In today’s demanding industrial applications, Aluminum Forging Alloys stand as the pinnacle of metallurgical achievement, offering unmatched strength-to-weight ratios and superior mechanical properties compared to cast alternatives. These specialized alloys undergo intense pressure and precise temperature control during the forging process, creating components with exceptional grain structure, improved fatigue resistance, and remarkable durability. MAIKONG specializes in transforming these premium materials into high-performance components that meet the most stringent industry requirements across aerospace, automotive, defense, and medical sectors.

The Superior Performance of Aluminum Forging Alloys

When engineering demands peak performance, Aluminum Forging Alloys deliver exceptional results through their refined microstructure and enhanced mechanical properties. The forging process aligns the grain structure of aluminum, creating parts with superior strength, durability, and reliability compared to cast alternatives.

Key Benefits of Forged Aluminum

- Superior strength-to-weight ratio

- Enhanced fatigue resistance

- Improved fracture toughness

- Exceptional dimensional stability

- Greater resistance to stress corrosion

- Refined grain structure for consistent performance

- Higher impact and shock resistance

Critical Applications

- Aerospace structural components

- Automotive suspension and engine parts

- Defense and military equipment

- Medical device components

- High-performance sporting equipment

- Marine and offshore applications

- Industrial machinery components

Aluminum Forging vs. Casting: A Comprehensive Comparison

Understanding the fundamental differences between forged and cast aluminum components is essential for making informed engineering decisions. The table below highlights why Aluminum Forging Alloys are preferred for critical applications where performance cannot be compromised.

| Comparison Criteria |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Superior strength due to dense, uniform grain structure |

