Cold forged type-ii anodized machined aluminum combines three powerful manufacturing processes to create components with exceptional strength, durability, and aesthetic appeal. This comprehensive guide explores how MAIKONG’s precision manufacturing techniques deliver superior aluminum components that outperform conventional manufacturing methods across various industries. Whether you’re seeking components for aerospace, automotive, or precision equipment applications, understanding the benefits of this specialized manufacturing approach can significantly enhance your product’s performance.

What Is Cold Forged Type-II Anodized Machined Aluminum?

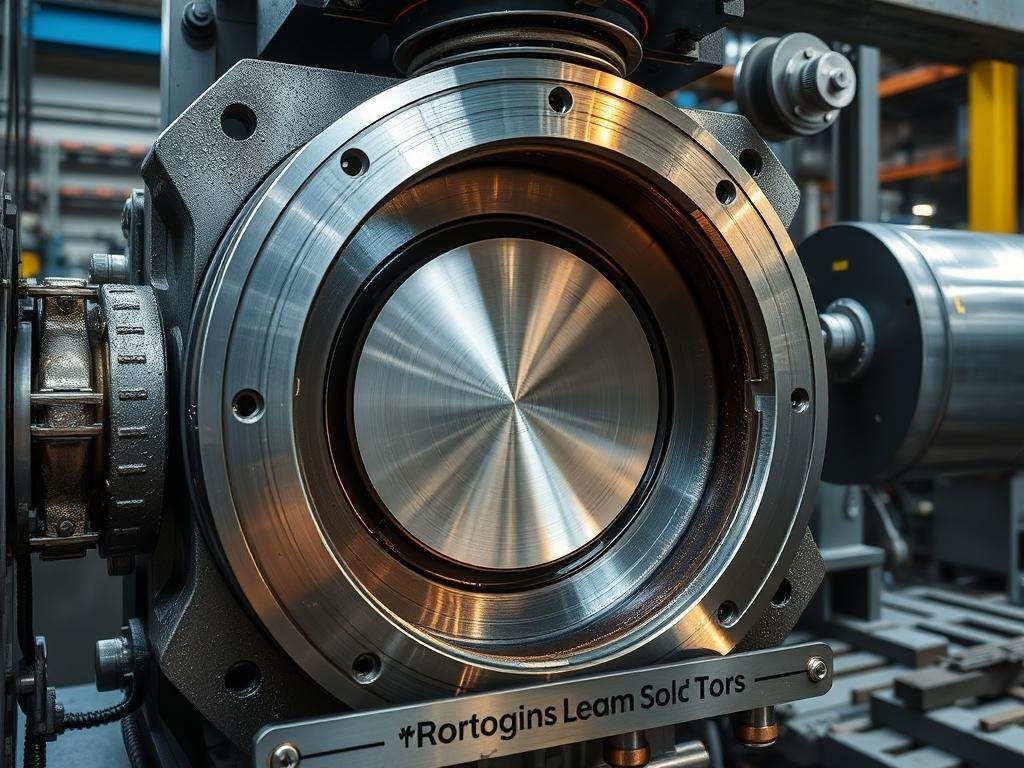

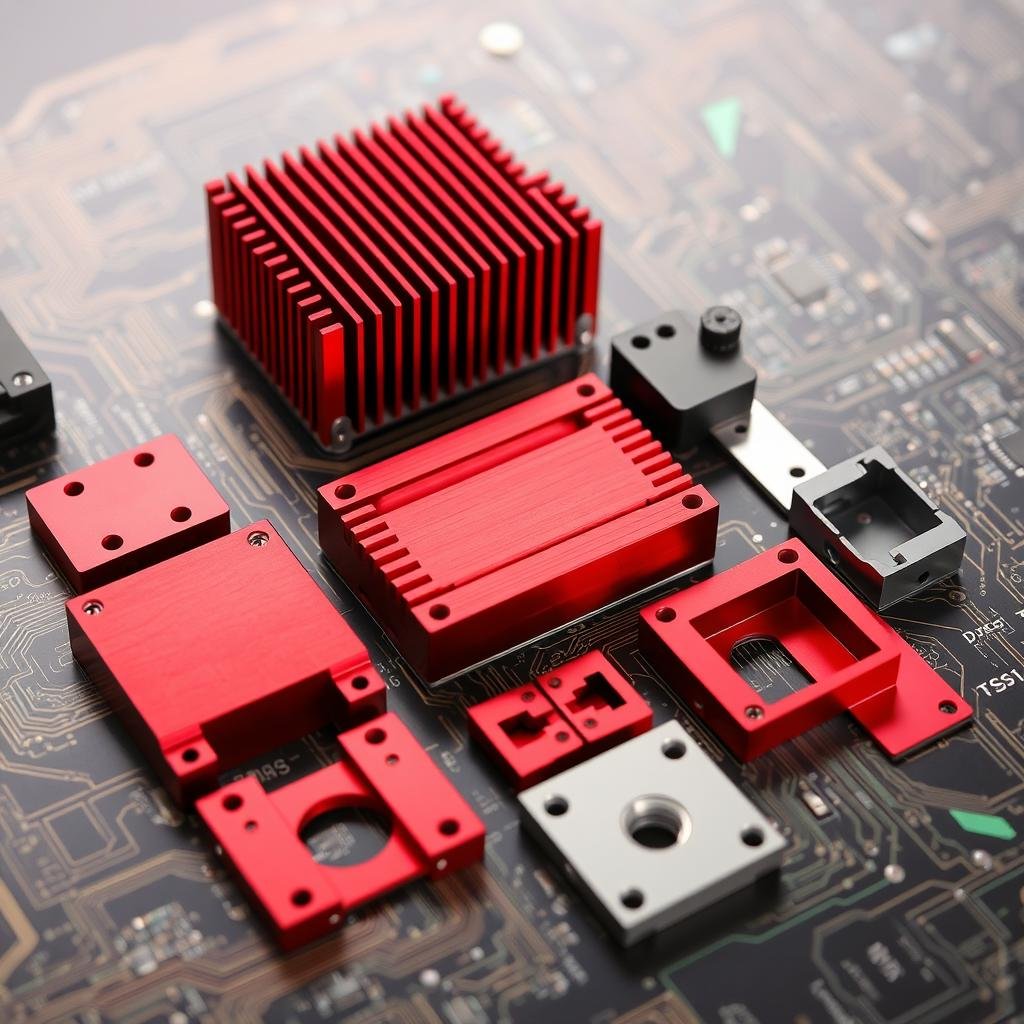

MAIKONG’s precision cold forged type-ii anodized machined aluminum components

Cold forged type-ii anodized machined aluminum represents a sophisticated manufacturing approach that combines three distinct processes to create superior metal components. The process begins with cold forging, which shapes aluminum without heating it to its recrystallization temperature. This is followed by precision CNC machining to achieve exact specifications, and finally, Type-II anodizing to create a protective oxide layer that enhances both durability and appearance.

At MAIKONG, we’ve perfected this integrated manufacturing approach to deliver components with exceptional strength-to-weight ratios, precise tolerances, and superior corrosion resistance. Our cold forged type-ii anodized machined aluminum parts offer significant advantages over components manufactured using conventional methods like casting or hot forging.

Need Custom Aluminum Components?

Contact our engineering team to discuss your specific requirements for cold forged type-ii anodized machined aluminum parts.

Get A Quick Quote

