When performance and precision matter, Benefits of Machining Parts from Billet become critical to your project’s success. Billet machining offers superior strength, dimensional accuracy, and material integrity that other manufacturing methods simply can’t match. Whether you’re developing aerospace components, high-performance automotive parts, or precision medical devices, understanding these advantages can help you make informed manufacturing decisions.

What Is Billet Machining and Why It Matters

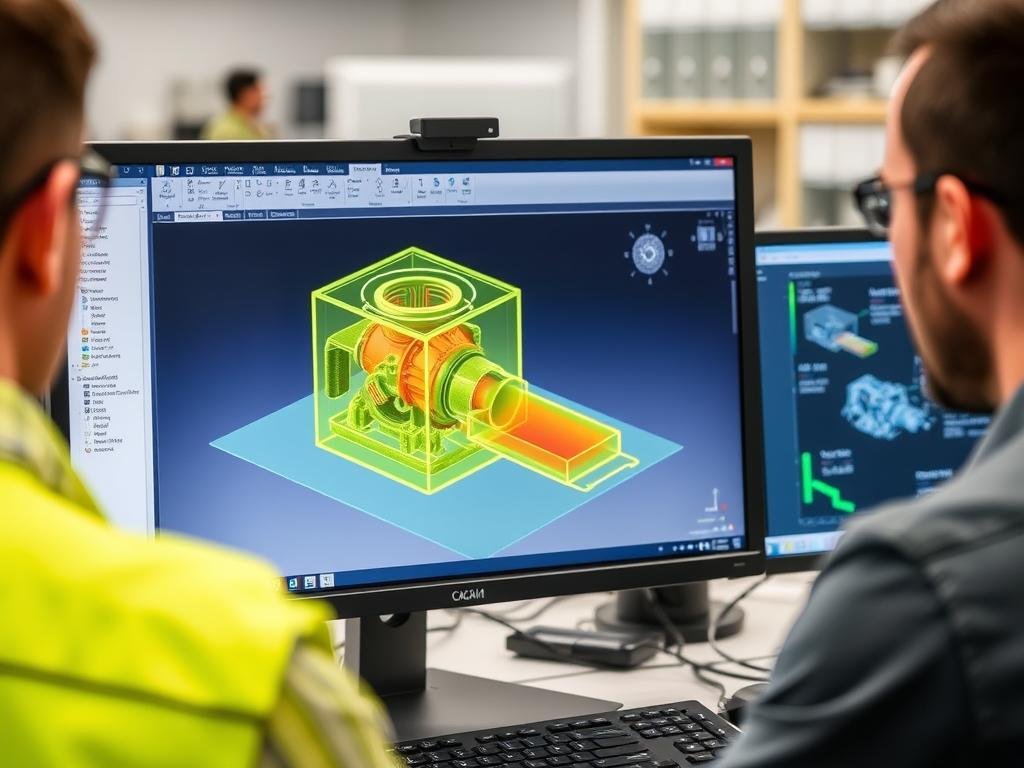

Billet machining is a subtractive manufacturing process that creates parts by removing material from a solid block (billet) of metal. Using computer numerical control (CNC) technology, the process transforms raw material into precisely engineered components with exceptional dimensional accuracy and material integrity.

Unlike casting or forging, which involve melting or deforming metal, billet machining preserves the original material structure. This results in parts with consistent properties throughout and superior mechanical performance in demanding applications.

The Fundamental Benefits of Machining Parts from Billet

The billet machining process starts with high-quality metal stock that has already undergone quality control. This ensures your finished parts begin with material that meets strict compositional and structural standards. The CNC machining process then precisely removes material to create the exact specifications required.

At MAIKONG, our 60+ CNC machines deliver over 100 tons of metal processing capacity monthly. We specialize in turning, milling, Swiss machining, and multi-axis machining to create parts that meet the most demanding requirements across industries.

