In today’s engineering landscape, material selection can make or break a project’s success. Aluminum Forged Alloys stand at the forefront of modern manufacturing, offering an exceptional balance of strength, weight, and durability that few materials can match. When precision and performance are non-negotiable, these specialized alloys deliver remarkable mechanical advantages that transform good designs into outstanding ones.At MAIKONG, we’ve perfected the art and science of aluminum forging, creating components that meet the most demanding specifications while maintaining cost-effectiveness. This comprehensive guide explores why Aluminum Forged Alloys deserve serious consideration in your next design project.

Superior Strength-to-Weight Ratio of Aluminum Forged Alloys

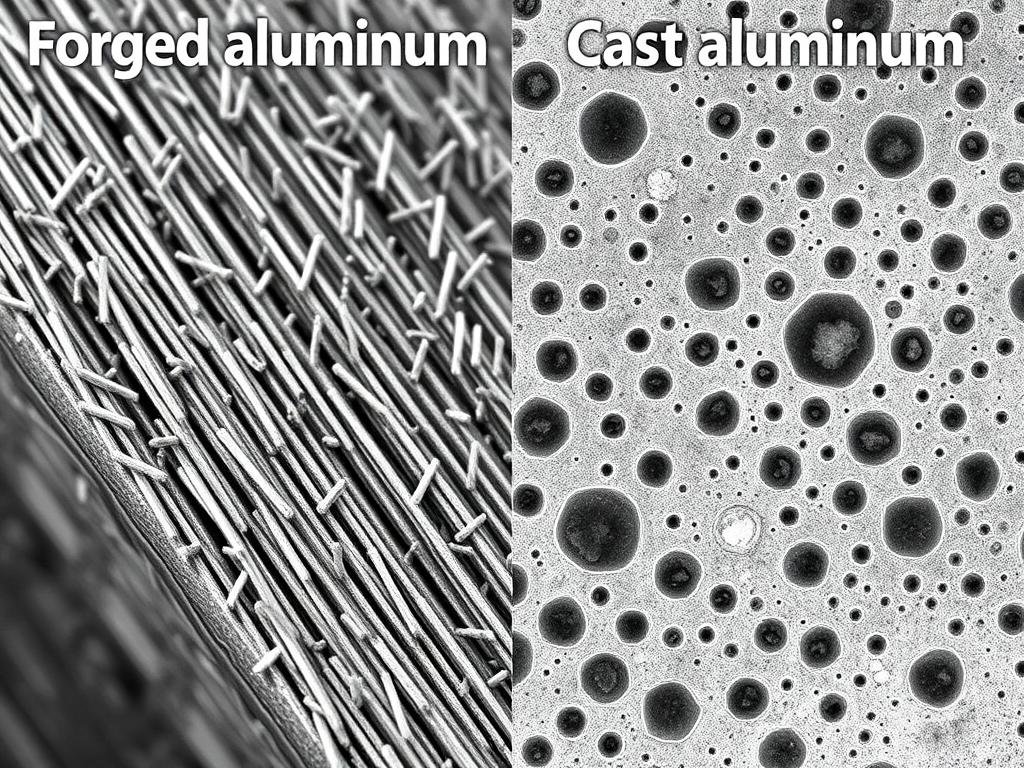

Optimized grain structure in MAIKONG’s forged aluminum components. https://maikongforge.us

The exceptional strength-to-weight ratio of Aluminum Forged Alloys represents a fundamental engineering advantage in applications where both performance and efficiency matter. These specialized alloys deliver remarkable structural integrity while maintaining the lightweight properties that aluminum is known for.

Through the forging process, aluminum’s internal grain structure undergoes significant refinement. This controlled deformation creates a denser, more uniform material with dramatically improved mechanical properties compared to cast or machined alternatives.

Need High-Performance Aluminum Components?

Our engineering team can help you select the optimal aluminum alloy for your specific application requirements.

Get Expert Advice

The forging process aligns the grain flow with the part geometry, creating a stronger, more resilient structure that can withstand higher stress levels. This alignment is particularly valuable in applications subject to dynamic loading, where fatigue resistance becomes critical to long-term performance.