The Cold Forging Process: Foundation for Superior Components

Cold forging is the critical first step in creating our cold forged type-ii anodized machined aluminum components. Unlike hot forging, cold forging shapes aluminum at room temperature, below its recrystallization point. This process offers several distinct advantages:

Benefits of Cold Forging Aluminum

- Enhanced grain structure alignment for superior strength

- Improved mechanical properties compared to cast aluminum

- Better dimensional accuracy and surface finish

- Higher fatigue resistance and durability

- Reduced material waste compared to machining from solid stock

MAIKONG’s cold forging facility in GD, SZ utilizes advanced hydraulic presses capable of exerting precise pressure to form aluminum components with consistent quality. Our engineering team carefully designs each forging process to optimize material flow and structural integrity, ensuring that every component meets the highest performance standards.

Aluminum Forging vs. Casting: Why Cold Forged Components Excel

When comparing manufacturing methods for aluminum components, the differences between forging and casting are significant. Cold forged type-ii anodized machined aluminum components offer substantial advantages over cast alternatives:

| Comparison Categories |

Cold Forged Aluminum |

Cast Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Lower due to potential air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

High strength-to-weight ratio |

Bulkier parts may be needed for equivalent strength |

MAIKONG’s cold forged type-ii anodized machined aluminum components leverage these inherent advantages to deliver superior performance in demanding applications. Our integrated manufacturing approach ensures that these benefits are fully realized in the final product.

