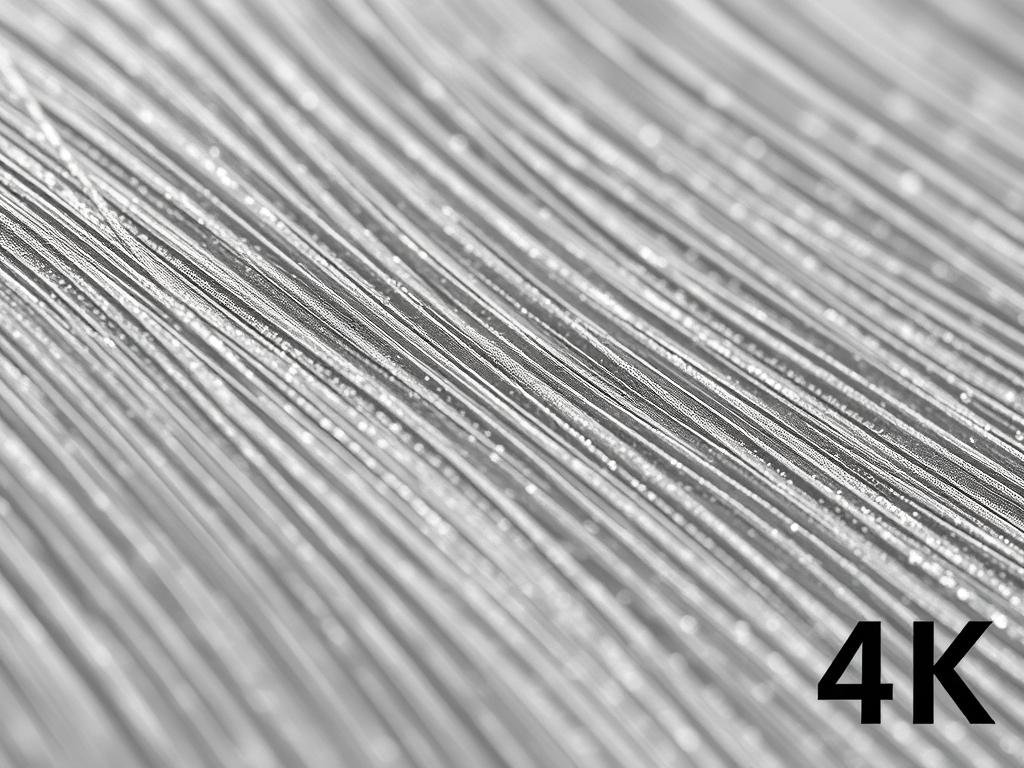

Forged aluminum, while not as strong as steel in absolute terms, offers impressive strength relative to its weight. The forging process significantly improves aluminum’s mechanical properties by aligning its grain structure and eliminating porosity.

Microscopic view of aligned grain structure in forged aluminum created during the forging process

Weight and Density Analysis

One of the most significant advantages of aluminum is its weight. With a density of approximately 2.7 g/cm³, aluminum is nearly three times lighter than steel (7.85 g/cm³). This weight difference makes forged aluminum the preferred choice for applications where weight reduction is critical.

Weight comparison of similarly sized components shows aluminum’s significant weight advantage

For weight-critical applications like aerospace components or automotive parts, the weight savings from using forged aluminum can translate to significant performance improvements and fuel efficiency gains.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer that provides excellent corrosion resistance in most environments. This self-healing barrier makes forged aluminum parts ideal for outdoor applications or environments with moisture exposure.

Steel, by comparison, is susceptible to rust and corrosion unless properly treated or alloyed. While treatments like galvanization or stainless steel alloys can improve corrosion resistance, they add cost and processing steps.

Need Help Selecting the Right Material?

Our engineers can analyze your application requirements and recommend the optimal material choice. Get expert advice tailored to your specific project needs.

