When it comes to high-performance engine blocks, the manufacturing method can significantly impact durability, weight, and overall performance. The debate between forged aluminum engine block vs machined options represents a critical decision point for automotive engineers, racing teams, and performance enthusiasts. This comprehensive guide explores the fundamental differences, advantages, and applications of each manufacturing process to help you make an informed decision for your specific requirements.

Understanding Aluminum Engine Block Manufacturing Methods

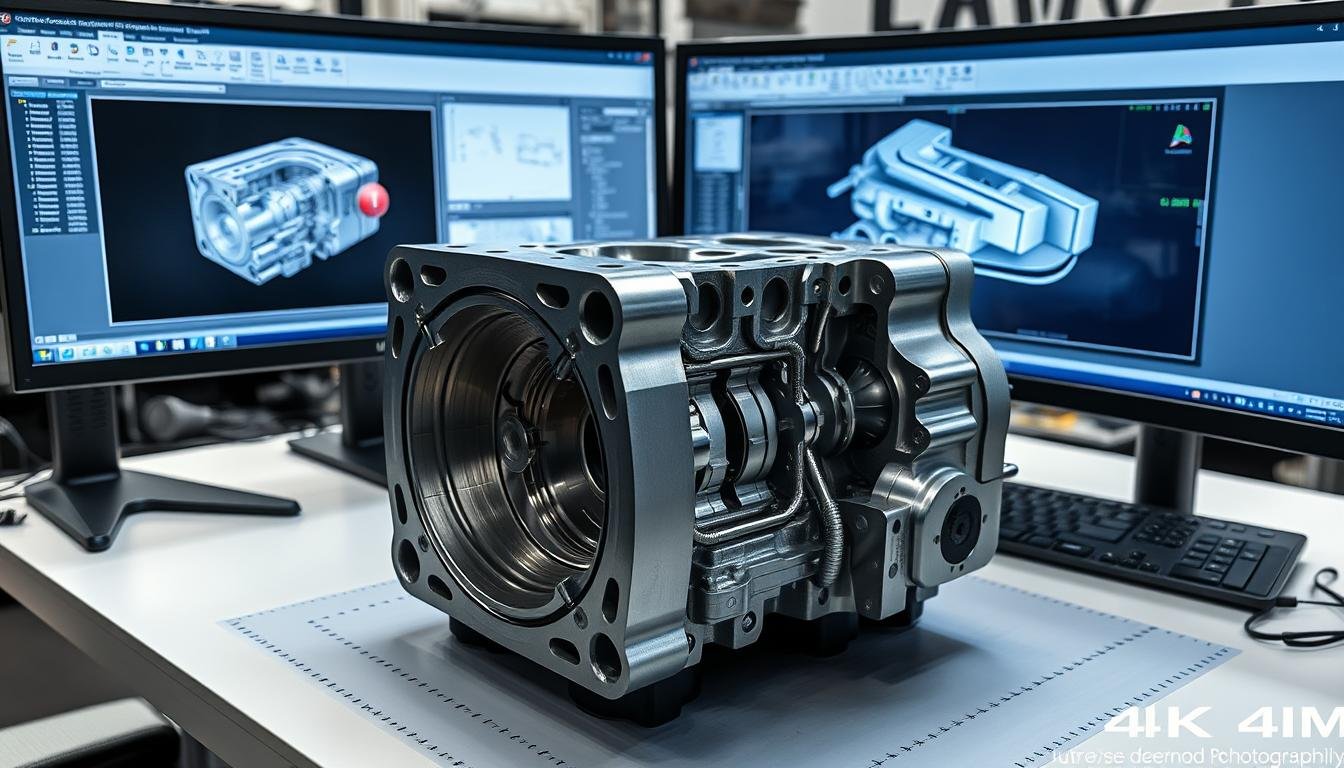

