The billet machining process represents a cornerstone of modern manufacturing, transforming raw metal stock into precision-engineered components with exacting tolerances. At MAIKONG, we’ve mastered this intricate process through decades of experience, state-of-the-art equipment, and rigorous quality control. Whether you need custom aluminum parts, steel components, or brass fittings, our comprehensive billet machining process delivers superior results for applications across aerospace, automotive, construction, and more industries.

What is the Billet Machining Process?

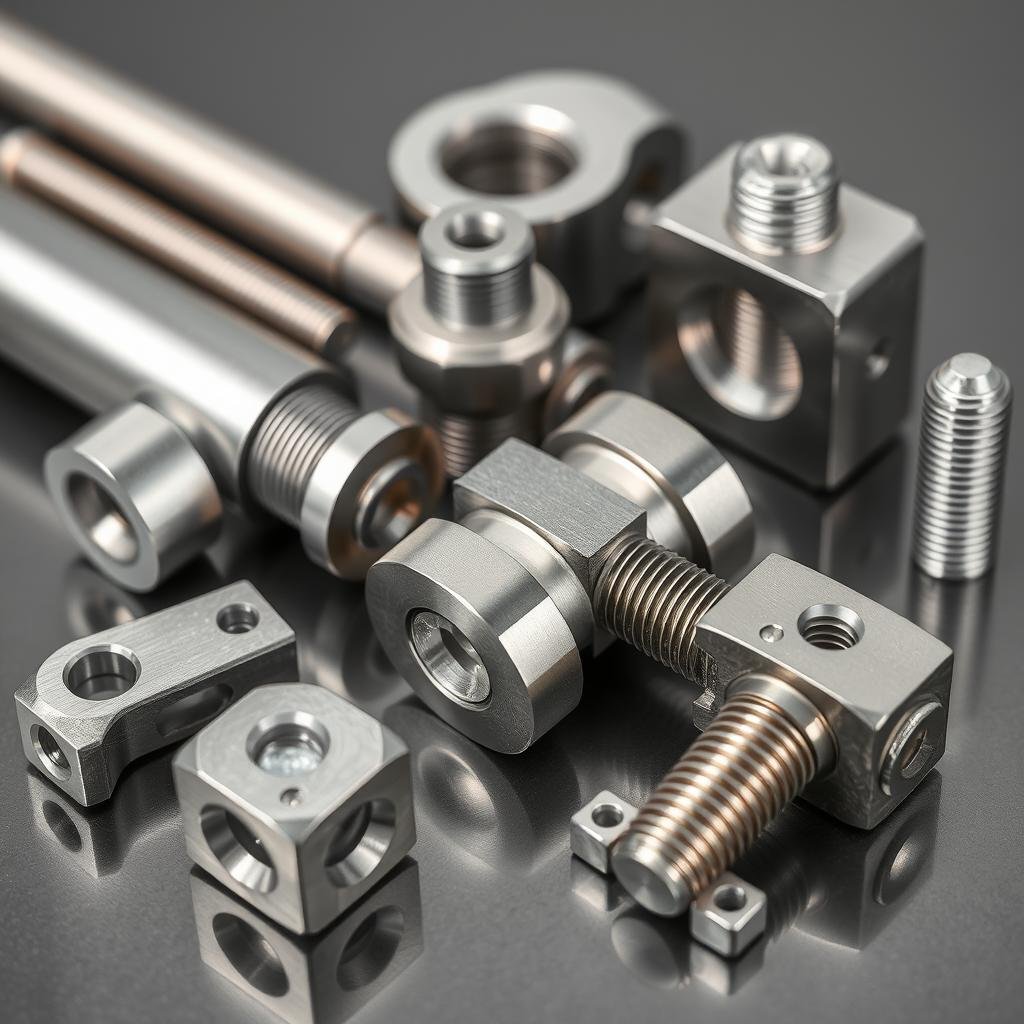

The billet machining process involves transforming solid blocks of metal, known as billets, into finished components through precise cutting, drilling, and shaping operations. Unlike casting or forging, which form parts by pouring molten metal or applying pressure, billet machining is a subtractive process that removes material to create the desired shape with exceptional accuracy.

Key Characteristics of Billet Machining

- Exceptional dimensional accuracy (tolerances as tight as ±0.0005″)

- Superior surface finish quality

- Consistent material properties throughout the component

- Ability to create complex geometries and internal features

- Excellent for both prototyping and production runs

Need Precision Machined Components?

MAIKONG offers comprehensive CNC machining services with 60+ machines and 100+ tons monthly capacity. Our expertise in the billet machining process ensures your parts meet exact specifications.

Get a Quick Quote

The Complete Billet Machining Process

At MAIKONG, our billet machining process follows a systematic approach to ensure consistent quality and precision. Each step is carefully executed by our skilled technicians using state-of-the-art equipment.

1. Material Selection

We begin by selecting the optimal material for your application, considering factors like mechanical properties, machinability, cost, and environmental conditions. Our material experts help you choose from aluminum alloys, steel, brass, and specialty metals.