Lower strength with potential air pockets and inclusions |

| Tensile Properties |

Excellent tensile strength and resistance |

Moderate tensile strength with variability |

| Fatigue Resistance |

Enhanced resistance against cyclic loading |

Lower fatigue resistance and predictability |

| Dimensional Accuracy |

Precise tolerances and consistency |

Potential shrinkage and dimensional variations |

| Surface Finish |

Smoother surfaces with minimal post-processing |

Often requires additional machining |

| Weight-to-Strength Ratio |

Optimized strength-to-weight performance |

Typically requires thicker sections for equivalent strength |

| Engineering Consistency |

Highly controlled material characteristics |

Greater variability between production runs |

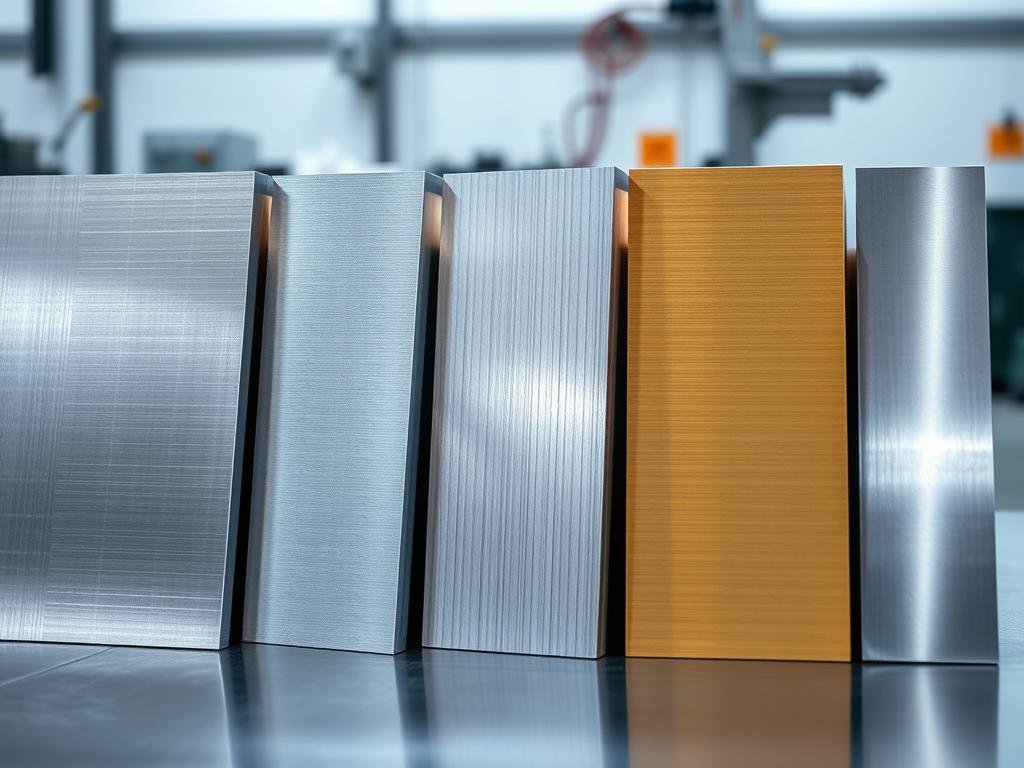

Common Aluminum Forging Alloys and Their Applications

MAIKONG works with a comprehensive range of Aluminum Forging Alloys, each offering specific performance characteristics suited to different applications. Our metallurgical expertise ensures the optimal alloy selection for your specific requirements.

2000 Series Alloys

The 2000 series, particularly 2014 and 2024, offers excellent strength-to-weight ratios and superior fatigue resistance. These copper-containing alloys are widely used in aerospace applications where structural integrity is critical.

- Aircraft structural components

- Aerospace fasteners

- Military equipment

- High-stress mechanical parts

6000 Series Alloys

The 6000 series, including 6061 and 6082, provides an excellent balance of strength, corrosion resistance, and formability. These magnesium and silicon alloys are versatile performers across multiple industries.

- Automotive components

- Marine applications

- Structural engineering

- Consumer products

7000 Series Alloys

The 7000 series, particularly 7075, delivers the highest strength among aluminum alloys. These zinc-containing alloys are chosen for applications where maximum strength and stress resistance are paramount.

- Aerospace structures

- Defense applications

- High-performance equipment

- Competition-grade sporting goods

MAIKONG’s Comprehensive Aluminum Forging Services

At MAIKONG, we deliver end-to-end solutions for aluminum forged components, from initial design consultation through production to finishing and quality assurance. Our state-of-the-art facility in GD, SZ houses over 60 CNC machines with a monthly capacity exceeding 100 tons of precision metal processing.

Design & Engineering

Our engineering team utilizes advanced CAD/CAM software to optimize component design for the forging process. We collaborate closely with clients to ensure designs maximize the inherent advantages of Aluminum Forging Alloys.