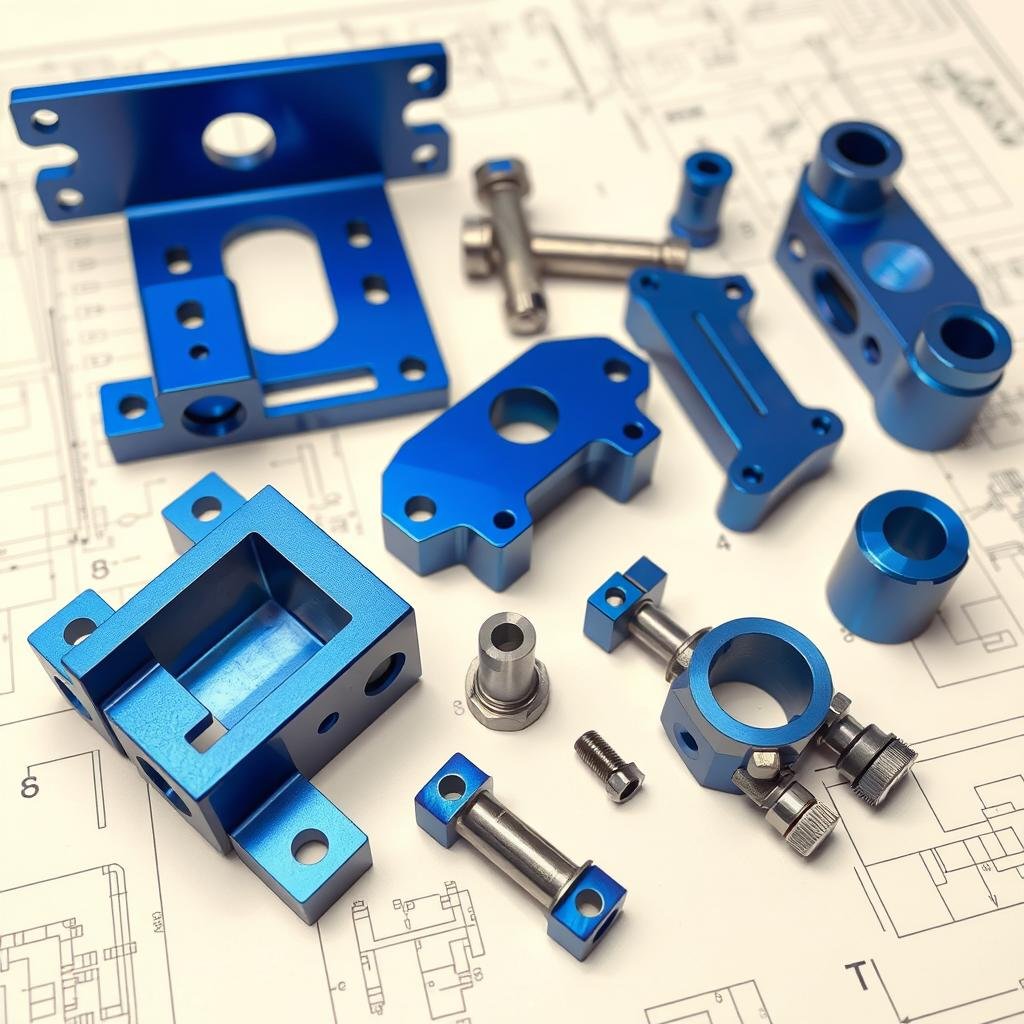

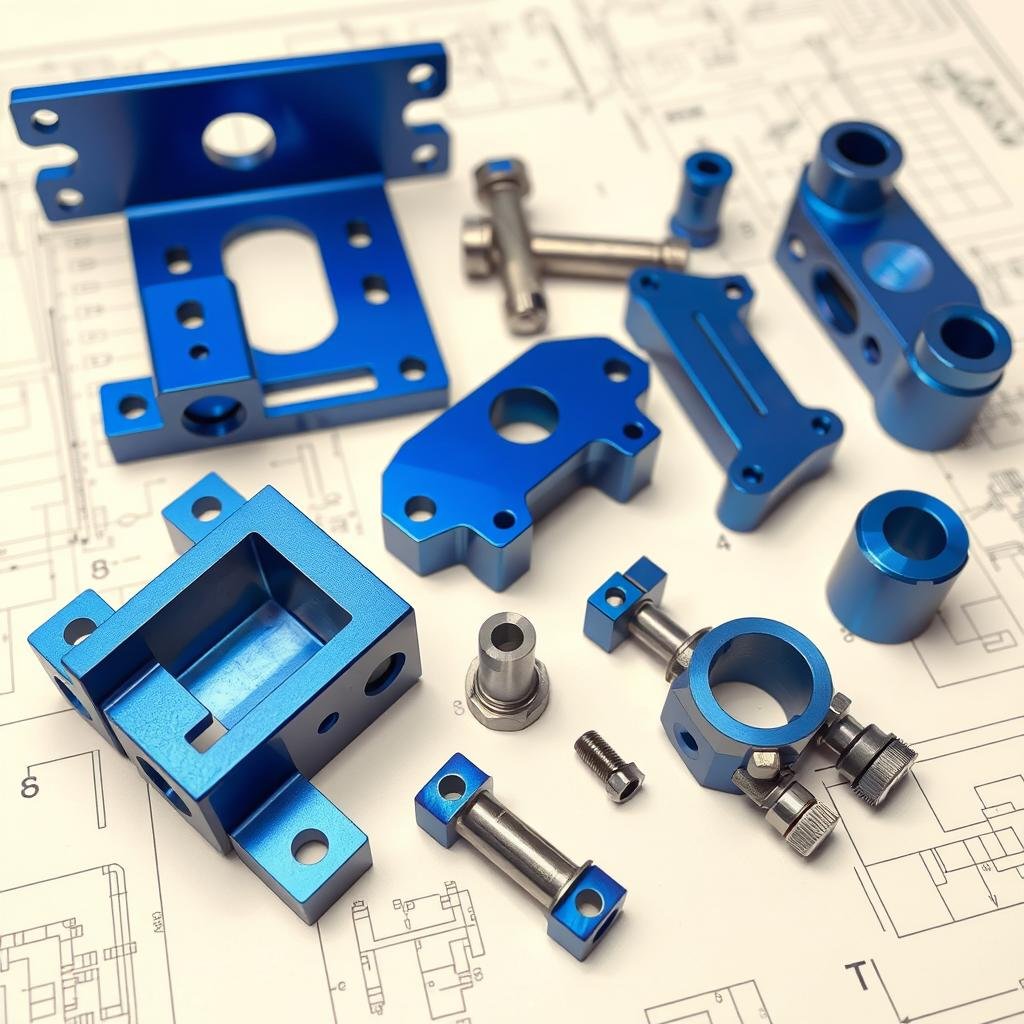

Precision CNC Machining: Achieving Exact Specifications

MAIKONG’s advanced CNC machining operations for cold forged aluminum components

After cold forging, our cold forged type-ii anodized machined aluminum components undergo precision CNC machining to achieve exact dimensional specifications and surface finishes. MAIKONG’s state-of-the-art machining facility includes:

CNC Milling Services

Our multi-axis CNC milling capabilities create complex prismatic shapes and flat surfaces with exceptional precision. These machines require no fixed tooling, offer high flexibility, and deliver extreme accuracy for your aluminum components.

CNC Turning Services

CNC turning is ideal for creating deep holes, machined threads, and cylindrical shapes with superior surface finishes. Our turning operations ensure precisely manufactured parts with fast turnaround times.

CNC SWISS Type Machining

For precision small parts and long shaft components, our CNC Swiss-type machining specializes in creating intricate features. Our equipment features dual spindles and multi-axis capabilities for one-stop manufacturing solutions.

With over 60 CNC machines and monthly metal processing capacity exceeding 100 tons, MAIKONG delivers both precision and volume for your cold forged type-ii anodized machined aluminum component needs.

Ready to Start Your Project?

Contact us today to discuss your specific machining requirements and receive a competitive quote.

Request Machining Quote

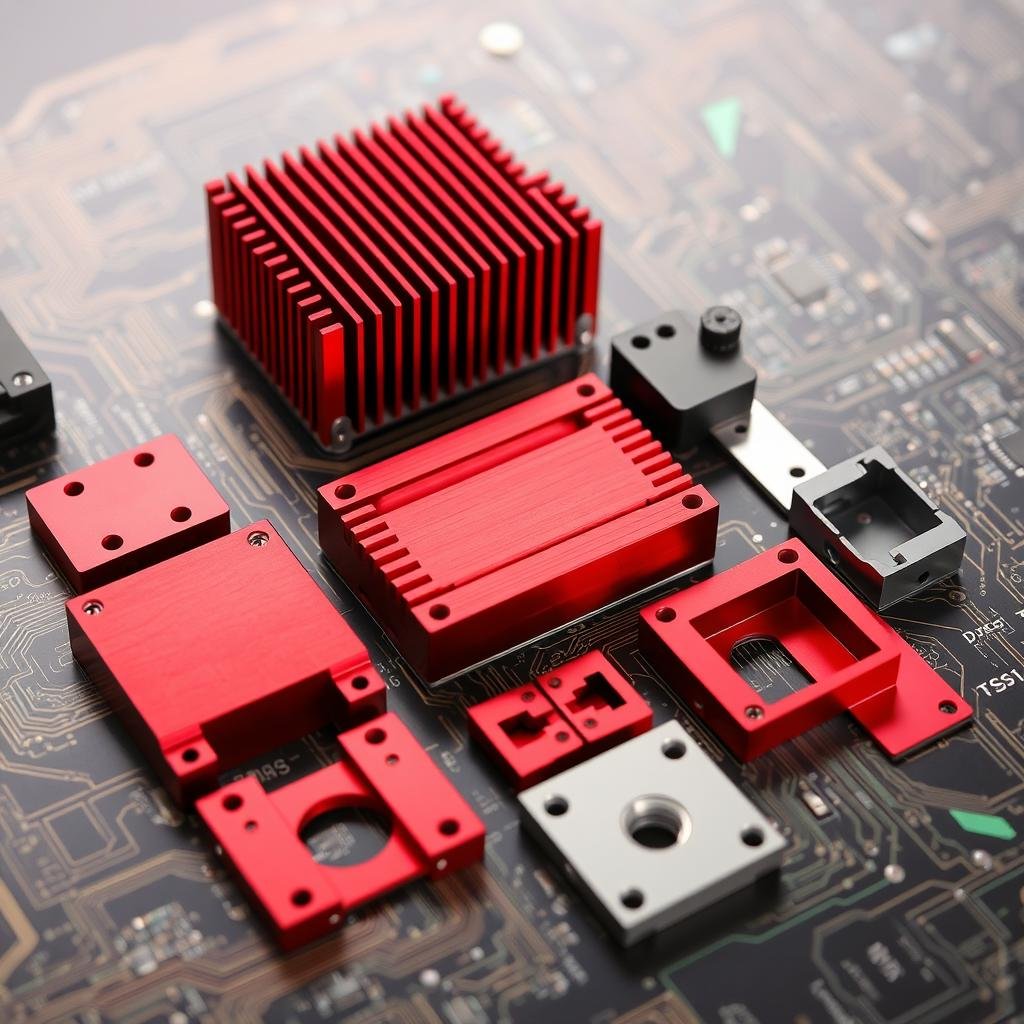

Type-II Anodizing: Enhanced Protection and Aesthetics

The final stage in creating cold forged type-ii anodized machined aluminum components is Type-II anodizing. This electrochemical process forms a protective oxide layer on the aluminum surface, enhancing both durability and appearance.