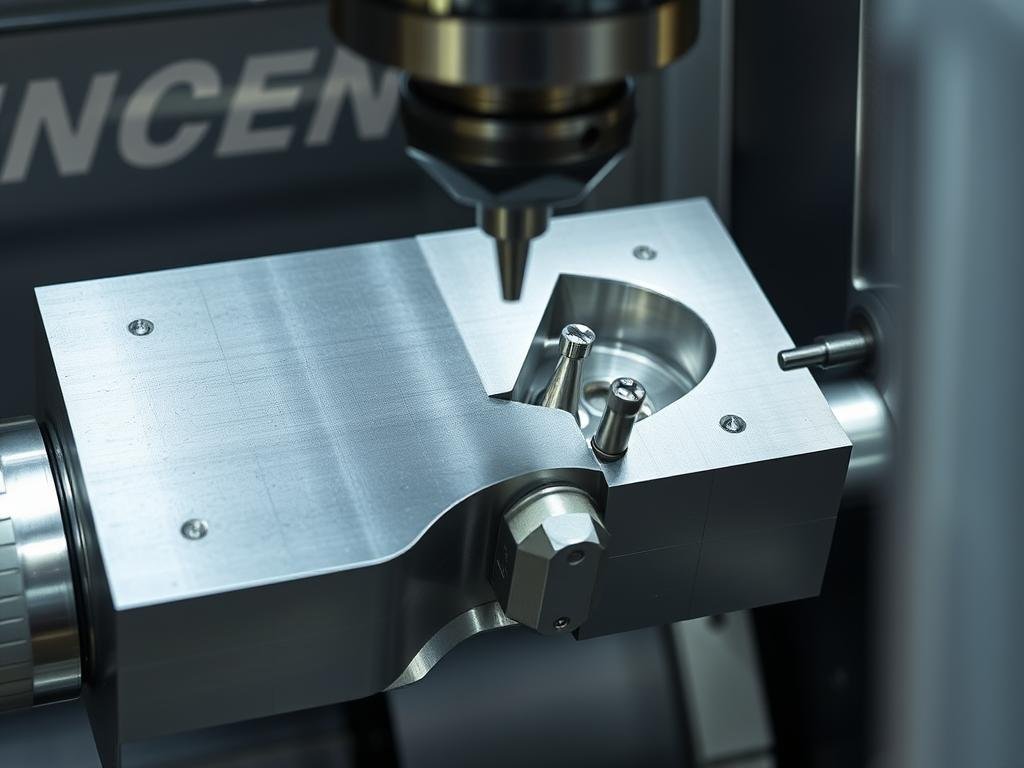

2. Design & CAD/CAM

Our engineering team uses advanced CAD/CAM software to create precise digital models of your components. We optimize designs for manufacturability while maintaining critical specifications and tolerances.

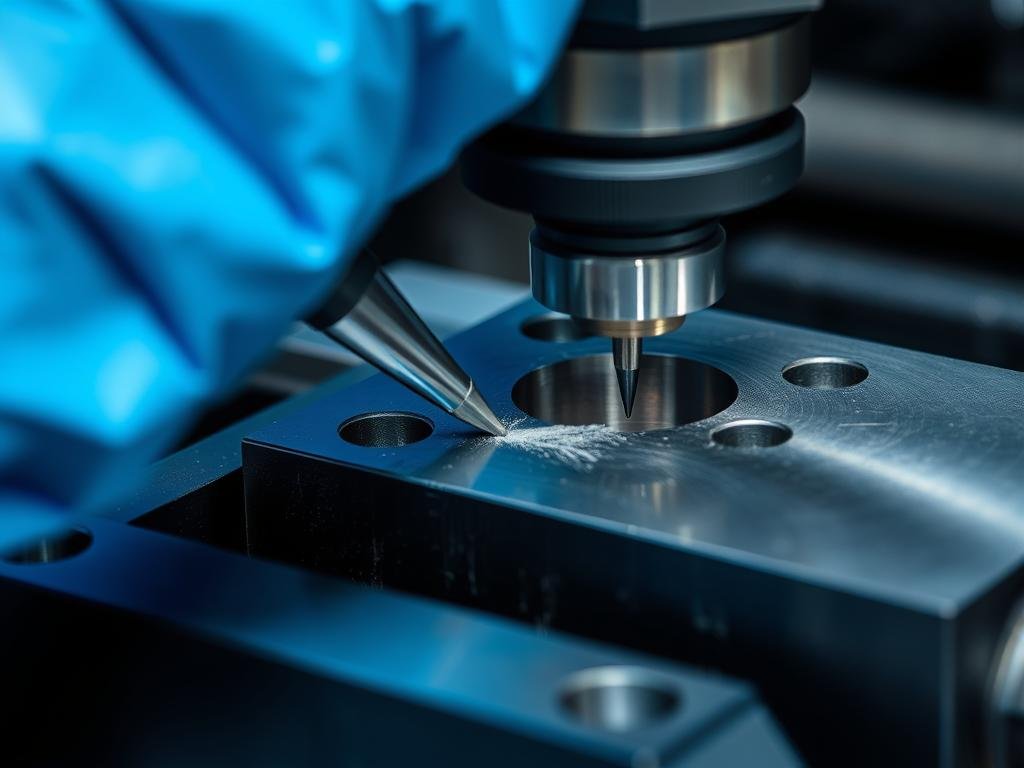

3. CNC Programming

Our programmers develop optimized toolpaths and cutting strategies to maximize efficiency and precision. This critical step determines the sequence of operations, cutting speeds, and tool selections for your specific component.

4. Billet Preparation

Raw billets are inspected, measured, and prepared for machining. This may include cutting to approximate size, deburring edges, and establishing reference surfaces for precise positioning in the machine.

