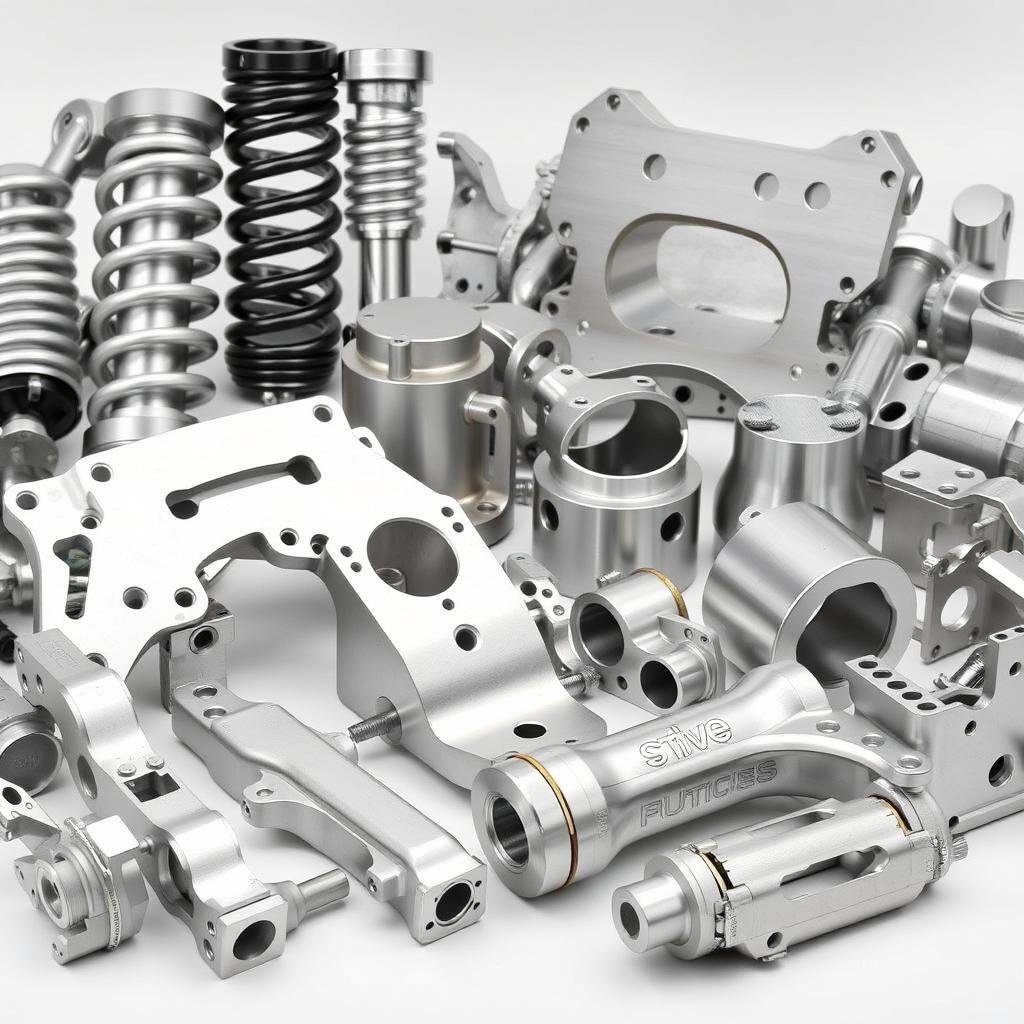

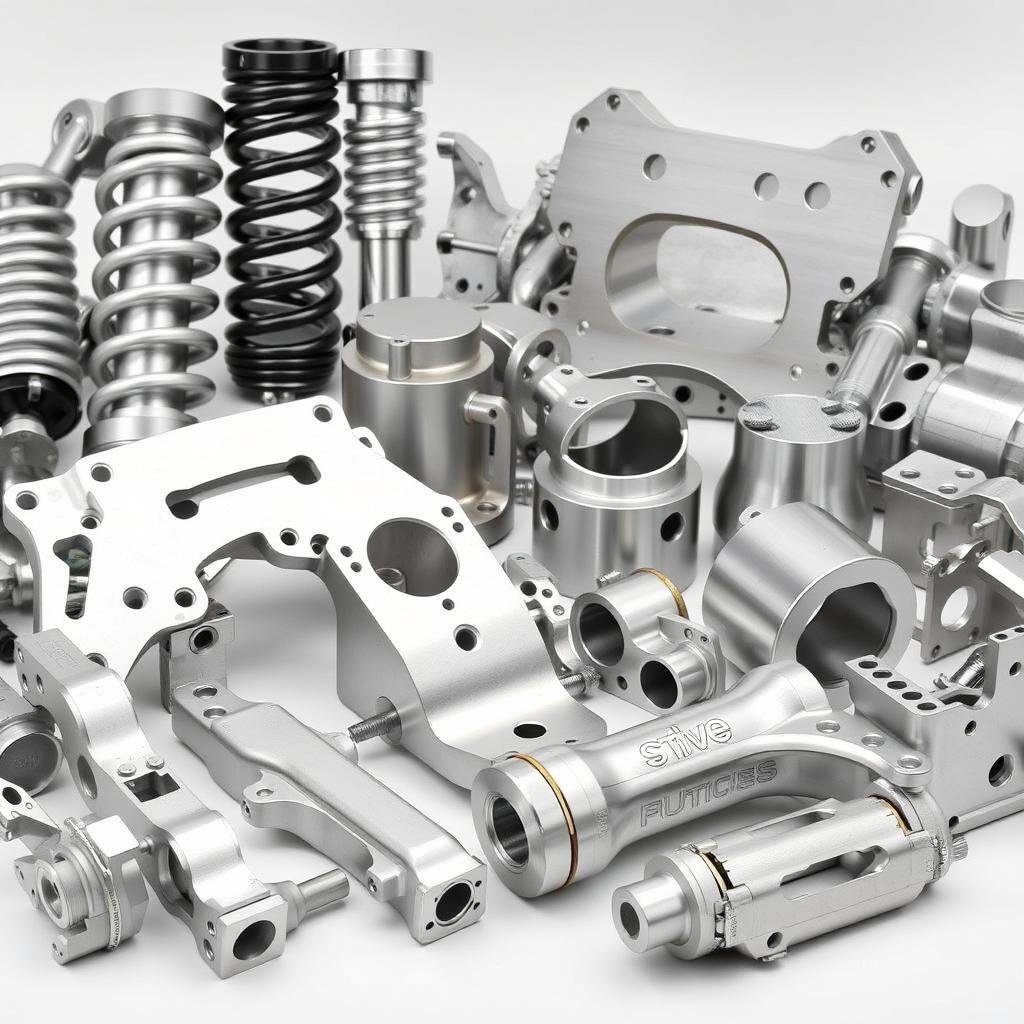

Welcome to MAIKONG, your trusted partner for premium Wholesale Aluminum Forged Products with unmatched quality and competitive pricing. With over 20 years of expertise in aluminum forging and CNC machining, we deliver precision-engineered components that meet the most demanding specifications across aerospace, automotive, and industrial applications. Our state-of-the-art facility in GD, SZ combines advanced technology with metallurgical expertise to provide superior aluminum forgings with exceptional strength-to-weight ratios.

Comprehensive Wholesale Aluminum Forged Products Manufacturing Capabilities

At MAIKONG, we specialize in delivering superior aluminum forgings through our comprehensive manufacturing processes. Our facility in GD, SZ houses state-of-the-art equipment that enables us to produce high-quality components with precision and consistency.