Request Material Consultation

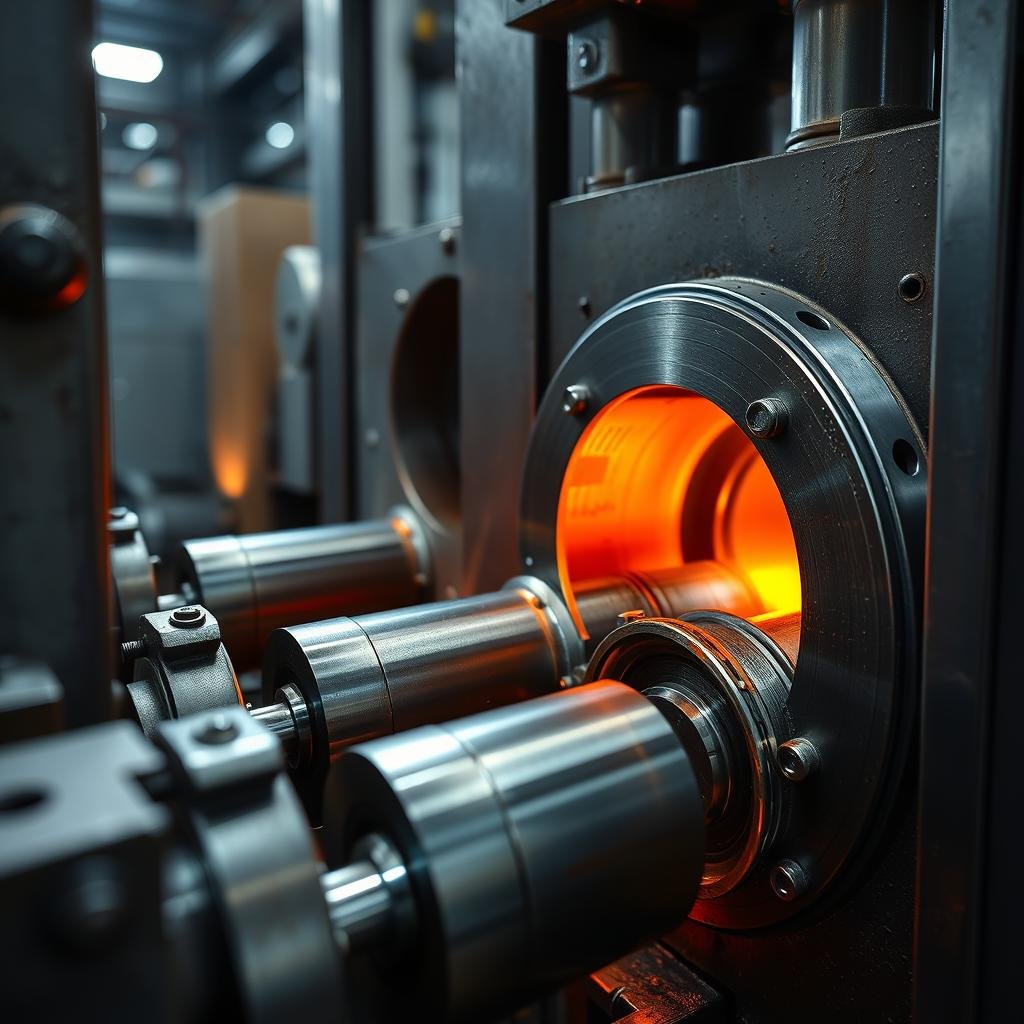

Manufacturing Processes: Forging vs Machining

The manufacturing method significantly impacts a component’s properties, cost, and performance. Understanding these processes helps in making informed material selection decisions.

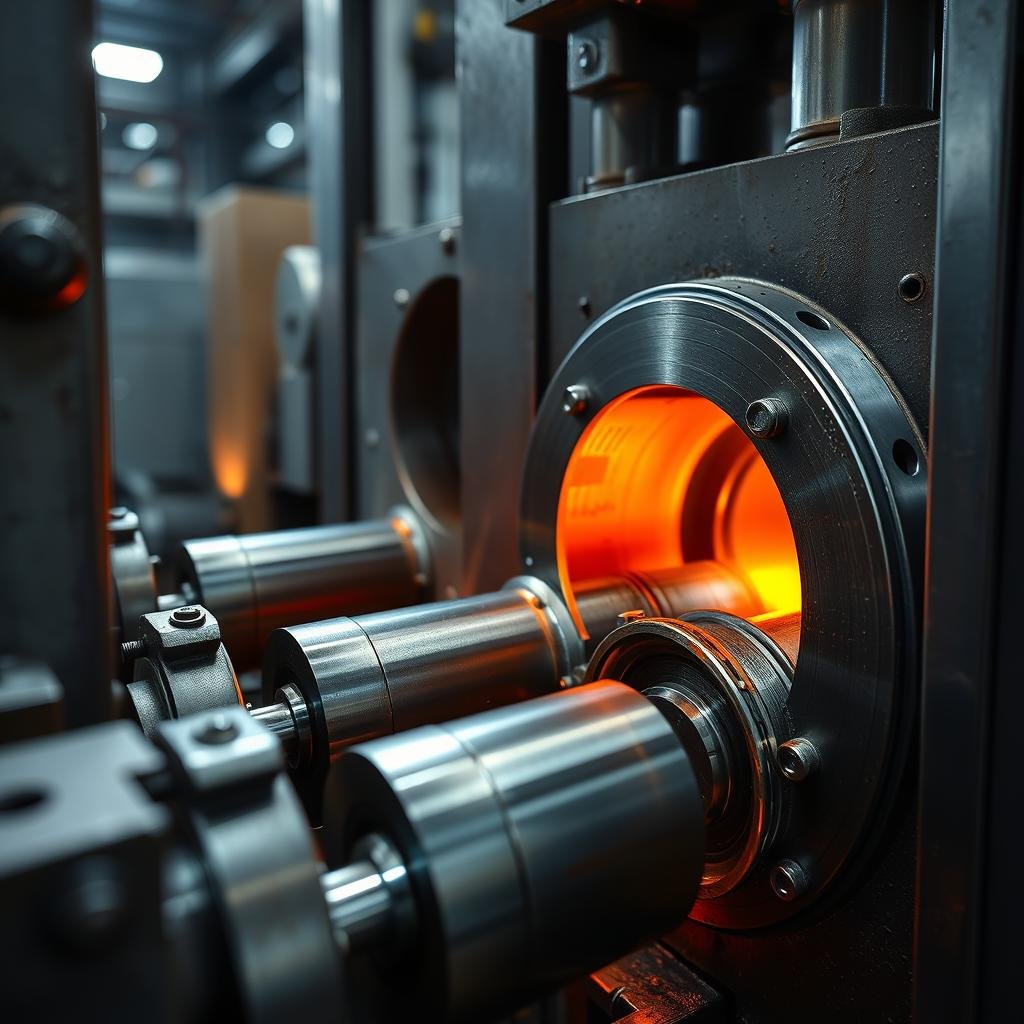

Aluminum forging process (left) compared to precision machining of steel (right)

Forged Aluminum Production Process

Aluminum forging involves heating aluminum billets to 300-500°C and applying pressure to shape the metal using dies. This process creates a directional grain flow that follows the part’s contours, enhancing strength and durability.

Aluminum forging process creates aligned grain structure for improved strength

Key advantages of the forging process include:

- Enhanced mechanical properties through grain alignment

- Elimination of internal porosity and defects

- Improved fatigue resistance and impact strength

- Near-net shape production with reduced material waste

- Consistent material properties throughout the part

Machined Steel Manufacturing

Steel machining is a subtractive process where material is removed from a solid block (billet) using cutting tools. CNC (Computer Numerical Control) machines precisely cut away material to create the desired shape with high dimensional accuracy.

