For procurement professionals navigating the complex world of custom metal fabrication, understanding billet machining terminology is crucial for making informed sourcing decisions. This comprehensive guide breaks down the essential concepts, processes, and considerations to help you communicate effectively with manufacturers and secure the highest quality components for your projects.

What Is Billet Machining and Why It Matters

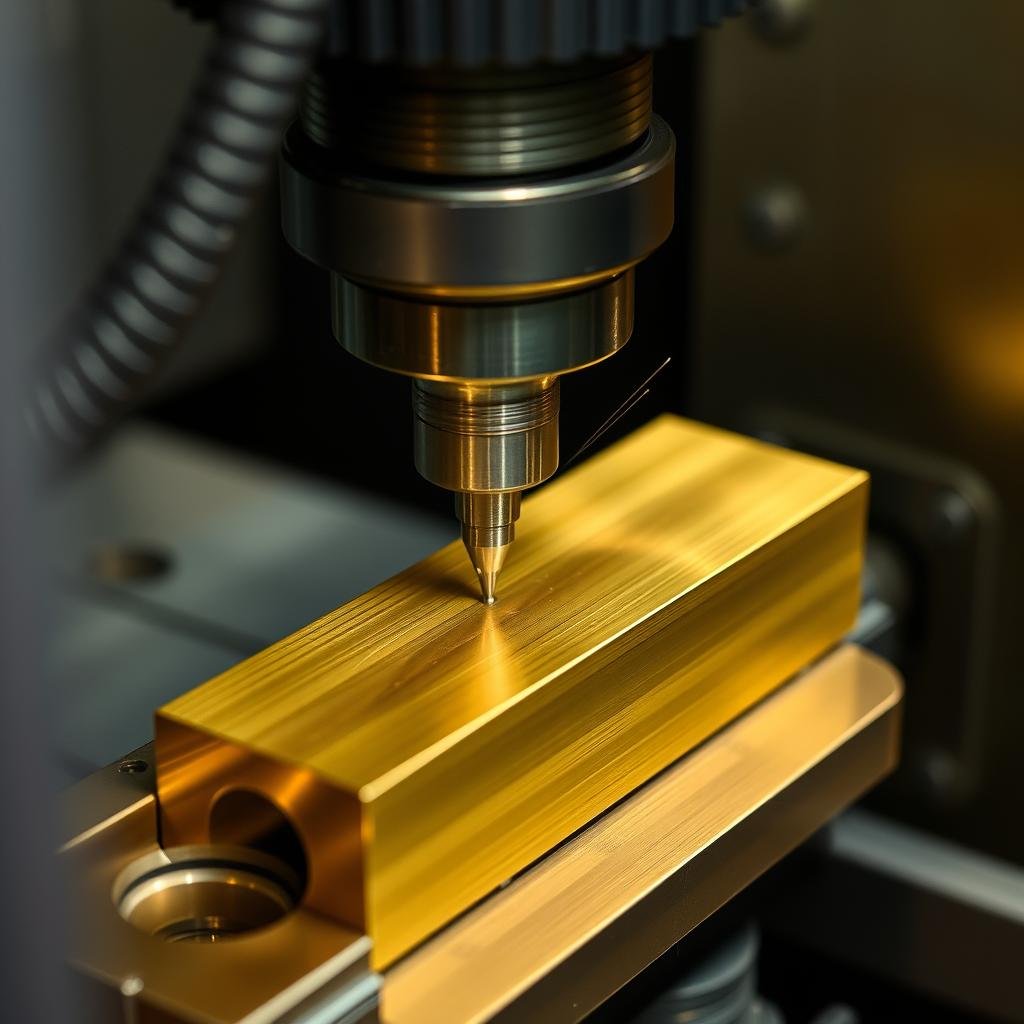

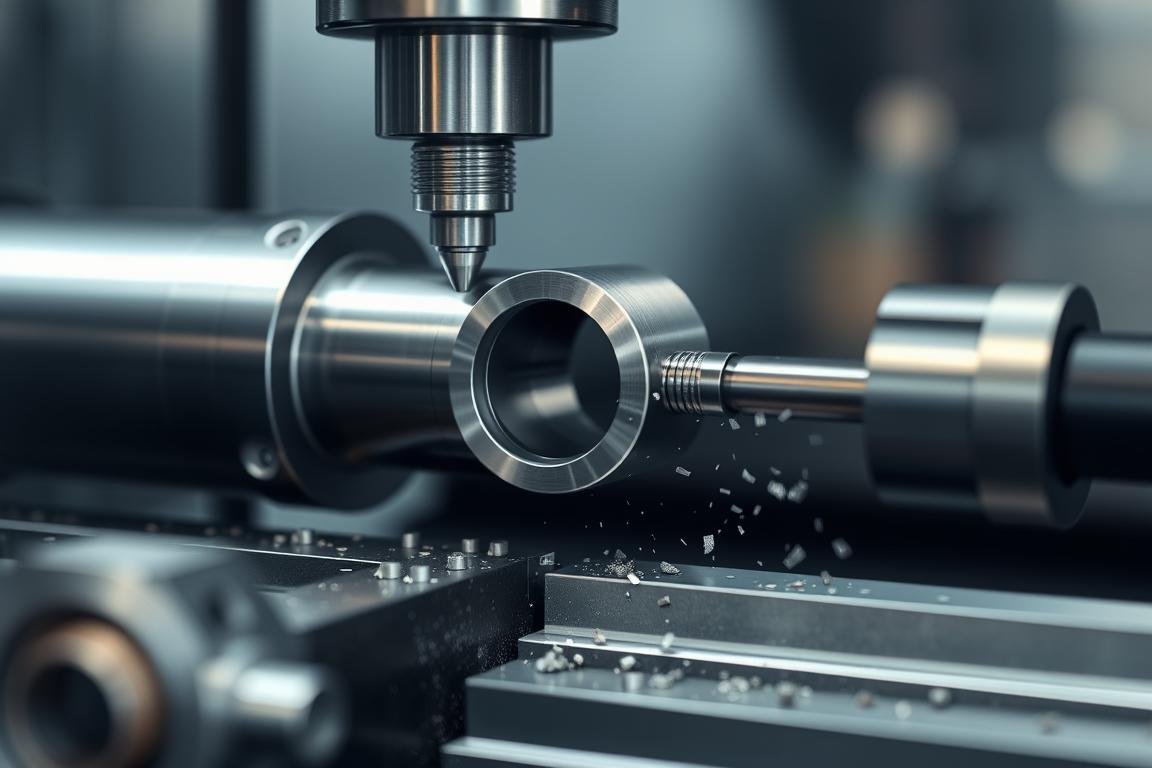

Precision CNC machining process at MAIKONG manufacturing facility

Precision CNC machining process at MAIKONG manufacturing facility

Billet machining refers to the manufacturing process where parts are created by removing material from a solid block of metal (the billet) using precision cutting tools. Unlike casting or forging, which form metal through melting or compression, billet machining is a subtractive process that offers exceptional precision and material integrity.

For procurement teams, understanding this process is essential because it directly impacts component quality, lead times, and project costs. The right manufacturing method for your application depends on various factors including production volume, material requirements, and performance specifications.

Key Differences: Billet Machining vs. Cast vs. Forged Manufacturing

Visual comparison of manufacturing methods: billet (left), cast (center), forged (right)

When evaluating manufacturing options, procurement teams must understand the fundamental differences between these three common methods:

| Manufacturing Method |

Process Description |

Ideal Applications |

Cost Considerations |

| Billet Machining |

Material removed from solid metal block using CNC equipment |

Low-volume production, prototypes, complex geometries |

Cost-effective for small runs, higher material waste |

| Cast Manufacturing |

Molten metal poured into molds and cooled to shape |

Complex shapes, high-volume production |

Low per-unit cost at scale, high tooling investment |

| Forged Manufacturing |

Metal heated and shaped using compressive force |

High-stress components, structural parts |

Higher strength-to-weight ratio, medium tooling costs |

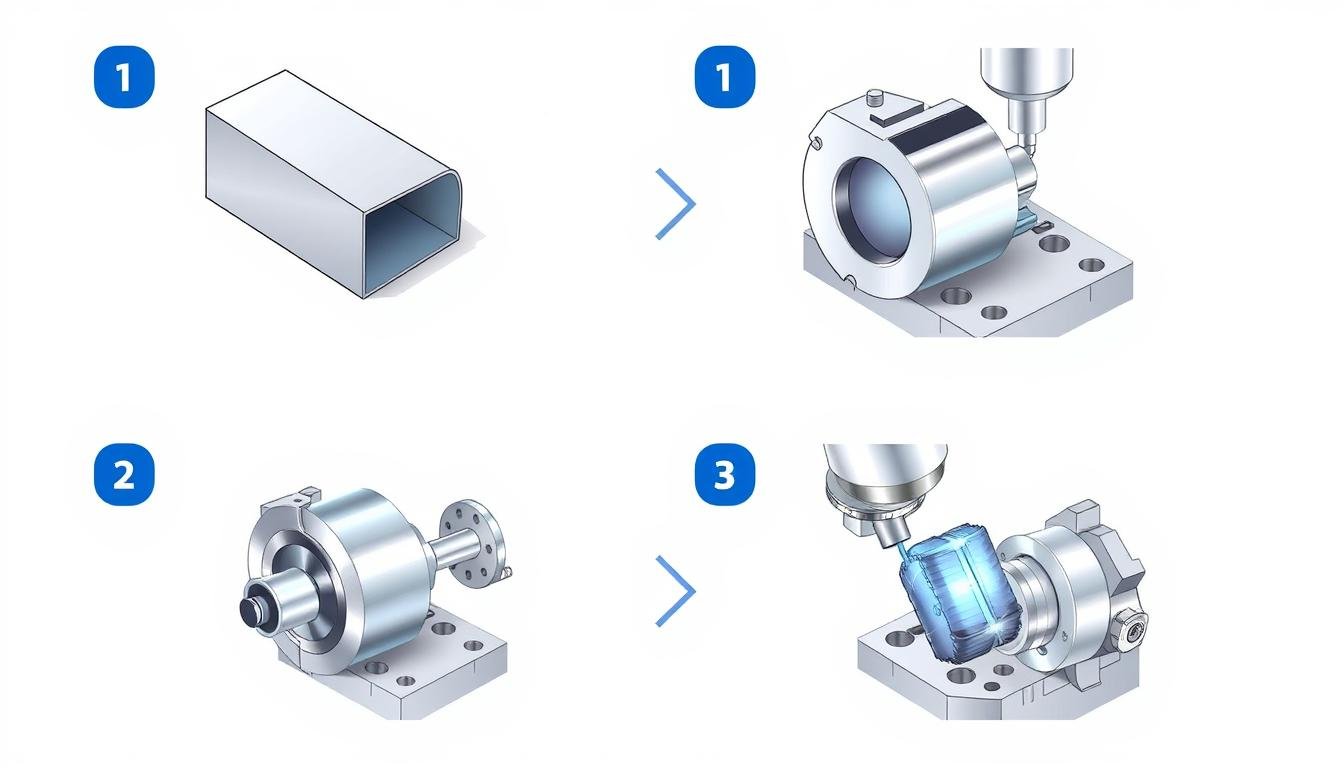

The Billet Machining Process Explained

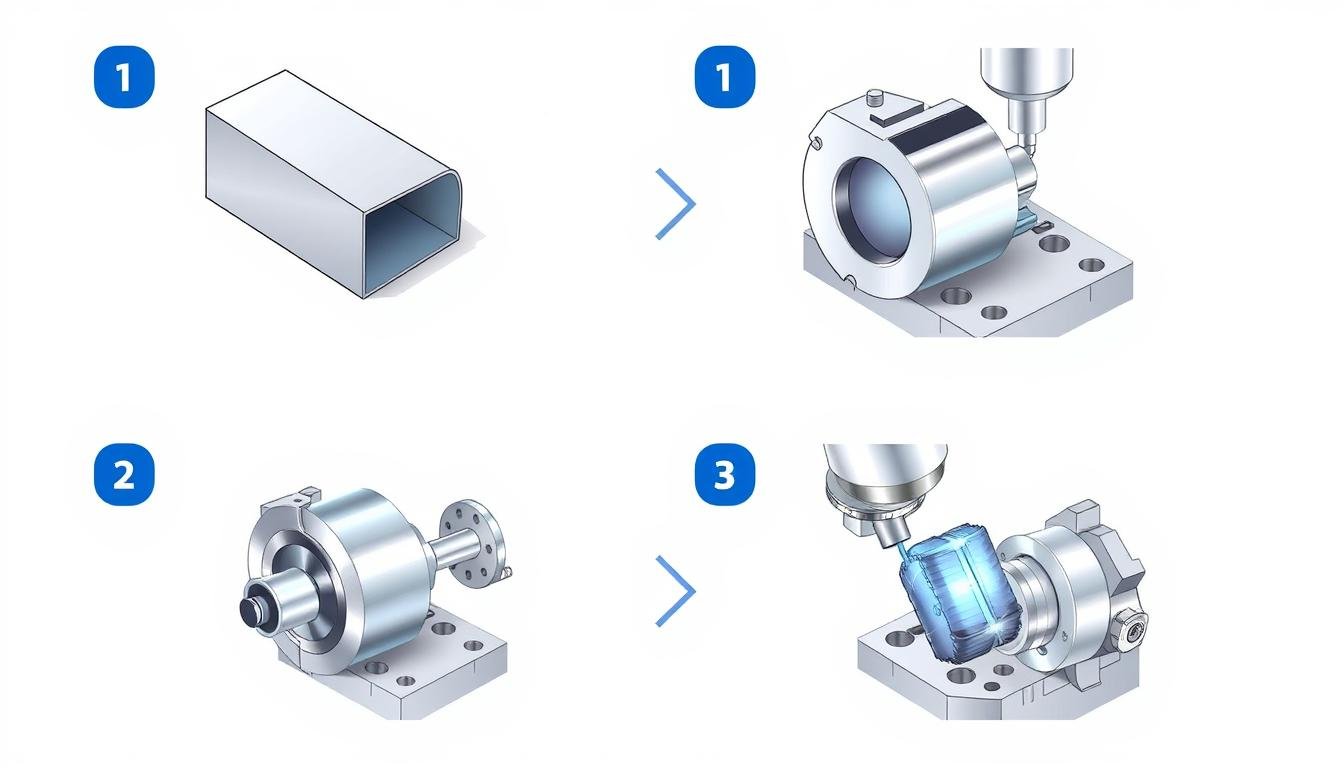

Complete billet machining workflow at MAIKONG production facility

Understanding the billet machining process helps procurement teams better evaluate manufacturing capabilities and quality standards:

- Material Selection: The process begins with choosing the appropriate metal billet (aluminum, steel, brass, etc.) based on application requirements.

- CAD/CAM Programming: Engineers create detailed digital models and toolpaths for CNC machines to follow.

- Initial Setup: The billet is secured in the CNC machine with precise fixturing to ensure accuracy.

- Rough Machining: Larger cutting tools remove excess material to create the basic shape.

- Precision Machining: Smaller tools create detailed features and achieve tight tolerances.

- Quality Inspection: Parts are measured against specifications using precision instruments.

- Surface Finishing: Additional processes like polishing or anodizing may be applied.

Need Expert Guidance on Your Next Project?

Our engineering team can help determine if billet machining is right for your application.