Superior Strength and Structural Integrity

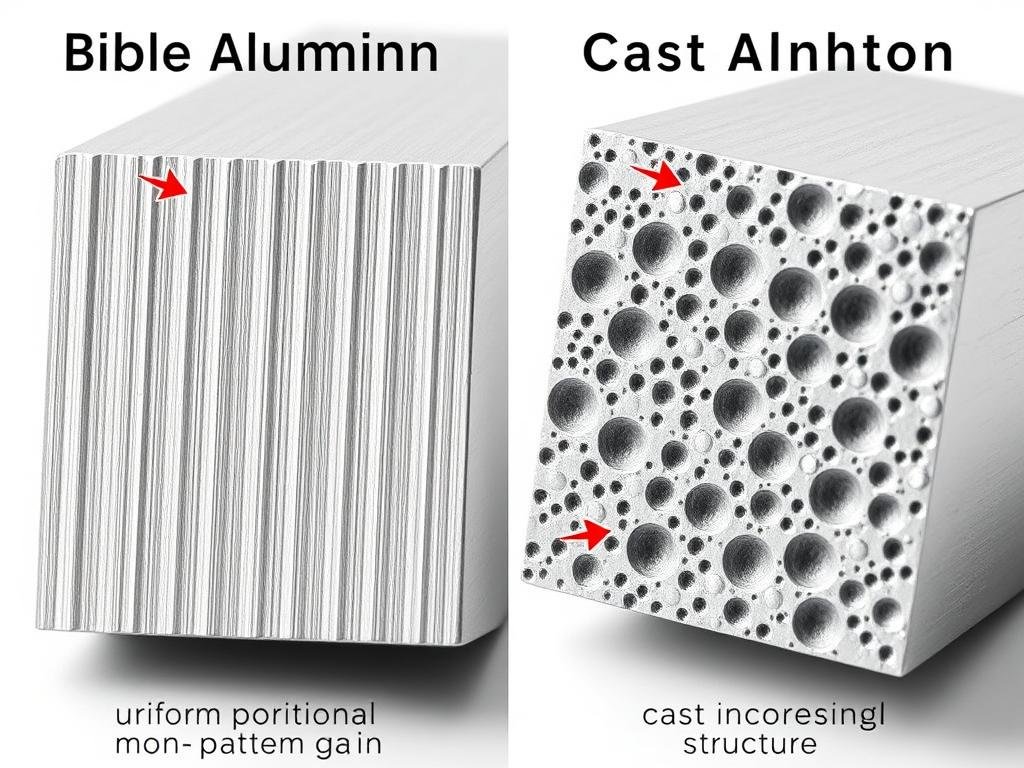

One of the primary Benefits of Machining Parts from Billet is the exceptional strength and structural integrity of the finished components. Unlike cast parts, which may contain porosity or inclusions, billet-machined parts maintain the consistent grain structure of the original material.

Billet Strength Advantages

- Uniform, non-directional grain structure throughout the part

- Higher tensile strength and improved fatigue resistance

- Absence of internal voids or porosity that can create weak points

- Consistent mechanical properties from part to part

- Superior performance under high stress and load conditions

Cast Part Limitations

- Potential for porosity and inclusions during casting process

- Inconsistent material density throughout the part

- Lower tensile strength compared to billet-machined parts

- Reduced fatigue resistance under cyclic loading

- Greater part-to-part variation in mechanical properties

Need High-Strength Custom Parts?

MAIKONG’s precision CNC machining services deliver superior strength and consistency for your most demanding applications.

Discuss Your Project

Unmatched Precision and Dimensional Accuracy

When comparing manufacturing methods, the precision Benefits of Machining Parts from Billet are unmatched. Modern CNC technology allows for extremely tight tolerances that simply aren’t possible with casting or even many forging operations.

Achieving Exceptional Tolerances

MAIKONG’s advanced CNC machining centers can consistently achieve tolerances as tight as ±0.0005 inches (0.0127mm). This level of precision is critical for components in aerospace, medical devices, and high-performance engines where even minor dimensional variations can impact functionality.