Aluminum Forged Alloys vs. Cast Aluminum: A Comprehensive Comparison

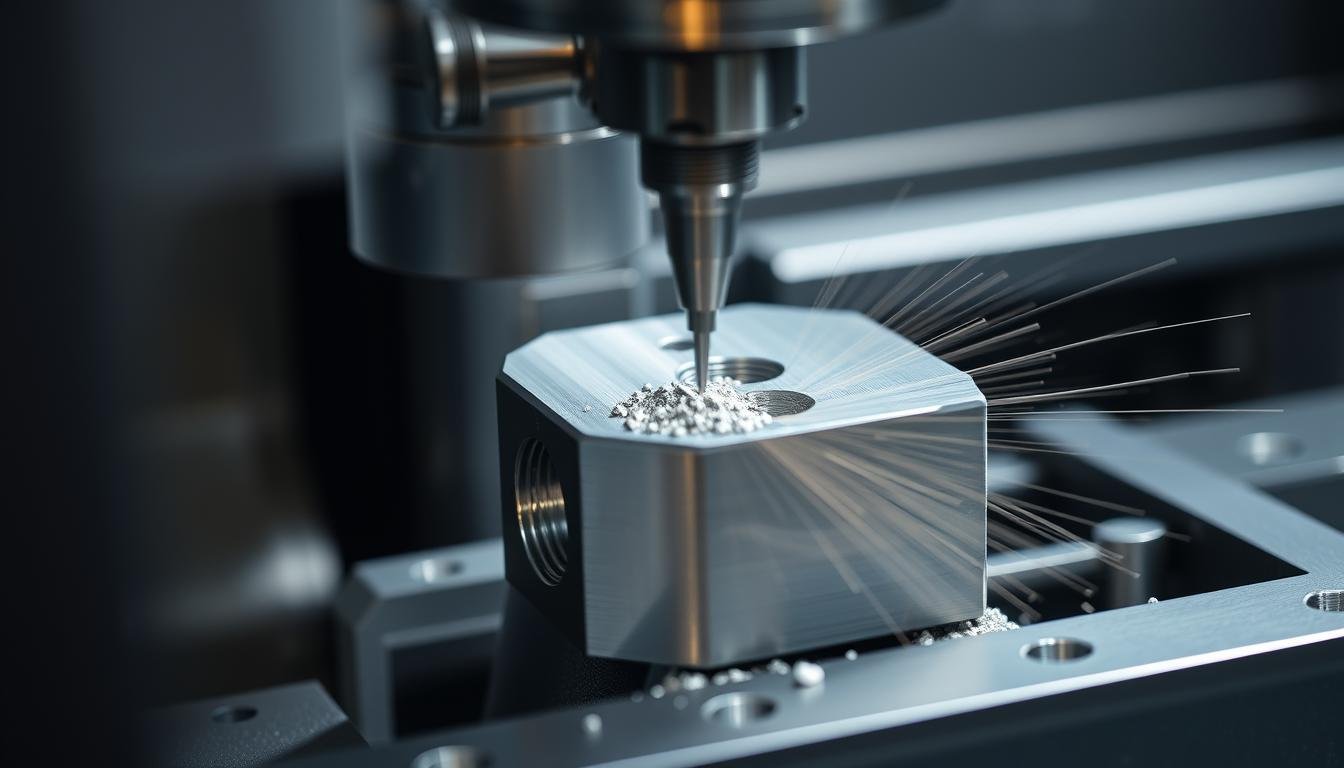

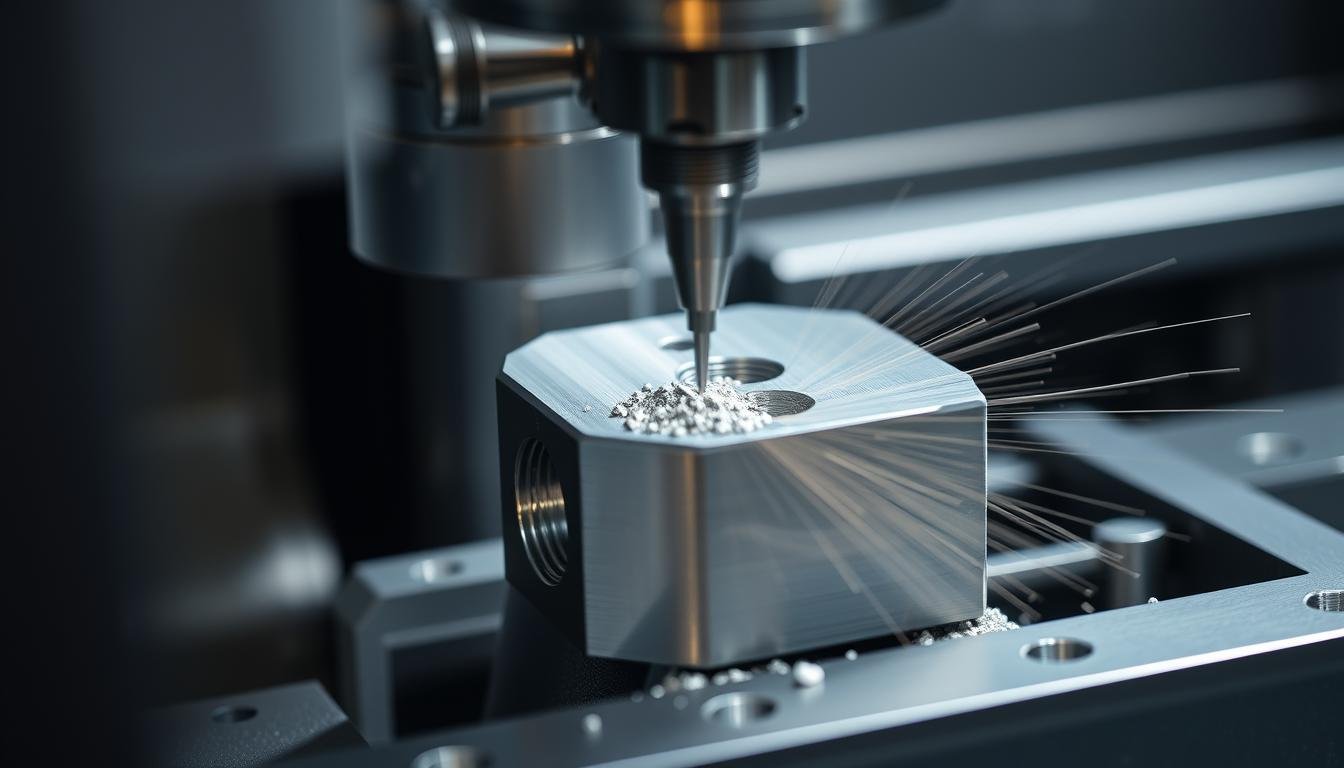

Microstructure comparison: Forged aluminum (left) vs. cast aluminum (right). https://maikongforge.us

Understanding the fundamental differences between forged and cast aluminum is essential when selecting materials for critical applications. While both methods have their place in manufacturing, the mechanical properties achieved through forging offer distinct advantages for components that must withstand significant stress.

| Comparison Categories |

Aluminum Forged Alloys |

Cast Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Heat Treatment Response |

✅ Responsive for controlled material properties |

Less predictable response |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed |

The superior mechanical properties of Aluminum Forged Alloys make them the preferred choice for applications where reliability, durability, and performance are critical. While casting offers advantages in creating complex geometries, the structural integrity of forged components provides greater confidence in demanding environments.

The MAIKONG Aluminum Forging Process

MAIKONG’s state-of-the-art aluminum forging facility. https://maikongforge.us

At MAIKONG, our aluminum forging process represents the culmination of decades of metallurgical expertise and precision engineering. We’ve refined each step to ensure optimal grain structure, dimensional accuracy, and mechanical properties in every component we produce.

Integrated CAD/CAM Design for Aluminum Forged Alloys

Our process begins with sophisticated CAD/CAM design, where our engineering team collaborates closely with clients to develop optimized forging solutions. Using advanced simulation tools, we can identify potential issues early and refine designs before production begins.