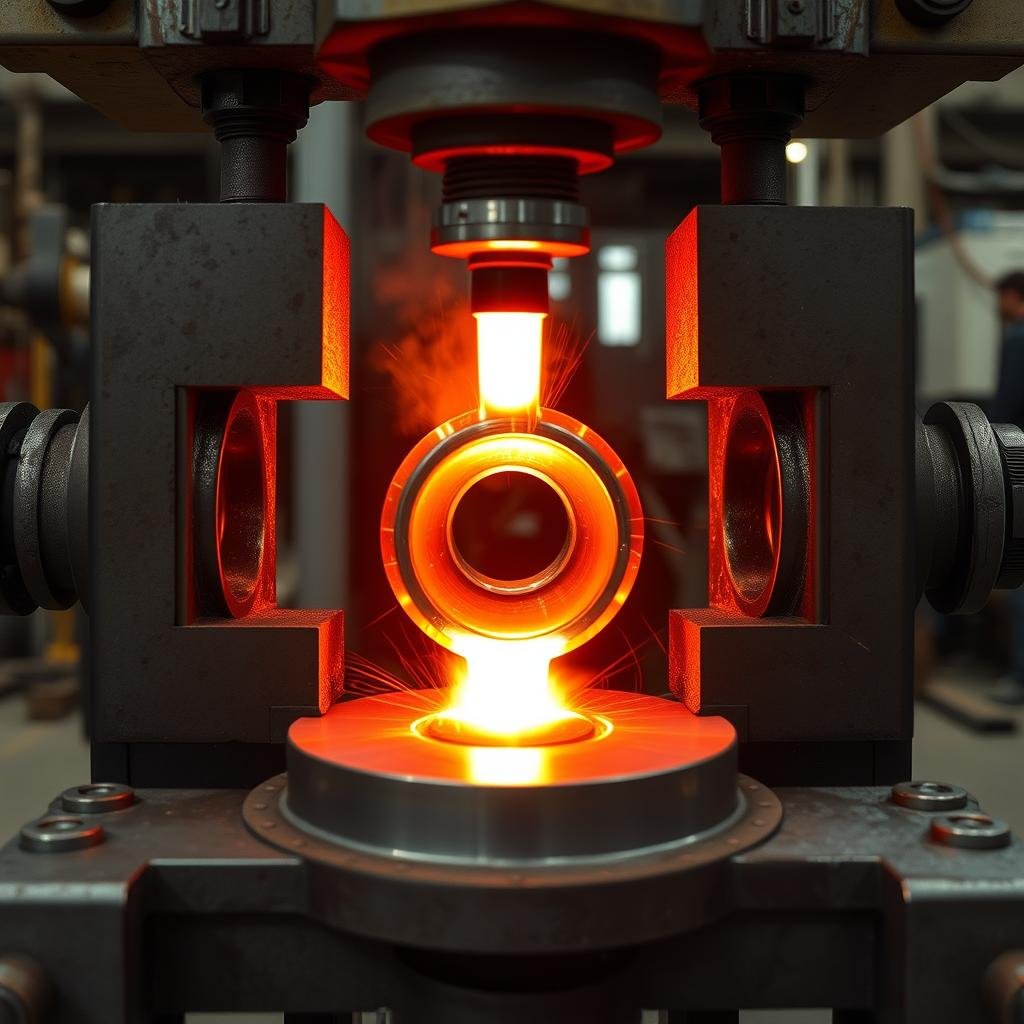

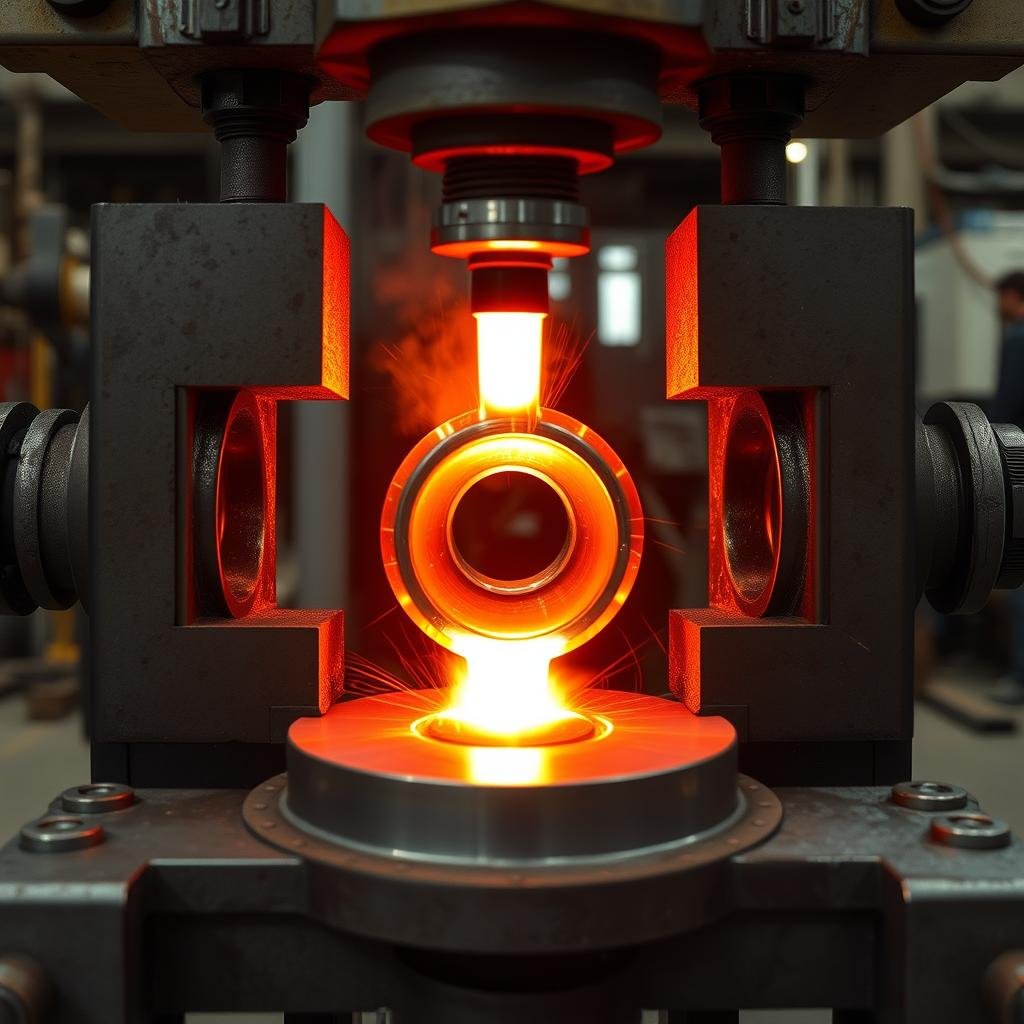

Open Die Forging

Our open die forging capabilities allow for the production of large, simple-shaped aluminum components with superior grain structure and mechanical properties. Ideal for aerospace and heavy industrial applications.

Closed Die Forging

Our precision closed die forging process creates complex aluminum components with tight tolerances and excellent surface finish. Perfect for automotive, aerospace, and precision mechanical applications.

