Making informed decisions about aluminum forging alloys requires understanding both immediate costs and long-term benefits. As manufacturing demands evolve, the strategic selection of high-grade alloys becomes increasingly critical for performance, durability, and overall value. This comprehensive analysis explores how investing in premium aluminum forging alloys delivers superior returns across multiple industries and applications.

Understanding Aluminum Forging Alloys: The Foundation of Modern Manufacturing

Aluminum forging alloys represent a specialized category of materials engineered for optimal performance under specific conditions. These alloys combine aluminum with precise amounts of elements like copper, magnesium, silicon, and zinc to achieve enhanced mechanical properties while maintaining aluminum’s inherent lightweight characteristics.

Different aluminum forging alloys offer unique property combinations for specific applications

Key Properties of Premium Aluminum Forging Alloys

- Superior strength-to-weight ratio

- Excellent corrosion resistance

- Enhanced thermal conductivity

- Improved fatigue resistance

- Exceptional machinability

- Dimensional stability

- Electrical conductivity

- Recyclability and sustainability

- Resistance to extreme temperatures

- Design flexibility for complex shapes

Comprehensive Cost-Benefit Analysis of Aluminum Forging Alloys

When evaluating the true value of aluminum forging alloys, manufacturers must consider both immediate investment and long-term returns. This analysis examines multiple factors that influence the total cost of ownership and performance benefits.

Comparative analysis of initial investment versus lifetime value for various manufacturing materials

Initial Investment Considerations

| Cost Factor |

Standard Alloys |

Premium Aluminum Forging Alloys |

Long-Term Impact |

| Material Cost |

Lower initial investment |

15-30% higher material cost |

Offset by extended service life and reduced maintenance |

| Tooling Requirements |

Standard tooling |

May require specialized dies |

Higher precision and longer tool life |

| Processing Complexity |

Simpler processing |

More precise temperature control |

Superior grain structure and mechanical properties |

| Quality Control |

Basic inspection |

Advanced testing requirements |

Fewer defects and failures in service |

Long-Term Value Proposition

Benefits of Premium Alloys

- Extended component lifespan (30-50% longer)

