The Brief History of Machining reveals a fascinating journey from rudimentary hand tools to sophisticated computer-controlled systems. This evolution has transformed manufacturing capabilities, enabling the precision and efficiency we rely on today. As we explore this technological progression, we’ll discover how ancient innovations laid the groundwork for modern machining techniques that companies like MAIKONG now use to create custom metal components with unprecedented accuracy.

Early Beginnings in the Brief History of Machining

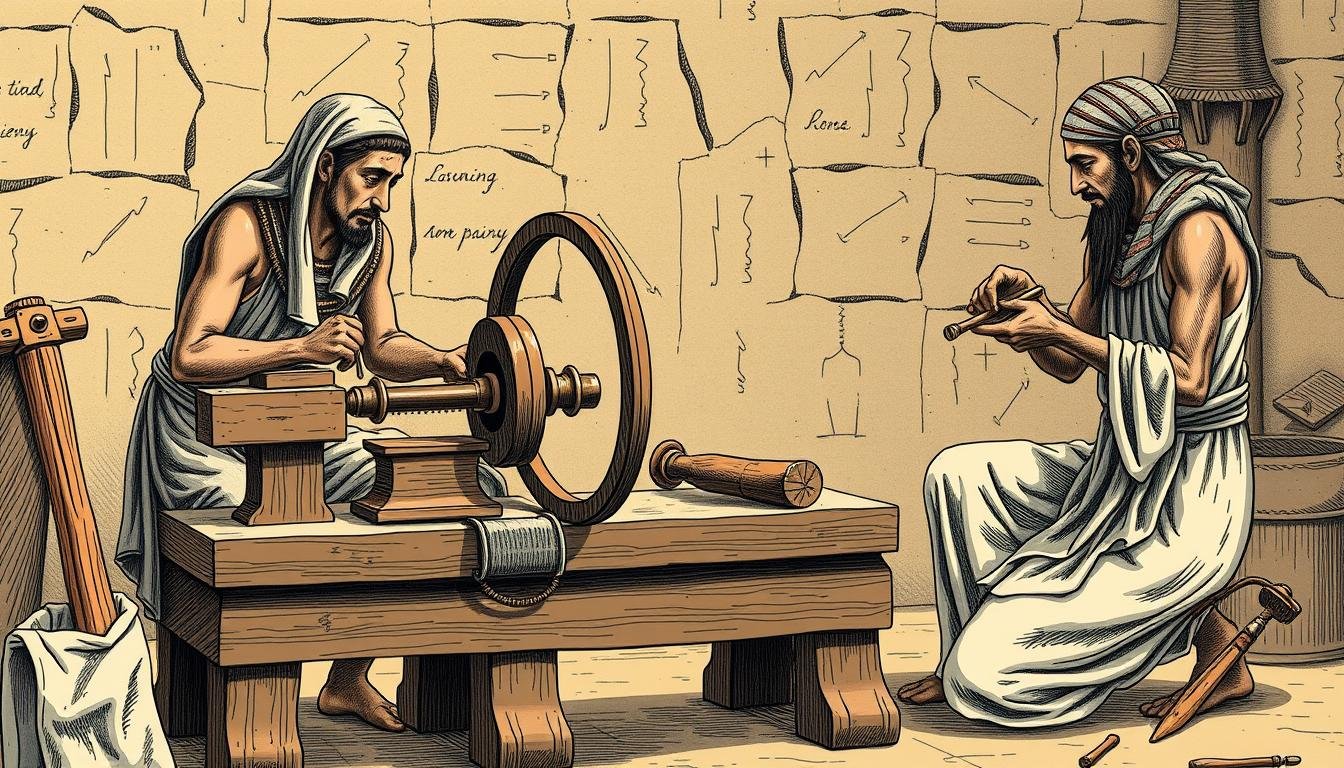

The origins of machining can be traced back to ancient civilizations where early craftsmen developed innovative methods to shape materials. The Egyptians, Greeks, and Romans pioneered fundamental techniques that would evolve over centuries into the advanced machining processes we use today.

Ancient Egyptian bow lathe – one of the earliest machining tools in history

Ancient Tools and Techniques

The earliest machining methods relied on manual dexterity and simple tools. The Egyptian bow lathe, developed around 1300 BCE, represents one of the first significant machining innovations. This primitive lathe required two operators—one to rotate the workpiece using a bow-like device, while the second used hand tools to shape the material.

These early lathes laid the foundation for rotary machining, a concept that remains central to modern turning operations. Ancient craftsmen used these tools to create wooden furniture components, decorative items, and practical implements with remarkable precision considering their technological limitations.

Industrial Revolution: A Turning Point in Machining History

The 18th century Industrial Revolution marked a watershed moment in the Brief History of Machining. This period saw the development of machine tools that would fundamentally transform manufacturing processes and capabilities.

Machine Tools and Mechanization

The invention of the steam engine provided a reliable power source for machine tools, enabling greater force and consistency than human power could achieve. James Nasmyth, a Scottish engineer, developed the first true milling machine around 1829. His design incorporated a rotary cutting tool and a multi-directional table, significantly enhancing precision and versatility.

Eli Whitney’s concept of interchangeable parts revolutionized manufacturing in the late 18th century. By standardizing components and creating machines capable of producing identical parts, Whitney laid the groundwork for mass production. This advancement dramatically impacted industries from firearms to textiles and transportation.

Precision Advancements

The late 19th century saw remarkable progress in precision machining techniques. Grinding machines played a crucial role in this evolution, enabling mass production of consistently high-quality components. These machines facilitated the transition from manual craftsmanship to mechanized production, increasing productivity while reducing costs.

War-Time Innovation

Both World Wars served as powerful catalysts for machining advancements. The urgent demand for military equipment drove innovations in technology, tooling, automation, and materials. These improvements not only supported war efforts but also had lasting impacts on manufacturing practices that continue to influence modern machining.