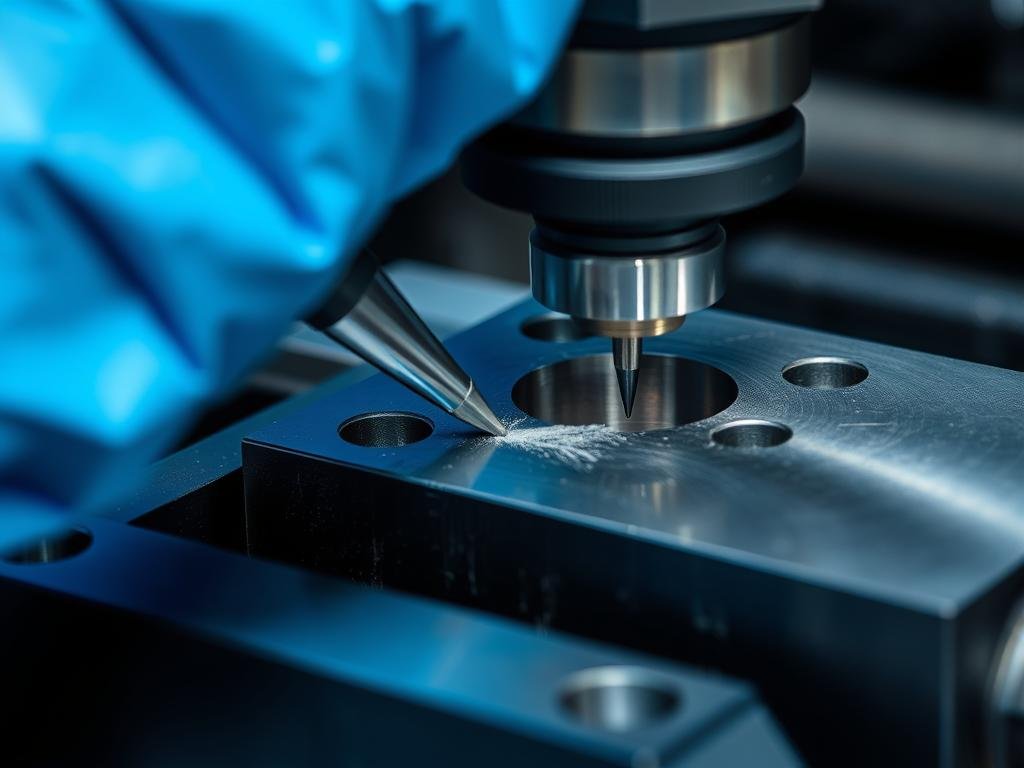

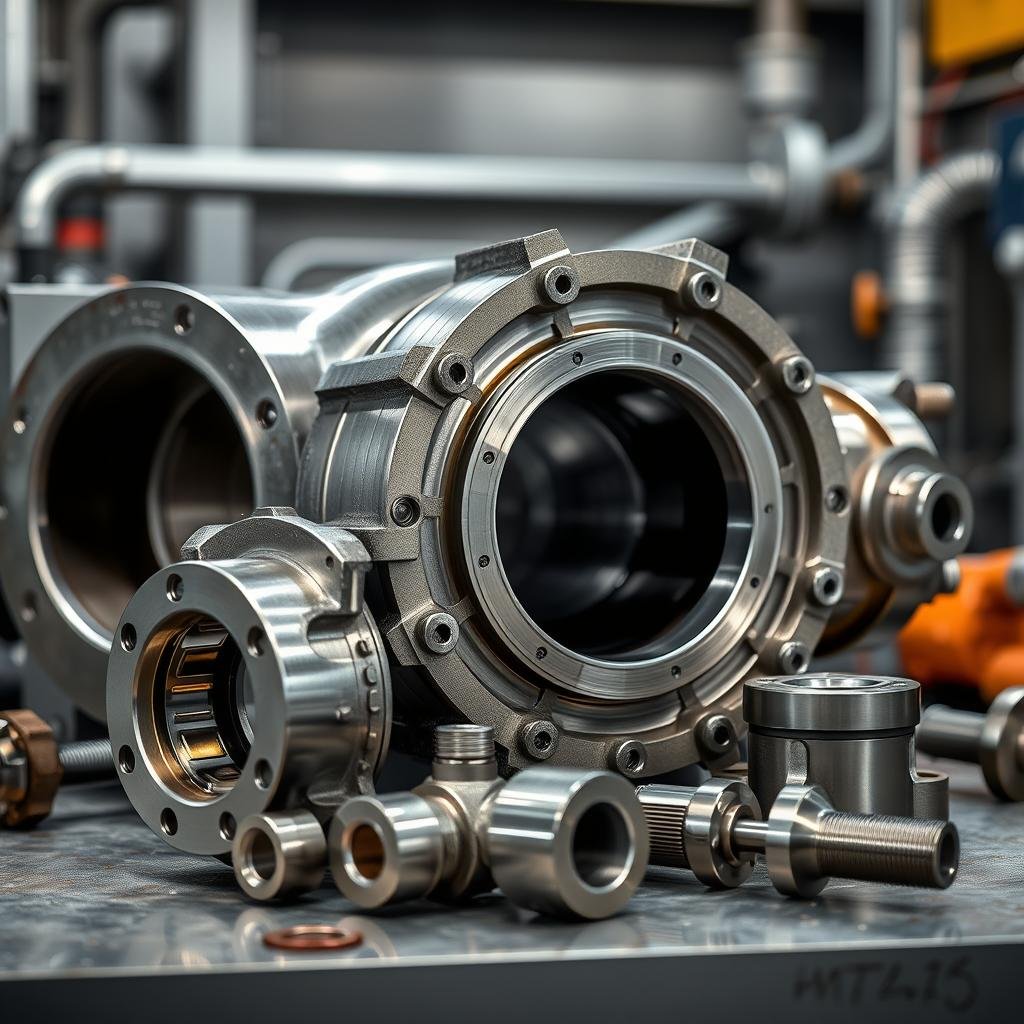

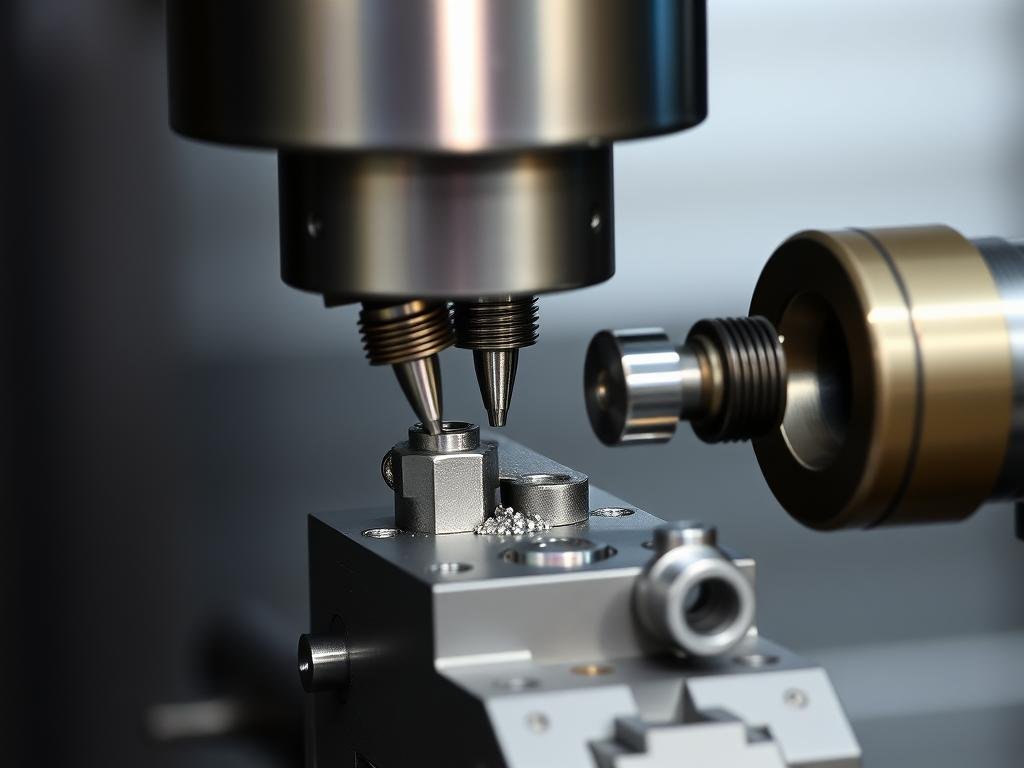

5. Primary Machining

Using our advanced CNC machines, we perform the initial cutting operations to establish the basic shape and features of your component. This may include milling, turning, drilling, and other operations depending on the design.

6. Secondary Operations

After primary machining, components often require additional operations such as tapping threads, reaming holes, chamfering edges, or creating special features that require separate setups or specialized tools.

7. Heat Treatment

When required, machined components undergo heat treatment to enhance mechanical properties such as hardness, strength, or stress relief. Our in-house heat treatment capabilities ensure precise control over this critical process.

8. Surface Finishing

We offer various surface finishing options including anodizing, powder coating, polishing, and plating to enhance appearance, corrosion resistance, and wear properties of your machined components.

9. Quality Inspection

Every component undergoes rigorous inspection using precision measuring equipment to verify dimensional accuracy, surface finish, and compliance with all specifications before final approval.

Expert Billet Machining Services

With 60+ CNC machines and 100+ tons monthly capacity, MAIKONG delivers precision-machined components that meet your exact specifications. Our comprehensive billet machining process ensures superior quality for every project.