- Reduced maintenance frequency and costs

- Lower weight reduces operational energy costs

- Enhanced performance in extreme conditions

- Improved safety margins and reliability

- Higher resale value for equipment

Considerations

- Higher initial material investment

- More specialized processing requirements

- May require updated design specifications

- Potential supplier limitations for specialty alloys

- Longer lead times for custom formulations

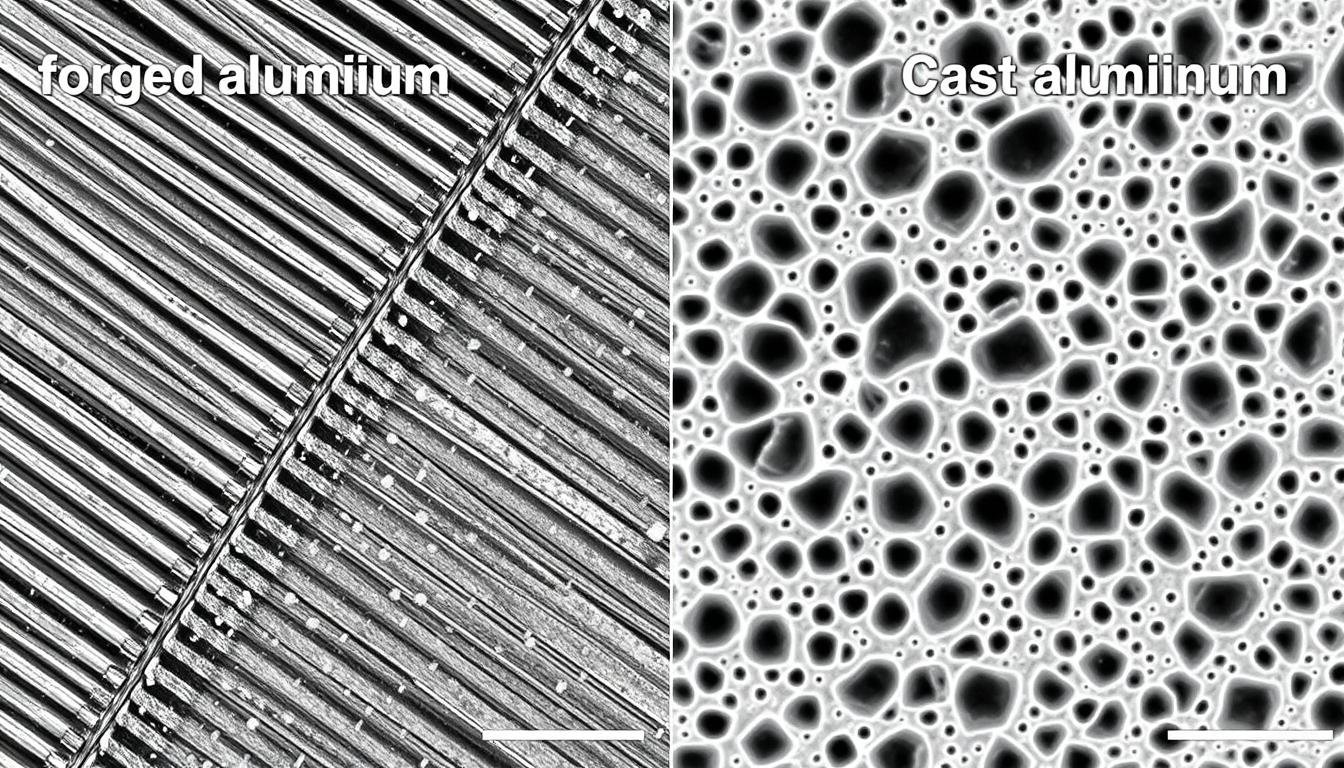

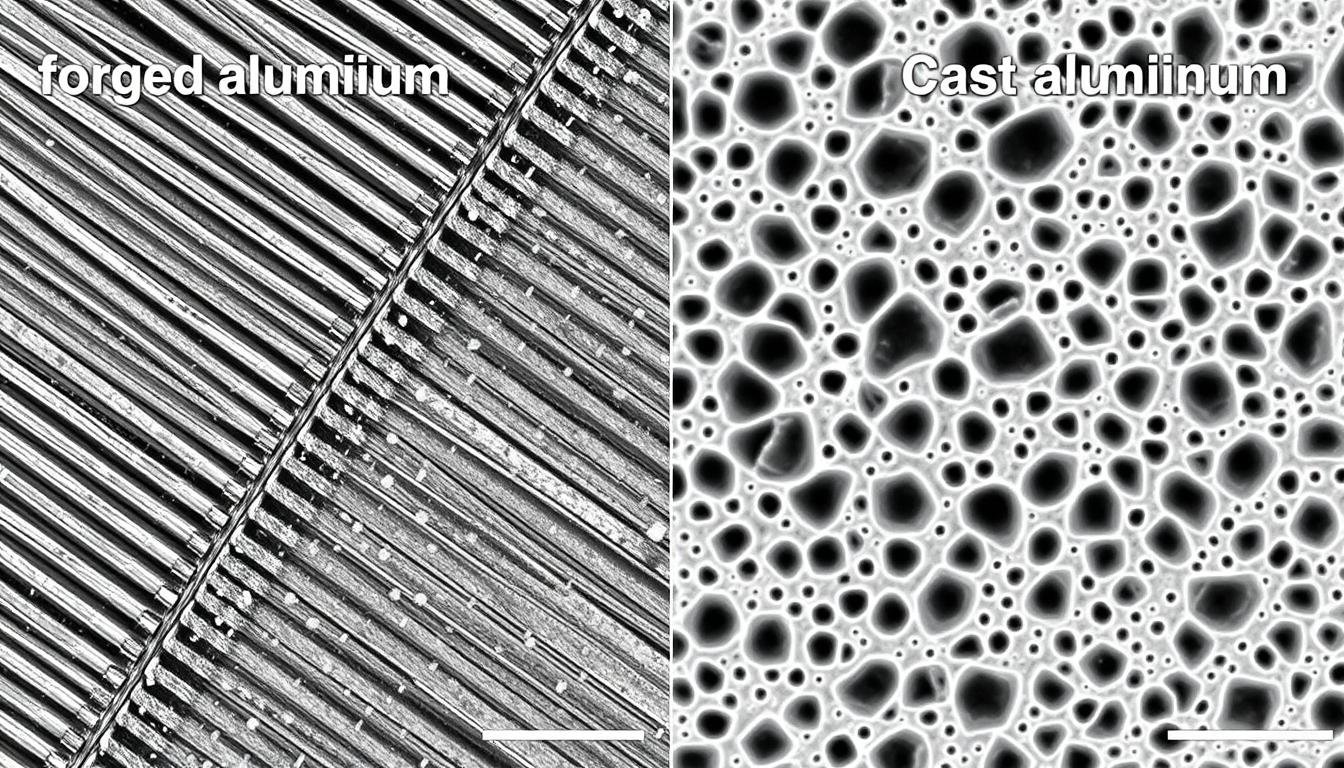

Forging vs. Casting: Why Aluminum Forging Alloys Deliver Superior Value

Understanding the fundamental differences between forging and casting processes is essential for making informed manufacturing decisions. The forging process aligns the grain structure of aluminum, creating components with superior mechanical properties compared to cast alternatives.