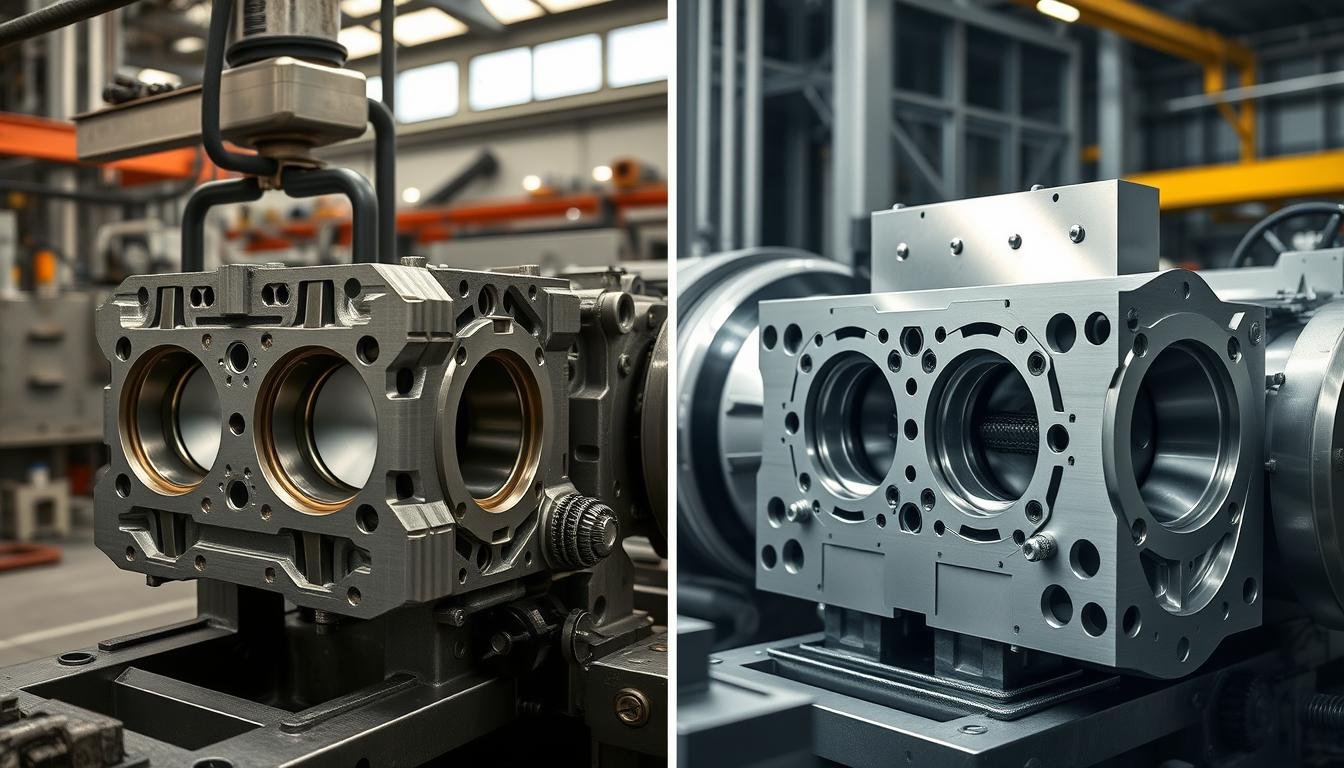

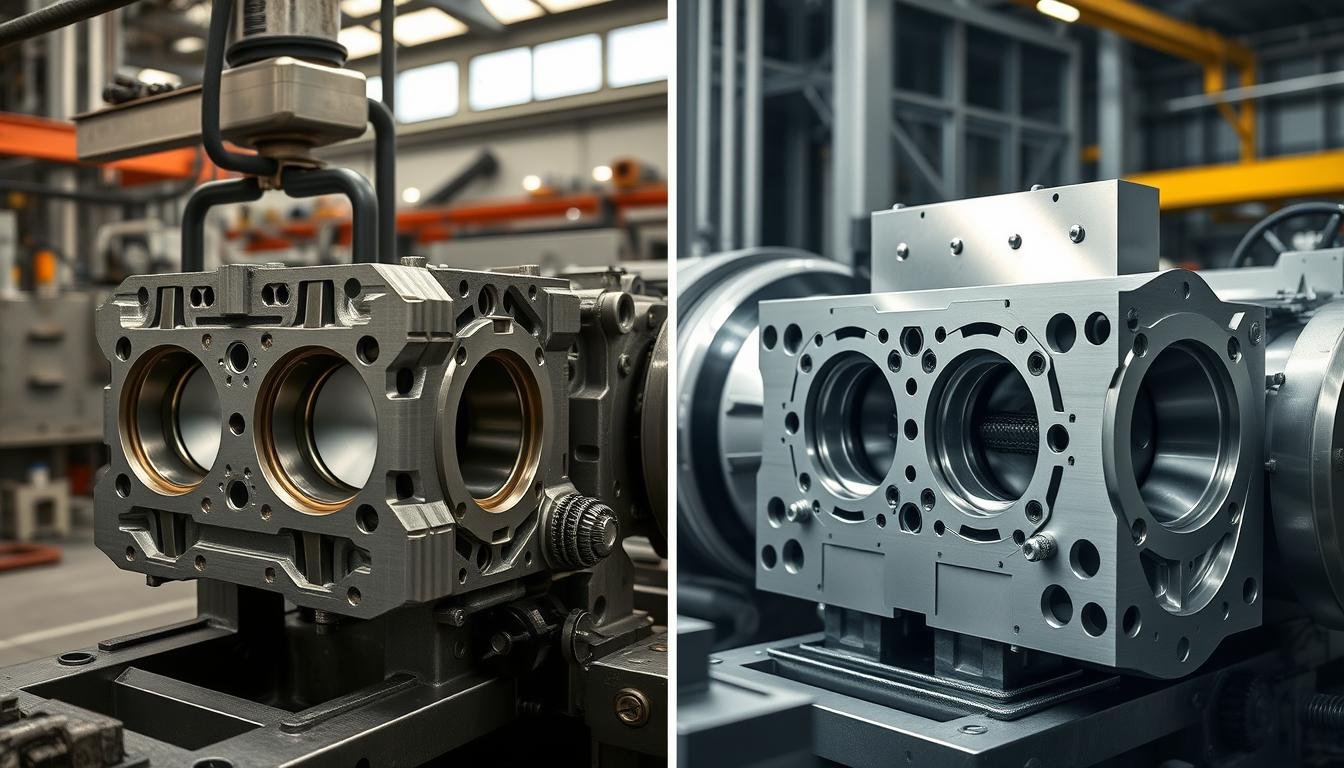

Different manufacturing processes for aluminum engine blocks

Different manufacturing processes for aluminum engine blocks

Engine blocks serve as the foundational structure of an engine, housing the cylinders and providing support for other critical components. Aluminum has become the material of choice for many high-performance applications due to its excellent strength-to-weight ratio. However, the method used to form this aluminum into an engine block plays a crucial role in determining its performance characteristics.