Contact Us on WhatsApp

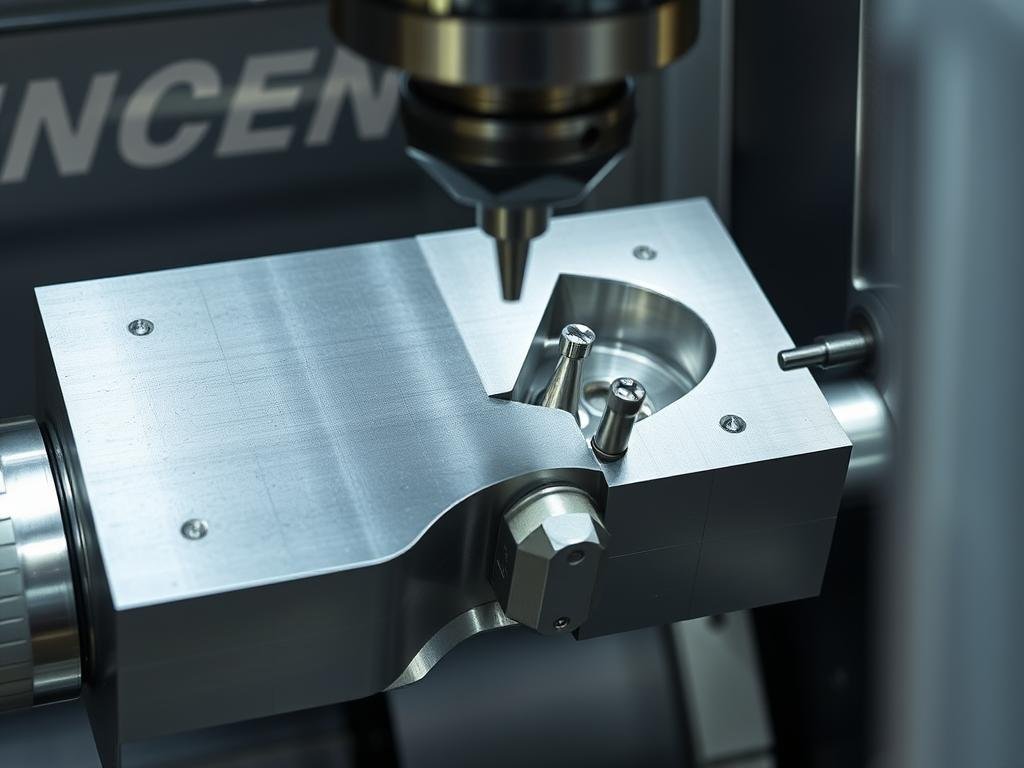

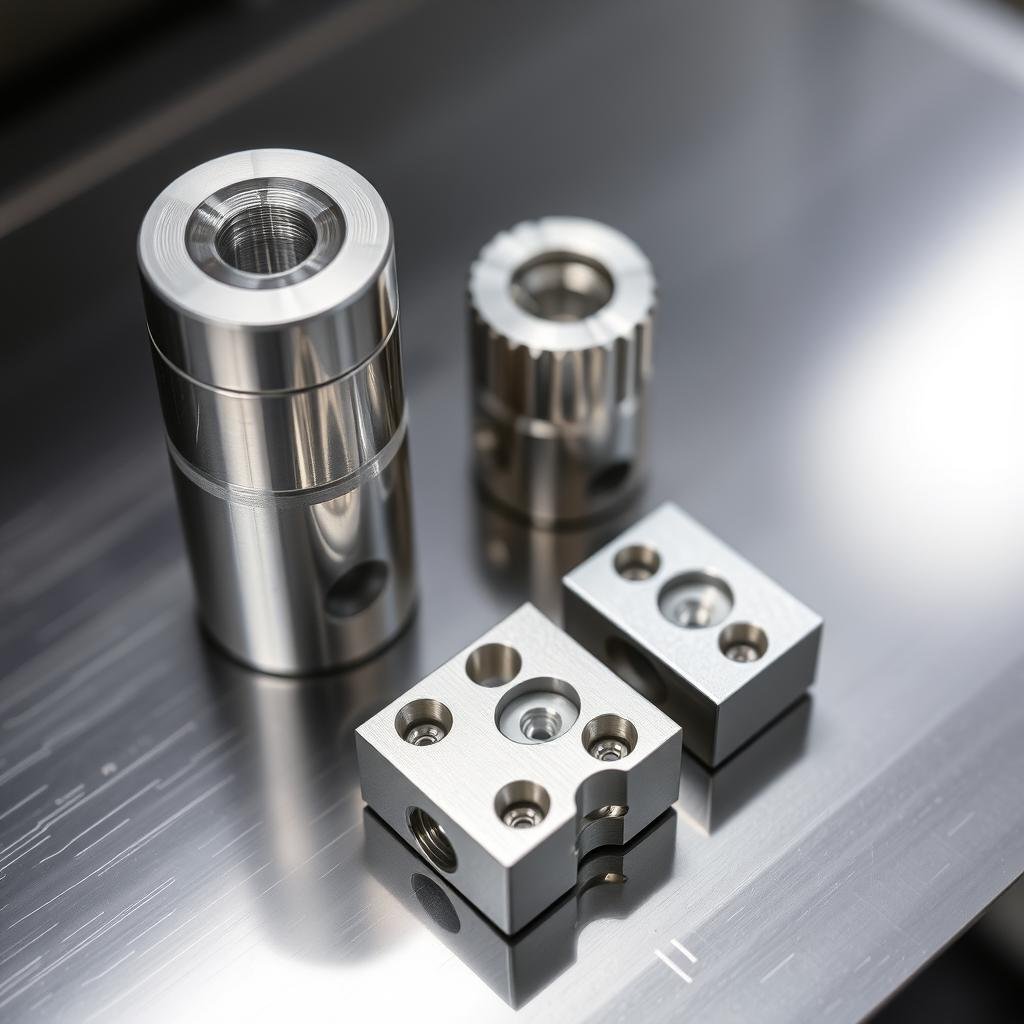

Our CNC Machining Capabilities

MAIKONG offers comprehensive machining services with state-of-the-art equipment and skilled technicians. Our facility in GD, SZ features over 60 CNC machines with a monthly capacity exceeding 100 tons of processed material.