Microstructural comparison: Forged aluminum (left) shows aligned grain structure versus cast aluminum (right)

| Comparison Categories |

Aluminum Forging Alloys |

Cast Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps for complex shapes |

Can achieve complex shapes in one session |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

Need Expert Guidance on Aluminum Forging Solutions?

MAIKONG’s engineering team can help you determine the optimal alloy selection for your specific application requirements.

Get Expert Consultation

Industry Applications: Where Aluminum Forging Alloys Deliver Maximum ROI

Different industries benefit from specific aluminum forging alloys based on their unique performance requirements. Understanding these applications helps identify where premium alloys deliver the greatest return on investment.

Aerospace

Aerospace applications demand the highest performance standards where weight reduction directly impacts fuel efficiency and operational costs. Premium aluminum forging alloys like 7075 and 2024 deliver:

- Critical weight savings

- Exceptional fatigue resistance

- Superior strength at high altitudes

- Reliable performance in temperature extremes

Automotive

Automotive manufacturers increasingly turn to aluminum forging alloys to meet stringent emissions standards and performance targets. Alloys like 6061 and 6082 provide:

- Vehicle weight reduction

- Improved fuel economy

- Enhanced crash performance

- Corrosion resistance in harsh environments

Industrial Equipment

Industrial applications benefit from aluminum forging alloys that deliver reliability in demanding environments. Alloys like 2014 and 7075 provide:

- Extended service life in harsh conditions

- Reduced maintenance requirements

- Energy savings through weight reduction

- Thermal management capabilities

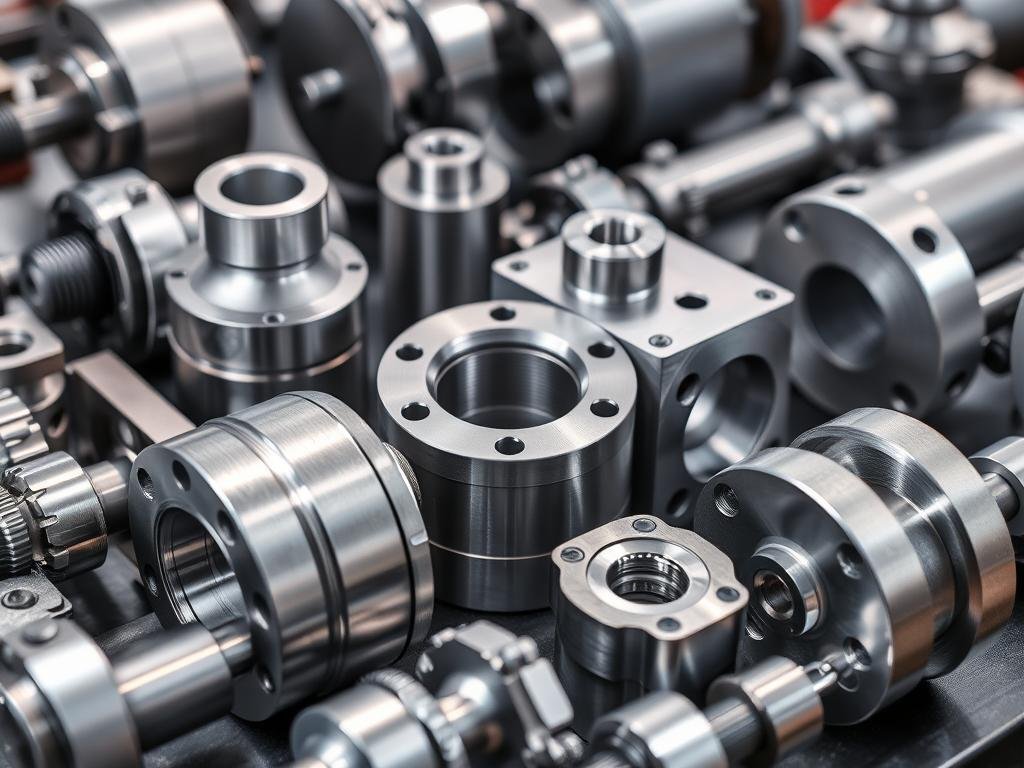

MAIKONG’s Advanced Aluminum Forging Alloys Capabilities

At MAIKONG, we combine technical expertise with state-of-the-art manufacturing facilities to deliver superior aluminum forging solutions. Our comprehensive approach ensures optimal performance and cost-effectiveness across the entire production process.