What is a Forged Aluminum Engine Block?

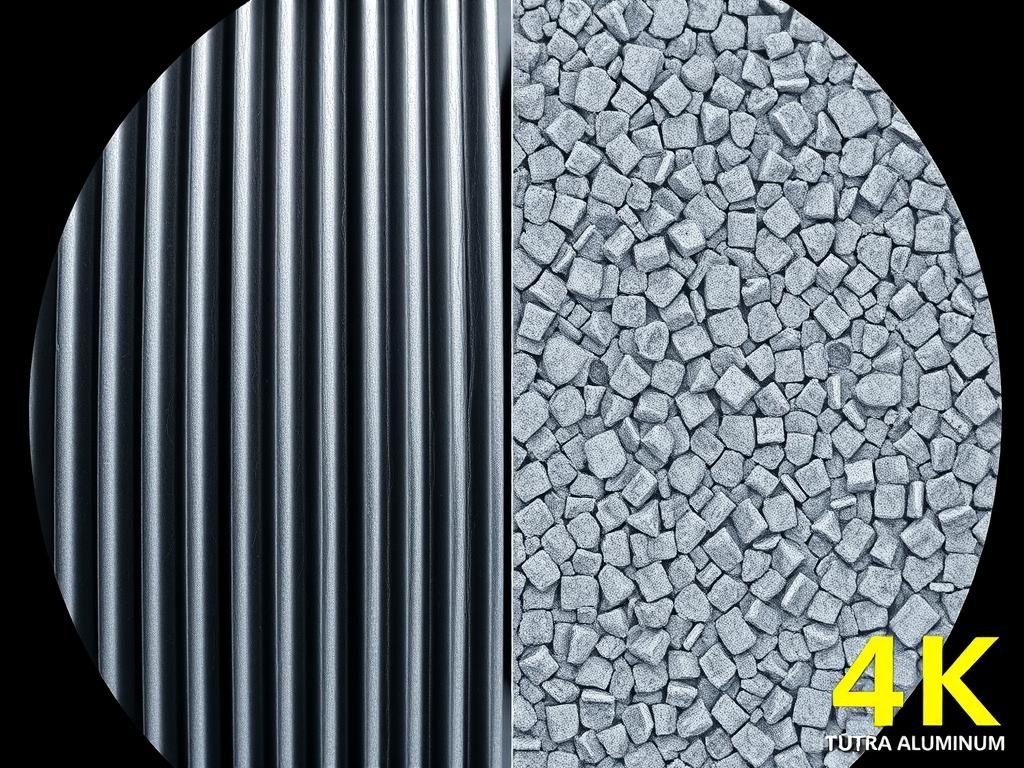

Forged aluminum engine blocks are manufactured through a process that applies intense pressure to aluminum billets, forcing the metal to conform to a specific shape. This process fundamentally alters the internal grain structure of the aluminum, creating a denser, more uniform material with enhanced mechanical properties. The forging process aligns the metal’s grain structure in a way that significantly improves strength and durability.

What is a Machined Aluminum Engine Block?

Machined aluminum engine blocks typically start as cast aluminum blocks that are then precision-machined to final specifications. The casting process involves pouring molten aluminum into molds where it solidifies into the rough shape of an engine block. CNC machining services then remove material to create precise dimensions, cylinder bores, and mounting surfaces. Some high-performance blocks are machined from solid aluminum billets, though this is less common for complete engine blocks due to cost and material waste considerations.