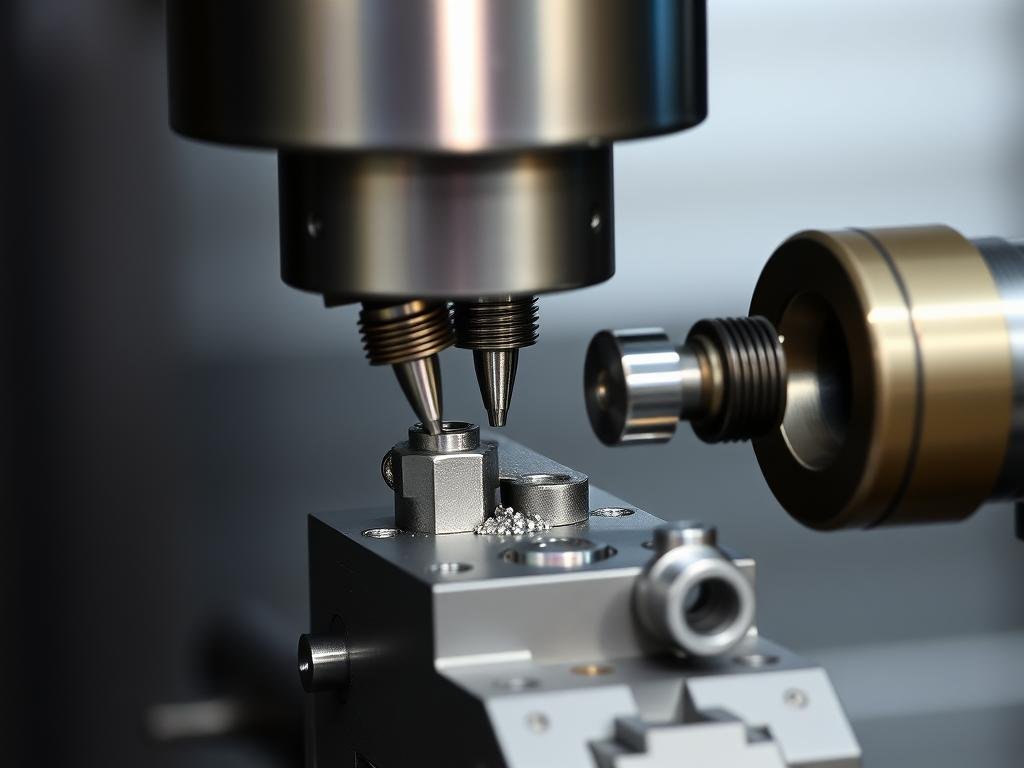

CNC Turning Services

Our CNC turning capabilities are ideal for creating precise cylindrical components, deep holes, machined threads, and parts requiring superior surface finishes. We specialize in both simple and complex turned components with tight tolerances.

CNC Milling Services

Our multi-axis CNC milling machines create complex prismatic shapes and flat surfaces with exceptional precision. This versatile process requires no fixed tooling, offering flexibility and accuracy for a wide range of applications.

Swiss-Type Machining

Our Swiss-type machining specializes in producing small precision parts and long shaft components. With dual spindles and multi-axis capabilities, we deliver exceptional accuracy for intricate components in a single setup.

Billet Machining vs. Other Manufacturing Methods

Understanding the differences between manufacturing methods helps in selecting the optimal process for your specific application. The billet machining process offers distinct advantages for many applications, but each method has its place in modern manufacturing.