| Manufacturing Method |

Typical Tolerances |

Surface Finish |

Dimensional Consistency |

| Billet CNC Machining |

±0.0005″ to ±0.001″ |

16-32 RMS |

Excellent |

| Die Casting |

±0.002″ to ±0.005″ |

63-125 RMS |

Good |

| Sand Casting |

±0.015″ to ±0.030″ |

250-500 RMS |

Fair |

| Forging |

±0.005″ to ±0.015″ |

125-250 RMS |

Good |

Material Selection Flexibility and Performance

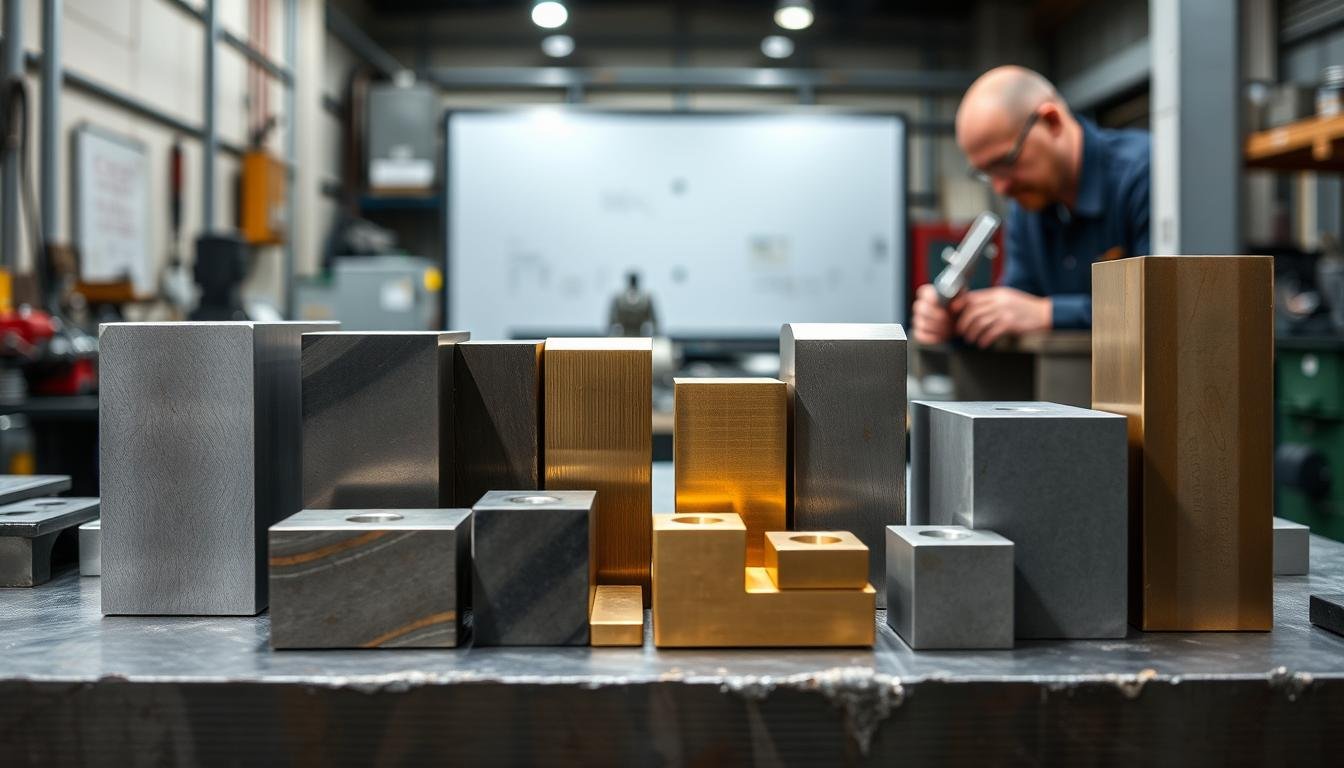

Another significant advantage in the Benefits of Machining Parts from Billet is the wide range of material options available. Unlike casting, which may be limited by mold requirements, or forging, which requires specific material properties, billet machining can work with virtually any machinable material.

Materials Optimized for Your Application

Aluminum Alloys

From aircraft-grade 7075 to corrosion-resistant 6061, aluminum billets offer excellent strength-to-weight ratios and machinability.

Steel & Stainless Steel

From tool steels to 316L stainless, steel billets provide exceptional strength, heat resistance, and durability for demanding applications.

Specialty Materials

Titanium, brass, copper, and engineering plastics can all be precision machined from billet for specialized performance requirements.

At MAIKONG, we maintain extensive inventory of premium-grade materials and conduct rigorous testing to ensure every billet meets specifications before machining begins. This quality control process is essential for producing consistent, high-performance parts.

Need Guidance on Material Selection?

Our engineering team can help you select the optimal material for your application requirements.

Contact Our Materials Experts

Design Flexibility and Customization

Unlimited Design Possibilities with Billet Machining

The design flexibility Benefits of Machining Parts from Billet extend far beyond what’s possible with other manufacturing methods. Without the constraints of molds or dies, engineers can create complex geometries, internal features, and precise details that would be impossible to cast or forge.

Complex Internal Features

Modern multi-axis CNC machines can create intricate internal passages, undercuts, and features that would require multiple operations or be impossible with other methods.