- Design optimization for forging

- Material selection consultation

- Finite element analysis

- Prototype development

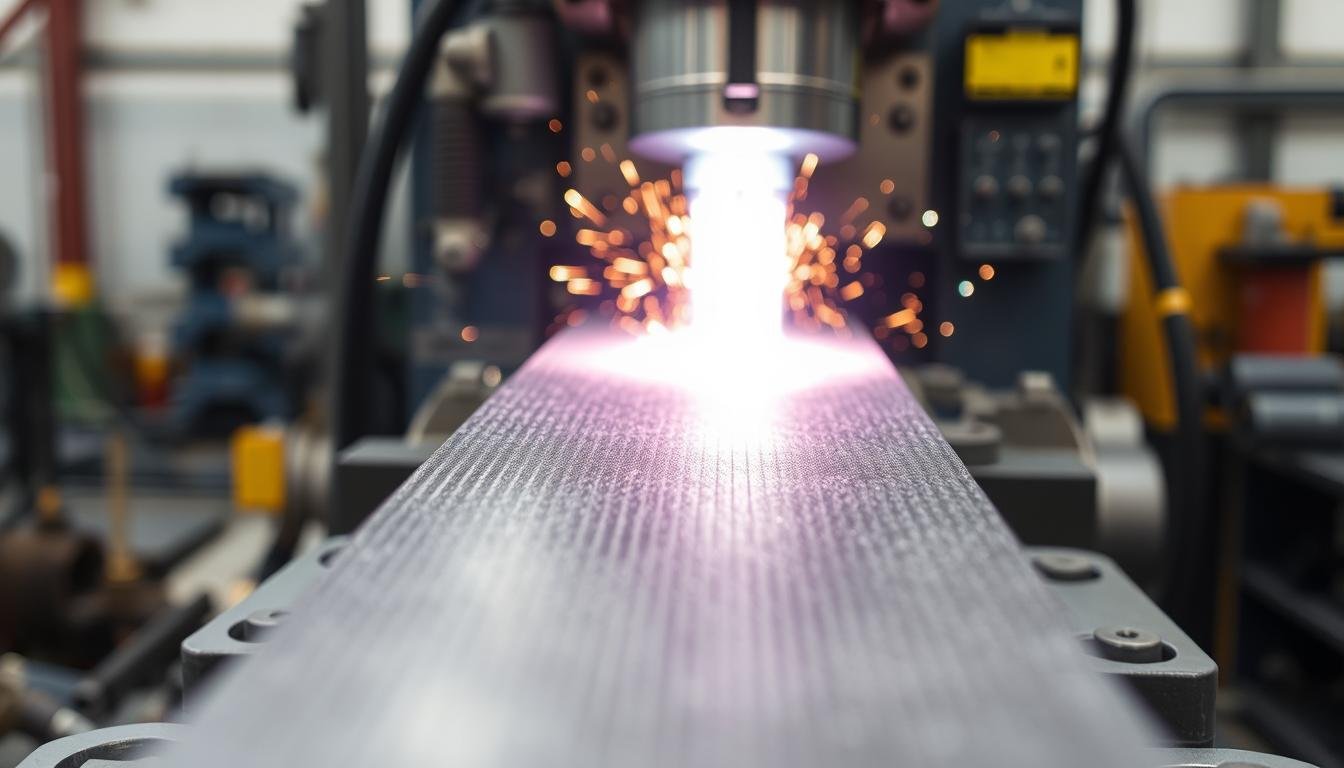

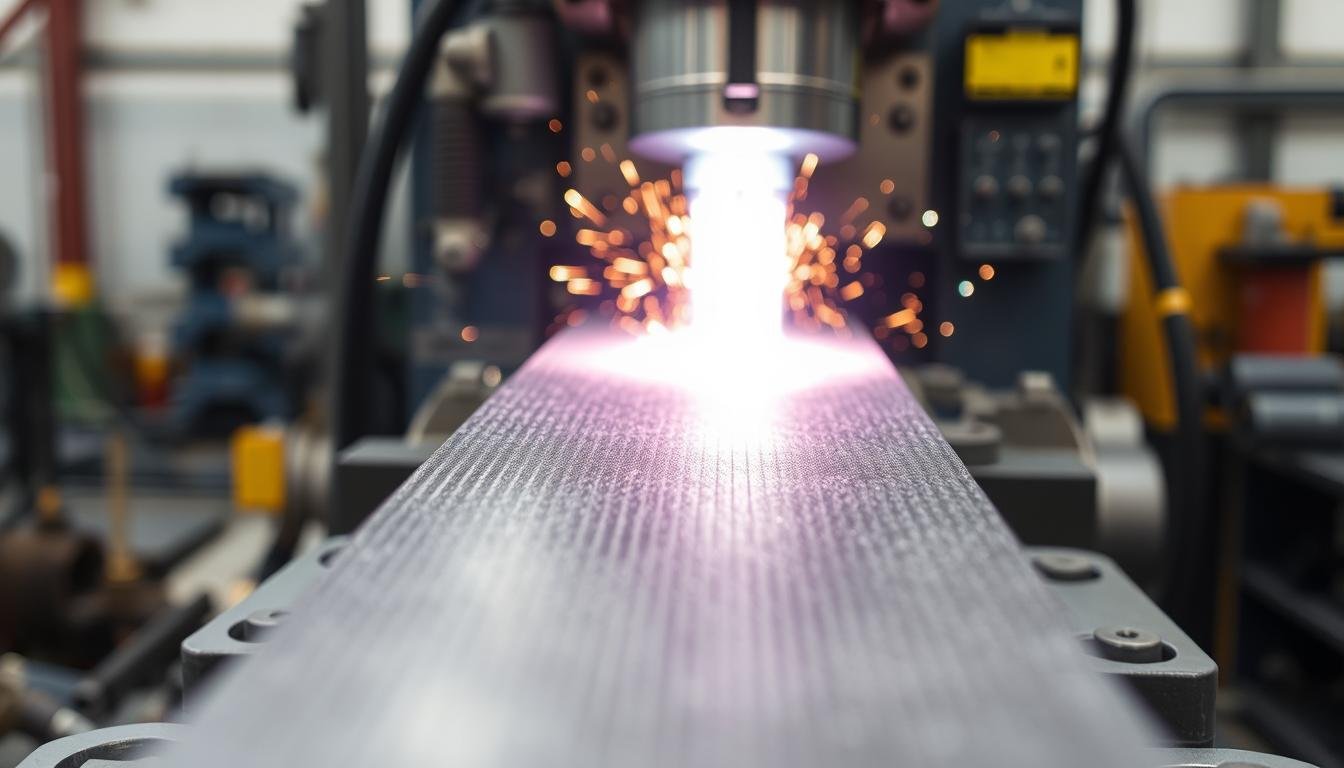

Forging & Heat Treatment

Our forging operations employ precise temperature control and hydraulic presses to create components with superior grain structure and mechanical properties. In-house heat treatment ensures optimal material performance.