| Feature |

Billet Machining |

Forging |

Casting |

| Strength |

High – Uniform grain structure |

Very High – Aligned grain flow |

Moderate – Potential for porosity |

| Precision |

Excellent (±0.0005″) |

Good after machining |

Moderate to Good |

| Complex Geometries |

Excellent for external features |

Limited complexity |

Excellent for internal features |

| Production Volume |

Low to Medium |

Medium to High |

Medium to High |

| Material Efficiency |

Lower (material removal) |

High |

Very High |

| Surface Finish |

Excellent |

Requires finishing |

Requires finishing |

| Cost for Low Volume |

Economical |

High (tooling costs) |

Moderate to High |

When to Choose Billet Machining

- When precision and tight tolerances are critical

- For prototyping and low to medium production volumes

- When complex external features are required

- When material properties must be consistent throughout

- For applications requiring excellent surface finish

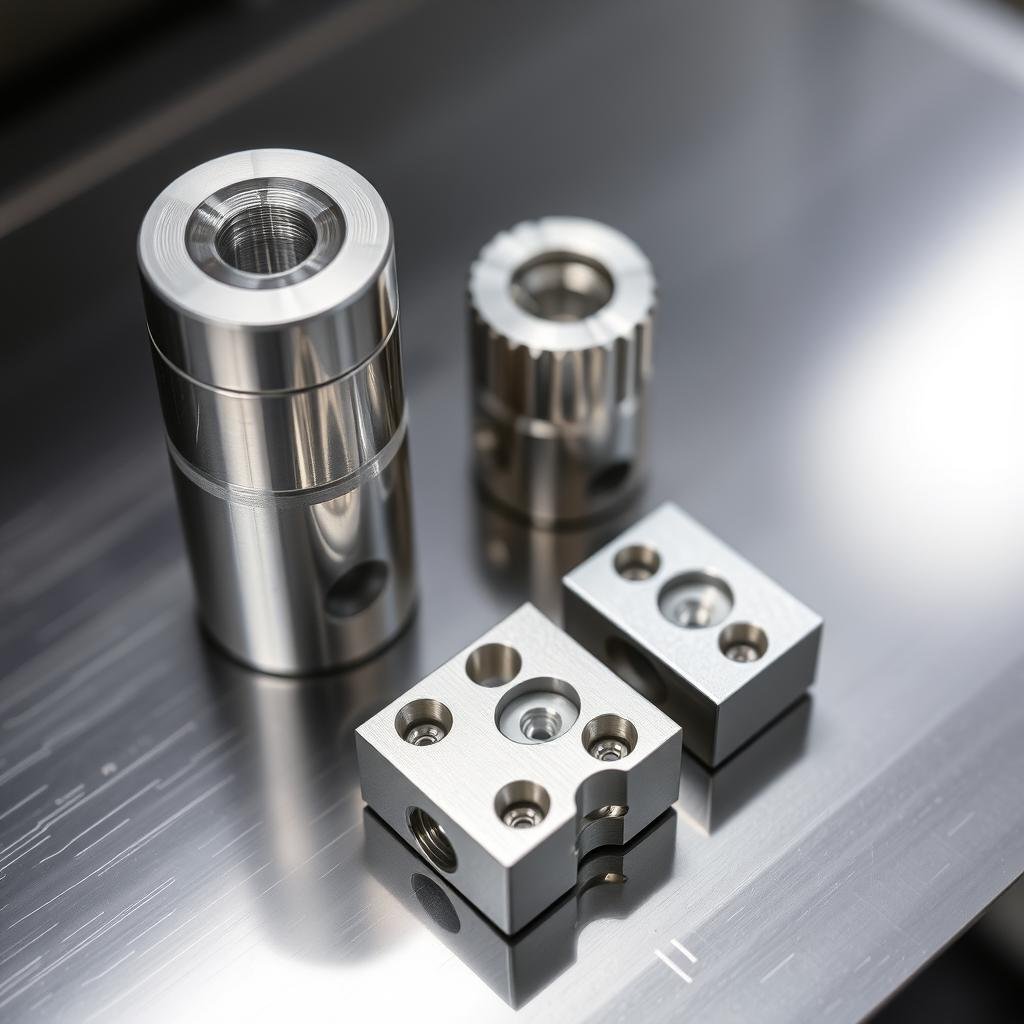

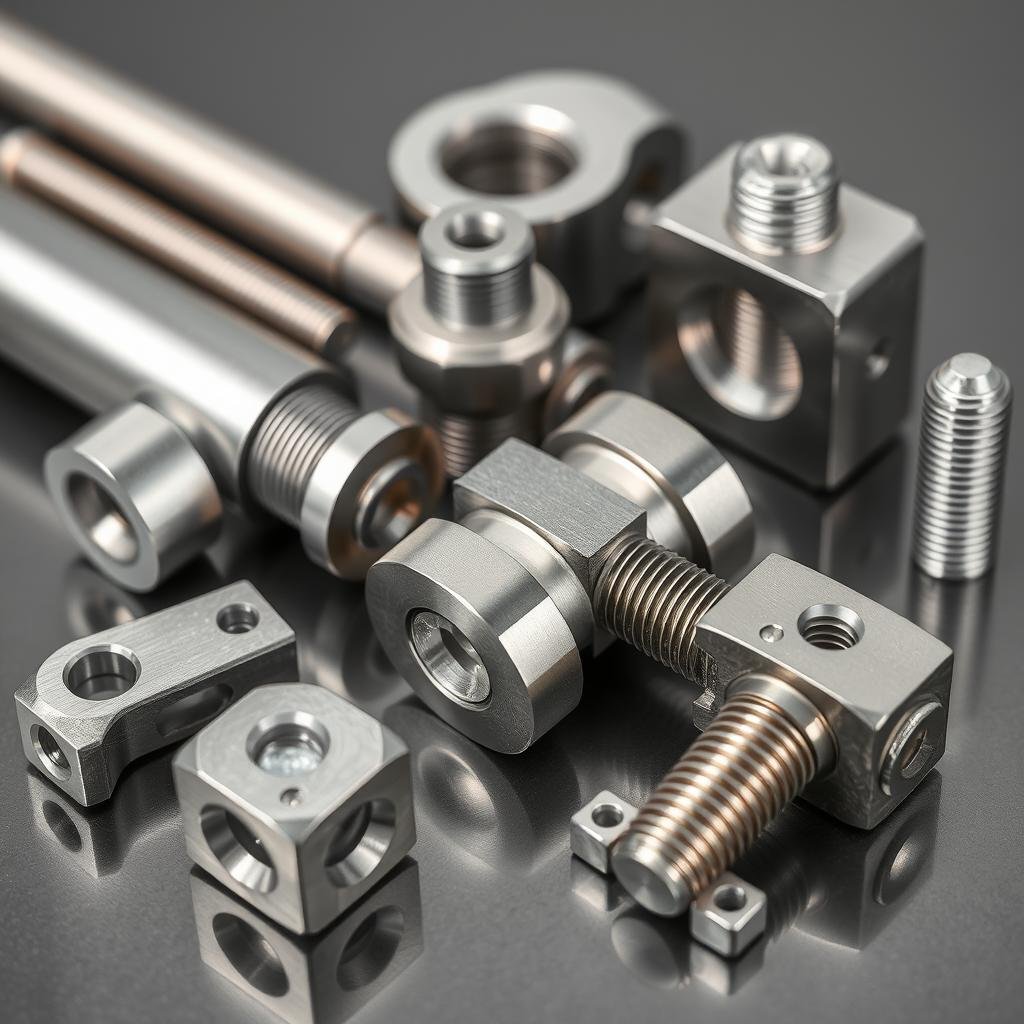

Materials for Billet Machining

At MAIKONG, we work with a wide range of materials to meet diverse application requirements. Our material selection expertise helps you choose the optimal alloy for your specific needs.