How Type-II Anodizing Works

Type-II anodizing, also known as sulfuric acid anodizing, creates a controlled form of corrosion that protects the underlying aluminum. The process involves:

- Cleaning and degreasing the machined aluminum components

- Immersing parts in a sulfuric acid electrolyte bath

- Applying electrical current to create an aluminum oxide layer

- Optional dyeing for aesthetic customization

- Sealing the porous oxide layer to enhance protection

The resulting anodic coating typically ranges from 0.0001″ to 0.0005″ (2.5-13 μm) in thickness, providing excellent protection while maintaining dimensional precision.

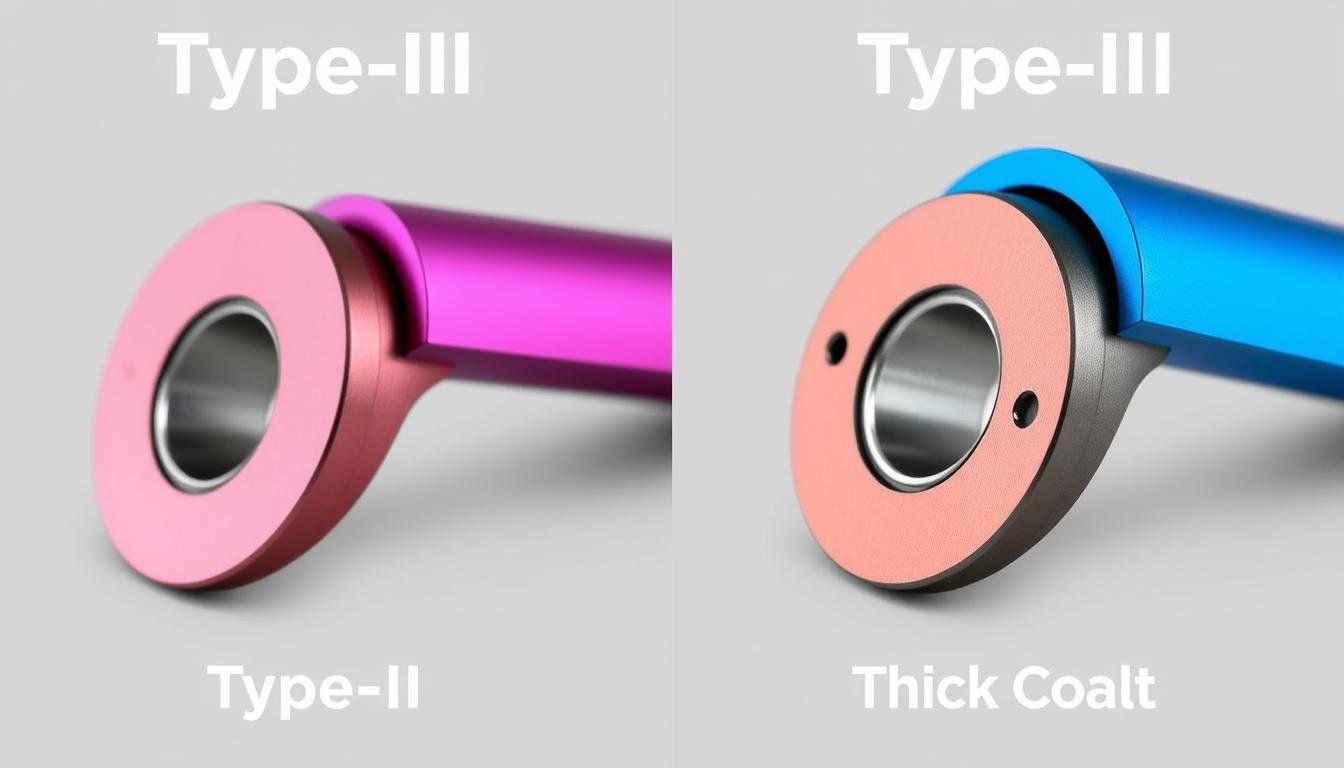

MAIKONG’s Type-II anodized components in various color options

Benefits of Type-II Anodizing for Cold Forged Machined Aluminum

Advantages of Type-II Anodizing

- Excellent corrosion resistance

- Good wear and abrasion protection

- Enhanced aesthetic appeal with various color options

- Electrical insulation properties

- Cost-effective surface treatment

- Environmentally friendly process

Limitations to Consider

- Less wear resistance than Type-III (hard coat) anodizing

- Thinner coating compared to Type-III anodizing

- May require additional sealing for maximum protection

- Not suitable for extreme wear applications

MAIKONG’s cold forged type-ii anodized machined aluminum components benefit from our precisely controlled anodizing process, ensuring consistent quality and appearance across production runs.