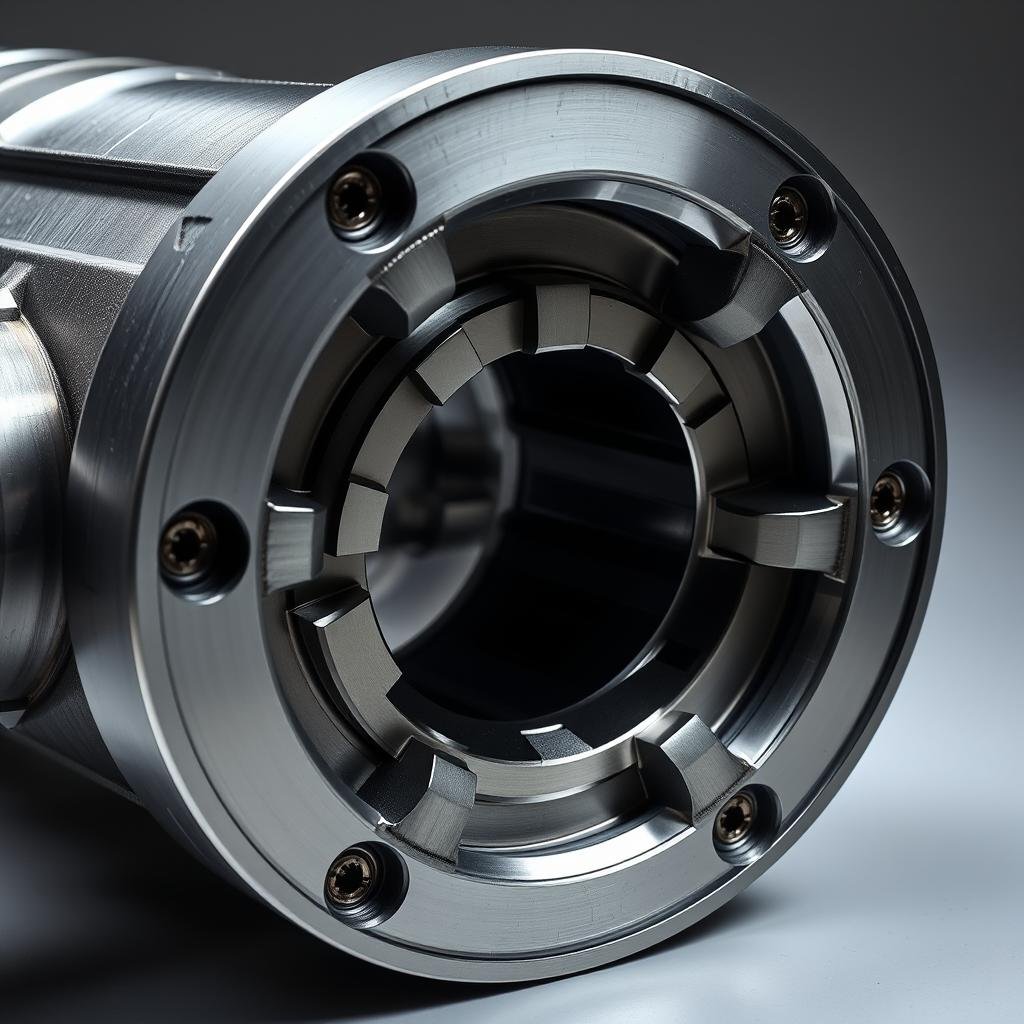

Precision CNC machining of steel components offers exceptional dimensional accuracy

Advantages of machined steel include:

- Exceptional dimensional precision and surface finish

- Ability to create complex geometries and features

- No need for specialized tooling for small production runs

- Consistent material properties from the original steel stock

- Flexibility to modify designs without significant retooling

Grain Structure and Material Performance

One of the most significant differences between forged aluminum vs machined steel lies in their grain structure. Forging aligns the metal’s grain flow with the part’s geometry, creating a fibrous structure that enhances strength in the directions of anticipated stress.

Directional grain structure in forged aluminum (left) vs uniform grain structure in machined steel (right)

Machined components maintain the original grain structure of the stock material, which is typically non-directional. While this provides uniform properties in all directions, it doesn’t offer the enhanced directional strength that forging provides.

Expert Manufacturing at MAIKONG

With advanced capabilities in both aluminum forging and precision steel machining, we can produce your components to exact specifications with industry-leading quality.

Discuss Your Manufacturing Needs

Strength-to-Weight Ratio: The Critical Metric

When evaluating forged aluminum vs machined steel, the strength-to-weight ratio often becomes the deciding factor for many applications. This metric measures how much load a material can bear relative to its weight.

Laboratory testing of strength-to-weight performance in comparable components

Comparative Strength Analysis

While steel offers higher absolute strength, aluminum’s lightweight nature gives it an impressive strength-to-weight ratio. For applications where weight reduction is critical, forged aluminum often provides the optimal balance.

| Material |

Density (g/cm³) |

Typical Tensile Strength (MPa) |

Strength-to-Weight Ratio |

| 6061-T6 Forged Aluminum |

2.7 |

310 |

115 |

| 7075-T6 Forged Aluminum |

2.81 |

572 |

204 |

| AISI 1045 Machined Steel |

7.85 |

565 |

72 |

| AISI 4140 Machined Steel |

7.85 |

655 |

83 |

The forging process further enhances aluminum’s performance by improving its fatigue resistance and durability, making it suitable for dynamic loading applications where weight is a concern.

Fatigue Performance Under Cyclic Loading

Components that experience repeated loading and unloading cycles require excellent fatigue resistance. Both materials have different fatigue performance characteristics:

Forged Aluminum Fatigue Performance

The aligned grain structure created during forging significantly improves aluminum’s fatigue resistance. Properly designed forged aluminum components can withstand millions of load cycles in weight-sensitive applications.