Manufacturing Processes: From Raw Material to Finished Engine Block

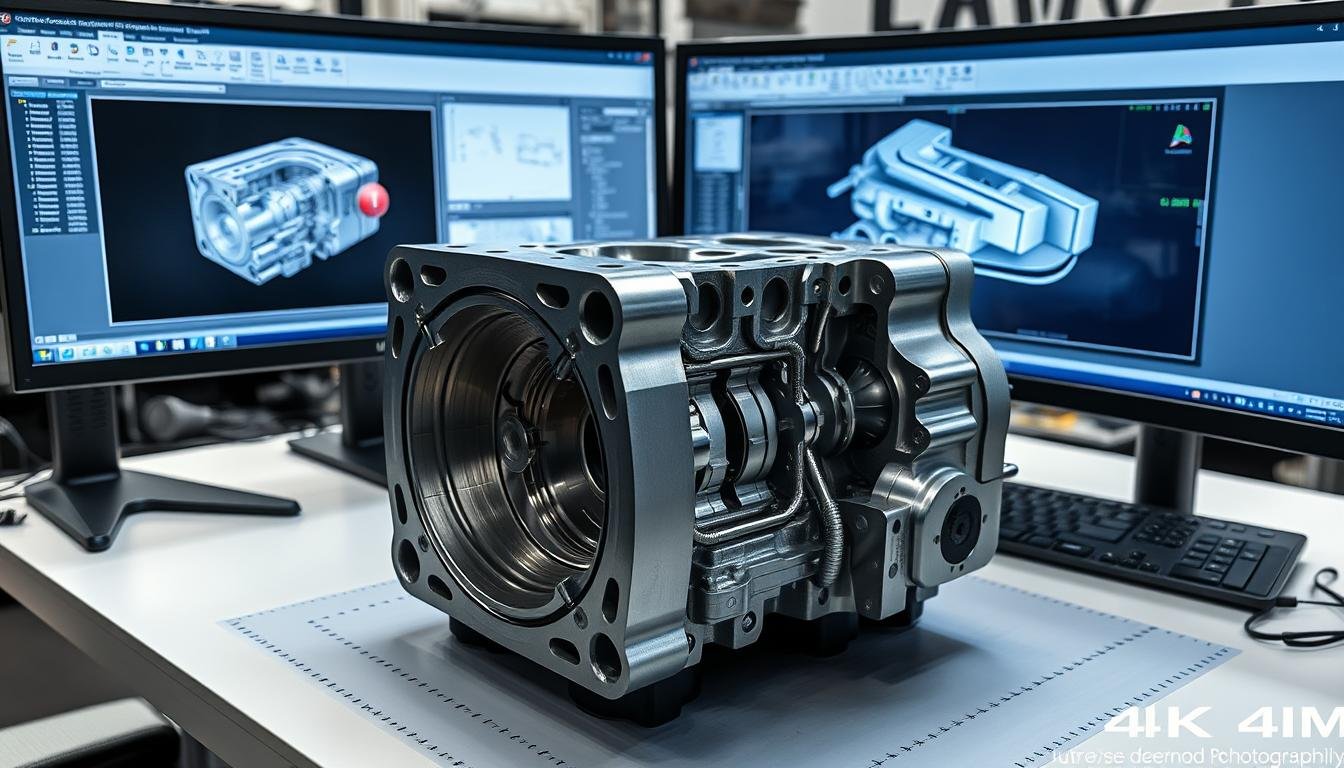

CAD/CAM design process for precision engine block manufacturing

Forged Aluminum Engine Block Manufacturing Process

The creation of a forged aluminum engine block involves several sophisticated steps:

- Material Selection: High-grade aluminum alloys (typically 6061 or 7075) are selected for their superior mechanical properties.

- Heating: The aluminum is heated to a specific temperature where it becomes malleable but remains solid.

- Compression: Hydraulic presses apply extreme pressure (often exceeding 10,000 tons) to form the aluminum into the desired shape.

- Grain Alignment: The forging process naturally aligns the metal’s grain structure, enhancing strength along key stress points.

- Heat Treatment: Controlled heating and cooling further enhance the mechanical properties of the forged component.

- Precision Machining: CNC machining creates precise dimensions, cylinder bores, and mounting surfaces.

Machined Aluminum Engine Block Manufacturing Process

Machined engine blocks follow a different production path:

- Casting: Molten aluminum is poured into molds to create the basic engine block shape.

- Solidification: The aluminum cools and solidifies, forming a cast block with a less uniform internal structure.

- Initial Machining: Rough machining removes excess material and creates basic features.

- Heat Treatment: The cast block undergoes heat treatment to improve strength and stability.

- Precision Machining: CNC machining services create final dimensions, cylinder bores, and critical surfaces.

- Surface Finishing: Various finishing processes improve appearance and corrosion resistance.