Get A Quick Quote

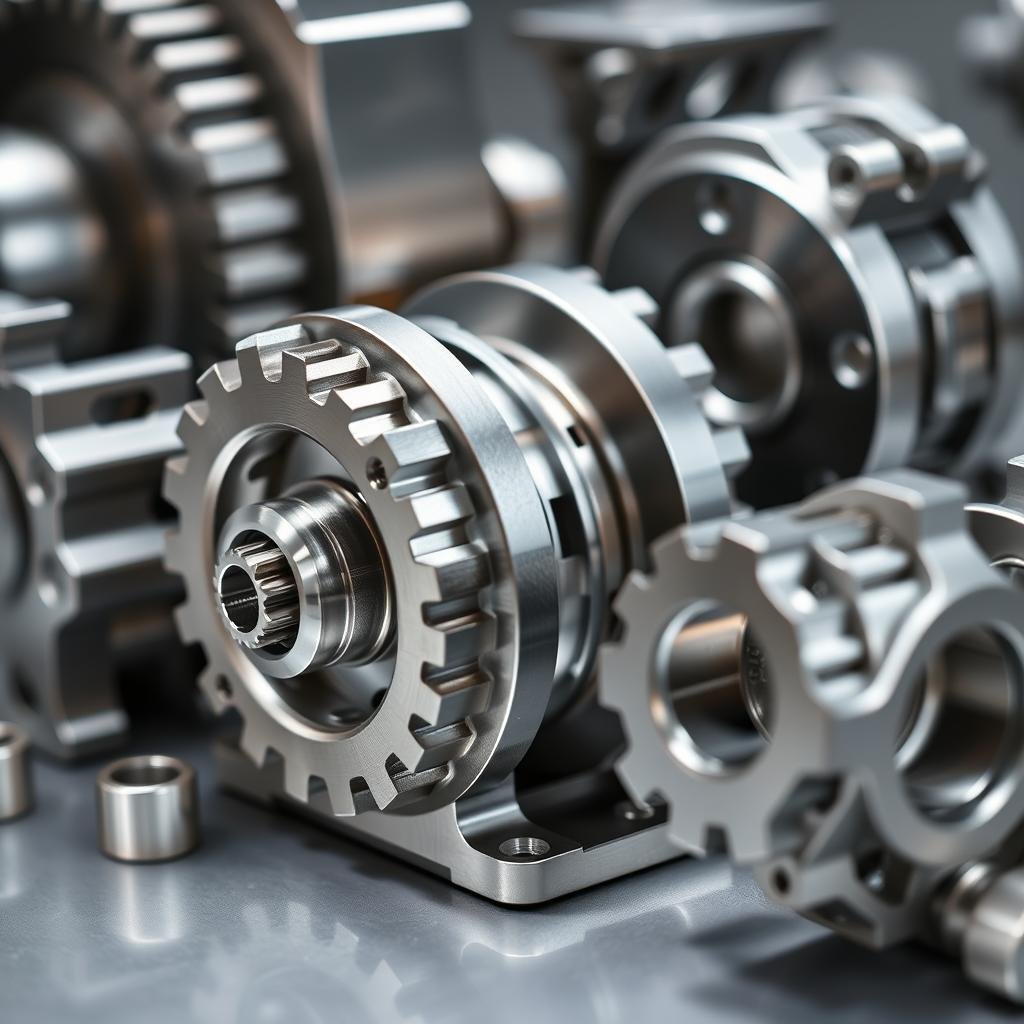

Advantages of Billet Machining for Critical Components

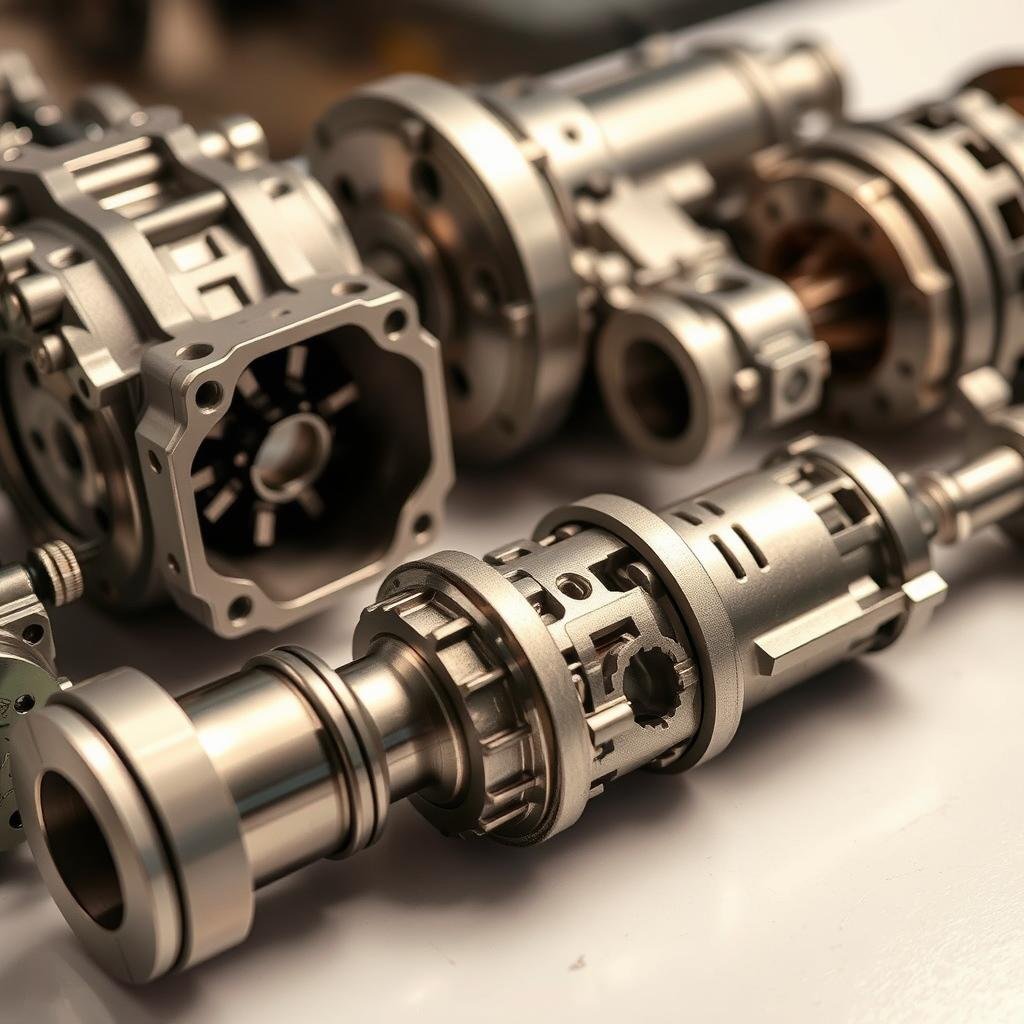

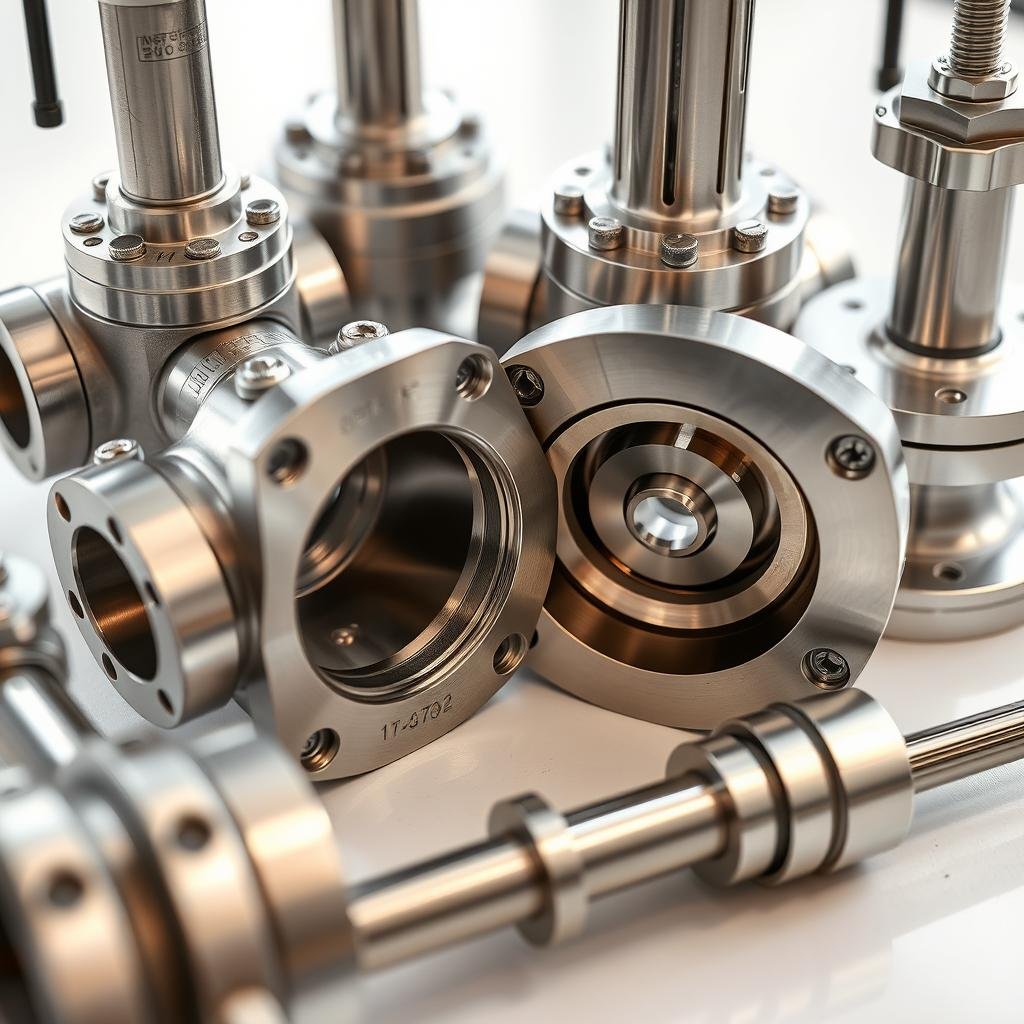

High-precision billet machined parts manufactured by MAIKONG

Advantages of Billet Parts

- Superior dimensional accuracy and tight tolerances

- Excellent surface finish directly from machining

- Consistent material properties throughout the part

- No tooling costs for low-volume production

- Flexibility for design modifications between production runs

- Higher strength than cast parts due to uniform grain structure