Material Selection

We carefully select premium aluminum alloys based on your specific application requirements, considering factors such as:

- Mechanical property requirements

- Weight constraints

- Corrosion resistance needs

- Heat treatment compatibility

- Cost considerations

Precision Tooling

Our tooling design ensures initial quality while regular maintenance preserves consistency—both critical for producing high-quality forgings. We invest in premium die materials and precision machining to achieve:

- Tight dimensional tolerances

- Excellent surface finish

- Extended tool life

- Consistent part quality

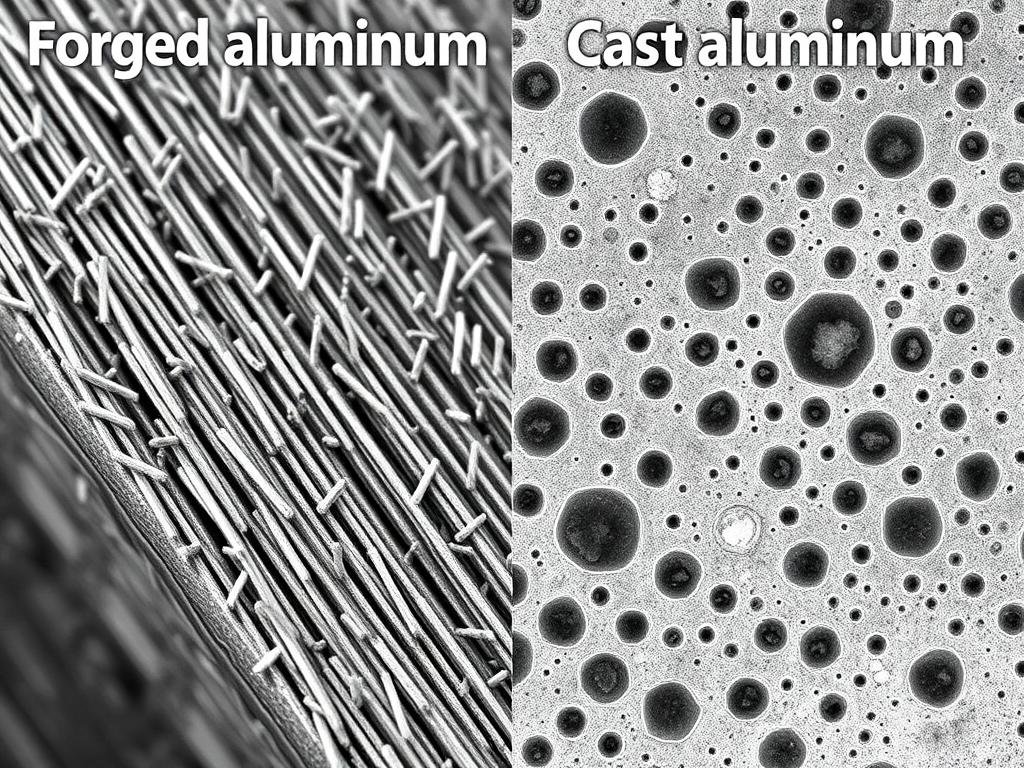

Precision CNC machining of forged aluminum components at MAIKONG. https://maikongforge.us

Heat Treatment and Properties Enhancement

MAIKONG’s controlled atmosphere heat treatment furnace. https://maikongforge.us

Heat treatment represents a critical phase in optimizing the mechanical properties of Aluminum Forged Alloys. At MAIKONG, we conduct comprehensive statistical analysis and documentation for our in-house heat treatment processes, ensuring consistent results that meet or exceed industry standards.

Solution Heat Treatment

Our solution heat treatment process dissolves alloying elements into the aluminum matrix, creating a supersaturated solid solution. This process:

- Homogenizes the microstructure

- Dissolves precipitates

- Prepares the material for aging

- Relieves internal stresses

Precipitation Hardening

Through carefully controlled aging processes, we achieve optimal precipitation hardening, which:

- Significantly increases strength

- Improves hardness

- Enhances wear resistance

- Maintains dimensional stability

Our heat treatment capabilities allow us to tailor the mechanical properties of aluminum components to meet specific application requirements. Whether you need maximum strength, enhanced corrosion resistance, or optimal fatigue performance, our metallurgical expertise ensures the right balance of properties.

Industry Applications for Aluminum Forged Alloys

Precision aerospace components manufactured from aluminum forged alloys. https://maikongforge.us

The exceptional mechanical properties of Aluminum Forged Alloys make them ideal for a wide range of demanding applications across multiple industries. At MAIKONG, we specialize in creating custom forged components that meet the specific requirements of diverse sectors.