Fatigue test results showing forged aluminum’s superior performance

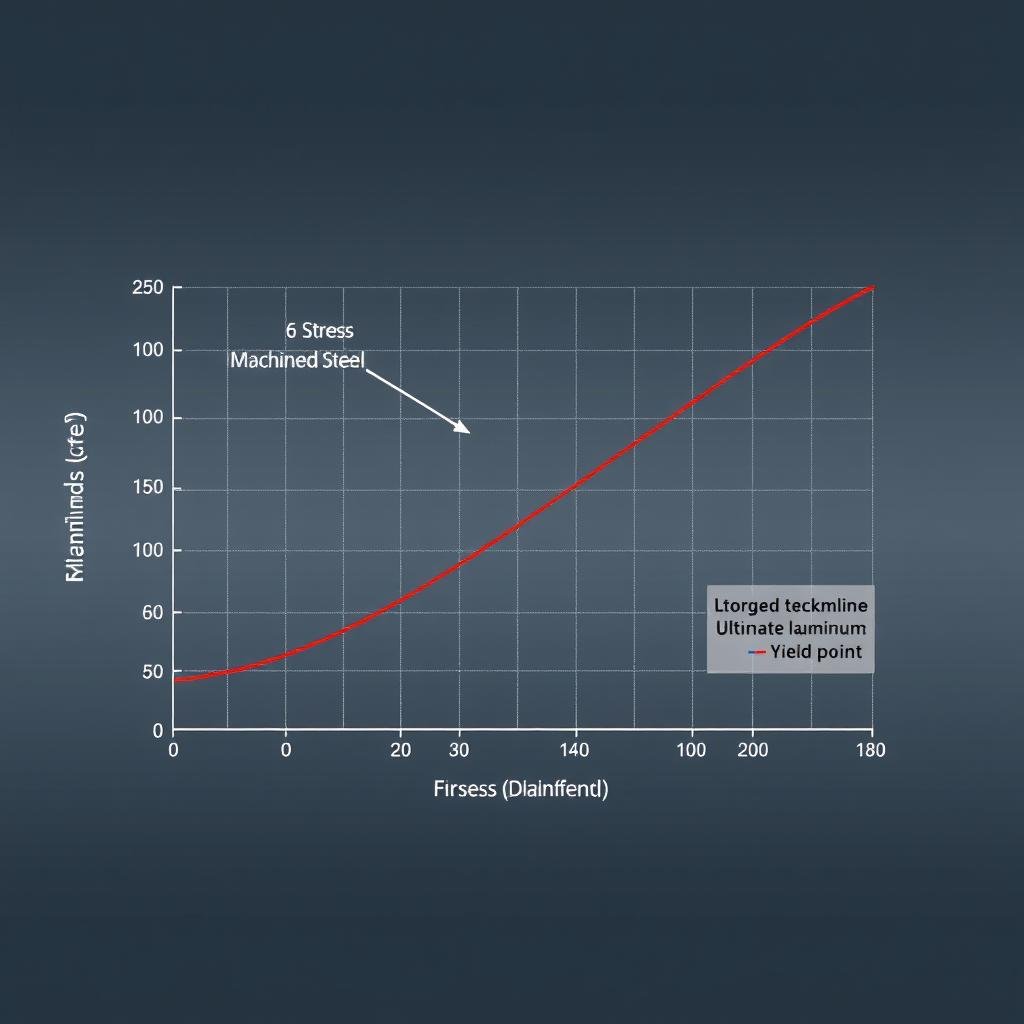

Machined Steel Fatigue Performance

Steel generally offers superior fatigue resistance in absolute terms, making it ideal for high-stress, long-life applications where weight is less critical. Its uniform grain structure provides consistent performance in all directions.

Stress-strain comparison showing steel’s higher absolute strength

Need Technical Assistance?

Our engineering team can help analyze your application’s stress requirements and recommend the optimal material solution.

Contact Our Engineers via WhatsApp

Industry Applications and Material Selection

The choice between forged aluminum vs machined steel varies widely across industries, depending on specific application requirements. Understanding where each material excels helps in making the optimal selection.