- Ideal for prototyping and testing before mass production

Limitations to Consider

- Higher material waste compared to other methods

- Potentially higher per-unit cost for large production runs

- Limited by machine work envelope for very large parts

- May require multiple setups for complex geometries

- Typically heavier than optimized forged components

- Less economical for simple geometries at high volumes

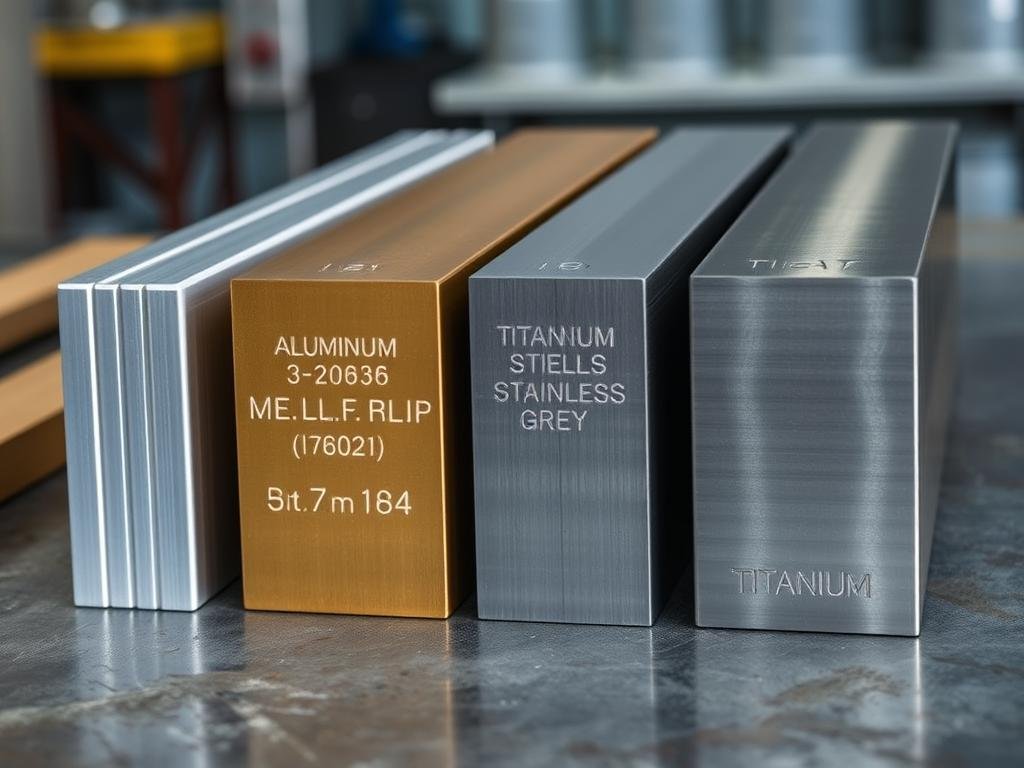

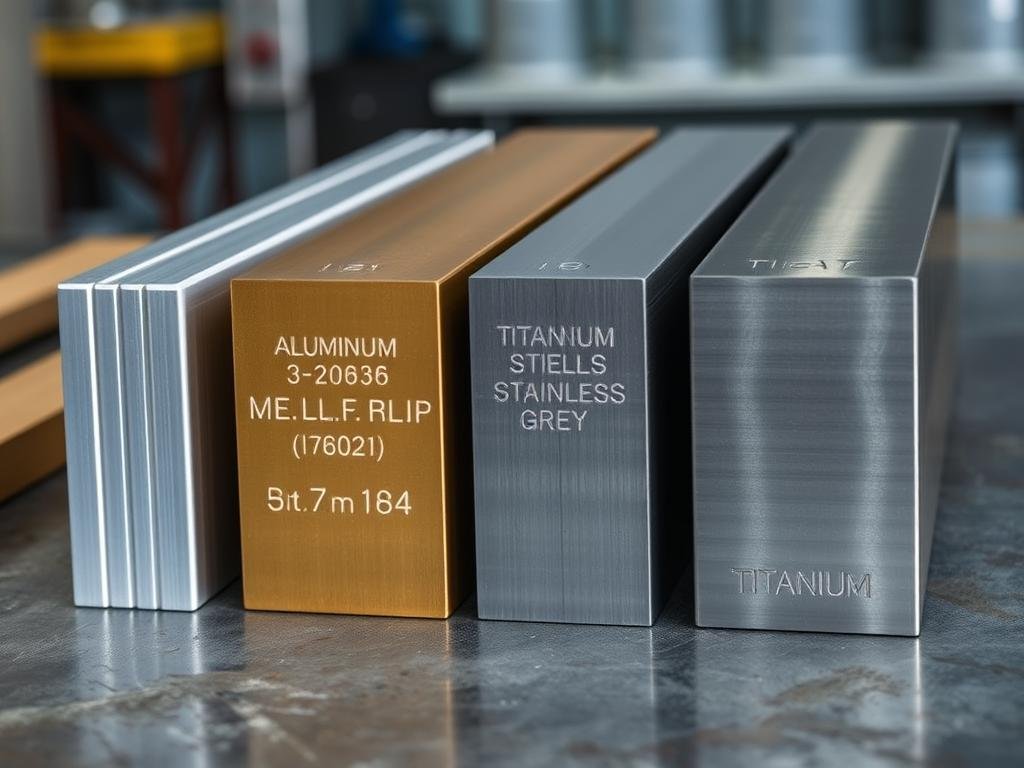

Materials Commonly Used in Billet Machining

Selection of premium metal billets used in MAIKONG’s manufacturing processes

Aluminum Alloys

Lightweight with excellent machinability, aluminum billets are ideal for aerospace, automotive, and consumer products. Common grades include 6061, 7075, and 2024.

Steel Varieties

From mild steel to tool steel and stainless varieties, steel billets offer strength and durability for industrial applications, tooling, and structural components.

Specialty Metals

Brass, copper, titanium, and exotic alloys can all be billet machined for specialized applications requiring unique properties like conductivity or corrosion resistance.