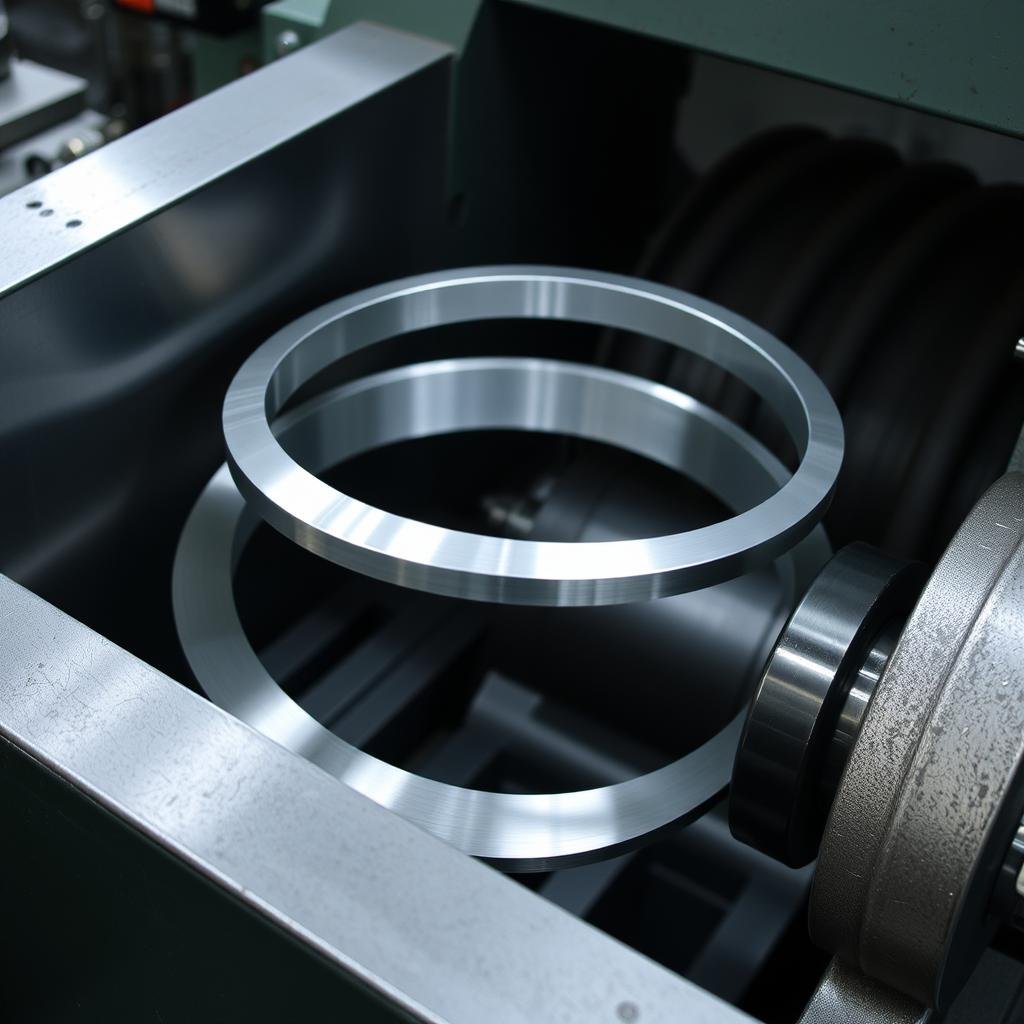

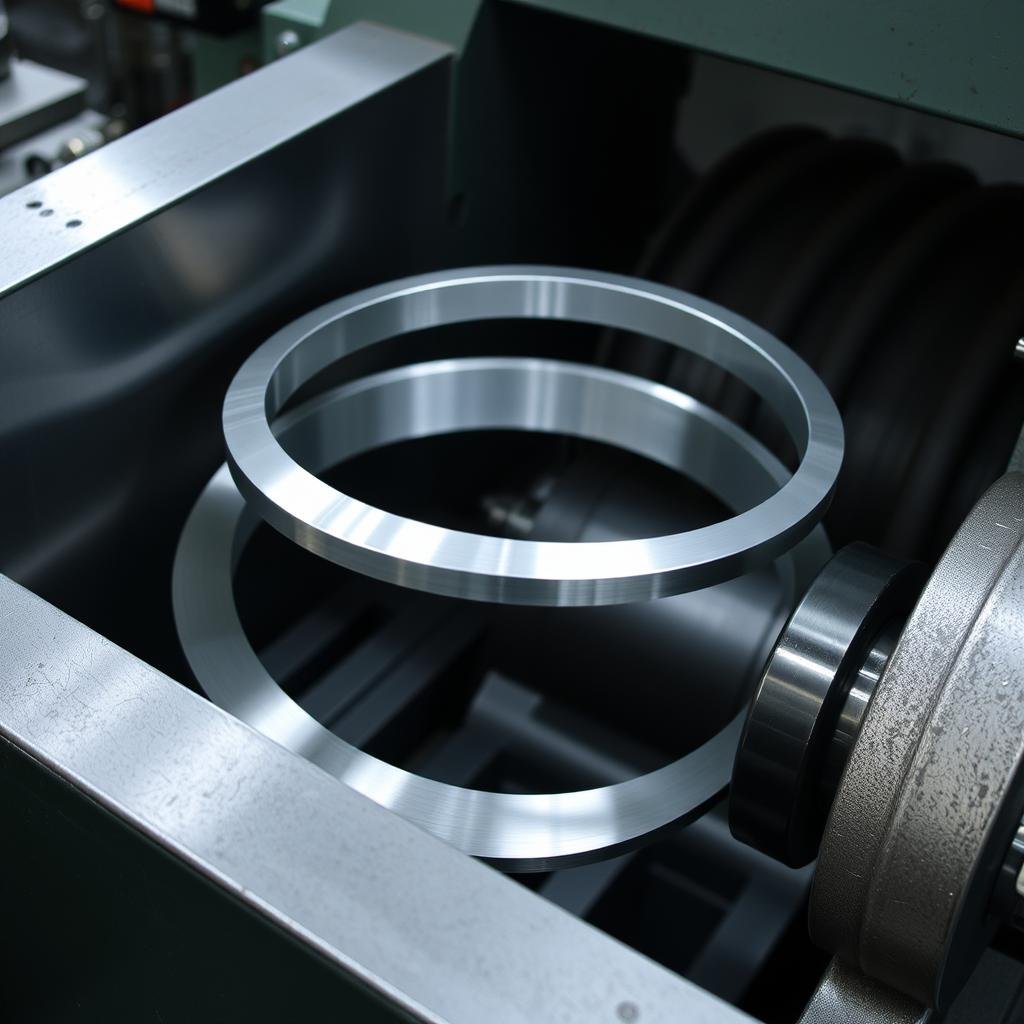

Ring Rolling

Specialized in producing seamless aluminum rings with diameters from 3″ to 72″ (76mm – 1,830mm) and weights up to 10,000 lbs. Ideal for aerospace, energy, and industrial applications.

Ready to Discuss Your Aluminum Forging Requirements?

Our engineering team is available to review your specifications and provide expert guidance on material selection, design optimization, and cost-effective manufacturing solutions.