Key Differences Between Forged and Machined Aluminum Engine Blocks

| Characteristic |

Forged Aluminum Engine Block |

Machined Aluminum Engine Block |

| Internal Structure |

Dense, aligned grain structure with minimal porosity |

Less uniform grain structure, potential for porosity |

| Strength |

Superior tensile and yield strength (typically 30-50% stronger) |

Good strength but less than forged alternatives |

| Weight |

Excellent strength-to-weight ratio, allowing for lighter designs |

May require additional material for equivalent strength |

| Fatigue Resistance |

Exceptional resistance to cyclic loading and stress |

Good but less resistant to high-stress applications |

| Heat Dissipation |

Excellent thermal conductivity due to dense structure |

Good thermal properties but may vary with casting quality |

| Manufacturing Complexity |

More complex, requiring specialized equipment |

Less complex, more widely available process |

| Cost |

Higher initial cost due to complex manufacturing |

Generally more cost-effective for production |

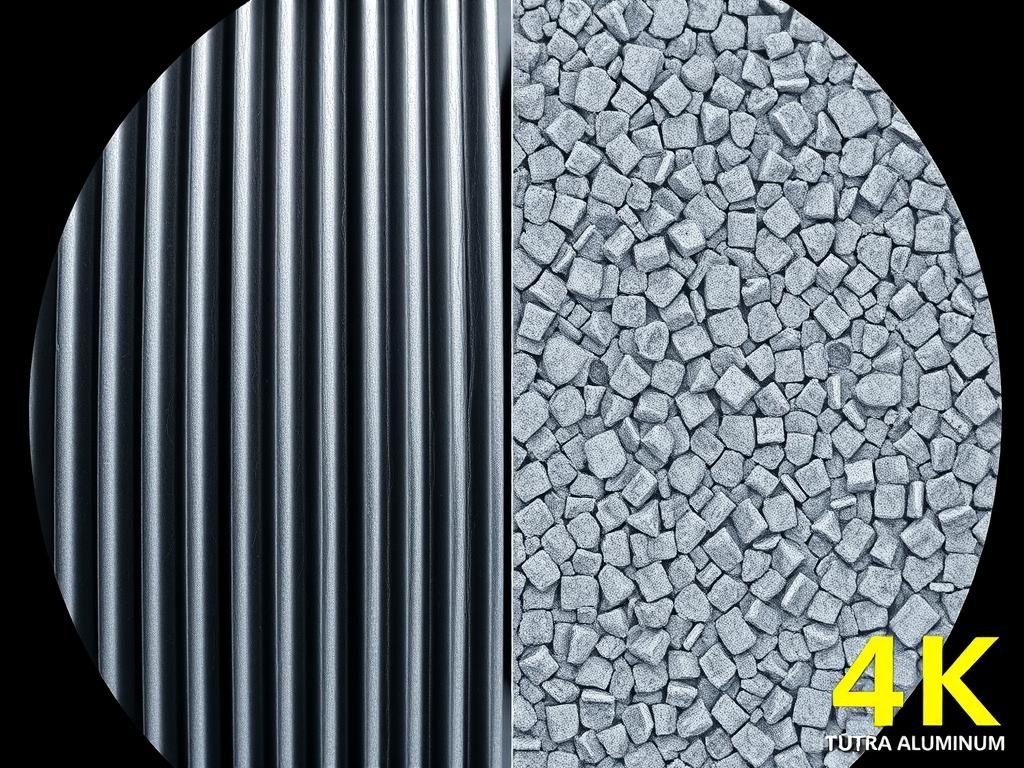

Microscopic comparison of grain structures in forged vs machined aluminum

Strength-to-Weight Ratio: The Critical Advantage

The strength-to-weight ratio is a fundamental consideration in engine design, particularly for high-performance and racing applications. This ratio directly impacts both performance and efficiency.

Forged Aluminum Advantage

Forged aluminum engine blocks offer a superior strength-to-weight ratio due to their dense, aligned grain structure. This allows engineers to design lighter blocks that maintain exceptional strength, resulting in:

- Reduced overall vehicle weight

- Improved power-to-weight ratio

- Enhanced acceleration and handling

- Better fuel efficiency

- Increased resistance to deformation under high cylinder pressures

Expert Aluminum Forging Services at MAIKONG

Our state-of-the-art forging facility produces high-performance aluminum components with superior strength-to-weight ratios. With 60+ CNC machines and 100+ tons of monthly metal processing capacity, we deliver precision and quality for your most demanding applications.

