In the competitive landscape of American manufacturing, the pursuit of quality and durability remains paramount. At the heart of this pursuit lies billet machining, a precision manufacturing process that transforms solid metal blocks into high-performance components. This advanced technique has become indispensable across industries where precision, strength, and reliability cannot be compromised. As global supply chains evolve, understanding how billet machining elevates American manufacturing standards becomes essential for companies seeking competitive advantages in quality and performance.

Understanding Billet Machining and Its Fundamental Role

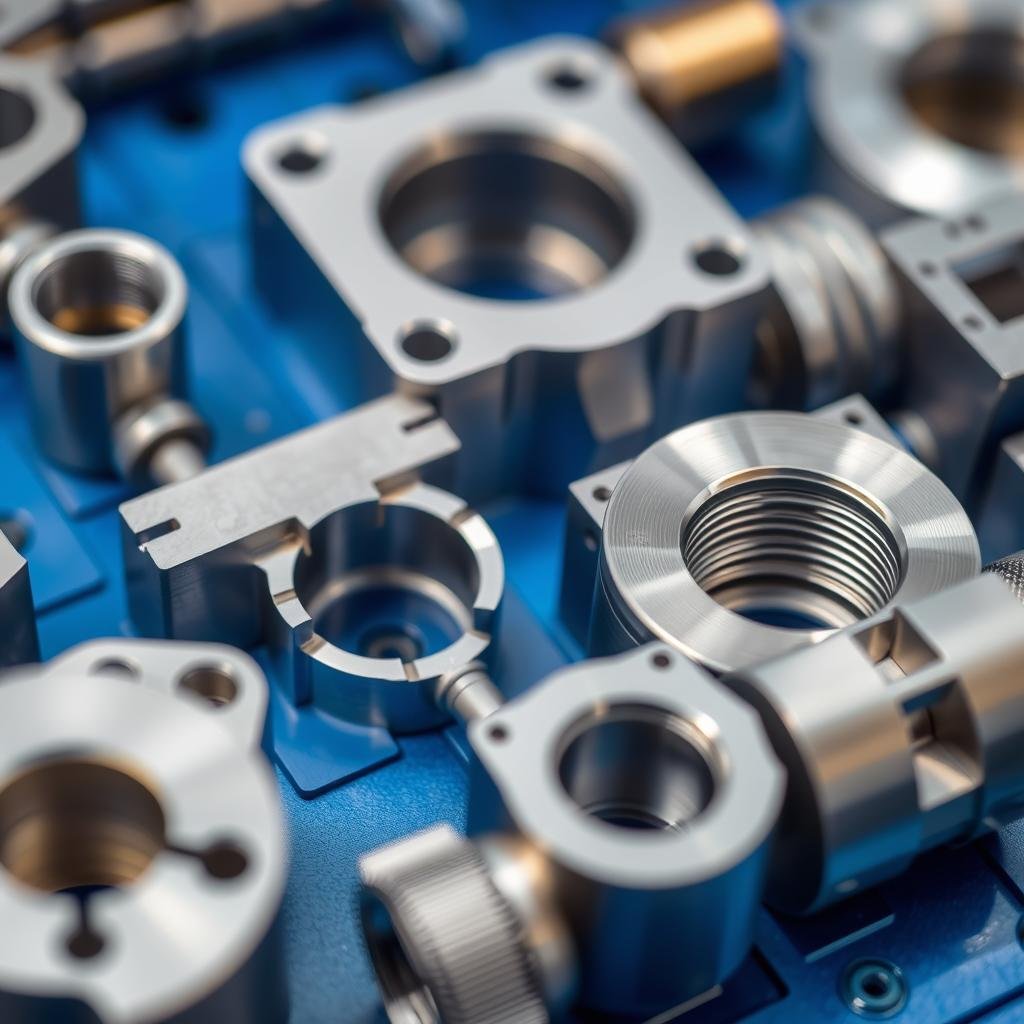

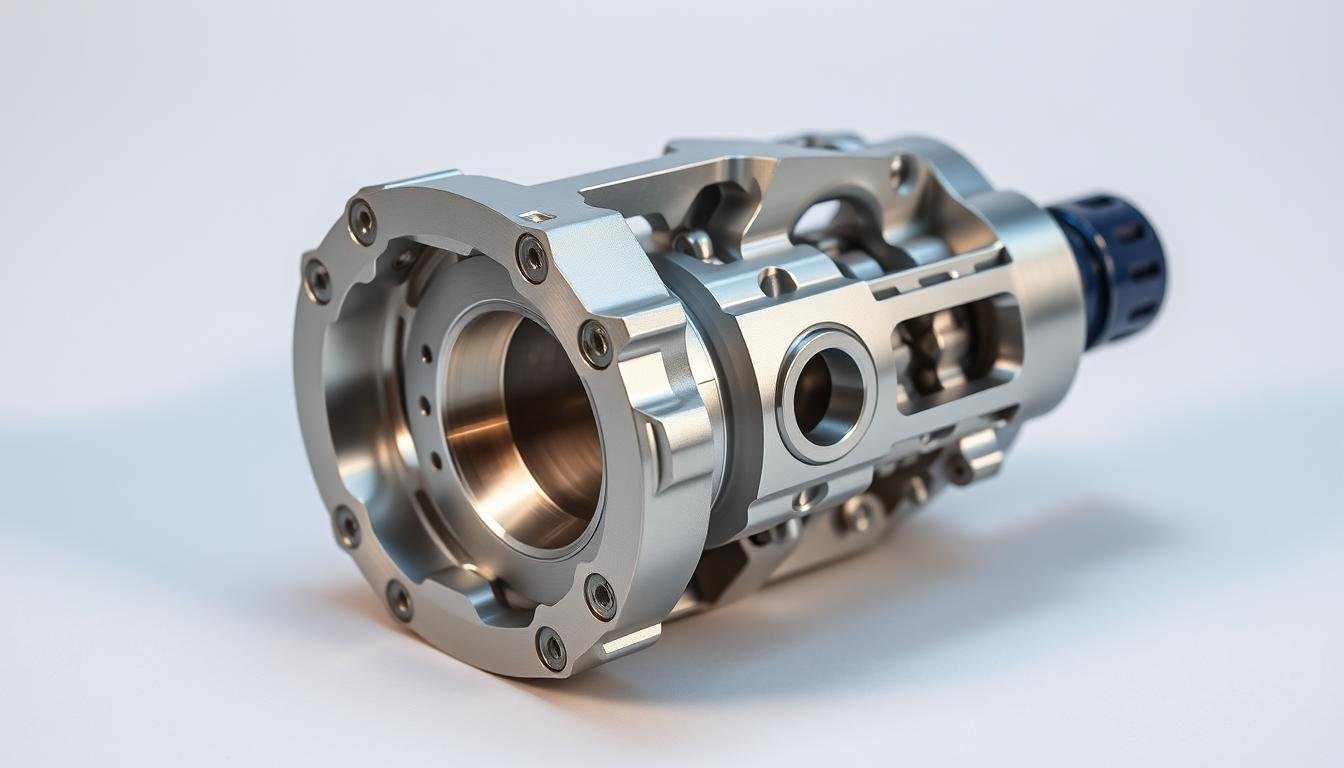

Precision CNC machining process transforming raw billet into finished component

Precision CNC machining process transforming raw billet into finished component

Billet machining refers to the process of creating components by removing material from solid metal blocks, known as billets. Unlike casting or forging, which form metal through molding or compression, billet manufacturing is a subtractive process that precisely cuts away excess material to reveal the final part.

The Billet Machining Process Explained

The process begins with a solid metal block, typically produced through continuous casting or hot rolling methods. These uniform blocks serve as the raw material for CNC (Computer Numerical Control) machining operations. Using multi-axis CNC equipment, manufacturers like MAIKONG can achieve extremely tight tolerances and complex geometries that would be difficult or impossible with other manufacturing methods.

Key Steps in the Billet Manufacturing Process:

- Material selection based on application requirements

- Billet preparation and mounting in CNC equipment

- Programming precise toolpaths for material removal

- Multi-stage machining operations (roughing, finishing)

- Quality inspection and verification of specifications

- Surface finishing and treatment as required

The resulting components feature excellent structural integrity and dimensional accuracy. This precision makes billet-machined parts ideal for applications where performance and reliability are critical factors.