Get A Quick Quote

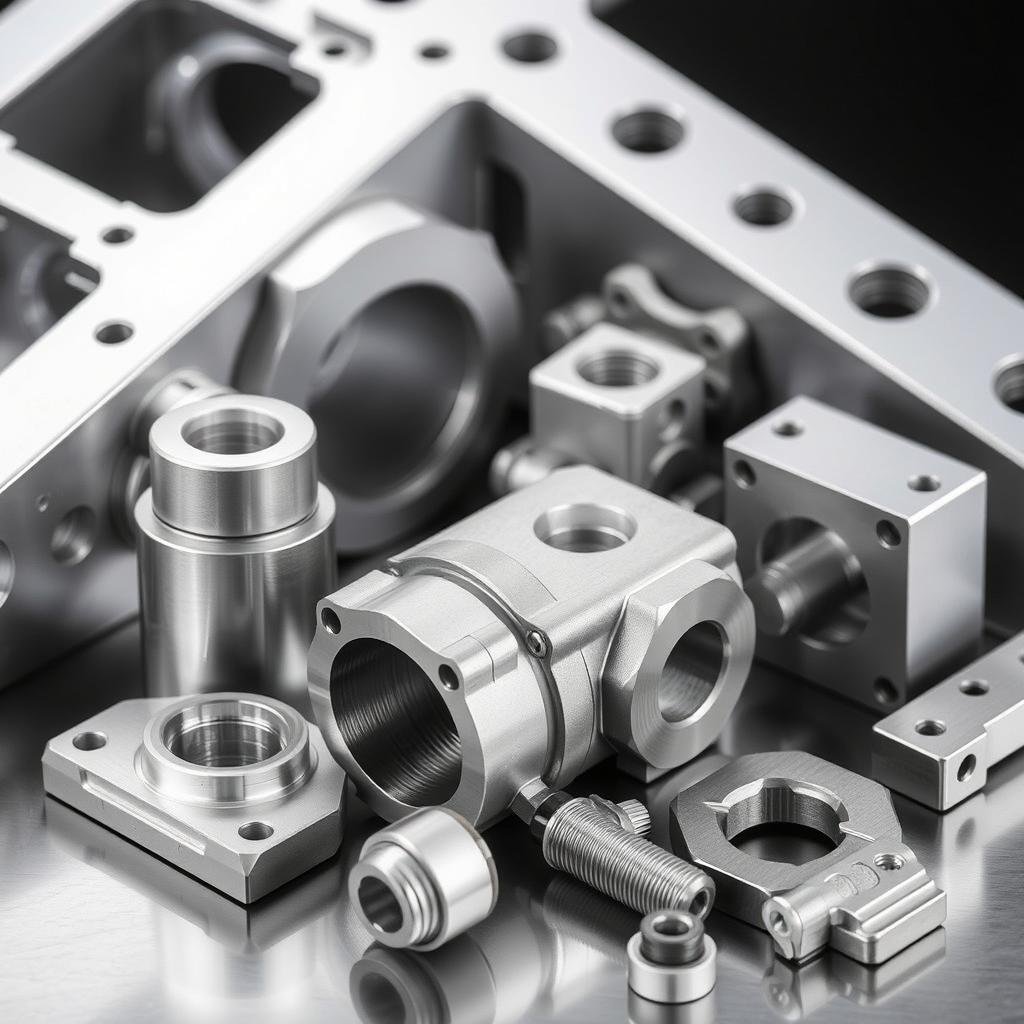

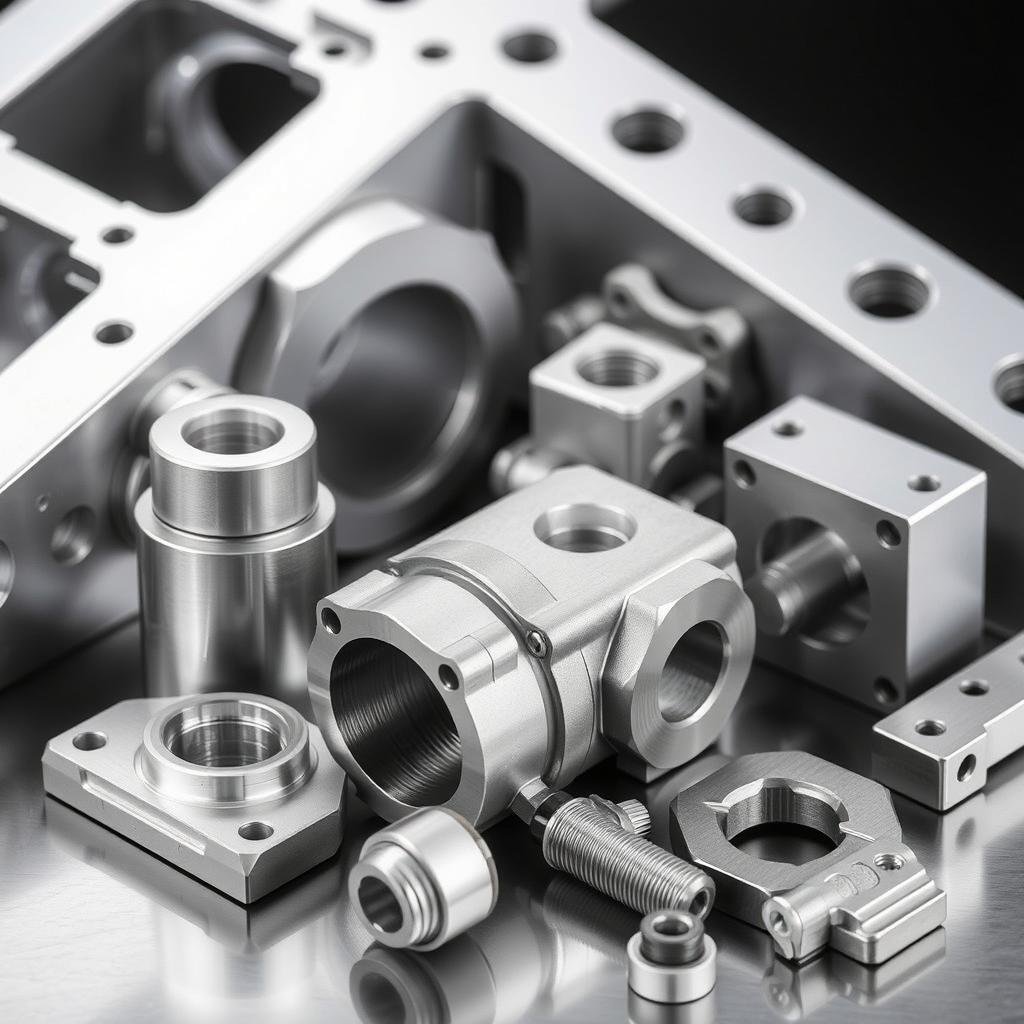

Advanced CNC Machining for Wholesale Aluminum Forged Products

MAIKONG offers comprehensive CNC machining services to complement our aluminum forging capabilities. With 60+ CNC machines and 100+ tons of monthly metal processing capacity, we provide end-to-end solutions from forging to precision finishing.

CNC Turning Services

Our CNC turning capabilities deliver precise cylindrical shapes, deep holes, and machined threads with superior surface finishes. Ideal for creating complex profiles on aluminum forged components with fast turnaround times.