Request a Consultation

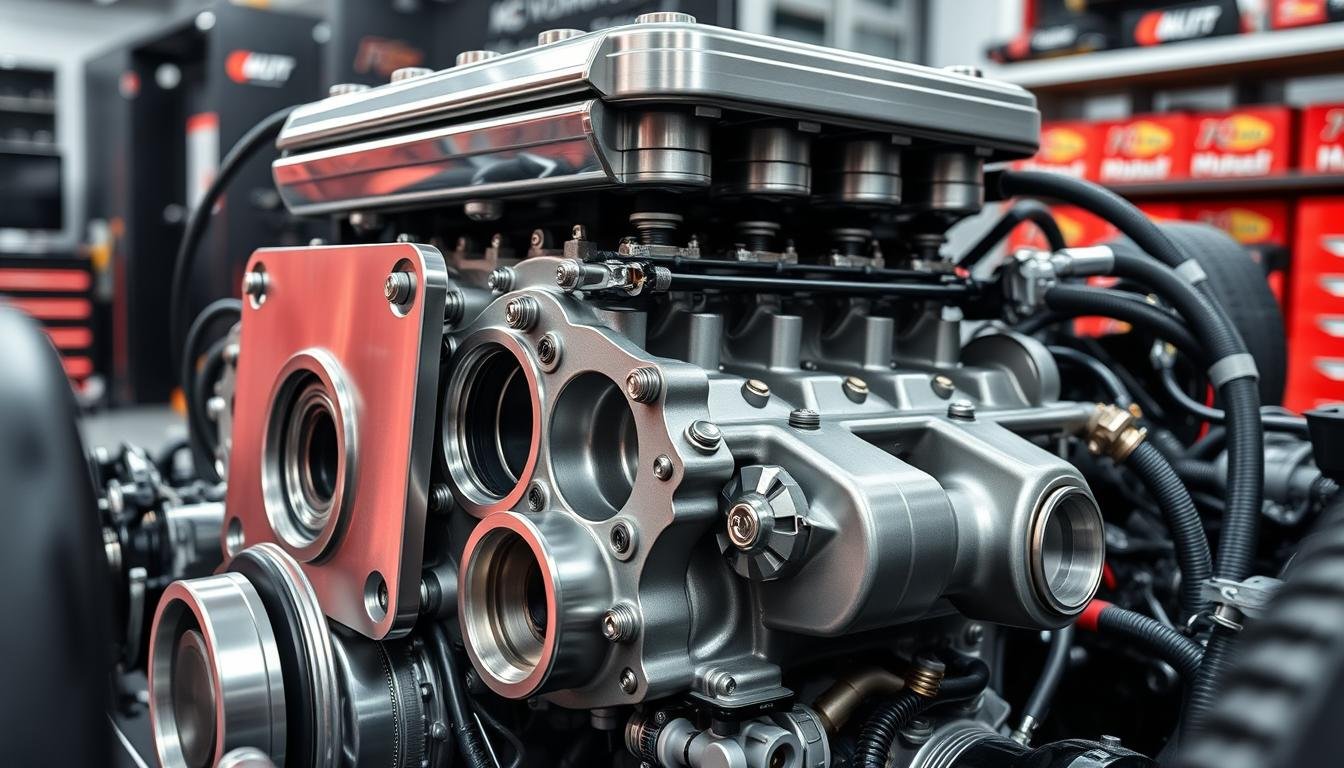

Applications and Industry Uses

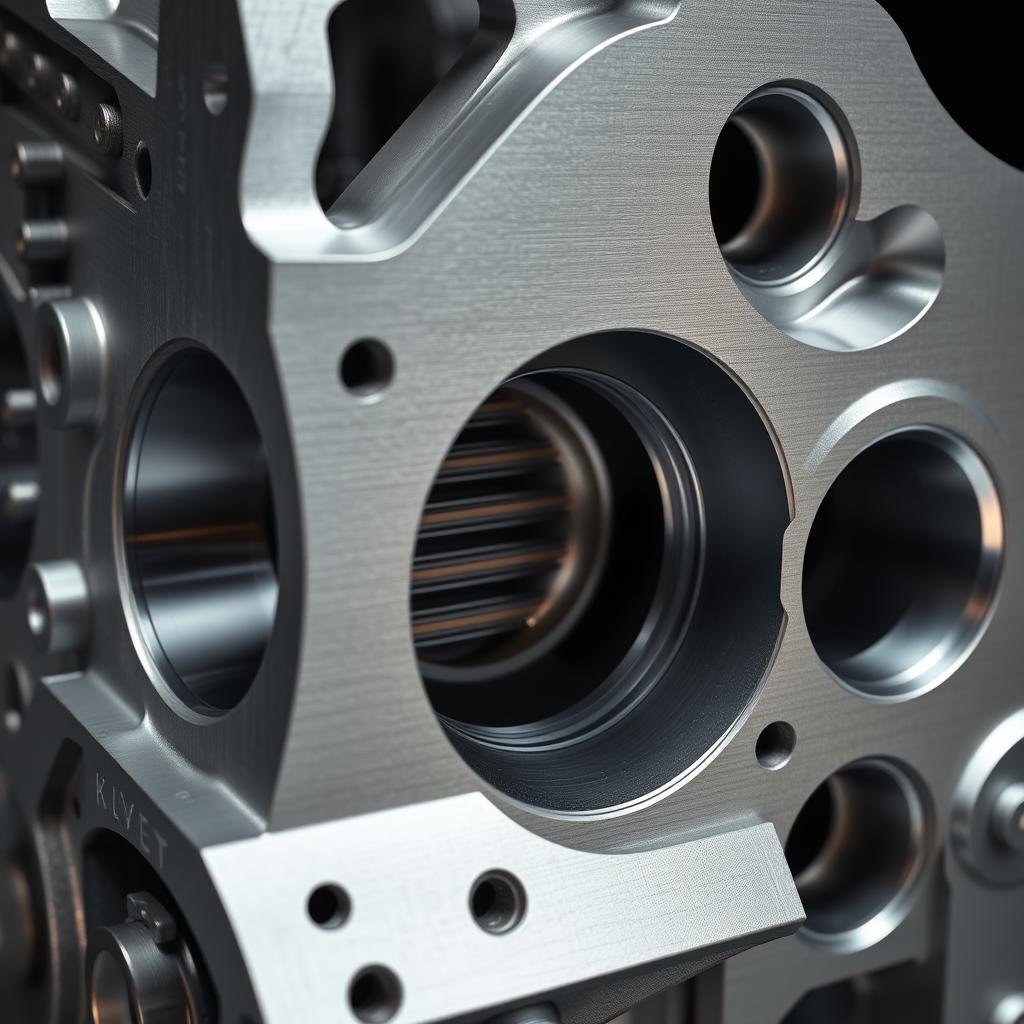

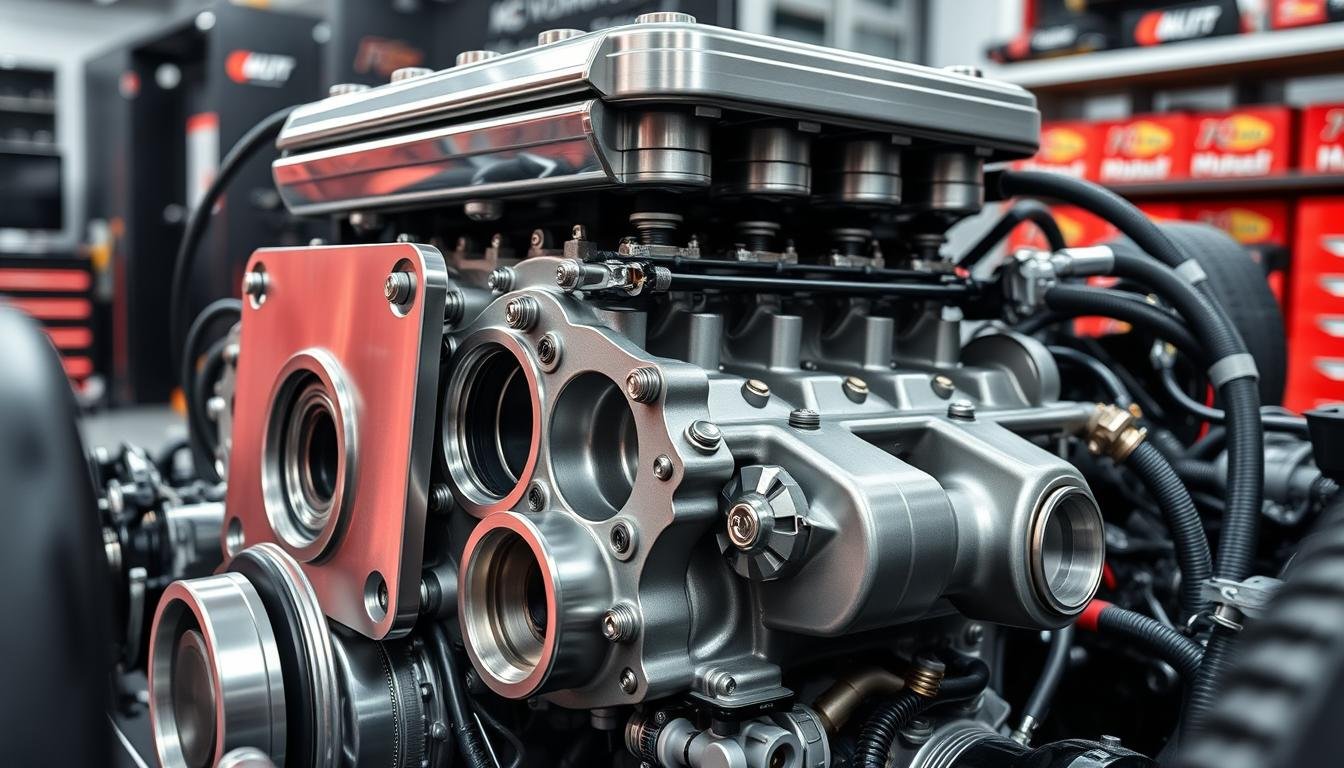

High-performance automotive application of forged aluminum engine blocks

When to Choose a Forged Aluminum Engine Block vs Machined

The selection between these manufacturing methods depends on your specific application requirements:

Ideal Applications for Forged Aluminum Blocks

- High-performance racing engines

- Engines with forced induction (turbocharging/supercharging)

- Applications requiring maximum strength and durability

- Extreme operating conditions

- Weight-critical applications

- High-revving engines with significant stress loads

Ideal Applications for Machined Aluminum Blocks

- Production vehicles with moderate performance requirements

- Cost-sensitive applications

- Naturally aspirated engines with lower stress loads

- Applications requiring complex internal geometries

- Situations where manufacturing volume is prioritized

- Engines with moderate operating conditions

Industry-Specific Applications

Automotive

From high-performance sports cars to racing vehicles, forged aluminum engine blocks provide the strength and lightweight properties needed for maximum performance. Production vehicles often utilize machined blocks for their cost-effectiveness and reliability.

Aerospace

Aircraft engines benefit from the exceptional strength-to-weight ratio of forged components, where every gram matters and reliability is paramount. The aligned grain structure provides superior resistance to the extreme conditions encountered in flight.

Marine