- Open die forging

- Closed die forging

- Solution heat treatment

- Aging and tempering

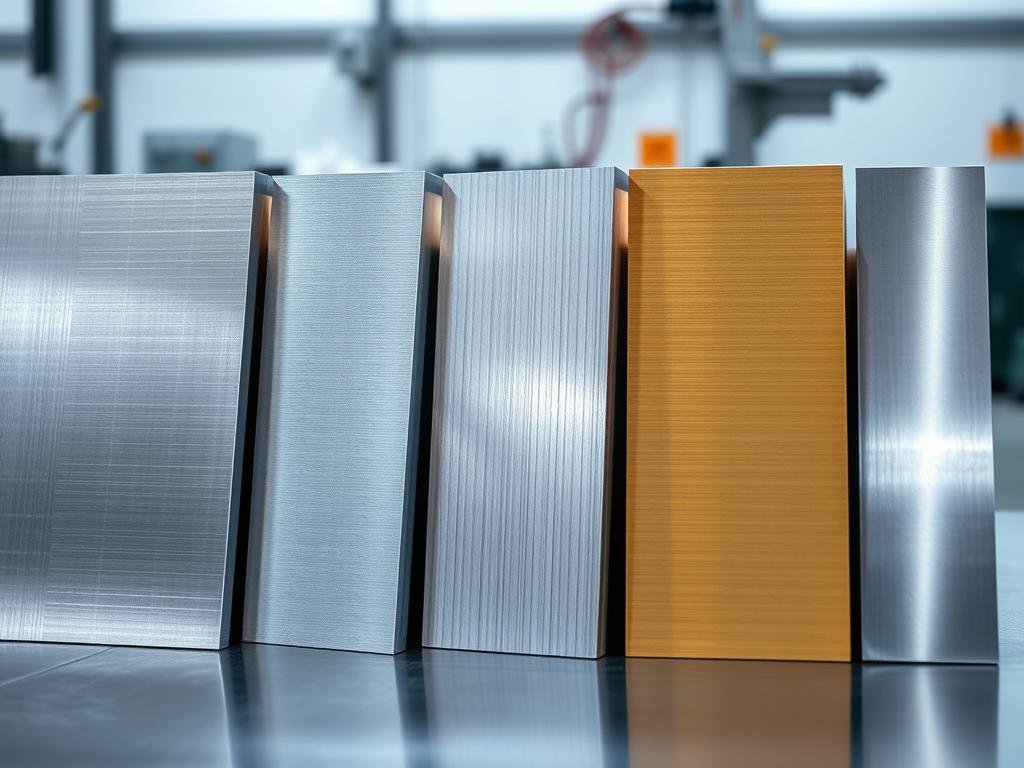

CNC Machining & Finishing

Our comprehensive CNC machining capabilities transform forged components into precision-finished parts ready for assembly. Advanced surface treatments enhance performance and aesthetics.