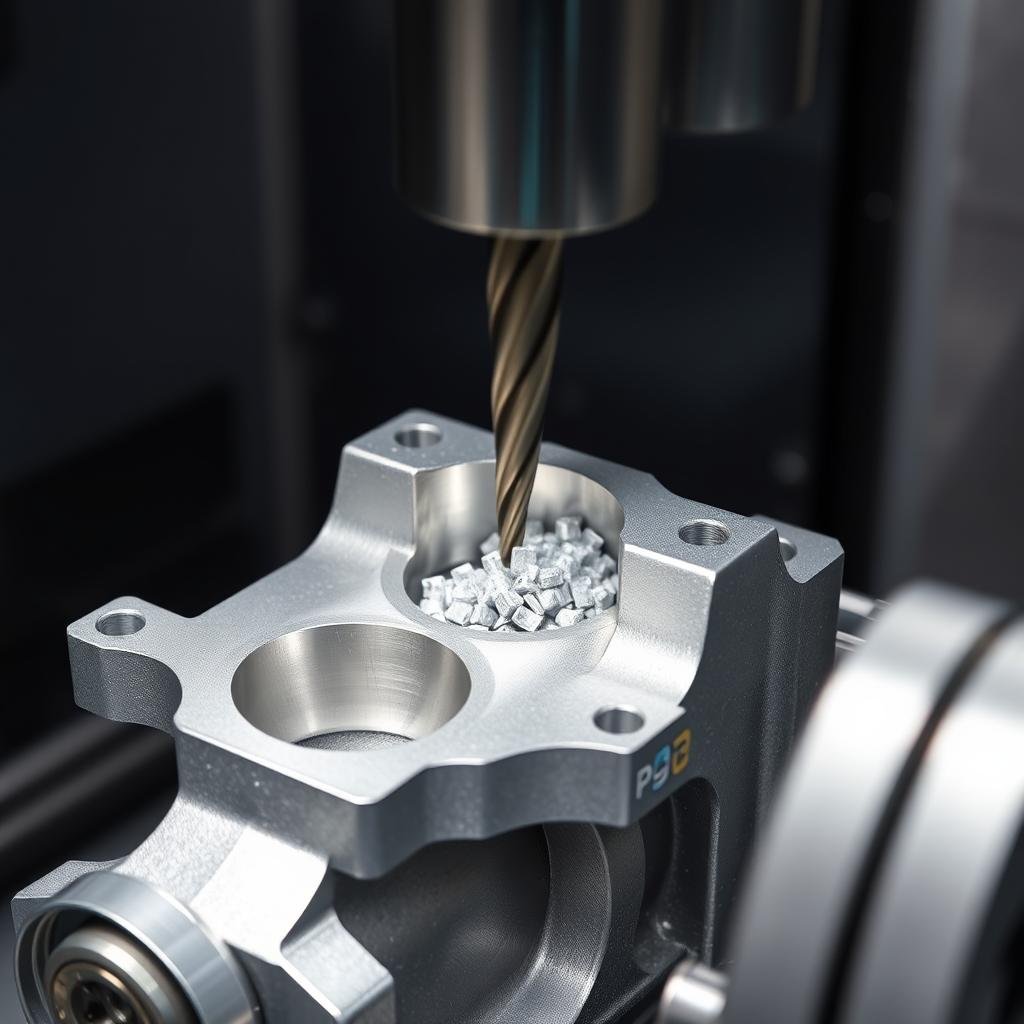

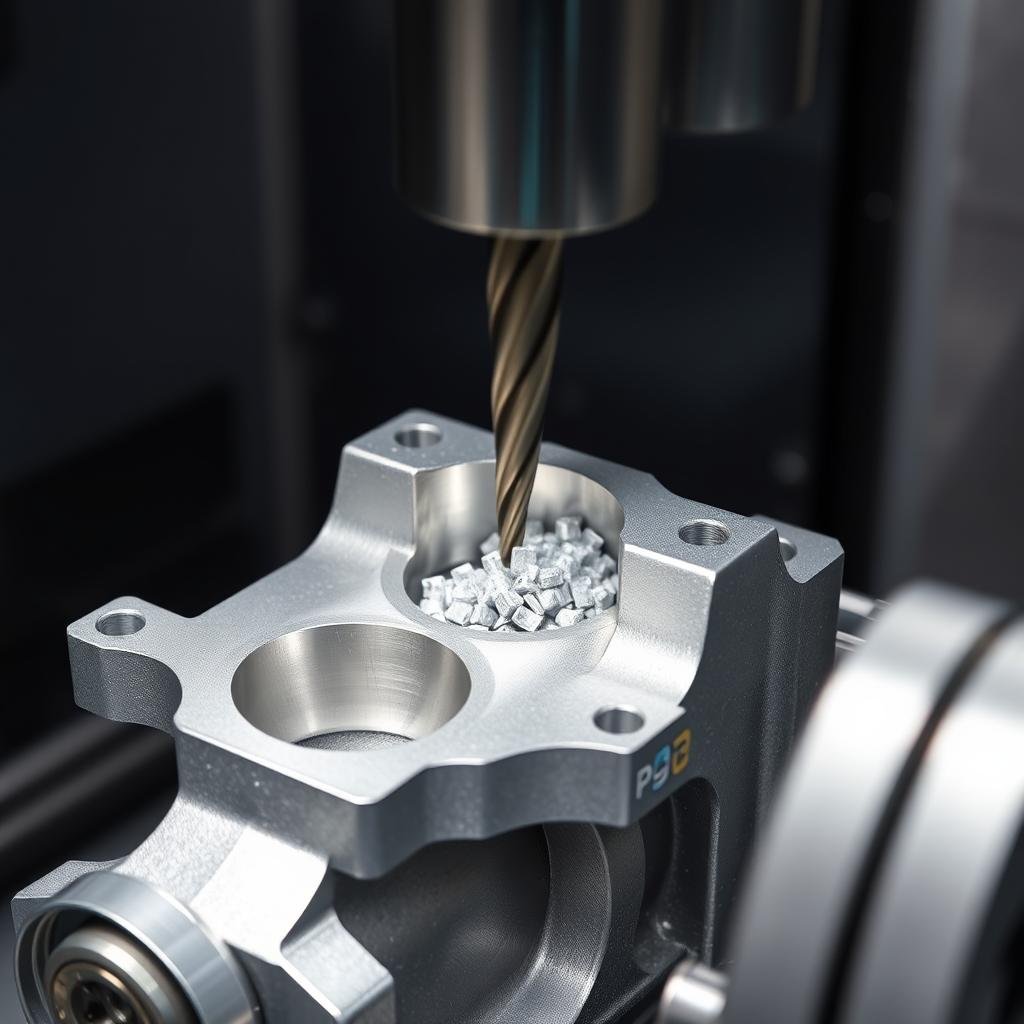

CNC Milling Services

Our multi-axis CNC milling capabilities create complex prismatic shapes and flat surfaces with high precision. No fixed tooling required, offering flexibility and accuracy for your most demanding aluminum components.