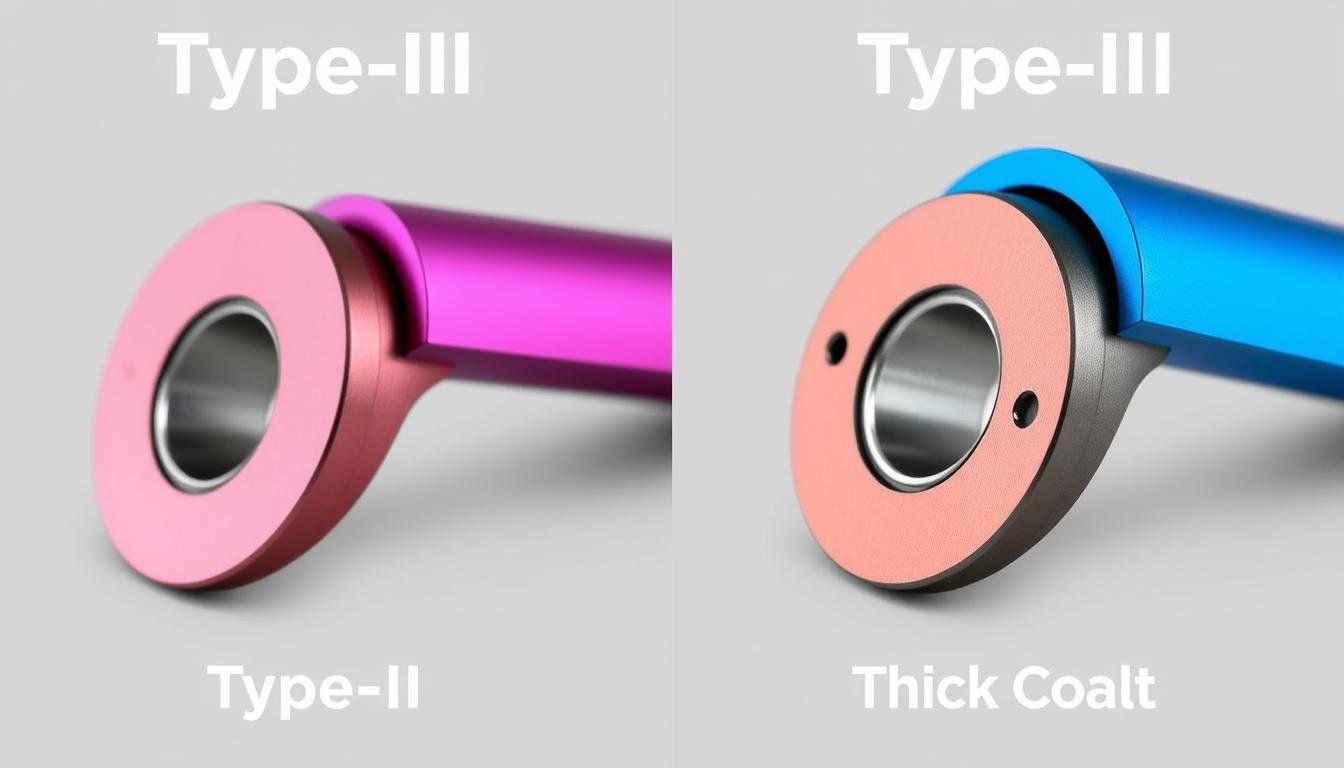

Type-II vs. Type-III Anodizing: Choosing the Right Finish

When considering surface treatments for cold forged type-ii anodized machined aluminum components, it’s important to understand the differences between Type-II and Type-III anodizing to select the most appropriate finish for your application:

| Characteristics |

Type-II Anodizing |

Type-III Anodizing (Hard Coat) |

| Protective Layer Thickness |

0.00007-0.001 in. (1.8-25 μm) |

0.0005-0.006 in. (13-150 μm) |

| Corrosion and Wear Resistance |

Good |

Very good |

| Aesthetics |

Excellent – Dyeing possible for various colors |

Limited – Generally best for non-visible parts |

| Cost |

More economical |

Higher cost |

| Common Applications |

Consumer products, architectural, decorative |

Industrial, military, high-wear applications |

While MAIKONG specializes in cold forged type-ii anodized machined aluminum components, we also offer Type-III anodizing for applications requiring enhanced wear resistance. Our engineering team can help you determine the most appropriate anodizing specification based on your component’s functional requirements and operating environment.