Comparing Billet Machining with Alternative Manufacturing Methods

To fully appreciate the value of billet machining, it’s important to understand how it compares to other common manufacturing methods like casting and forging. Each approach offers distinct advantages depending on application requirements, production volume, and performance criteria.

| Manufacturing Aspect |

Billet Machining |

Cast Manufacturing |

Forged Manufacturing |

| Process Type |

Subtractive (material removal) |

Additive (pouring into molds) |

Deformative (reshaping with pressure) |

| Grain Structure |

Uniform, non-directional |

Random with potential voids |

Directional, follows part contours |

| Dimensional Accuracy |

Excellent (±0.0005″) |

Good (±0.010″) |

Moderate (±0.015″) |

| Material Strength |

Very good |

Moderate |

Excellent |

| Surface Finish |

Excellent |

Fair to good |

Requires post-processing |

| Cost-Effectiveness |

Best for low volumes |

Best for high volumes |

Best for medium volumes |

| Material Waste |

Higher |

Lower |

Minimal |

| Lead Time |

Short to moderate |

Longer (tooling required) |

Moderate (die preparation) |

When to Choose Billet Machining Over Alternatives

Billet Machining Advantages

- Superior precision and dimensional accuracy

- Excellent surface finish with minimal post-processing

- Ideal for prototyping and low-volume production

- No tooling costs for initial production

- Greater design flexibility and modification capability

- Consistent material properties throughout the part

- Better for complex internal features and geometries

Billet Machining Limitations

- Higher material waste compared to other methods

- Less economical for very high volumes

- Longer machining time for complex geometries

- Limited to machinable materials

- May have higher per-unit costs in production

- Not ideal for extremely large components

- May require multiple setups for complex parts

The decision between manufacturing methods should be based on specific project requirements, including performance needs, production volume, budget constraints, and timeline considerations. MAIKONG’s engineering team can help determine the optimal approach for your specific application.

Quality Factors That Make Billet Machining Superior

The exceptional quality of billet-machined components stems from several key factors inherent to the manufacturing process. These quality advantages directly translate to improved performance and longevity in finished products.

Material Integrity and Structural Consistency

Unlike cast parts, which may contain porosity or inclusions, billet-machined components start with solid metal stock that has already undergone quality verification. This ensures consistent material properties throughout the entire part, eliminating internal defects that could compromise structural integrity.

Material Selection Flexibility

Billet machining accommodates a wide range of materials, including:

- Aircraft-grade aluminum alloys (6061, 7075)

- Stainless steel varieties (303, 304, 316)

- Tool steels for high-wear applications

- Brass and bronze alloys

- Titanium for aerospace and medical applications

- Engineering plastics for specialized uses

Precision and Dimensional Accuracy

Modern CNC equipment used in billet machining can achieve tolerances as tight as ±0.0005 inches (0.0127mm). This exceptional precision ensures perfect fit and function in assemblies where components must work together flawlessly. At MAIKONG, our advanced multi-axis CNC machines maintain this precision consistently across production runs.

4.8

Manufacturing Precision Rating

Surface Finish Quality

4.8

Complex Geometry Capability

4.7

Key Applications Where Billet Machining Excels

The superior quality and precision of billet-machined components make them ideal for applications where performance, reliability, and durability are critical. Here are key industries and applications where this manufacturing method delivers exceptional results:

Aerospace

Critical structural components, mounting brackets, hydraulic manifolds, and control system parts where weight reduction and absolute reliability are essential.

Automotive

Performance engine components, custom suspension parts, specialized brackets, and fluid system components that require precise tolerances and excellent strength-to-weight ratios.

Medical

Surgical instruments, diagnostic equipment components, implant prototypes, and specialized medical device parts that demand biocompatibility and precision.

Defense

Weapon system components, communication equipment housings, vehicle parts, and specialized tactical equipment requiring durability in extreme conditions.

Robotics

Structural frames, actuator housings, end effectors, and precision movement components that require exact specifications and lightweight strength.