MAIKONG’s state-of-the-art forging facility in GD, SZ specializes in precision aluminum components

Our Comprehensive Aluminum Forging Process

Design & Engineering

- Advanced CAD/CAM capabilities

- Finite element analysis

- Material optimization

- Design for manufacturability

Manufacturing Excellence

- Precision forging equipment

- Controlled heat treatment

- CNC machining services

- Surface treatment options

Quality Assurance

- Comprehensive material testing

- Dimensional verification

- Non-destructive testing

- Full documentation packages

Ready to Optimize Your Manufacturing Process?

Contact MAIKONG today to discuss how our aluminum forging expertise can enhance your product performance while reducing total ownership costs.

Contact Us on WhatsApp

Call: 8613-51090-74-01

Strategic Material Selection: Choosing the Right Aluminum Forging Alloys

Selecting the optimal aluminum alloy for your application requires balancing performance requirements, processing considerations, and cost factors. MAIKONG’s materials expertise helps clients navigate these decisions to maximize value.

Strategic material selection process for optimizing performance and cost-effectiveness

Common Aluminum Forging Alloys and Their Applications

| Alloy |

Key Properties |

Typical Applications |

Cost-Benefit Consideration |

| 6061 |

Excellent corrosion resistance, good formability, medium strength |

Structural components, frames, marine applications |

Excellent value for general-purpose applications |

| 7075 |

Very high strength, good fatigue resistance, moderate corrosion resistance |

Aerospace structural parts, high-stress components |

Premium cost justified for critical high-performance applications |

| 2024 |

High strength, excellent fatigue resistance, moderate machinability |

Aircraft structures, truck wheels, screw machine products |

Higher cost offset by superior mechanical properties |

| 5083 |

Exceptional corrosion resistance in marine environments, good weldability |

Marine components, cryogenic applications, pressure vessels |

Specialized alloy with excellent value in corrosive environments |

Factors Influencing Alloy Selection

Performance Requirements

- Mechanical strength needs

- Operating environment

- Temperature conditions

- Fatigue considerations

- Corrosion exposure

Manufacturing Considerations

- Formability characteristics

- Machinability requirements

- Heat treatment response

- Surface finish needs

- Production volume

Quality Assurance in Aluminum Forging Alloys Manufacturing

MAIKONG’s comprehensive quality management system ensures consistent performance and reliability in every aluminum forging we produce. Our rigorous testing and inspection protocols verify that all components meet or exceed specified requirements.

MAIKONG’s advanced testing laboratory ensures consistent alloy performance

Our Quality Assurance Process

Material Verification

- Chemical composition analysis

- Mechanical property testing

- Microstructure examination

- Traceability documentation

Process Controls

- Temperature monitoring

- Forging pressure verification

- Heat treatment certification

- Statistical process control

Final Inspection

- Dimensional verification

- Surface quality assessment

- Non-destructive testing

- Performance validation

4.8

Customer Satisfaction

Case Studies: ROI of Premium Aluminum Forging Alloys

Real-world examples demonstrate how strategic investment in high-grade aluminum forging alloys delivers measurable returns across different applications and industries.

Case study: Aerospace component redesign using premium aluminum alloys resulted in 30% weight reduction

Automotive Weight Reduction

Challenge: A leading automotive manufacturer needed to reduce vehicle weight to meet emissions standards while maintaining safety performance.

Solution: MAIKONG engineered custom 7075 aluminum forging alloys components to replace steel parts in the suspension system.

Results:

- 22% weight reduction in targeted components

- 3.5% improvement in fuel efficiency

- Maintained safety performance standards

- 15% reduction in total ownership costs

Industrial Equipment Durability

Challenge: A manufacturing client experienced frequent failures with cast components in high-stress applications.

Solution: Replacement with custom-engineered 6061-T6 aluminum forging alloys components with optimized grain structure.

Results:

- Component lifespan increased by 300%

- Maintenance intervals extended from quarterly to annual

- 40% reduction in unplanned downtime

- ROI achieved within 9 months of implementation

Maximizing Value Through Strategic Aluminum Forging Alloys Selection

Investing in high-grade aluminum forging alloys represents a strategic decision that balances initial costs against long-term performance benefits. By partnering with MAIKONG, manufacturers gain access to industry-leading expertise in material selection, process optimization, and quality assurance.

Our comprehensive approach ensures that your aluminum components deliver maximum value throughout their service life, with optimized performance, reduced maintenance requirements, and enhanced reliability in demanding applications.

Contact MAIKONG today to discover how our aluminum forging solutions can help you achieve your performance and cost-efficiency goals.