Visual comparison of Type-II (left) and Type-III (right) anodized components

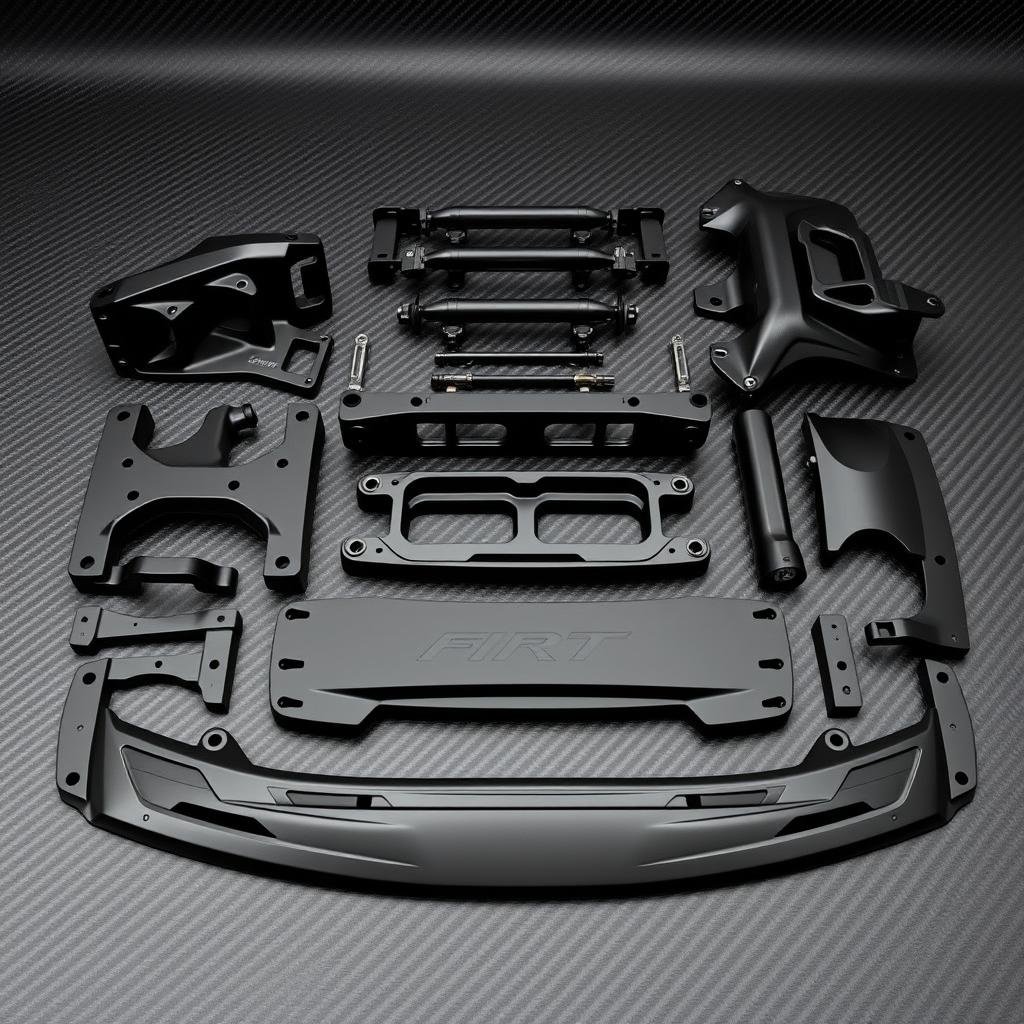

Applications for Cold Forged Type-II Anodized Machined Aluminum

Cold forged type-ii anodized machined aluminum components excel in applications requiring an optimal balance of strength, weight, corrosion resistance, and aesthetic appeal. MAIKONG supplies these specialized components to various industries:

Aerospace

Aerospace

Automotive

Automotive

Medical Devices

Medical Devices

Electronics

Electronics

Sporting Goods

Sporting Goods

Defense

Defense

The versatility of cold forged type-ii anodized machined aluminum makes it suitable for both structural and aesthetic applications. MAIKONG’s engineering team works closely with clients to optimize component design for specific industry requirements.

Explore Industry-Specific Solutions

Contact our specialists to discuss how our cold forged type-ii anodized machined aluminum components can meet your industry’s unique requirements.