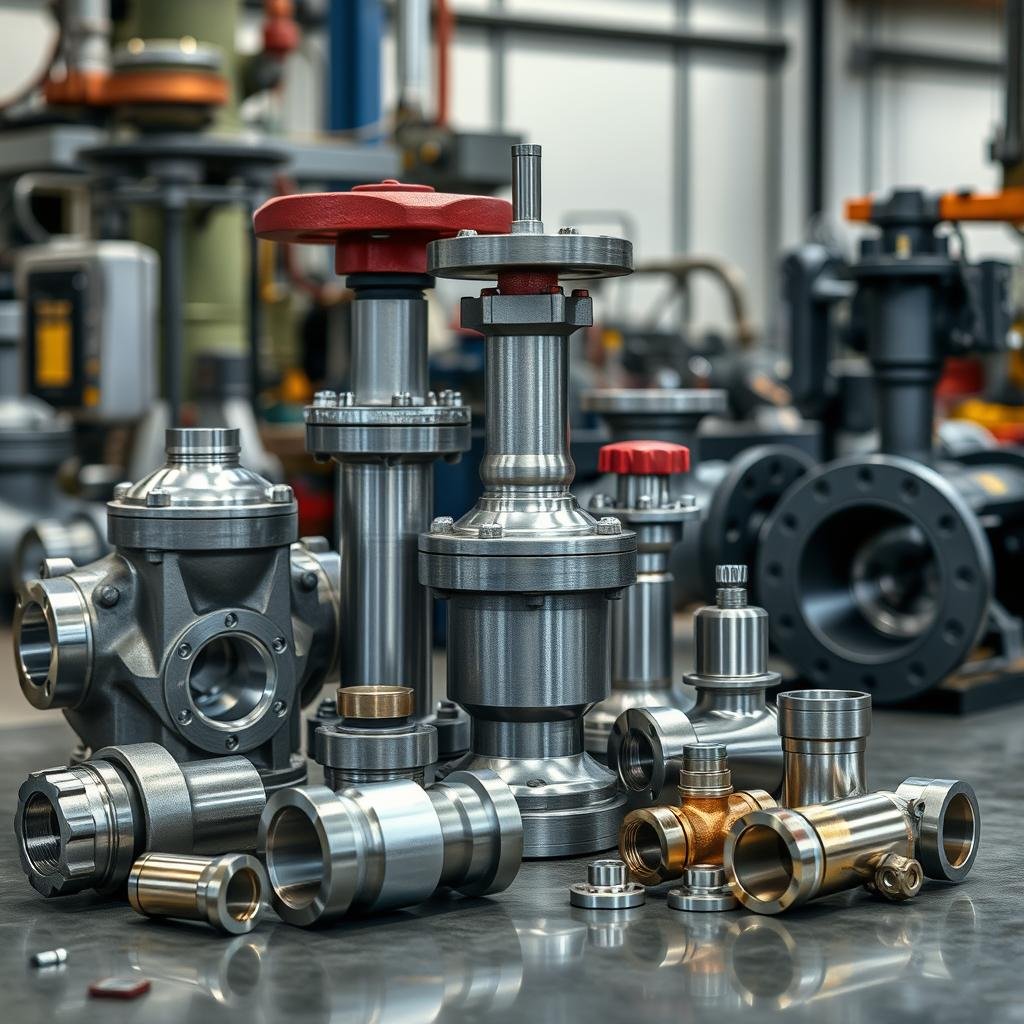

Oil & Gas

Valve components, pump parts, instrumentation housings, and connection systems that must withstand high pressure, temperature, and corrosive environments.

Need Custom Billet-Machined Components for Your Industry?

MAIKONG specializes in precision billet machining for demanding applications across industries. Our engineering team can help determine if billet machining is right for your specific requirements.