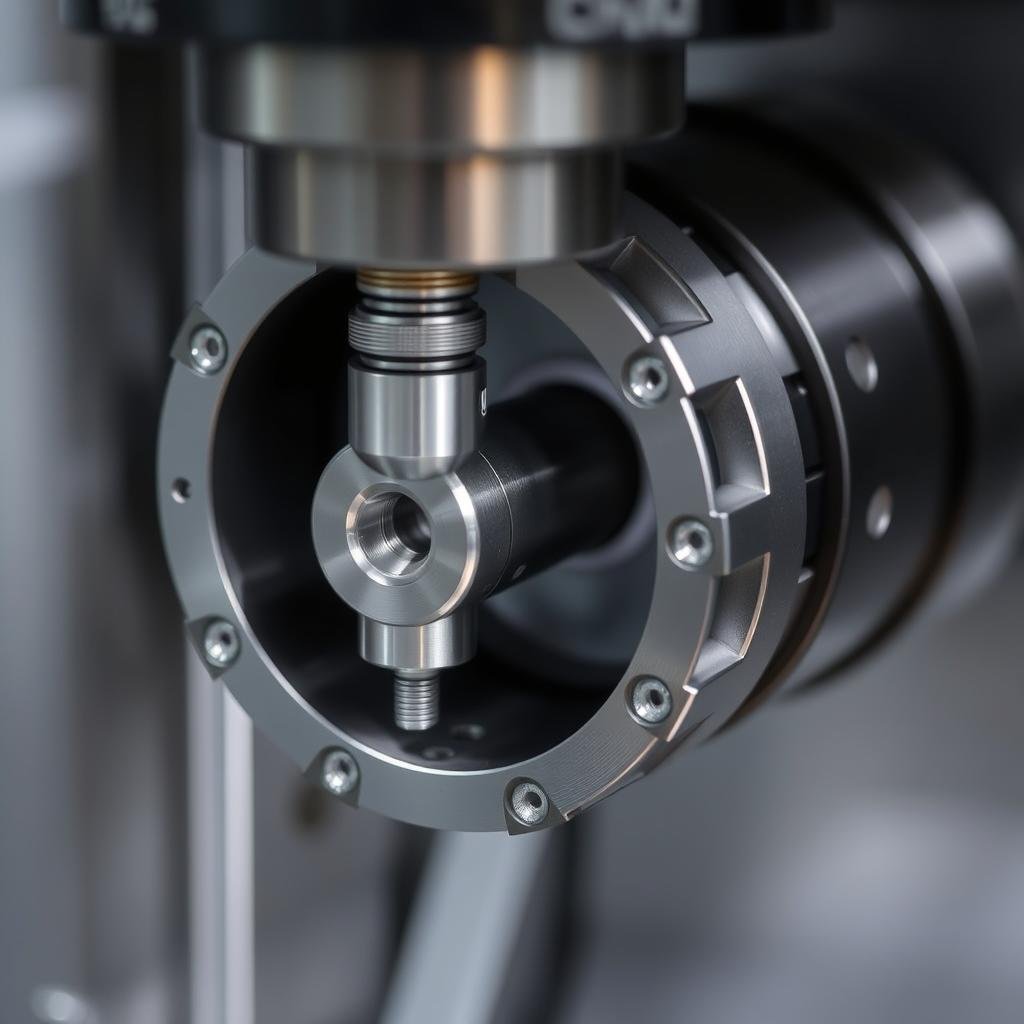

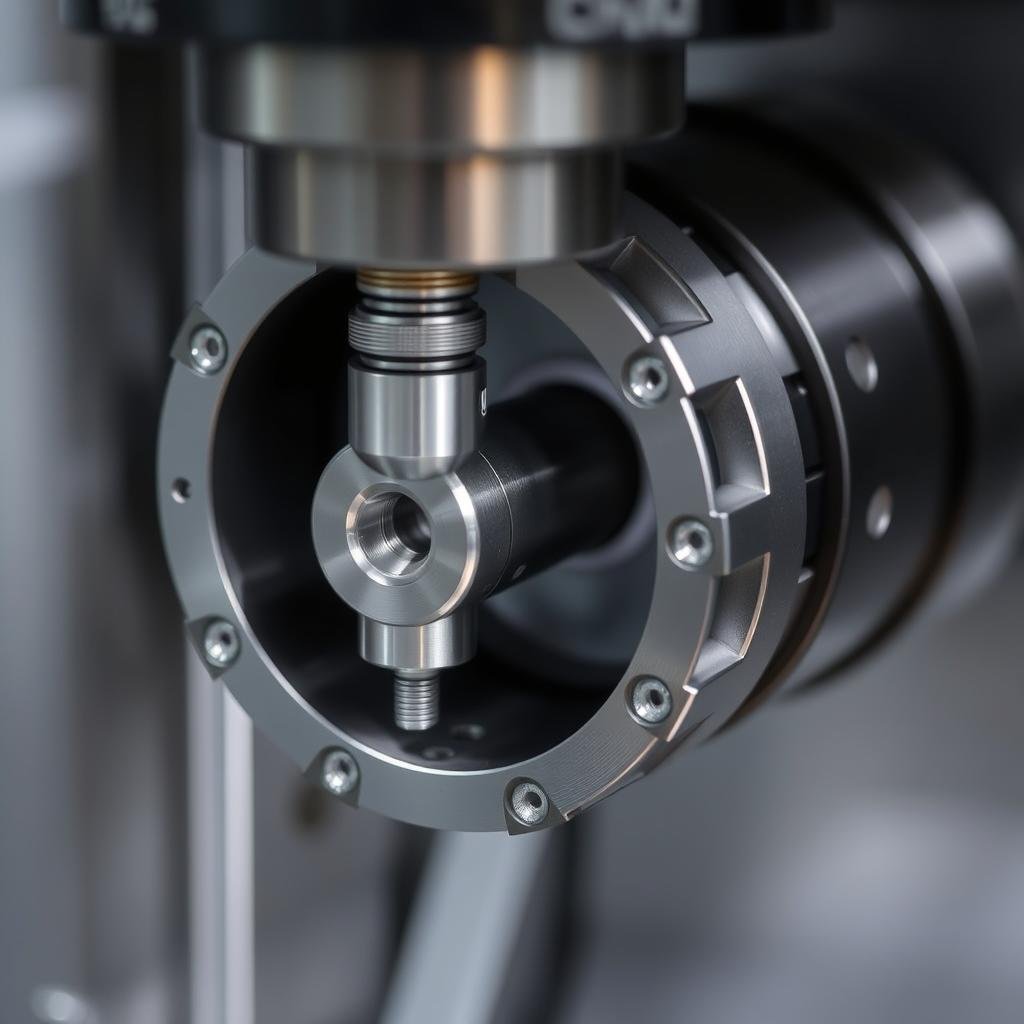

CNC Swiss-Type Machining

Specialized in precision small parts and long shaft components, our Swiss-type machining features dual spindles and multi-axis capabilities. This one-stop solution ensures the highest level of accuracy for your aluminum components.

Need Precision CNC Machining for Your Aluminum Forgings?

Contact our technical team today to discuss your specific requirements and discover how our integrated forging and CNC machining capabilities can deliver superior results.

Contact via WhatsApp

Email Us

Why Choose MAIKONG’s Wholesale Aluminum Forged Products

Aluminum forging offers significant advantages over other manufacturing methods, particularly for applications requiring superior strength, reliability, and performance. At MAIKONG, we’ve perfected the art and science of aluminum forging to deliver components that exceed expectations.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Critical Applications |

✅ Structural members and load-bearing capabilities |

Limited suitability for critical applications |

“The forging process aligns the grain structure of aluminum, significantly enhancing its mechanical properties and making it the ideal choice for applications where performance and safety are critical.”

– MAIKONG Engineering Team

Experience the MAIKONG Difference

Our aluminum forgings deliver superior performance, reliability, and value. Contact us today to discuss how our forging expertise can benefit your applications.

Get A Quick Quote

Premium Aluminum Alloys for Superior Forged Products

At MAIKONG, we work with a comprehensive range of aluminum alloys to meet diverse application requirements. Each alloy offers specific properties optimized for different industries and performance needs.

6061 Aluminum Forging

Excellent corrosion resistance and weldability, ideal for structural applications. Our 6061 forgings offer superior strength-to-weight ratio for automotive, marine, and architectural applications.

7075 Aluminum Forging

Superior strength-to-weight ratio, commonly used in aerospace and automotive industries. Our 7075 forgings deliver exceptional performance for critical, high-stress applications.

2024 Aluminum Forging

High fatigue resistance and excellent strength, best for aerospace components. Our 2024 forgings provide reliable performance in demanding, safety-critical applications.

Need a Custom Aluminum Alloy Solution?

Our metallurgical experts can help you select the optimal aluminum alloy for your specific application requirements.

+86 13510907401

Or email us at: Lucy@maikongforge.us

Industry Applications for Wholesale Aluminum Forged Products

MAIKONG’s aluminum forgings serve diverse industries with specialized requirements. Our components deliver exceptional performance across multiple sectors where reliability, precision, and quality are paramount.

Aerospace Applications

Our aerospace-grade aluminum forgings include structural components, landing gear parts, engine mounts, and fuel system components. These critical parts meet stringent industry standards for performance and reliability.

Automotive Applications

From suspension components to engine parts, our automotive aluminum forgings deliver superior performance, weight reduction, and reliability for standard and high-performance vehicles.

Industrial Applications

Our industrial aluminum forgings include structural connectors, load-bearing joints, hydraulic components, and machinery parts designed for demanding operational environments.

Defense Applications

MAIKONG produces specialized aluminum forgings for defense applications, including vehicle components, weapon mounting systems, and structural elements that meet strict military specifications.

Medical Applications

Our medical-grade aluminum forgings include equipment components, orthopedic device parts, and surgical instrument elements manufactured to exacting standards for safety and reliability.

Energy Applications

From oil and gas equipment to renewable energy systems, our aluminum forgings provide reliable performance in challenging environments where corrosion resistance and strength are critical.

Discover How MAIKONG Can Support Your Industry

Our engineering team specializes in developing custom aluminum forging solutions for specific industry applications. Contact us to discuss your unique requirements.