- Multi-axis CNC machining

- Precision turning and milling

- Surface treatments and anodizing

- Quality inspection and certification

Ready to Discuss Your Aluminum Forging Requirements?

Our engineering team is available to review your specifications and provide expert guidance on material selection, design optimization, and manufacturing processes.

Get A Quick Quote

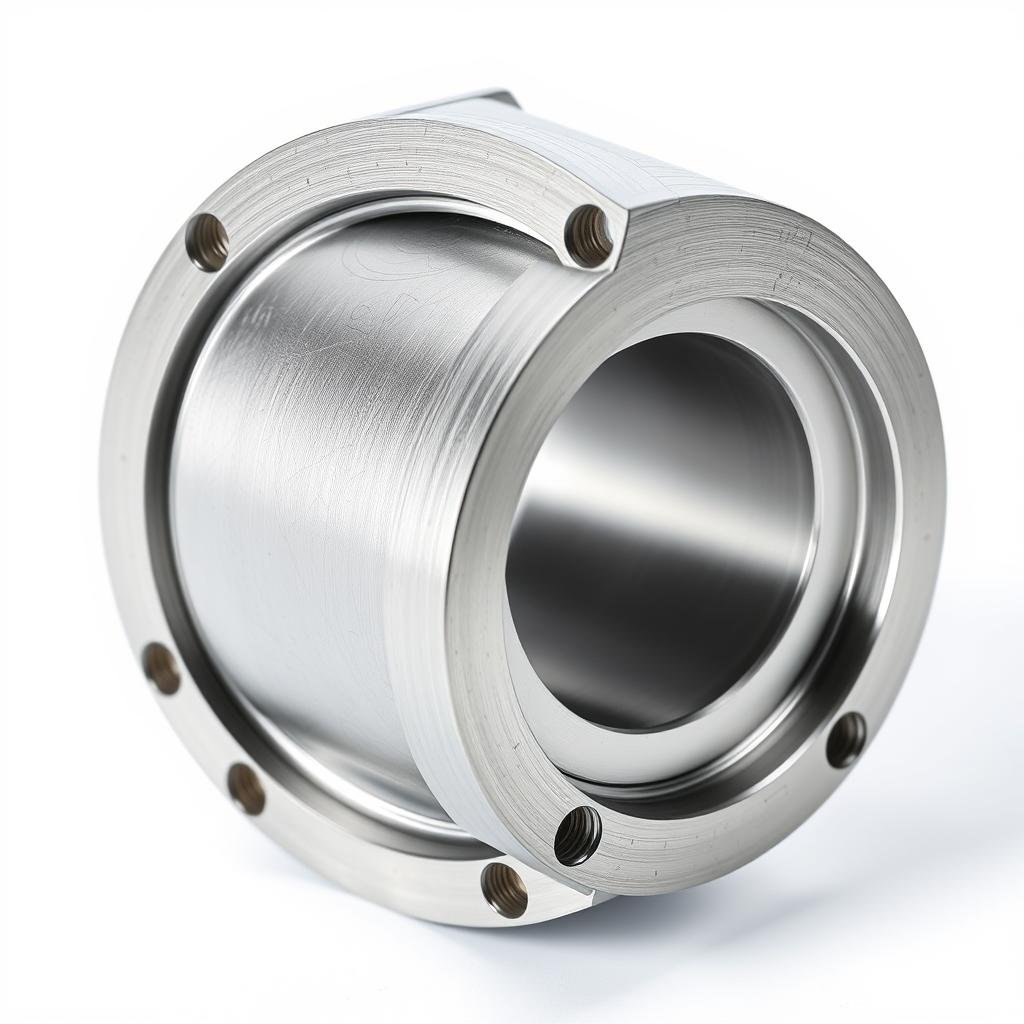

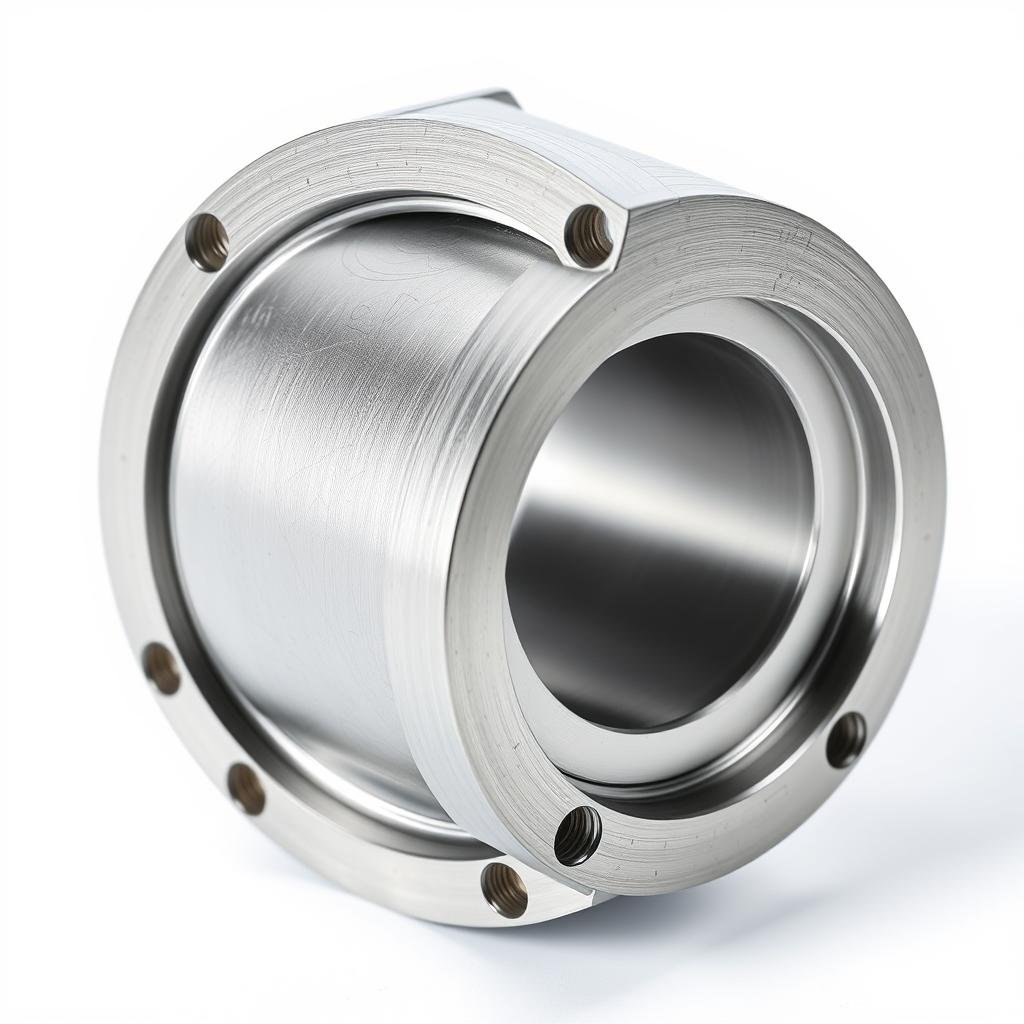

Advanced CNC Machining for Aluminum Forged Parts

MAIKONG combines the inherent advantages of Aluminum Forging Alloys with precision CNC machining to deliver components with exceptional dimensional accuracy and surface finish. Our comprehensive machining capabilities ensure your forged components meet the most demanding specifications.

CNC Turning Services

Our CNC turning capabilities are ideal for creating precision cylindrical components from aluminum forgings. We specialize in producing deep holes, machined threads, and complex profiles with superior surface finishes.