Aluminum Alloys

Lightweight with excellent corrosion resistance and good machinability. Common alloys include 6061, 7075, and 2024 for aerospace, automotive, and general engineering applications.

Steel Alloys

Outstanding strength and durability. We machine carbon steels, alloy steels, tool steels, and stainless steels for applications requiring high strength and wear resistance.

Brass & Copper

Excellent electrical conductivity and corrosion resistance. Ideal for electrical components, decorative hardware, and applications requiring antimicrobial properties.

Need Help Selecting the Right Material?

Our materials experts can help you choose the optimal alloy for your application, balancing performance requirements with cost considerations.

Email Our Materials Team

Quality Assurance in the Billet Machining Process

Quality is built into every step of our billet machining process. MAIKONG maintains ISO 9001:2015 certification and implements comprehensive quality management systems including 6S, PDCA, and lean production principles.

Our Quality Control Process

- Raw material verification and testing

- First article inspection and approval

- In-process inspection at critical stages

- Dimensional verification using precision measuring equipment

- Surface finish and visual inspection

- Final quality certification and documentation

MAIKONG Quality Commitment: Every component we produce undergoes rigorous inspection to ensure it meets or exceeds all specifications. Our comprehensive quality management system and skilled technicians guarantee consistent results for even the most demanding applications.

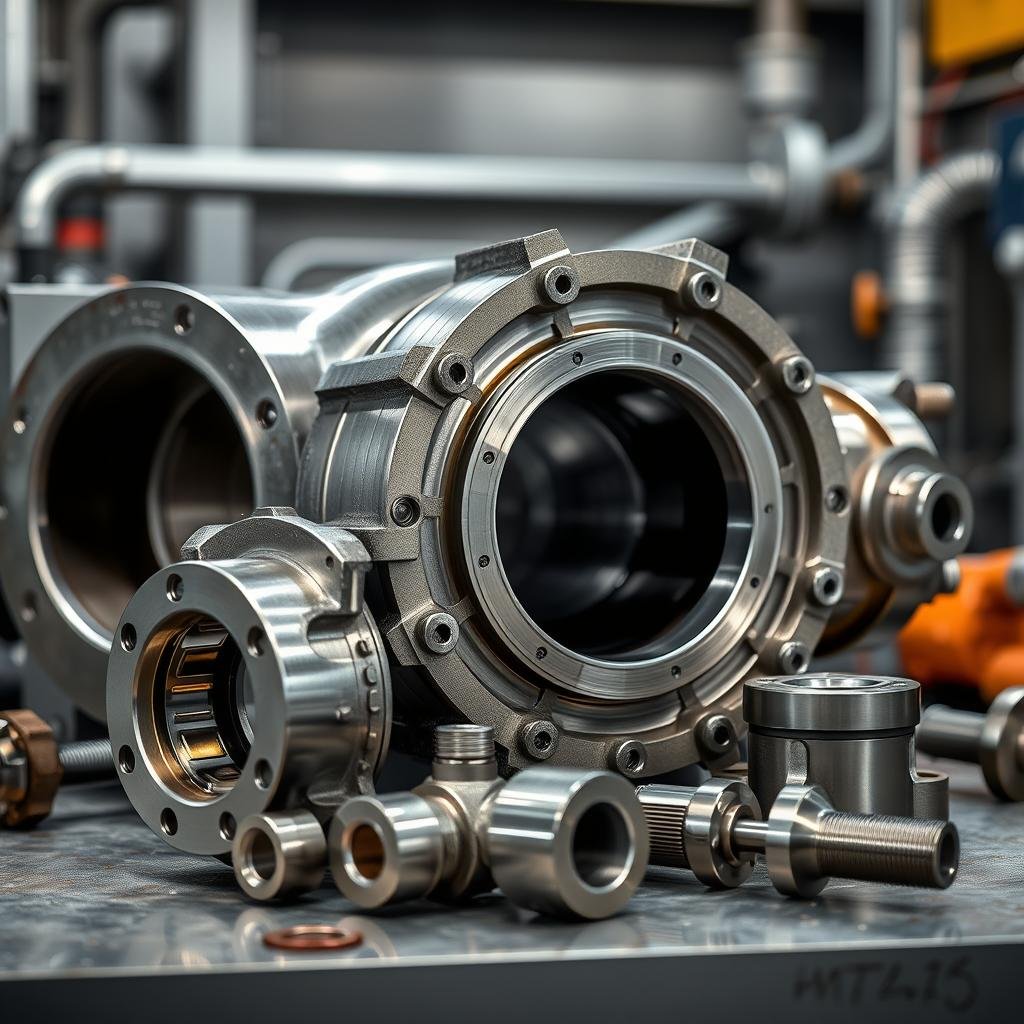

Industries We Serve

MAIKONG’s precision billet machining process serves diverse industries with custom components that meet exacting standards. Our expertise spans multiple sectors where quality and reliability are paramount.

Aerospace

Lightweight, high-strength components with exceptional reliability for commercial and defense aerospace applications.

Automotive

Precision engine components, transmission parts, and performance upgrades requiring tight tolerances and excellent surface finishes.

Medical

Surgical instruments, implant components, and medical device parts manufactured to exacting standards in controlled environments.

Electronics

Precision housings, heat sinks, and structural components for electronic devices requiring thermal management and EMI shielding.

Construction

Custom architectural hardware, structural components, and specialized fittings for commercial and residential construction projects.

Industrial

Durable, precision-engineered components for manufacturing equipment, material handling systems, and industrial machinery.