Get A Quick Quote

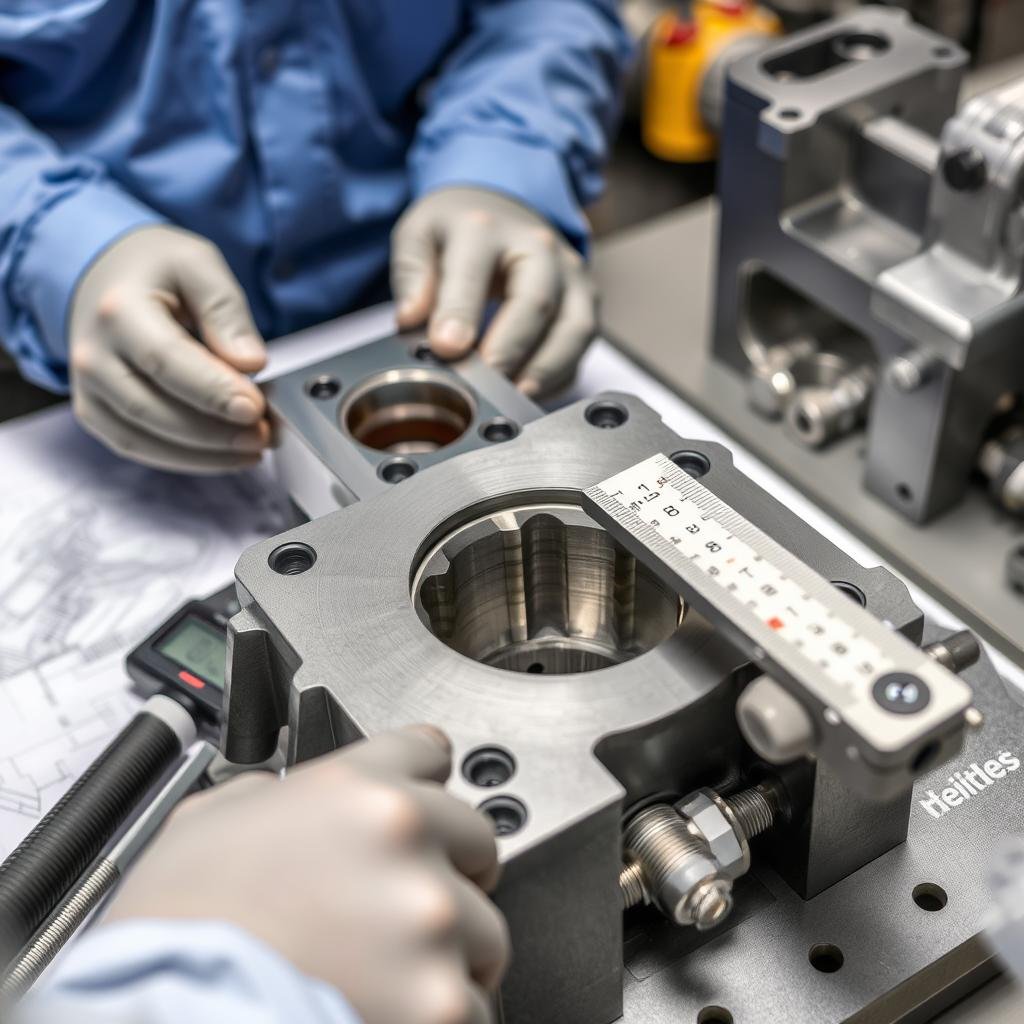

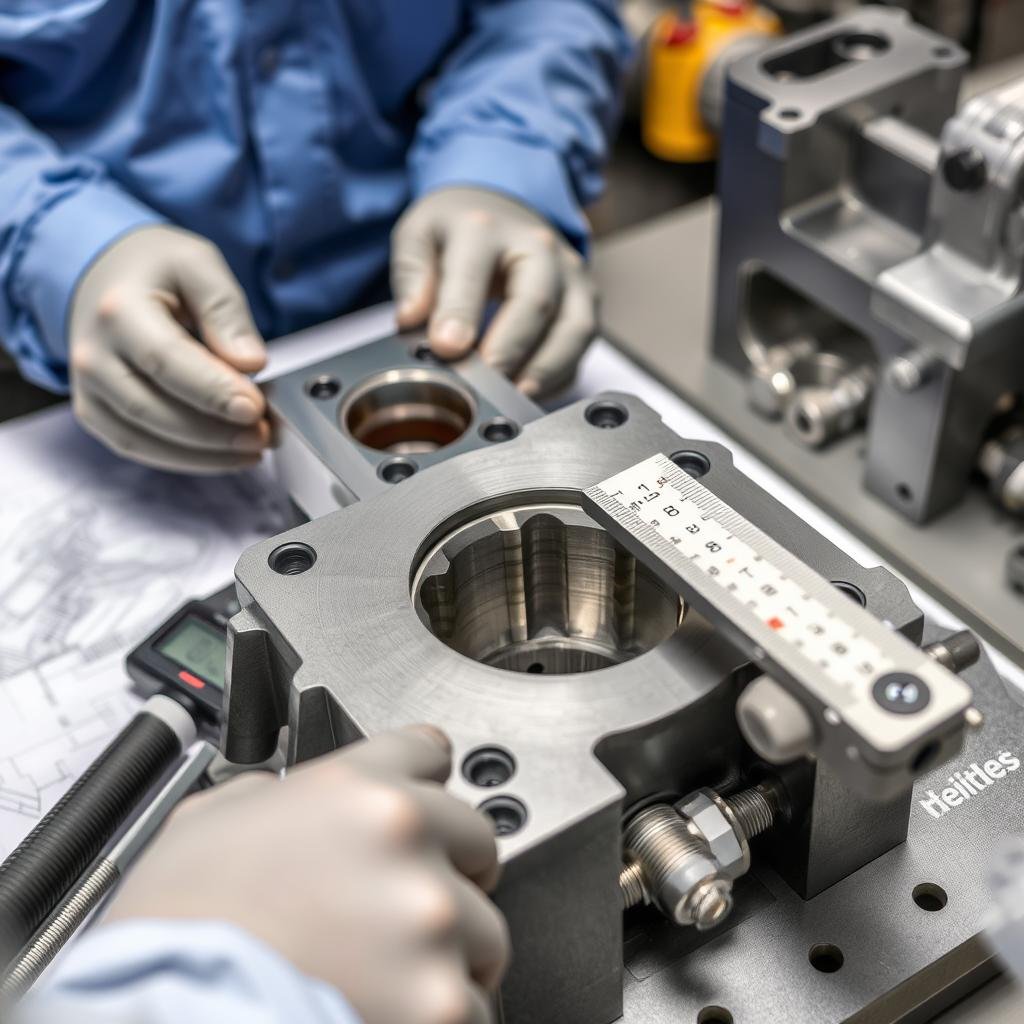

Quality Assurance for Premium Wholesale Aluminum Forged Products

At MAIKONG, quality is the foundation of everything we do. Our comprehensive quality management system ensures that every aluminum forged component meets or exceeds the most demanding specifications and standards.

Our Quality Commitments

- ISO 9001:2015 certified quality management system

- 100% material traceability from raw material to finished product

- Comprehensive testing including chemical analysis, mechanical properties, and dimensional inspection

- Advanced non-destructive testing capabilities including ultrasonic and penetrant testing

- Statistical process control for consistent quality across production runs

- Detailed quality documentation and certification packages

“Quality expresses a component’s capacity for fully satisfying the customer’s needs and expectations. At MAIKONG, we let the numbers speak for themselves through rigorous testing and validation.”

Quality You Can Trust

Experience the MAIKONG difference with aluminum forgings that consistently meet the highest quality standards. Contact us to learn more about our quality assurance processes.