Aerospace

- Structural components

- Landing gear parts

- Engine mounts

- Control system components

- Hydraulic fittings

Automotive

- Suspension components

- Engine parts

- Transmission components

- Steering systems

- Performance wheels

Industrial

- Hydraulic components

- Valve bodies

- Pump housings

- Structural connectors

- High-pressure fittings

High-performance automotive components manufactured from aluminum forged alloys. https://maikongforge.us

Medical

- Surgical instrument components

- Imaging equipment structures

- Prosthetic device parts

- Medical device housings

Defense

- Weapons components

- Tactical equipment parts

- Vehicle armor mounts

- Communication device housings

Sports & Recreation

- Bicycle components

- Golf club heads

- Climbing equipment

- High-performance marine parts

The versatility of Aluminum Forged Alloys makes them suitable for virtually any application where strength, weight, and reliability are critical factors. Our engineering team works closely with clients to select the optimal alloy and forging process for each specific use case.

Quality Assurance for Aluminum Forged Components

Rigorous quality control inspection at MAIKONG’s facility. https://maikongforge.us

At MAIKONG, quality is not just a department—it’s a core value embedded in every aspect of our operation. Our comprehensive quality control procedures ensure that every forged component meets stringent standards for dimensional accuracy, material properties, and surface finish.

Our Quality Control Process

Material Verification

We conduct thorough testing of incoming materials to verify chemical composition and mechanical properties, ensuring that only premium-grade aluminum alloys enter our production process.

In-Process Inspection

Throughout the forging and machining processes, our quality technicians perform regular inspections to catch any potential issues before they affect the final product.

Dimensional Verification

Using advanced measurement technologies, including coordinate measuring machines (CMM) and optical scanning, we verify that all components meet precise dimensional specifications.

Mechanical Testing

We regularly perform hardness testing, tensile testing, and other mechanical evaluations to confirm that our forged components deliver the expected performance characteristics.

MAIKONG’s material testing laboratory ensures consistent quality. https://maikongforge.us

Experience Our Quality Difference

Contact us today to discuss your aluminum forging requirements and discover how our quality-focused approach can benefit your projects.

Request a Quote

Call: 8613-51090-74-01

MAIKONG’s Comprehensive Manufacturing Services

Advanced CNC machining capabilities complement our forging expertise. https://maikongforge.us

At MAIKONG, we offer a complete range of manufacturing services that extend well beyond aluminum forging. Our integrated approach allows us to provide end-to-end solutions, from initial design to finished components ready for assembly.

CNC Machining Services

Our state-of-the-art CNC machining center is equipped with advanced multi-axis machines capable of precise and intricate operations on forged components.

- CNC Turning

- CNC Milling

- Swiss-Type Machining

- Multi-Axis Machining

Metal Forging Expertise

Beyond aluminum, we offer comprehensive forging capabilities for a variety of metals to meet diverse application requirements.

- Aluminum Forging

- Steel Forging

- Brass Forging

- Custom Alloy Forging

Surface Treatment

Our surface treatment capabilities enhance both the appearance and performance of forged components for various applications.

- Anodizing

- Painting

- Laser Engraving

- Sand Blasting

With over 60 CNC machines and a monthly metal processing capacity exceeding 100 tons, MAIKONG has the resources and expertise to handle projects of any scale. Our comprehensive capabilities allow us to maintain strict quality control throughout the entire manufacturing process, ensuring consistent results that meet your exact specifications.

Advanced surface treatment processes enhance performance and aesthetics. https://maikongforge.us

Elevate Your Designs with Aluminum Forged Alloys

The mechanical advantages of Aluminum Forged Alloys make them an exceptional choice for applications where performance, reliability, and efficiency are paramount. By partnering with MAIKONG, you gain access to world-class manufacturing capabilities and metallurgical expertise that can transform your designs from concept to reality.

Whether you’re developing aerospace components, automotive parts, medical devices, or industrial equipment, our comprehensive forging and machining services provide the foundation for success. Contact us today to explore how Aluminum Forged Alloys can enhance your next project.