- Multi-axis turning

- Thread machining

- Groove and undercut features

- Tight tolerance cylindrical forms

CNC Milling Services

Our advanced milling centers transform aluminum forgings into complex prismatic shapes with precise flat surfaces, pockets, and contours. Multi-axis capabilities ensure accuracy without fixed tooling requirements.

- 3-axis, 4-axis, and 5-axis milling

- Complex pocket machining

- Contour surfacing

- Precision hole patterns

Swiss-Type Machining

For small, intricate aluminum components requiring exceptional precision, our Swiss-type machining services deliver outstanding results. Dual spindles and multi-axis capabilities provide one-stop manufacturing solutions.

- Small diameter precision parts

- Long shaft components

- Complex geometries

- Tight tolerance features

Quality Assurance for Aluminum Forged Components

At MAIKONG, quality is built into every step of our manufacturing process. Our comprehensive quality management system ensures that all aluminum forged components meet or exceed industry standards and customer specifications.

Material Verification

Our in-house material laboratory conducts comprehensive testing to verify the chemical composition and mechanical properties of all Aluminum Forging Alloys. This ensures consistency, strength, and performance in every component we produce.

- Chemical composition analysis

- Mechanical property testing

- Microstructure examination

- Hardness testing

Dimensional Inspection

Advanced measurement systems verify that all forged and machined components meet precise dimensional requirements. Our quality team employs both traditional and cutting-edge inspection technologies.

- Coordinate measuring machines (CMM)

- Optical measurement systems

- Surface finish analysis

- Geometric dimensioning and tolerancing

4.9

Quality Management System

Industry Applications for Aluminum Forging Alloys

Aluminum Forging Alloys are the material of choice across numerous industries where performance, reliability, and weight considerations are critical. MAIKONG serves diverse sectors with custom forged aluminum components tailored to specific application requirements.

Automotive Suspension Component

Aerospace Structural Fitting

Medical Device Component

Aerospace & Defense

The aerospace industry demands the highest performance from aluminum components. Our forged parts deliver the exceptional strength-to-weight ratio and reliability required for critical applications.

- Structural components

- Landing gear parts

- Engine mounts

- Control system components

Automotive & Transportation

Vehicle manufacturers rely on aluminum forgings to reduce weight while maintaining strength and safety. Our components help improve fuel efficiency and performance.

- Suspension components

- Steering knuckles

- Engine parts

- Transmission components

Medical & Precision Equipment

The medical industry benefits from the exceptional cleanliness and precision of forged aluminum components. Our parts meet the stringent requirements for medical devices and equipment.

- Surgical instrument components

- Imaging equipment structures

- Laboratory device frames

- Prosthetic component supports

US Agent Partnership Opportunities

MAIKONG is actively seeking US-based agents to represent our premium aluminum forging and machining services. Join our growing network of partners and benefit from our competitive pricing, exceptional quality, and comprehensive manufacturing capabilities.

Partner Benefits

- Competitive commission structure

- Technical support from our engineering team

- Comprehensive product training

- Marketing materials and samples

- Dedicated account management

- Priority production scheduling

Partner Requirements

- Established presence in relevant industries

- Technical understanding of metal manufacturing

- Commitment to regular communication

- Proactive customer relationship management

- Minimum annual sales targets

- Professional representation of MAIKONG brand

Become a MAIKONG US Agent

Contact us today to discuss partnership opportunities and discover how representing MAIKONG’s aluminum forging services can benefit your business.

Contact Our Partnership Team

Why Choose MAIKONG for Aluminum Forging Alloys

MAIKONG combines metallurgical expertise, advanced manufacturing capabilities, and customer-focused service to deliver exceptional aluminum forged components. Our commitment to quality, competitive pricing, and comprehensive services makes us the ideal partner for your aluminum forging requirements.

The superior strength, integrity, and performance of Aluminum Forging Alloys can only be fully realized through expert manufacturing processes. At MAIKONG, we transform these exceptional materials into components that exceed expectations and deliver lasting value.

– MAIKONG Engineering Team

Start Your Aluminum Forging Project Today

Contact our team to discuss your requirements and discover how MAIKONG’s aluminum forging expertise can benefit your next project.

Get Started Now