Marine engines face unique challenges from corrosion and constant vibration. Forged aluminum components offer enhanced durability in these harsh environments, while machined options provide cost-effective solutions for less demanding applications.

Quality Control in Aluminum Engine Block Manufacturing

Precision quality control inspection at MAIKONG’s manufacturing facility

Quality control is critical in ensuring the performance and reliability of aluminum engine blocks. At MAIKONG, we implement comprehensive testing and verification procedures throughout the manufacturing process:

- Material Verification: Spectroscopic analysis confirms the exact composition of aluminum alloys before processing.

- Non-Destructive Testing: Ultrasonic and X-ray inspections detect any internal defects or inconsistencies.

- Dimensional Inspection: Precision measurement using coordinate measuring machines (CMM) ensures adherence to exact specifications.

- Hardness Testing: Verifies the material has achieved the required mechanical properties after heat treatment.

- Pressure Testing: Confirms the integrity of water jackets and oil passages within the block.

- Surface Finish Analysis: Ensures critical surfaces meet specification requirements.

“Quality isn’t just inspected into a product; it’s built into every step of our manufacturing process. Our ISO 9001:2015 certified quality management system ensures consistent excellence in every engine block we produce.”

– MAIKONG Quality Control Team

MAIKONG’s Manufacturing Capabilities

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

With over 60 CNC machines and a monthly metal processing capacity exceeding 100 tons, MAIKONG offers comprehensive manufacturing solutions for both forged and machined aluminum components:

Forging Capabilities

- Advanced hydraulic forging presses

- Precision die design and manufacturing

- Controlled heating and cooling processes

- Specialized handling for aluminum alloys

- Uniform heat treatment facilities

CNC Machining Services

- Multi-axis CNC milling and turning

- Precision CNC machining for tight tolerances

- Custom CNC parts manufacturing

- CNC prototyping services

- High-volume production capacity

Additional Services

- Material testing laboratory

- Surface treatments and finishes

- Custom metal fabrication

- Contract manufacturing CNC

- Comprehensive quality assurance

MAIKONG’s advanced material testing laboratory ensures quality and consistency

Cost Considerations: Forged Aluminum Engine Block vs Machined

Understanding the cost implications of different manufacturing methods is essential for making informed decisions:

| Cost Factor |

Forged Aluminum |

Machined Aluminum |

| Initial Tooling |

Higher – Requires specialized forging dies |

Lower – Standard machining tools |

| Material Utilization |

Better – Less material waste |

Lower – Significant material removal |

| Production Volume |

More economical at higher volumes |

Cost-effective for smaller batches |

| Processing Time |

Longer – Multiple heating and forming steps |

Shorter – Direct machining process |

| Long-term Value |

Higher – Extended durability and performance |

Good value for standard applications |

Cost analysis comparison between manufacturing methods

Value Proposition: While forged aluminum engine blocks typically have a higher initial cost, they often provide better long-term value through extended durability, superior performance, and enhanced resale value. For high-performance applications, the additional investment frequently delivers significant returns through improved reliability and reduced maintenance costs.

Case Studies: Real-World Performance

High-performance racing application showcasing forged aluminum engine block benefits

Performance Racing Application

A professional racing team switched from machined to forged aluminum engine blocks for their competition vehicles. The results were significant:

- 15% weight reduction in the engine block

- Increased ability to withstand higher boost pressures

- Improved reliability under extreme racing conditions

- Enhanced heat dissipation during extended high-RPM operation

- Zero mechanical failures over an entire racing season

Production Vehicle Application

A manufacturer of premium sports cars implemented a hybrid approach:

- Forged aluminum for critical high-stress components

- Precision-machined cast aluminum for the main block structure

- Result: Optimal balance of performance, weight, and cost

- 30% improvement in engine durability testing

- Cost-effective solution for production volumes

Partner with MAIKONG for Your Engine Block Manufacturing

Whether you need forged aluminum components for maximum performance or precision-machined parts for cost-effective production, our team of experts can help determine the optimal manufacturing approach for your specific requirements.

Get a Custom Quote

Future Trends in Aluminum Engine Block Manufacturing

Next-generation manufacturing technologies for aluminum engine blocks

The landscape of engine block manufacturing continues to evolve with emerging technologies and changing industry demands:

- Hybrid Manufacturing Approaches: Combining the advantages of forging and machining to optimize performance and cost.

- Advanced Aluminum Alloys: Development of new alloy compositions specifically engineered for engine block applications.

- Additive Manufacturing: 3D printing technologies enabling complex internal geometries previously impossible with traditional methods.

- Computational Optimization: Advanced simulation tools allowing for more precise stress analysis and material distribution.

- Sustainable Manufacturing: Reduced energy consumption and improved material utilization in the manufacturing process.

At MAIKONG, we continuously invest in research and development to stay at the forefront of these emerging technologies, ensuring our customers benefit from the latest advancements in aluminum engine block manufacturing.

Conclusion: Making the Right Choice for Your Application

The decision between a forged aluminum engine block vs machined options ultimately depends on your specific performance requirements, budget constraints, and production volumes. Forged aluminum offers superior strength, durability, and performance characteristics, making it ideal for high-stress applications where reliability is paramount. Machined aluminum provides a cost-effective solution for many standard applications with good overall performance.

At MAIKONG, we specialize in both manufacturing methods, providing comprehensive solutions tailored to your exact specifications. Our team of experts can help you navigate the decision-making process, ensuring you select the optimal manufacturing approach for your unique requirements.

Contact MAIKONG Today for Expert Consultation

Our team of experienced engineers and manufacturing specialists is ready to assist with your aluminum engine block and component needs. With our comprehensive capabilities in forging, machining, and quality control, we deliver precision parts that meet the most demanding specifications.

Email: Lucy@maikongforge.us

Get A Quick Quote

MAIKONG’s engineering team provides expert consultation on engine block design and manufacturing

Frequently Asked Questions

What is the main advantage of a forged aluminum engine block over a machined one?

The primary advantage of a forged aluminum engine block is its superior strength and durability due to the aligned grain structure created during the forging process. This results in better resistance to high pressures, improved fatigue resistance, and enhanced overall performance in high-stress applications. Forged blocks typically offer a better strength-to-weight ratio, allowing for lighter yet stronger engine components.

Are forged aluminum engine blocks worth the additional cost?

For high-performance applications, racing engines, or situations involving forced induction (turbocharging/supercharging), the additional cost of forged aluminum engine blocks is typically justified by their superior strength, durability, and performance characteristics. For standard production vehicles or applications with moderate performance requirements, machined blocks often provide a more cost-effective solution with adequate performance.

Can MAIKONG produce custom engine blocks to specific designs?

Yes, MAIKONG specializes in custom manufacturing of both forged and machined aluminum engine blocks according to client specifications. Our comprehensive capabilities include CAD/CAM design assistance, material selection consultation, prototype development, and full production manufacturing. We work closely with clients to ensure their specific performance requirements and design parameters are met with precision.

What quality control measures does MAIKONG implement for engine block manufacturing?

MAIKONG implements comprehensive quality control procedures throughout the manufacturing process, including material verification through spectroscopic analysis, non-destructive testing using ultrasonic and X-ray inspections, precision dimensional inspection with coordinate measuring machines, hardness testing, pressure testing of water jackets and oil passages, and surface finish analysis. Our ISO 9001:2015 certified quality management system ensures consistent excellence in every component we produce.

Different manufacturing processes for aluminum engine blocks

Different manufacturing processes for aluminum engine blocks