Email Our Quality Team

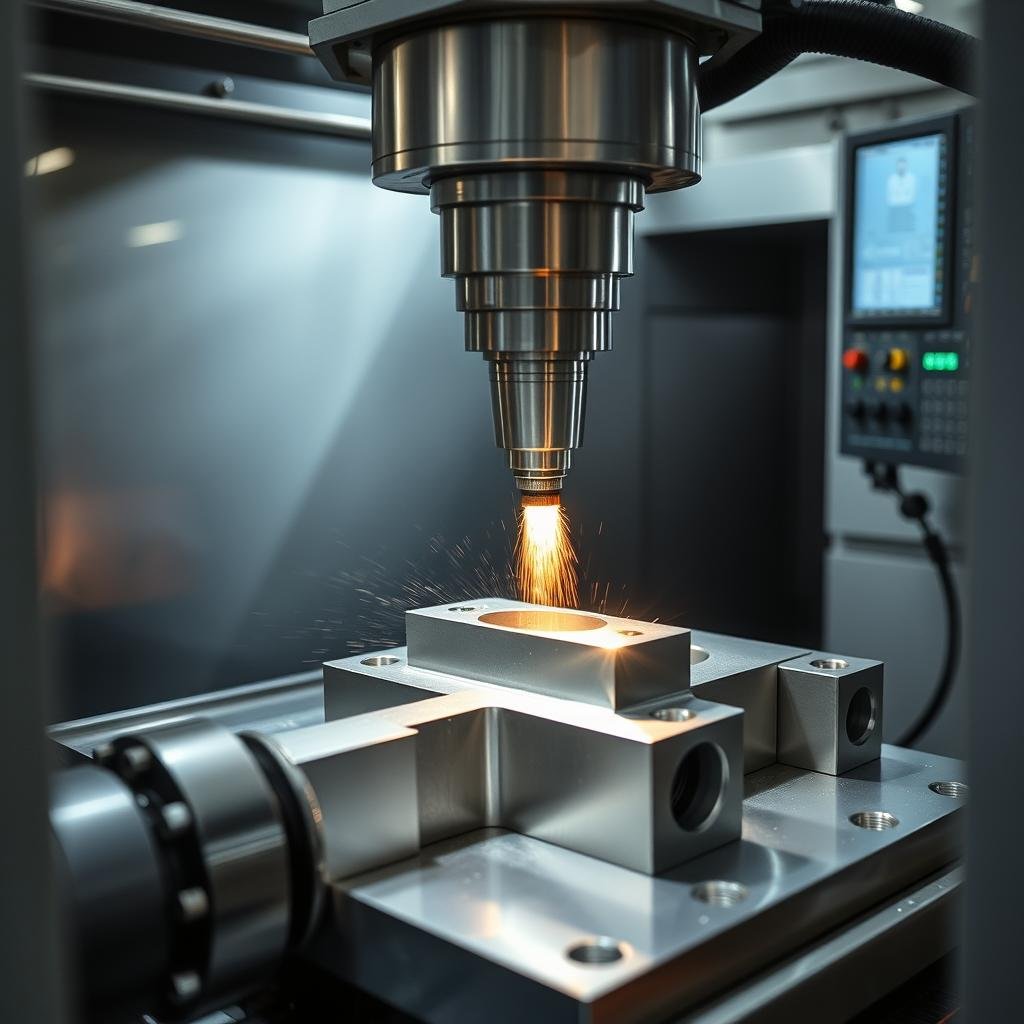

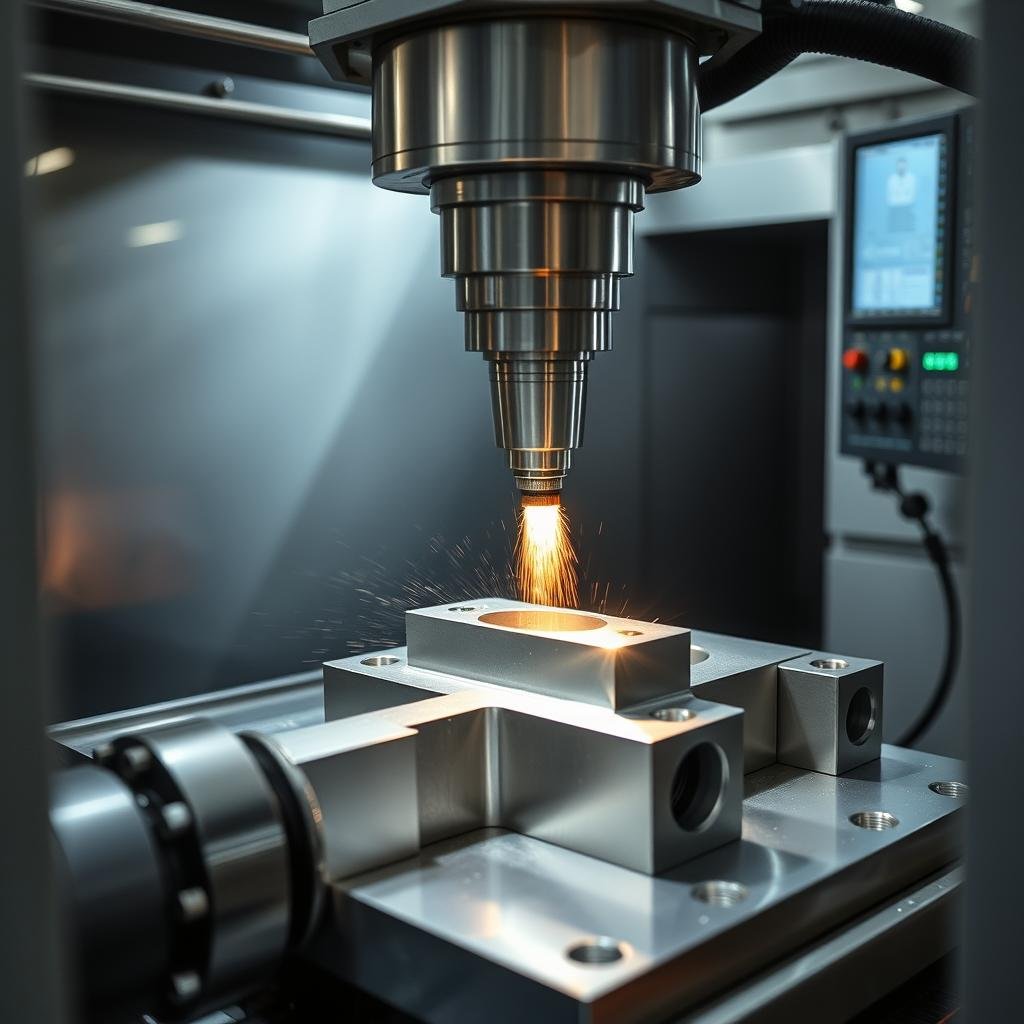

Our Comprehensive Manufacturing Process

MAIKONG’s integrated manufacturing approach ensures quality and consistency at every stage, from initial design to final inspection of your aluminum forged products.

Design & Engineering

Our engineering team collaborates with customers to optimize designs for manufacturability. Using advanced CAD/CAM tools and finite element analysis, we simulate the forging process to predict performance and identify potential issues before production.

Material Selection

We carefully select the optimal aluminum alloy based on mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness for your specific application requirements.

Tooling Design

Our tooling design ensures initial quality, while regular maintenance preserves consistency. Both are critical for producing high-quality aluminum forgings with precise dimensions and excellent surface finish.

Forging Operations

Our forging workshop is equipped to accommodate diverse aluminum forging specifications, from small precision components to large structural parts, with strict process controls to ensure consistency.

Heat Treatment

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment processes, ensuring optimal mechanical properties for each aluminum alloy and application.

Precision Machining

Our machining workshop is equipped with state-of-the-art CNC machines capable of precise and intricate forging machining operations to achieve final dimensions and surface finishes.

Partner with MAIKONG for Your Complete Aluminum Forging Needs

From design to delivery, our integrated manufacturing process ensures quality, consistency, and value for your aluminum forged components.

Get A Quick Quote

Become a US Distributor for MAIKONG’s Premium Aluminum Forgings

MAIKONG is actively seeking distribution partners across the United States to represent our high-quality aluminum forged products. As a MAIKONG distributor, you’ll gain access to our comprehensive product line, competitive pricing, and exceptional technical support.

Distributor Benefits

- Exclusive territorial rights in your region

- Competitive pricing structure with attractive margins

- Comprehensive technical and sales support

- Regular new product introductions

- Co-marketing opportunities and materials

- Dedicated account management

Why Choose MAIKONG for Your Wholesale Aluminum Forged Products

MAIKONG combines advanced manufacturing capabilities, metallurgical expertise, and customer-focused service to deliver superior aluminum forged products for the most demanding applications. With our comprehensive capabilities from forging to precision machining, we provide complete solutions that meet your exact specifications.

The MAIKONG Advantage

- Over 20 years of aluminum forging expertise

- Comprehensive in-house capabilities from forging to finishing

- ISO 9001:2015 certified quality management system

- Advanced metallurgical testing and quality assurance

- Competitive pricing with excellent value

- Responsive technical support and customer service