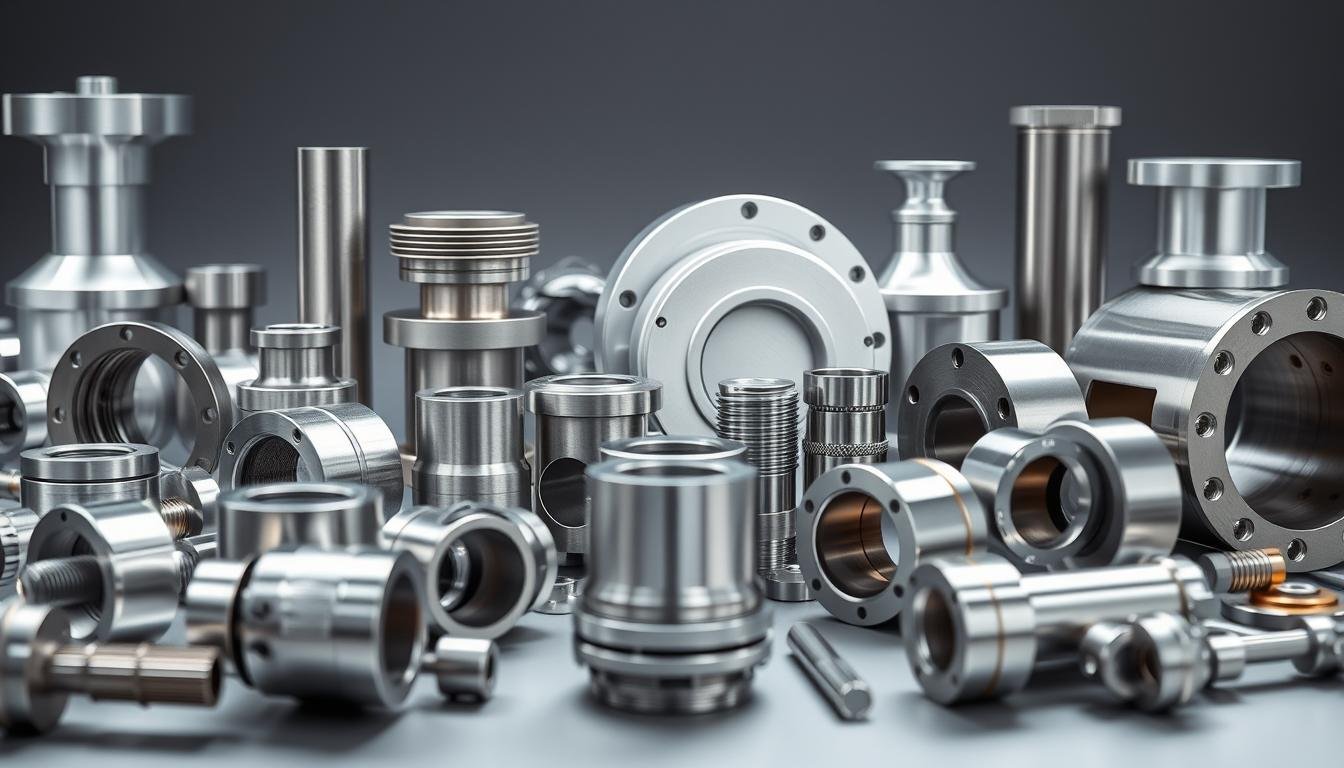

Various components manufactured from forged aluminum and machined steel across industries

Aerospace Applications

The aerospace industry prioritizes weight reduction without compromising safety, making forged aluminum a preferred choice for many structural components.

Forged aluminum aerospace components offer exceptional strength-to-weight ratio

Common aerospace applications include:

- Structural airframe components

- Landing gear components

- Engine mounts and brackets

- Control system components

- Fuel system components

Automotive Industry

Automotive manufacturers use both materials strategically, balancing performance, weight, and cost considerations.

Forged Aluminum Automotive Applications

- Wheels and suspension components

- Engine blocks and cylinder heads

- Transmission cases

- Connecting rods and pistons

- Structural reinforcements

Forged aluminum wheels combine strength with weight reduction

Machined Steel Automotive Applications

- Crankshafts and camshafts

- Gears and transmission components

- Chassis and structural elements

- High-stress engine components

- Safety-critical systems

Machined steel crankshafts provide durability for high-stress applications

Industrial Equipment and Machinery

Industrial applications often prioritize durability, reliability, and cost-effectiveness, with material selection varying based on specific requirements.

Industrial components utilize both materials based on specific performance requirements

Typical industrial applications include:

Forged Aluminum Applications

- Hydraulic system components

- Pneumatic fittings and valves

- Heat sinks and thermal management

- Lightweight structural elements

- Corrosion-resistant components

Machined Steel Applications

- Heavy-duty gears and shafts

- High-pressure components

- Wear-resistant surfaces

- Load-bearing structural elements

- High-temperature applications

Industry-Specific Solutions

MAIKONG specializes in custom manufacturing solutions tailored to your industry’s specific requirements. Our expertise spans aerospace, automotive, industrial, and more.