Rapid Design Iterations

Without tooling costs, design changes can be implemented quickly. This makes billet machining ideal for prototyping and low-volume production where designs may evolve.

“The ability to machine complex geometries from a single piece of material eliminates weak points from joints and fasteners, creating parts with superior structural integrity for critical applications.”

– MAIKONG Engineering Team

Billet vs. Cast vs. Forged: A Comprehensive Comparison

Understanding the full spectrum of Benefits of Machining Parts from Billet requires comparing it to alternative manufacturing methods. Each approach has distinct advantages and limitations that make it suitable for different applications.

| Comparison Factor |

Billet Machining |

Casting |

Forging |

| Material Strength |

Excellent – Preserves original material properties |

Fair – Potential for porosity and inclusions |

Excellent – Enhanced grain structure |

| Dimensional Accuracy |

Excellent (±0.0005″) |

Fair to Good (±0.005″) |

Good (±0.010″) |

| Surface Finish |

Excellent |

Fair |

Good (requires machining) |

| Complex Geometries |

Excellent for external features, good for internal |

Excellent for complex internal geometries |

Limited by die design |

| Material Waste |

Higher (subtractive process) |

Low |

Low to moderate |

| Production Volume |

Ideal for low to medium volumes |

Ideal for high volumes |

Ideal for medium to high volumes |

| Tooling Cost |

Low (standard tooling) |

Moderate to high (molds required) |

High (dies required) |

| Lead Time |

Short |

Moderate (mold creation) |

Long (die creation) |

When to Choose Billet Machining

The Benefits of Machining Parts from Billet make it the ideal choice for:

- High-precision components with tight tolerances

- Parts requiring superior strength and material integrity

- Low to medium production volumes

- Applications where design flexibility is critical

- Projects requiring rapid prototyping or iterations

- Components with complex external geometries

Industry Applications for Billet-Machined Parts

Aerospace and Defense

The aerospace industry relies heavily on the Benefits of Machining Parts from Billet for critical components. The exceptional strength-to-weight ratio, material traceability, and precision of billet-machined parts make them ideal for structural components, engine parts, and control systems where failure is not an option.

Automotive Performance

High-performance automotive applications benefit from billet-machined components that can withstand extreme conditions. Engine blocks, cylinder heads, connecting rods, and suspension components machined from billet deliver superior strength and reliability for racing and premium vehicles.

Medical and Precision Instruments

The medical industry demands the highest levels of precision and material purity. Surgical instruments, implantable devices, and diagnostic equipment benefit from the controlled material properties and exceptional finish quality of billet-machined components.

Specialized in Your Industry?

MAIKONG has experience across multiple industries. Let us bring our expertise to your specific application.

Email Our Industry Specialists

MAIKONG’s Advanced Billet Machining Capabilities

At MAIKONG, we’ve invested in state-of-the-art equipment and expert personnel to deliver the full Benefits of Machining Parts from Billet to our customers. Our comprehensive capabilities ensure we can meet your most demanding requirements.

CNC Turning Services

Our advanced CNC turning centers create precise cylindrical parts with superior surface finishes. Ideal for shafts, bushings, and cylindrical components with tight tolerances.

CNC Milling Services

Multi-axis CNC milling machines produce complex prismatic shapes and flat surfaces with exceptional accuracy. Perfect for housings, brackets, and structural components.

Swiss-Type Machining

Specialized in precision small parts and long shaft components. Our dual-spindle, multi-axis Swiss machines deliver one-stop solutions for intricate parts.

Quality Assurance and Certification

Every part we produce undergoes rigorous inspection using advanced metrology equipment. Our quality management system ensures consistent adherence to specifications and industry standards.

MAIKONG by the Numbers:

- 60+ CNC machines with latest technology

- 100+ tons monthly metal processing capacity

- Tolerances as tight as ±0.0005 inches

- ISO 9001:2015 certified quality management system

- Comprehensive in-house testing laboratory

Experience the Superior Benefits of Machining Parts from Billet

From aerospace to automotive, medical to industrial applications, billet-machined parts deliver the precision, strength, and reliability that modern engineering demands. MAIKONG combines advanced technology, material expertise, and manufacturing excellence to bring these benefits to your projects.

Our commitment to quality, competitive pricing, and customer satisfaction has made us a trusted partner for companies across the United States seeking high-performance custom machined components.

Ready to Discuss Your Project?

Contact MAIKONG today to learn how our billet machining expertise can benefit your next project. We’re currently seeking distribution partners across the United States.