Get A Quick Quote

Or contact us directly: 8613-51090-74-01

MAIKONG’s Advanced Billet Machining Capabilities

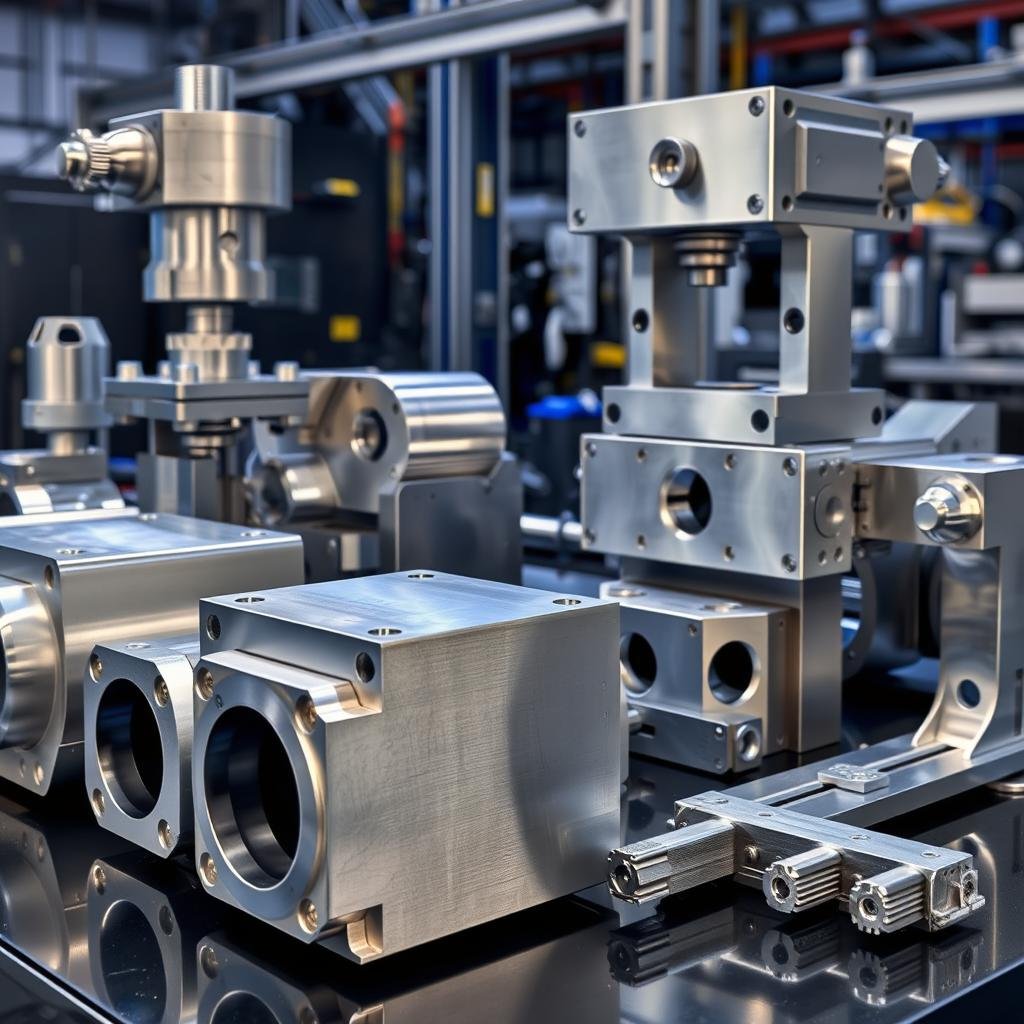

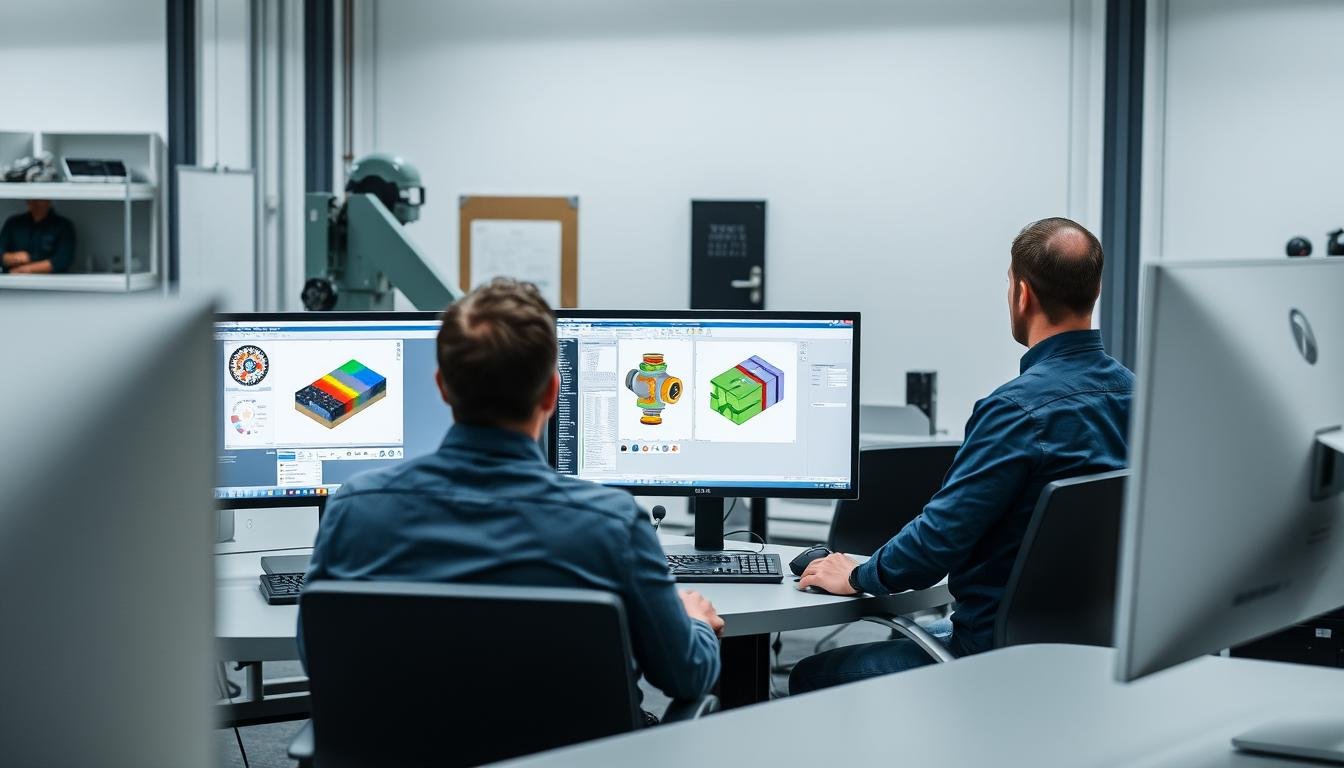

MAIKONG’s advanced manufacturing facility with multi-axis CNC equipment

At MAIKONG, we’ve invested in cutting-edge technology and skilled personnel to deliver exceptional billet-machined components. Our comprehensive capabilities ensure we can meet the most demanding specifications across diverse industries.

Our Manufacturing Technology

CNC Machining Equipment

- Multi-axis CNC machining centers (3-axis, 4-axis, 5-axis)

- CNC turning centers with live tooling capabilities

- Swiss-type precision machining for small components

- High-speed machining for efficient production

- Large-capacity machining for oversized components

Quality Verification Systems

- Coordinate Measuring Machines (CMM) for dimensional verification

- Optical measurement systems for surface inspection

- Material testing equipment for property verification

- Advanced metrology tools for in-process inspection

- Comprehensive quality documentation systems

Comprehensive Manufacturing Services

Beyond core billet machining capabilities, MAIKONG offers a complete suite of manufacturing services to deliver finished components ready for your application:

CNC Milling Services

Precision multi-axis milling for complex geometries, pockets, contours, and features requiring tight tolerances and excellent surface finish.

CNC Turning Services

High-precision turning for cylindrical components, threading, grooving, and complex profiles with exceptional concentricity and dimensional accuracy.

Surface Treatments

Comprehensive finishing services including anodizing, plating, painting, powder coating, passivation, and specialized surface treatments for performance enhancement.

Heat Treatment

Specialized heat treatment processes to enhance material properties, including hardening, tempering, annealing, and stress relief for optimal component performance.

Assembly Services

Component assembly capabilities to deliver ready-to-use subassemblies, reducing your integration time and ensuring proper fit and function.

Quality Assurance

Rigorous quality control protocols including First Article Inspection, in-process verification, and final dimensional reporting to ensure specification compliance.