Modern CNC Machining Evolution

The 1950s witnessed a revolutionary development in the Brief History of Machining with the birth of Computer Numerical Control (CNC) technology. This innovation fundamentally transformed manufacturing capabilities and continues to evolve today.

The CNC Revolution

CNC technology combined the power of computers with precision machining, automating processes that previously required manual control. The first CNC machine prototype was developed in 1952 by researchers at MIT, following the creation of the first Numerical Control (NC) machine in 1949. By 1958, CNC machines were patented, setting the stage for a manufacturing revolution.

The integration of Computer-Aided Design (CAD) systems in the 1970s further accelerated CNC adoption. By 1989, CNC machining had become the standard for large-volume manufacturing, dramatically improving productivity, quality, and dimensional repeatability while reducing production costs.

Advanced Manufacturing Techniques

Today’s machining landscape includes diverse technologies like high-speed machining (HSM), multi-axis CNC systems, and hybrid manufacturing approaches. Modern CNC machines can perform complex operations with minimal human intervention, achieving tolerances and geometries that would be impossible through manual methods.

MAIKONG’s Advanced Manufacturing Capabilities

Building on the rich Brief History of Machining, MAIKONG has developed comprehensive manufacturing capabilities that combine traditional expertise with cutting-edge technology. Our facilities in GD, SZ are equipped to deliver precision components that meet the most demanding specifications.

MAIKONG’s state-of-the-art CNC machining facility in GD, SZ

CNC Machining Excellence

MAIKONG operates over 60 CNC machines with a monthly metal processing capacity exceeding 100 tons. Our comprehensive CNC machining services deliver precision fabrication of plastic and metal parts in any volume. We specialize in turning, milling, Swiss machining, multi-axis machining, surface grinding, and laser engraving, ensuring all materials meet exact specifications through our best-in-class testing and verification laboratory.

CNC Turning Services

Our CNC turning capabilities create deep holes, machined threads, and cylindrical shapes with superior surface finishes. When you need precisely manufactured parts with fast turnaround, MAIKONG’s turning solutions deliver exceptional results.

CNC Milling Services

MAIKONG’s milling services produce complex prismatic shapes and flat surfaces for diverse commercial and industrial applications. Our multi-axis metal CNC machines require no fixed tooling, offering high flexibility and extreme accuracy.

Swiss-Type Machining

Our Swiss-type machining specializes in precision small parts and long shaft components. With dual spindles and multi-axis capabilities, we provide one-stop solutions that ensure the highest accuracy without requiring additional equipment.

Discover Our Precision Machining Solutions

Looking for high-quality, cost-effective machining services? Contact our team to discuss your specific requirements.

Get A Quick Quote

Metal Forging Expertise

Beyond machining, MAIKONG excels in metal forging—a process that complements our machining capabilities to deliver components with exceptional strength and performance characteristics.

Aluminum Forging Advantages

Forging aligns the grain structure of aluminum to maximize impact toughness, fracture resistance, and fatigue strength. This process ensures consistent performance and quality, making forged aluminum ideal for applications where performance and safety are critical.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

Full Service Supply Center

MAIKONG offers comprehensive solutions from design to finished product, ensuring quality at every stage of production. Our integrated approach delivers superior results while maximizing efficiency and cost-effectiveness.

CAD/CAM Design

Our engineering team uses advanced analysis software to identify and mitigate potential issues early in the design process, optimizing both product performance and manufacturability.

Material Selection

We thoroughly evaluate mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness to select the optimal material for each application.

Tooling Design

Our tooling expertise ensures initial quality, while regular maintenance preserves consistency—both critical factors in producing high-quality forgings and machined components.

Heat Treatment

In-house heat treatment with comprehensive statistical analysis and documentation ensures optimal material properties for each component.

Precision CNC Machining

Our state-of-the-art CNC machines perform precise and intricate operations on forged components to achieve final dimensions and features.

Surface Treatment

We offer comprehensive surface finishing options including anodizing, painting, laser engraving, and sand blasting to enhance appearance, performance, and durability.

Quality Assurance and Certification

Quality is the cornerstone of MAIKONG’s operations. Our comprehensive quality management system ensures that every component meets or exceeds customer specifications and industry standards.

Comprehensive Quality Control

Our quality engineering team monitors production processes at all stages, from raw material to finished product. This vigilance ensures consistency and quality across all components. The advantages of our in-house production—from raw materials through forging, heat treatment, CNC milling, and surface treatment—allow continuous quality oversight.

MAIKONG holds ISO 9001:2015 certification, demonstrating our commitment to quality management systems that consistently deliver products meeting customer and regulatory requirements.

Partner With MAIKONG for Superior Manufacturing

Experience the difference that precision machining and forging can make for your products. Contact us today to discuss your requirements or request a quote.

WhatsApp: +86 13-51090-74-01

Email: Lucy@maikongforge.us

Get A Quick Quote

Continuing the Legacy of Machining Excellence

The Brief History of Machining shows a remarkable journey from simple hand tools to sophisticated computer-controlled systems. At MAIKONG, we honor this legacy by combining traditional craftsmanship with cutting-edge technology to deliver exceptional machined and forged components.

Our comprehensive capabilities—spanning CNC machining, metal forging, precision machining, and custom metal fabrication—position us as an ideal partner for US businesses seeking high-quality, cost-effective manufacturing solutions. We invite distributors across the United States to explore partnership opportunities with MAIKONG and experience our commitment to excellence firsthand.

Precision machined components manufactured by MAIKONG

Ancient Egyptian bow lathe – one of the earliest machining tools in history

Ancient Egyptian bow lathe – one of the earliest machining tools in history