Request Industry-Specific Consultation

Cost Considerations and Economic Analysis

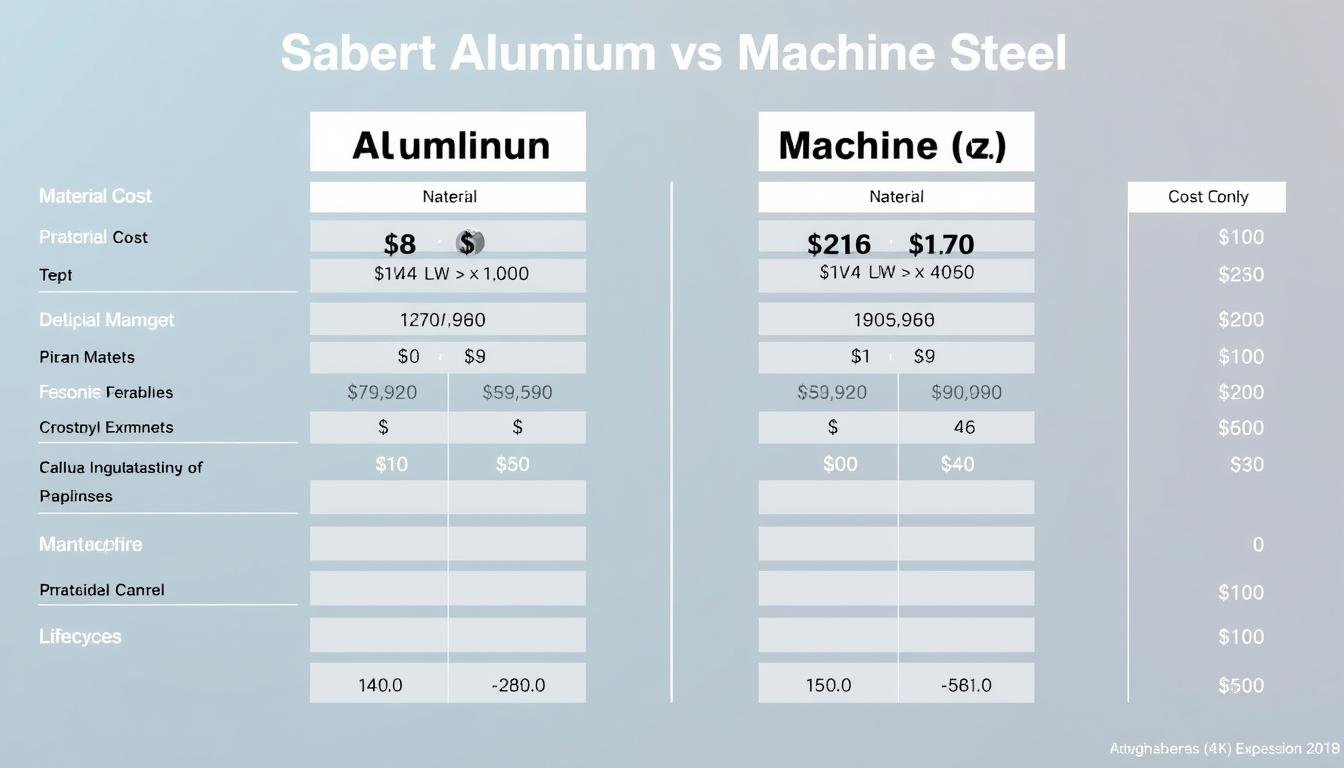

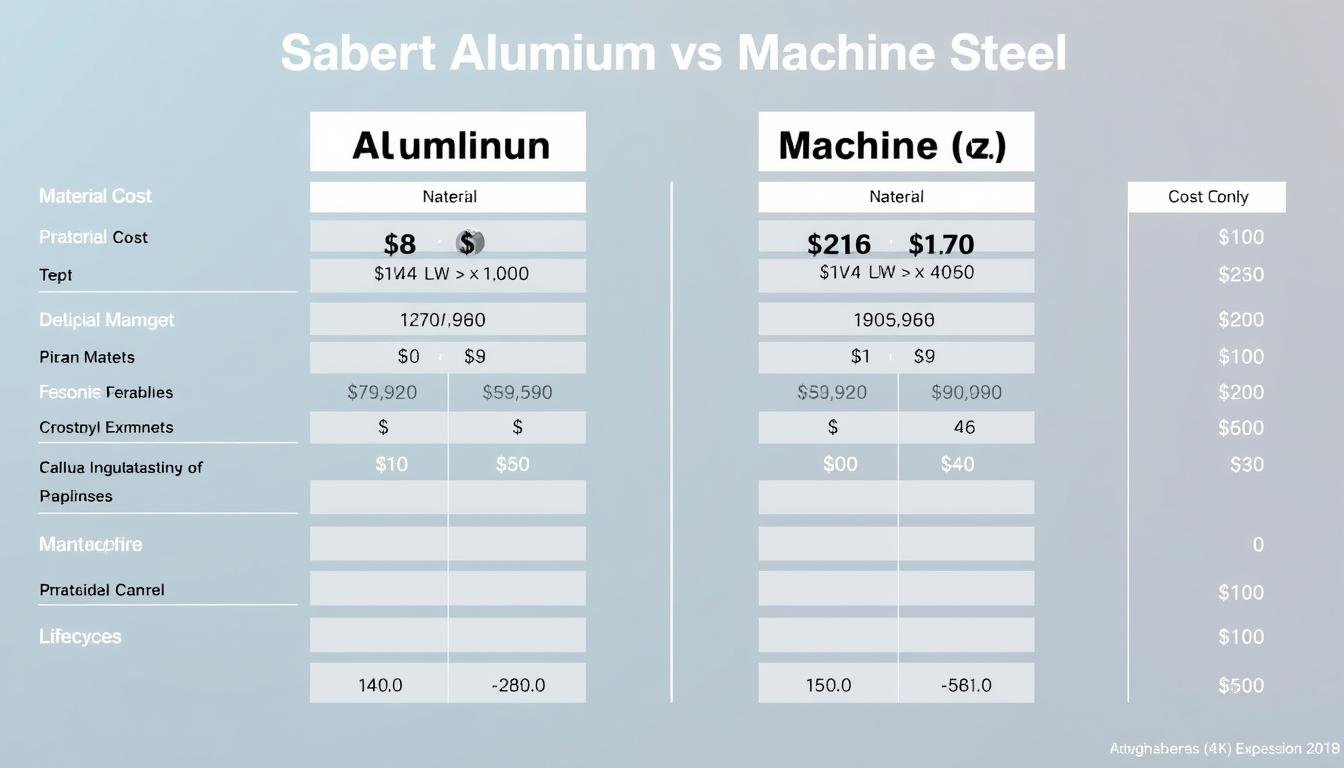

When comparing forged aluminum vs machined steel, cost factors extend beyond just material prices to include manufacturing processes, production volumes, and lifecycle considerations.

Comprehensive cost analysis comparing total ownership costs between materials

Initial Production Costs

Several factors influence the initial production costs for both materials:

| Cost Factor |

Forged Aluminum |

Machined Steel |

| Raw Material Cost |

Higher |

Lower |

| Tooling Investment |

Higher (dies required) |

Lower (standard tooling) |

| Energy Consumption |

Moderate (lower forging temperatures) |

Higher (more cutting energy) |

| Production Speed |

Faster for high volumes |

Faster for low volumes |

| Material Utilization |

Higher (near-net shape) |

Lower (subtractive process) |

For high-volume production, the initial tooling investment for forging can be offset by faster production cycles and reduced material waste. For low-volume or prototype production, machining often proves more economical due to lower setup costs.