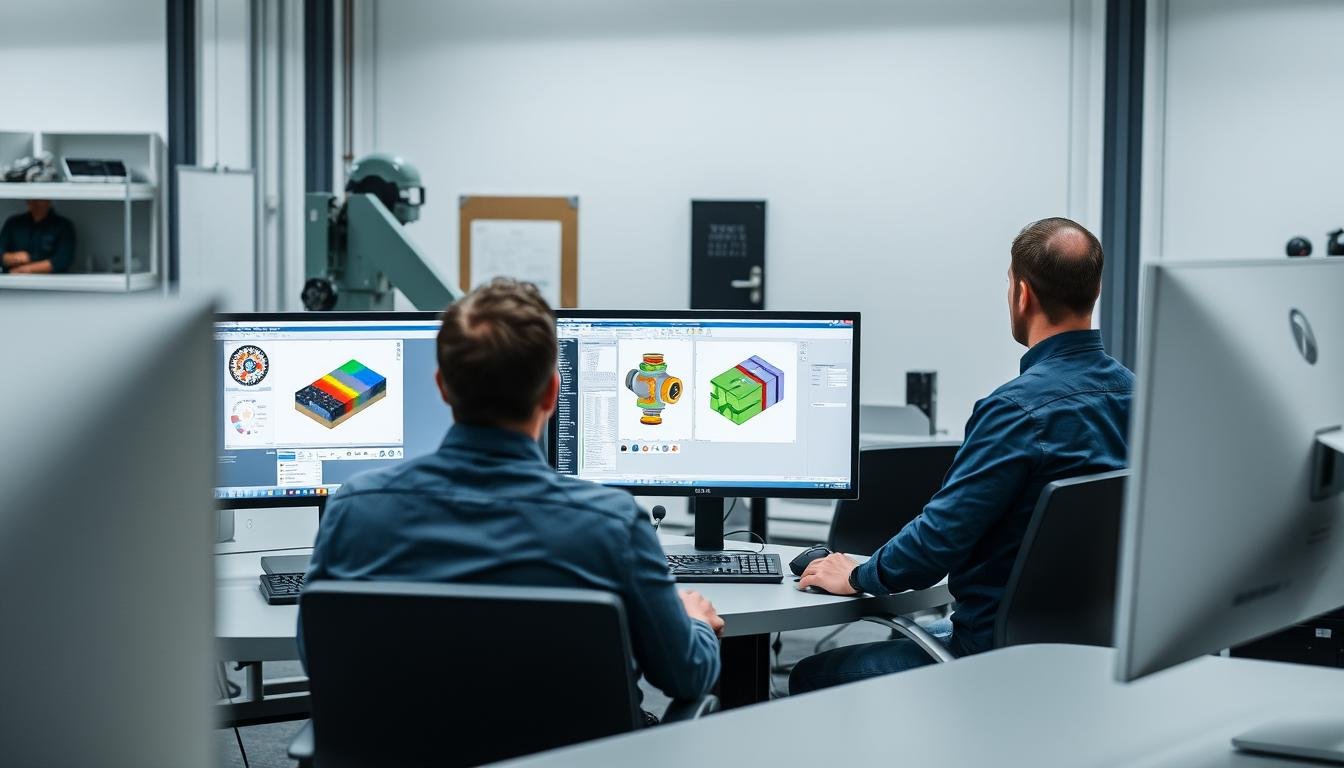

Design Considerations for Optimal Billet Machining Results

Achieving the best results with billet machining requires thoughtful design approaches that leverage the strengths of the process while minimizing potential limitations. MAIKONG’s engineering team works closely with clients to optimize designs for manufacturability without compromising performance.

CAD/CAM optimization for efficient billet machining processes

Design for Manufacturability (DFM) Principles

Recommended Design Practices

- Maintain consistent wall thicknesses where possible

- Design with standard tool sizes in mind

- Include appropriate fillets and radii on internal corners

- Consider tool access for internal features

- Minimize deep pockets that require specialized tooling

- Design parts to minimize the number of setups required

Design Elements to Avoid

- Extremely thin walls that may vibrate during machining

- Unnecessarily deep holes with high aspect ratios

- Sharp internal corners that require additional operations

- Features requiring specialized or custom tooling

- Geometries that require multiple complex setups

- Designs that generate excessive material waste

“The most efficient billet-machined components balance design requirements with manufacturing considerations. Our engineering team can help optimize your designs for both performance and cost-effectiveness.”

– MAIKONG Engineering Team

Material Selection Guidance

Choosing the right material for your billet-machined components is critical to achieving desired performance characteristics. Our materials expertise helps guide optimal selection based on your specific requirements:

| Material Type |

Key Properties |

Ideal Applications |

Machinability |

| 6061 Aluminum |

Good strength, excellent corrosion resistance, heat treatable |

General-purpose structural components, fixtures, brackets |

Excellent |

| 7075 Aluminum |

High strength, good fatigue resistance, heat treatable |

Aerospace components, high-stress applications |

Very Good |

| 304 Stainless Steel |

Excellent corrosion resistance, good strength, non-magnetic |

Food processing, medical, chemical applications |

Moderate |

| 4140 Alloy Steel |

High strength, good toughness, heat treatable |

Gears, shafts, mechanical components |

Good |

| Brass |

Good corrosion resistance, electrical conductivity |

Electrical components, decorative parts |

Excellent |

| Titanium |

Exceptional strength-to-weight ratio, biocompatible |

Aerospace, medical implants, high-performance |

Challenging |

Billet Machining Success Stories

The true value of billet machining becomes evident through real-world applications. Here are examples of how MAIKONG’s precision manufacturing capabilities have delivered exceptional results for clients across different industries:

Aerospace Structural Component

Challenge: An aerospace client needed a complex structural bracket with extremely tight tolerances and specific weight requirements. The part featured thin walls, complex pockets, and critical mounting points.