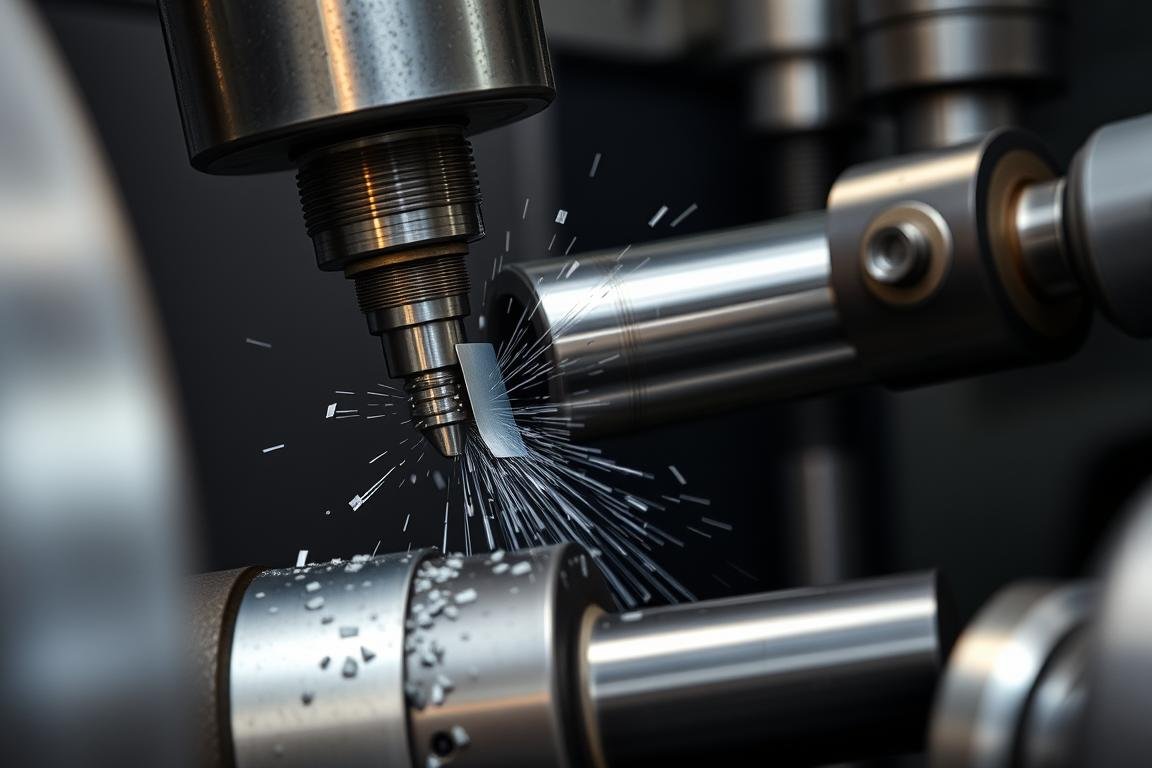

MAIKONG’s Advanced Billet Machining Capabilities

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

At MAIKONG, we’ve established ourselves as industry leaders in precision billet machining and metal forging. Our comprehensive capabilities ensure we can meet the most demanding specifications for clients across diverse industries.

Our CNC Machining Services

With over 60 advanced CNC machines and 100+ tons of monthly metal processing capacity, MAIKONG delivers exceptional precision for both plastic and metal components at any volume. Our specialized services include:

CNC Turning Services

Our CNC turning capabilities excel at creating deep holes, machined threads, and cylindrical shapes with superior surface finishes. When precision and fast turnaround are essential, our turning solutions deliver outstanding results.