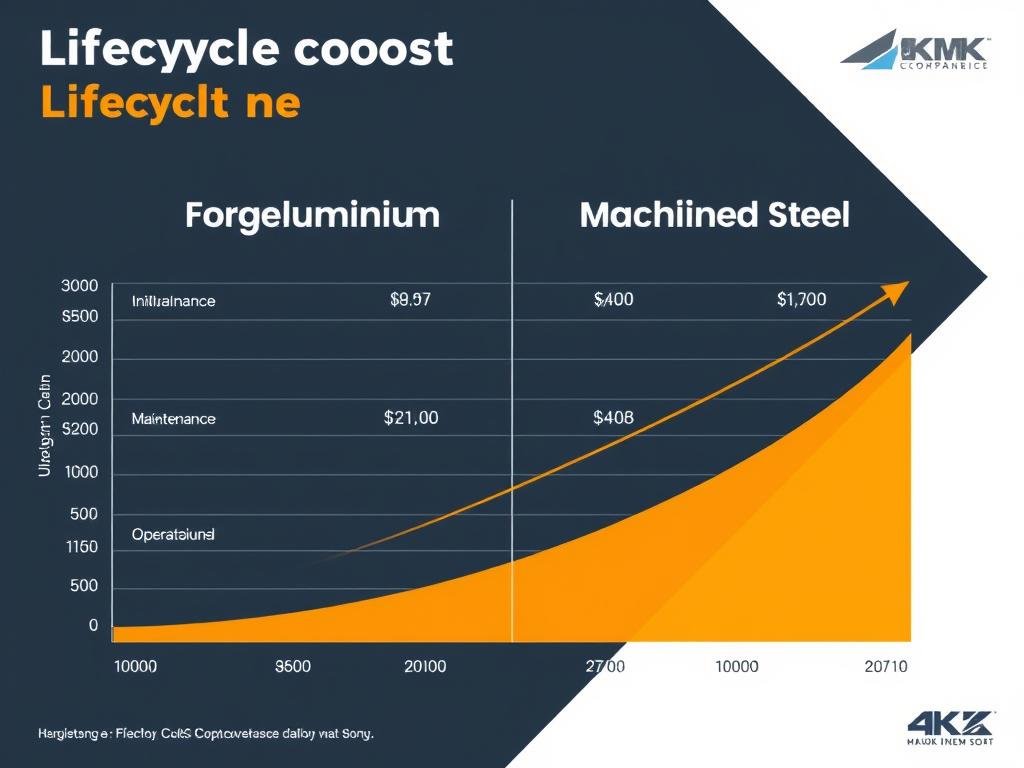

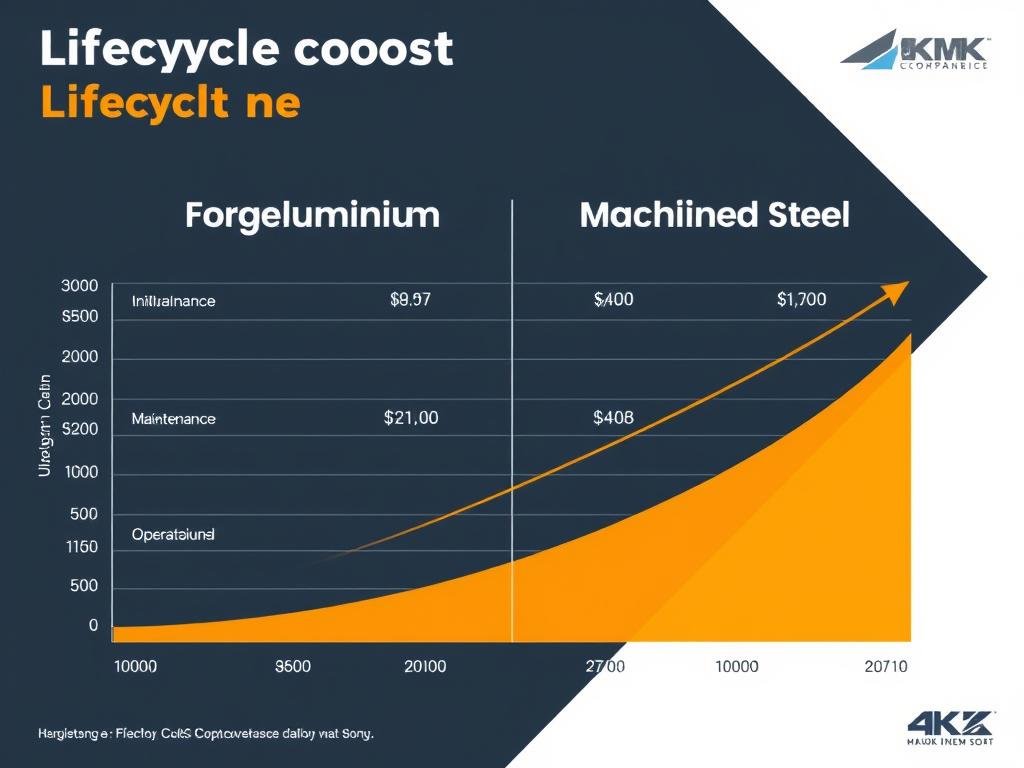

Lifecycle Cost Considerations

Beyond initial production costs, lifecycle considerations can significantly impact the total cost of ownership:

Forged Aluminum Lifecycle Benefits

- Weight reduction leading to fuel/energy savings

- Excellent corrosion resistance reducing maintenance

- Good thermal conductivity for heat-dissipating applications

- Higher value in recycling at end of life

- Potential for extended service life in certain applications

Machined Steel Lifecycle Benefits

- Superior durability in high-stress applications

- Better wear resistance reducing replacement frequency

- Higher temperature resistance for extreme environments

- Lower initial material and production costs

- Established recycling infrastructure

Lifecycle cost analysis showing total ownership costs over a 10-year period

The optimal material choice often depends on your specific application requirements, production volume, and lifecycle considerations. MAIKONG’s engineering team can help analyze these factors to determine the most cost-effective solution for your project.

Get a Competitive Quote

MAIKONG offers competitive pricing on both forged aluminum and machined steel components. Contact us for a detailed quote tailored to your specifications.

Request Custom Quote

MAIKONG’s Manufacturing Capabilities

At MAIKONG, we specialize in both aluminum forging and precision steel machining, offering comprehensive manufacturing solutions to meet your specific requirements.