Email Our Specialists

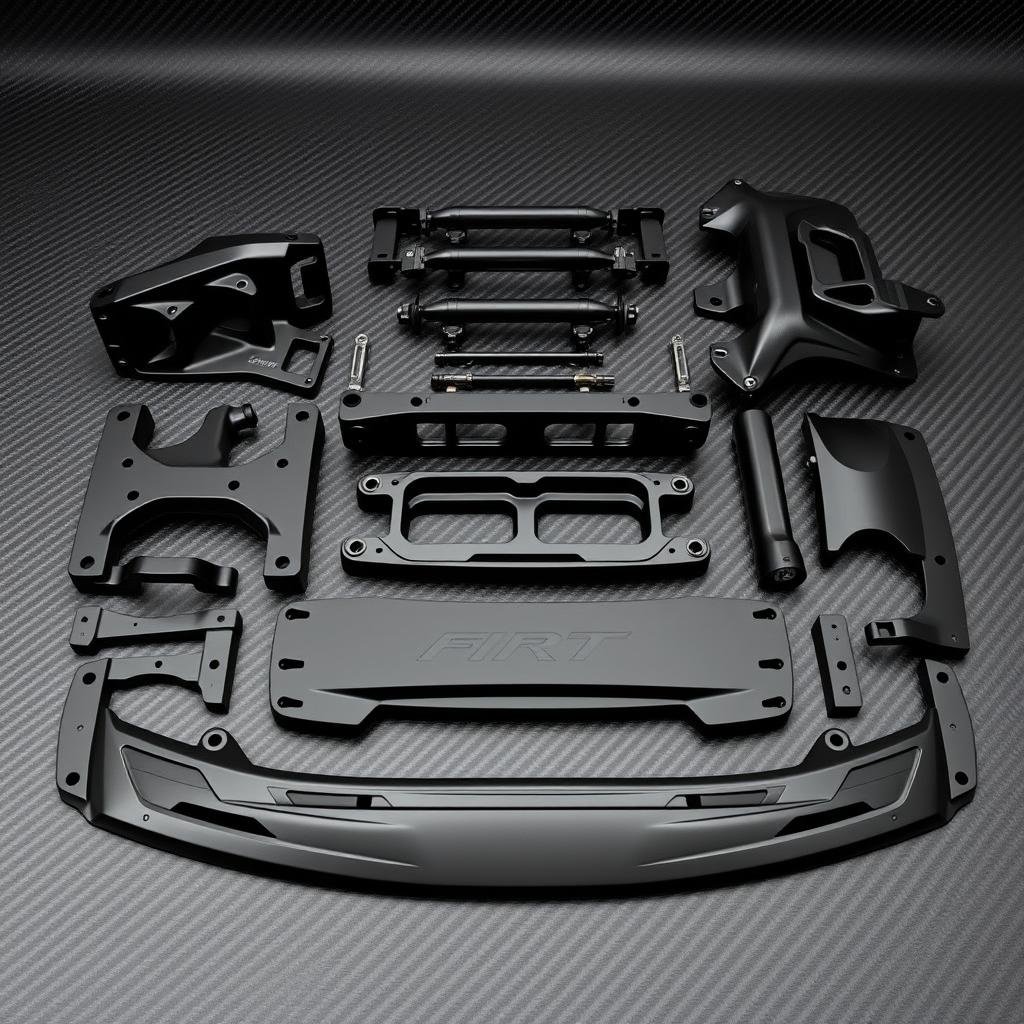

MAIKONG’s Integrated Manufacturing Process

At MAIKONG, we’ve developed a comprehensive manufacturing process for cold forged type-ii anodized machined aluminum components that ensures consistent quality and performance:

MAIKONG’s end-to-end manufacturing process

Design & Engineering

- CAD/CAM design optimization

- Material selection consulting

- Finite element analysis

- Design for manufacturability

Production

- Cold forging with precision dies

- Multi-axis CNC machining

- Heat treatment optimization

- Type-II anodizing process

Quality Assurance

- Dimensional inspection

- Material testing

- Surface finish verification

- Performance validation

Our integrated approach ensures that each cold forged type-ii anodized machined aluminum component meets exact specifications while minimizing lead times and production costs. MAIKONG’s manufacturing facility in GD, SZ combines advanced technology with skilled craftsmanship to deliver superior aluminum components.

Quality Control for Cold Forged Type-II Anodized Machined Aluminum

MAIKONG maintains rigorous quality control procedures throughout the manufacturing process for cold forged type-ii anodized machined aluminum components. Our comprehensive approach includes:

- Material Verification: Testing of aluminum alloy composition and properties

- Forging Process Monitoring: Continuous monitoring of forging parameters

- Dimensional Inspection: Precision measurement of machined features

- Surface Quality Assessment: Evaluation of anodized layer thickness and quality

- Performance Testing: Validation of mechanical properties

- Documentation: Comprehensive quality records for traceability

Our quality management system is certified to ISO 9001:2015 standards, ensuring consistent adherence to established quality procedures. Each batch of cold forged type-ii anodized machined aluminum components undergoes thorough inspection before shipment.

MAIKONG’s quality control inspection process

MAIKONG Quality Commitment: We stand behind every cold forged type-ii anodized machined aluminum component we produce. Our quality guarantee ensures that your parts will meet or exceed specified requirements for dimensional accuracy, surface finish, and performance characteristics.

Partner with MAIKONG for Your Aluminum Component Needs

MAIKONG is seeking distributors and partners across the United States for our premium cold forged type-ii anodized machined aluminum components. As a leading manufacturer with extensive capabilities in aluminum forging, CNC machining, and surface treatments, we offer:

Why Choose MAIKONG?

- Comprehensive manufacturing capabilities from design to finished product

- Cost-effective production without compromising quality

- Extensive experience in aluminum forging and precision machining

- Flexible production capacity to accommodate various order volumes

- Consistent quality backed by rigorous quality control procedures

- Responsive customer service and technical support

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

Become a MAIKONG Distributor

Join our network of distributors across the United States. Contact us today to discuss partnership opportunities for our cold forged type-ii anodized machined aluminum components.

Contact Our Partnership Team

Conclusion: The MAIKONG Advantage in Cold Forged Type-II Anodized Machined Aluminum

Cold forged type-ii anodized machined aluminum components represent the pinnacle of aluminum manufacturing technology, combining the structural benefits of cold forging, the precision of CNC machining, and the protective qualities of Type-II anodizing. MAIKONG has mastered this integrated approach to deliver superior components that meet the most demanding requirements.

Whether you need aerospace-grade structural components, precision automotive parts, or aesthetically pleasing consumer product elements, our comprehensive manufacturing capabilities ensure that your cold forged type-ii anodized machined aluminum components will exceed expectations for performance, durability, and appearance.

Contact MAIKONG today to discuss your specific requirements and discover how our expertise in aluminum manufacturing can enhance your products and streamline your supply chain.

Ready to Get Started?

Contact us today to discuss your cold forged type-ii anodized machined aluminum component needs.

Get A Quick Quote

Aerospace

Aerospace Automotive

Automotive Medical Devices

Medical Devices Electronics

Electronics Sporting Goods

Sporting Goods Defense

Defense