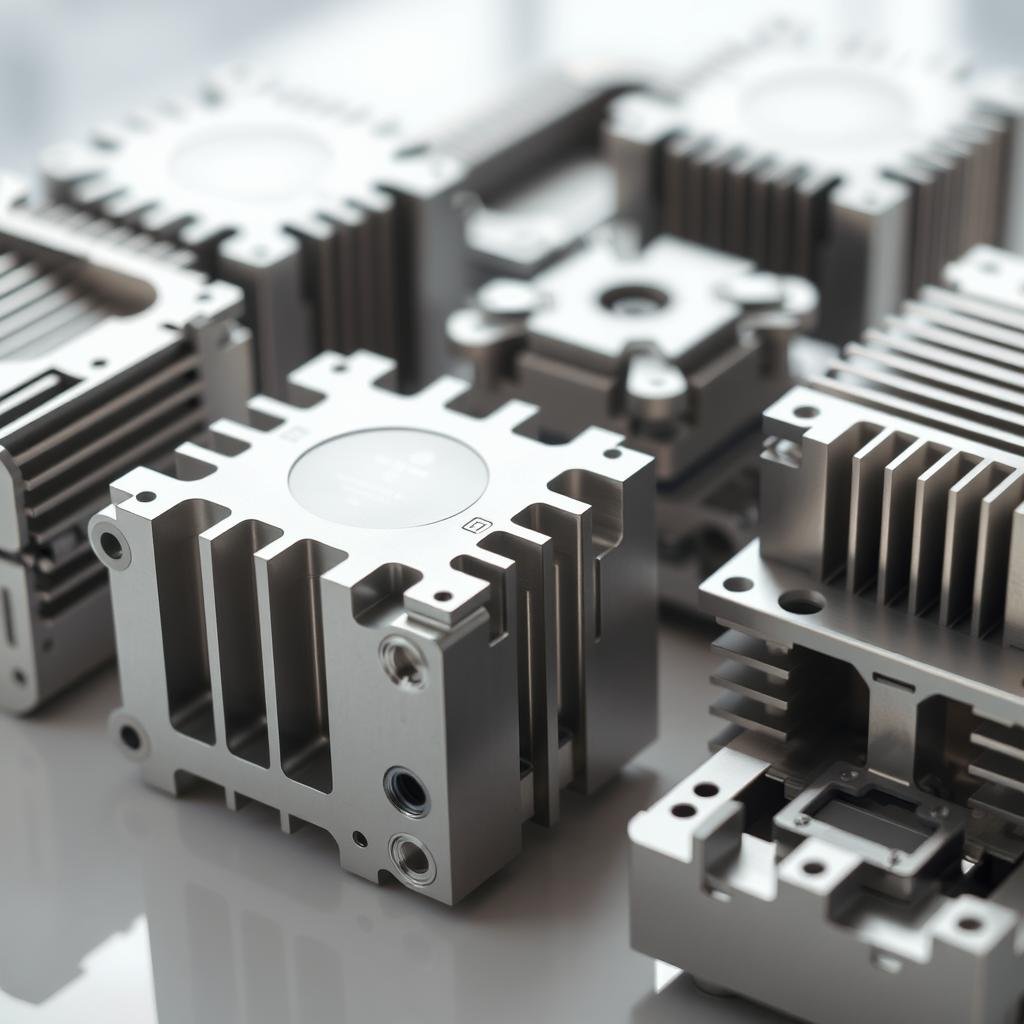

CNC Milling Services

Our multi-axis CNC milling equipment creates complex prismatic shapes and flat surfaces for countless commercial and industrial applications. With no fixed tooling requirements, these systems offer exceptional flexibility and accuracy.

Swiss-Type Machining

Our Swiss-type machining specializes in precision small parts and long shaft components. Featuring dual spindles and multi-axis capabilities, this technology provides complete one-stop solutions with unmatched accuracy.

Ready to Discuss Your Specific Requirements?

Contact our engineering team for expert consultation on your next project.

Comparing Billet Machining vs. Forging: Making the Right Choice

Direct comparison: Billet machined component (left) vs. forged component (right)

As both a manufacturer of billet machined parts and a specialist in metal forging, MAIKONG offers unique insights into choosing the optimal manufacturing method for your application:

| Characteristic |

Billet Machined Parts |

Forged Parts |

Best For |

| Grain Structure |

Non-directional (uniform) |

Directional (follows part contours) |

Forging for high-stress applications |

| Strength |

Good and consistent |

Superior, especially under load |

Forging for structural components |

| Precision |

Excellent (±0.001″ typical) |

Requires secondary machining |

Billet for tight tolerances |

| Production Volume |

Ideal for low to medium |

Economical at higher volumes |

Application-dependent |

| Material Utilization |

Higher waste (30-80%) |

More efficient (10-30% waste) |

Forging for material efficiency |

| Design Flexibility |

Excellent for complex geometries |

Limited by die design |

Billet for complex designs |

| Lead Time |

Faster for prototypes/small runs |

Longer initial setup, faster at scale |

Billet for rapid prototyping |

Quality Assurance in Billet Machining

MAIKONG’s rigorous quality inspection process for machined components

At MAIKONG, quality is built into every step of our manufacturing process. Our comprehensive quality assurance protocols include:

- Material Verification: Testing to confirm chemical composition and mechanical properties

- In-Process Inspection: Regular checks during machining to prevent defects

- Dimensional Verification: Precision measurement using CMM and other advanced tools

- Surface Finish Analysis: Ensuring components meet appearance and function requirements

- Functional Testing: Validating performance under simulated operating conditions

- Documentation: Comprehensive quality reports and material certifications

Our facility maintains ISO 9001:2015 certification, ensuring consistent quality management across all manufacturing processes.

Industries Benefiting from Precision Billet Machining

MAIKONG’s billet machined components serve diverse industries worldwide

Aerospace & Defense

Lightweight, high-strength components with exceptional reliability for critical applications where failure is not an option.

Automotive & Transportation

Performance-critical components for engines, transmissions, and structural applications where precision and durability are essential.

Medical & Healthcare

Ultra-precise instruments and implantable devices manufactured to exacting standards with biocompatible materials.

Electronics & Communications

Housings, heat sinks, and structural components requiring precise tolerances and excellent thermal management properties.

Industrial Equipment

Durable, precision-engineered components for manufacturing equipment, robotics, and heavy machinery applications.

Energy & Oil/Gas

High-performance components designed to withstand extreme pressures, temperatures, and corrosive environments.

Partner with MAIKONG for Your Billet Machining Needs

MAIKONG’s engineering team provides expert consultation on manufacturing solutions

As both producers and consumers of precision components, we understand the critical importance of consistency, strength, and dimensional accuracy in every machined part. Our dedicated focus on crafting superior components enables us to fulfill your requirements for precision machining, heat treating, and comprehensive testing.

Become a US Distributor for MAIKONG

We’re actively seeking distribution partners across the United States to represent our high-quality machined and forged components. As a MAIKONG distributor, you’ll benefit from:

- Competitive pricing that maximizes your margins

- Consistent, ISO-certified quality management

- Comprehensive technical support from our engineering team

- Diverse manufacturing capabilities to serve multiple industries

- Reliable lead times and delivery schedules

Ready to Discuss Distribution Opportunities?

Contact our partnership team today to explore how we can work together.

Become a US Distributor

Or contact us directly:

Conclusion: Making Informed Billet Machining Decisions

Understanding the terminology, processes, and considerations of billet machining empowers procurement teams to make better sourcing decisions. Whether you’re looking for prototype development, low-volume production, or components with exceptional precision, MAIKONG offers the expertise, capabilities, and quality assurance to meet your needs.

Our comprehensive manufacturing services span billet machining, metal forging, and precision finishing, providing end-to-end solutions for the most demanding applications. Contact us today to discuss your specific requirements and discover why leading companies trust MAIKONG for their critical component manufacturing.

Precision CNC machining process at MAIKONG manufacturing facility

Precision CNC machining process at MAIKONG manufacturing facility