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

Our Comprehensive Services

Aluminum Forging Services

- Hot and cold forging capabilities

- Custom die design and fabrication

- Wide range of aluminum alloys

- Near-net shape production

- High-volume capacity

Our advanced aluminum forging process

Precision Steel Machining

- Multi-axis CNC machining centers

- Precision turning and milling

- Complex geometry capabilities

- Tight tolerance machining

- Various steel alloy processing

Our precision CNC machining capabilities

Value-Added Services

- Heat treatment and surface finishing

- Quality testing and certification

- Engineering support and design optimization

- Prototyping and small batch production

- Assembly and packaging

Our comprehensive quality control processes

Our Full-Service Manufacturing Process

MAIKONG offers a complete end-to-end manufacturing solution, from initial design consultation through to finished component delivery:

Our comprehensive manufacturing process ensures quality at every step

- CAD/CAM Engineering: Advanced design and simulation tools to optimize component performance

- Material Selection: Expert guidance on selecting the optimal material for your application

- Tooling Design: Custom tooling designed for efficient production and consistent quality

- Forging/Machining: State-of-the-art equipment for precision manufacturing

- Heat Treatment: Controlled processes to enhance material properties

- Surface Finishing: Comprehensive finishing options including anodizing, painting, and plating

- Quality Control: Rigorous inspection and testing to ensure conformance to specifications

- Packaging and Delivery: Secure packaging and reliable logistics solutions

Partner with MAIKONG for Your Manufacturing Needs

Whether you need forged aluminum components, precision machined steel parts, or guidance on material selection, our team is ready to support your project from concept to completion.

Start Your Project Today

Quality Assurance and Certifications

At MAIKONG, quality is built into every step of our manufacturing process. We maintain rigorous quality control procedures to ensure that all components meet or exceed industry standards and customer specifications.

Our comprehensive quality control laboratory ensures consistent product excellence

Our Quality Control Process

Every component we manufacture undergoes a comprehensive quality verification process:

- Material Verification: Chemical composition and mechanical property testing

- In-Process Inspection: Continuous monitoring during manufacturing

- Dimensional Verification: Precision measurement using advanced CMM equipment

- Surface Quality Inspection: Visual and automated inspection systems

- Mechanical Testing: Hardness, tensile, and fatigue testing as required

- Non-Destructive Testing: Ultrasonic, magnetic particle, and dye penetrant inspection

- Final Inspection: Comprehensive verification before shipment

Precision dimensional verification using advanced coordinate measuring machines

Industry Certifications

MAIKONG maintains key industry certifications that demonstrate our commitment to quality and continuous improvement:

ISO 9001:2015

Our quality management system is certified to ISO 9001:2015 standards, ensuring consistent quality processes throughout our organization.

IATF 16949

We maintain IATF 16949 certification for automotive quality management systems, demonstrating our capability to serve automotive industry clients.

Material Certifications

We provide comprehensive material certifications and test reports to verify chemical composition and mechanical properties.

Quality You Can Trust

Experience MAIKONG’s commitment to quality excellence. Our rigorous quality assurance processes ensure that your components meet the highest standards for performance and reliability.

Discuss Your Quality Requirements

Making the Right Choice: Forged Aluminum vs Machined Steel

Selecting between forged aluminum vs machined steel requires careful consideration of your specific application requirements, performance needs, and economic constraints.

When to Choose Forged Aluminum

- Weight reduction is a primary concern

- Corrosion resistance is important

- High strength-to-weight ratio is needed

- Complex shapes with directional strength are required

- High-volume production can offset tooling costs

- Thermal conductivity is beneficial

When to Choose Machined Steel

- Maximum absolute strength is required

- High wear resistance is necessary

- Operating in extreme temperatures

- Low-volume or prototype production

- Budget constraints favor lower material costs

- Highly complex geometries are needed

At MAIKONG, we specialize in both forged aluminum and machined steel manufacturing, offering expert guidance to help you select the optimal material for your specific application. Our engineering team can analyze your requirements and recommend the most appropriate solution to meet your performance, cost, and timeline objectives.

Our engineering team provides expert consultation on material selection

Ready to Start Your Project?

Contact MAIKONG today to discuss your manufacturing needs. Whether you need forged aluminum components, precision machined steel parts, or guidance on material selection, our team is ready to help.

Email: Lucy@maikongforge.us

Frequently Asked Questions

What are the main differences between forged aluminum and machined steel?

The key differences between forged aluminum vs machined steel include weight (aluminum is about 1/3 the weight of steel), strength (steel has higher absolute strength while aluminum offers better strength-to-weight ratio), corrosion resistance (aluminum naturally forms a protective oxide layer), and manufacturing process (forging aligns grain structure while machining maintains the original grain structure).

Which material is more cost-effective?

Cost-effectiveness depends on your specific application. While steel typically has lower raw material costs, aluminum can offer lifecycle cost advantages through weight reduction and corrosion resistance. For high-volume production, forged aluminum’s near-net shape capabilities can reduce machining costs. For low-volume or prototype production, machined steel often has lower tooling costs.

Can MAIKONG produce both forged aluminum and machined steel components?

Yes, MAIKONG specializes in both aluminum forging and precision steel machining. Our comprehensive manufacturing capabilities allow us to produce components in either material based on your specific requirements. We can also provide guidance on material selection to help you choose the optimal solution for your application.

What industries does MAIKONG serve?

MAIKONG serves a wide range of industries including aerospace, automotive, industrial equipment, medical devices, consumer products, and more. Our manufacturing capabilities and quality management systems are designed to meet the demanding requirements of these diverse sectors.

How do I request a quote for my project?

You can request a quote by visiting our website at https://maikongforge.us/contact/, calling us at +86 13-51090-74-01, or emailing Lucy@maikongforge.us. Please provide as much detail as possible about your project requirements, including specifications, quantities, and timeline to receive the most accurate quote.

Material samples showing the distinctive properties of forged aluminum (left) and machined steel (right)

Material samples showing the distinctive properties of forged aluminum (left) and machined steel (right)