Solution: MAIKONG’s engineering team optimized the design for billet machining, selecting 7075-T6 aluminum for its excellent strength-to-weight ratio. Our 5-axis CNC machining centers produced components with tolerances within ±0.001″ while maintaining wall thickness consistency.

Result: The client received components that exceeded specifications, passed all quality verification tests, and contributed to a 12% weight reduction in their assembly without compromising structural integrity.

Medical Device Housing

Challenge: A medical equipment manufacturer required a complex housing for a diagnostic device with intricate internal features, precise mounting points, and biocompatible material requirements.

Solution: MAIKONG utilized billet machining with 316L stainless steel to create the housing. Our Swiss-type machining capabilities allowed for the precise internal features, while comprehensive quality control ensured dimensional accuracy and surface finish requirements were met.

Result: The client received components that maintained dimensional stability, passed biocompatibility testing, and enabled reliable assembly of their diagnostic equipment. Production lead times were reduced by 35% compared to their previous supplier.

Quality Assurance in the Billet Machining Process

At MAIKONG, quality isn’t just inspected—it’s built into every step of our manufacturing process. Our comprehensive quality management system ensures consistent results that meet or exceed client specifications.

Precision verification using advanced metrology equipment

Our Quality Control Process

Material Verification

- Incoming material certification review

- Material property testing when required

- Traceability documentation

- Proper material handling and storage

In-Process Inspection

- First article inspection (FAI)

- Dimensional verification during production

- Statistical process control (SPC)

- Tool wear monitoring and compensation

Final Verification

- Comprehensive dimensional inspection

- Surface finish verification

- Functional testing when applicable

- Detailed quality documentation

MAIKONG Quality Commitment: Our manufacturing facility maintains rigorous quality standards to ensure consistent, reliable results. We provide comprehensive quality documentation with every order, including material certifications, dimensional reports, and process verification records as required.

Partner with MAIKONG for Superior Billet Machining Solutions

MAIKONG offers more than just manufacturing services—we provide comprehensive partnership to ensure your components meet the highest standards of quality and performance. Our team works closely with clients throughout the entire process, from initial design consultation through final delivery.

Why Choose MAIKONG

- Technical Expertise: Our engineering team brings decades of combined experience in precision manufacturing

- Advanced Equipment: State-of-the-art CNC machinery capable of handling the most demanding specifications

- Quality Focus: Comprehensive quality management system ensuring consistent results

- Competitive Pricing: Excellent value without compromising quality or performance

- Comprehensive Services: Complete manufacturing solutions from design assistance through finishing

- Responsive Communication: Dedicated project management and clear, timely communication

What industries does MAIKONG typically serve with billet machining services?

MAIKONG provides precision billet machining services across diverse industries including aerospace, automotive, medical, defense, oil & gas, robotics, and general industrial applications. Our capabilities are particularly valuable for applications requiring high precision, complex geometries, and excellent material properties.

What is the typical lead time for billet-machined components?

Lead times vary based on complexity, quantity, and current production schedule. Simple components may be completed in 1-2 weeks, while more complex parts typically require 3-4 weeks. For urgent projects, we offer expedited services when possible. Contact us with your specific requirements for an accurate timeline estimate.

Does MAIKONG offer design assistance for billet-machined components?

Yes, our engineering team provides comprehensive design assistance to optimize components for billet machining. We can review existing designs for manufacturability, suggest improvements for cost reduction or performance enhancement, and help translate functional requirements into manufacturable specifications. This collaborative approach ensures the best possible outcomes for your projects.

Conclusion: The Enduring Value of Quality Billet Machining

In today’s competitive manufacturing landscape, the quality and durability of components directly impact product performance, reliability, and customer satisfaction. Billet machining continues to stand out as a premier manufacturing method for applications where precision, material integrity, and dimensional accuracy cannot be compromised.

By partnering with MAIKONG for your precision manufacturing needs, you gain access to advanced capabilities, engineering expertise, and a commitment to quality that ensures your components will meet or exceed expectations. From initial concept through final delivery, our team works diligently to deliver the exceptional results your products deserve.

Contact MAIKONG today to discuss how our billet machining services can contribute to your manufacturing success and help you deliver superior products to your customers.

Precision CNC machining process transforming raw billet into finished component

Precision CNC machining process transforming raw billet into finished component