In today’s competitive manufacturing landscape, selecting the right Aluminum Forging Alloys for Industrial Buyers can significantly impact product performance, durability, and cost-effectiveness. This comprehensive guide explores the critical factors in choosing optimal aluminum alloys for industrial forging applications, helping procurement specialists and engineers make informed decisions that align with their specific requirements.

Different aluminum alloy grades used in industrial forging applications at MAIKONG’s facility

Different aluminum alloy grades used in industrial forging applications at MAIKONG’s facility

Understanding Aluminum Forging Alloys for Industrial Buyers: The Fundamentals

Aluminum forging is a metal forming process that shapes aluminum through compressive forces, creating components with superior mechanical properties and dimensional accuracy. The process aligns the metal’s grain structure, enhancing strength and durability while maintaining aluminum’s inherent lightweight characteristics.

Why Aluminum Alloys Excel in Industrial Applications

Aluminum alloys offer an exceptional combination of properties that make them ideal for industrial forging applications:

- Outstanding strength-to-weight ratio

- Excellent corrosion resistance

- Superior thermal conductivity

- Enhanced fatigue resistance

- 100% recyclability for sustainability

These properties translate to tangible benefits in manufacturing:

- Reduced overall product weight

- Extended service life in harsh environments

- Improved energy efficiency

- Lower maintenance costs

- Reduced environmental impact

Critical Factors in Selecting the Right Aluminum Forging Alloys

When evaluating Aluminum Forging Alloys for Industrial Buyers, several key factors must be considered to ensure optimal performance in your specific application:

Mechanical Requirements

Consider tensile strength, yield strength, fatigue resistance, and hardness requirements based on operational stresses and loads.

Environmental Factors

Evaluate exposure to corrosive environments, temperature extremes, and weather conditions that may affect alloy performance.

Manufacturing Considerations

Assess formability, machinability, weldability, and heat treatment response to ensure efficient production.

MAIKONG materials engineers analyzing aluminum alloy properties for optimal industrial applications

Most Popular Aluminum Forging Alloys and Their Applications

Different industrial applications require specific aluminum alloy properties. Here’s a comprehensive breakdown of the most commonly used alloys in industrial forging:

| Alloy |

Key Properties |

Ideal Applications |

Industry Sectors |

| 6061 |

Excellent corrosion resistance, good formability, medium strength |

Structural components, frames, brackets |

Automotive, marine, general industrial |

| 7075 |

Very high strength, good fatigue resistance, moderate corrosion resistance |

Critical structural parts, high-stress components |

Aerospace, defense, high-performance automotive |

| 2024 |

High strength, excellent fatigue resistance, good machinability |

Aircraft structures, gears, shafts |

Aerospace, precision machinery |

| 5083 |

Superior corrosion resistance in saltwater, good weldability |

Marine components, chemical processing equipment |

Marine, chemical, offshore |

| 7050 |

High strength, excellent stress corrosion resistance, good toughness |

Aircraft bulkheads, structural components |

Aerospace, defense |

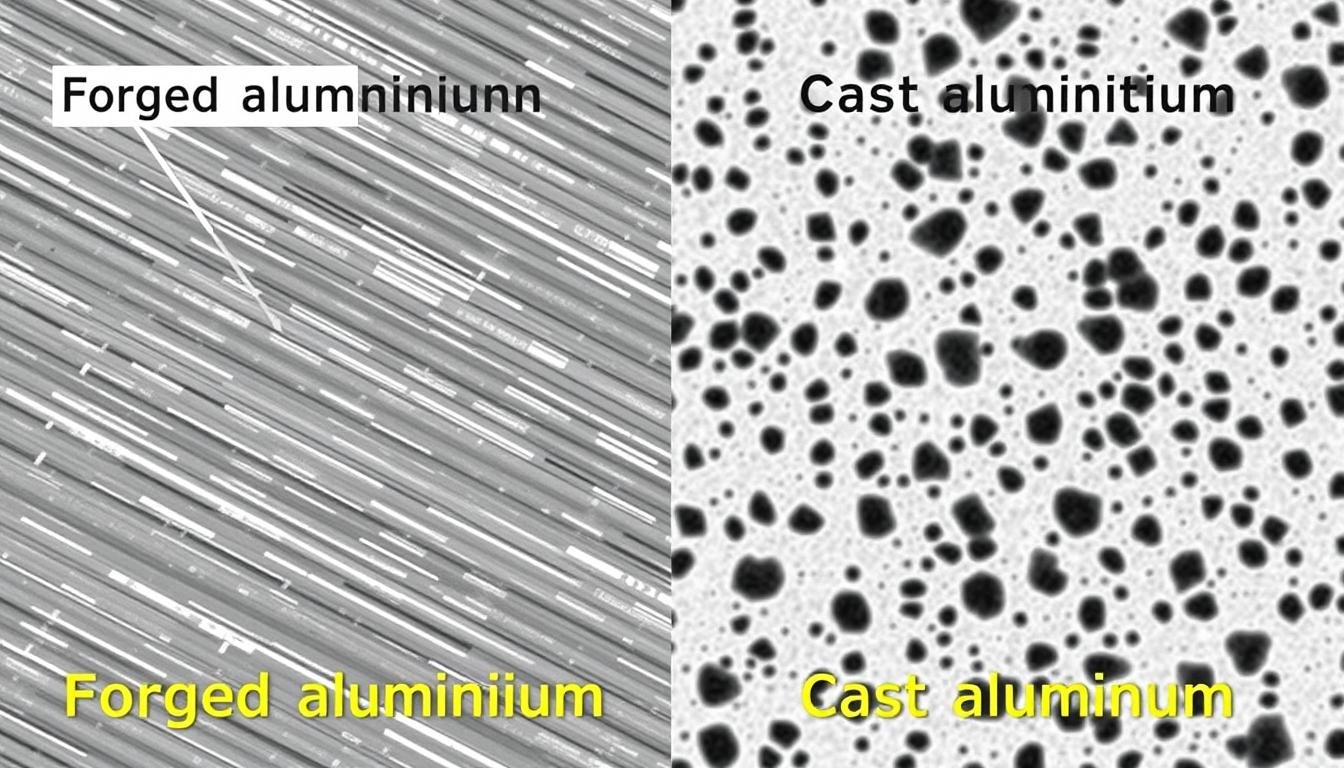

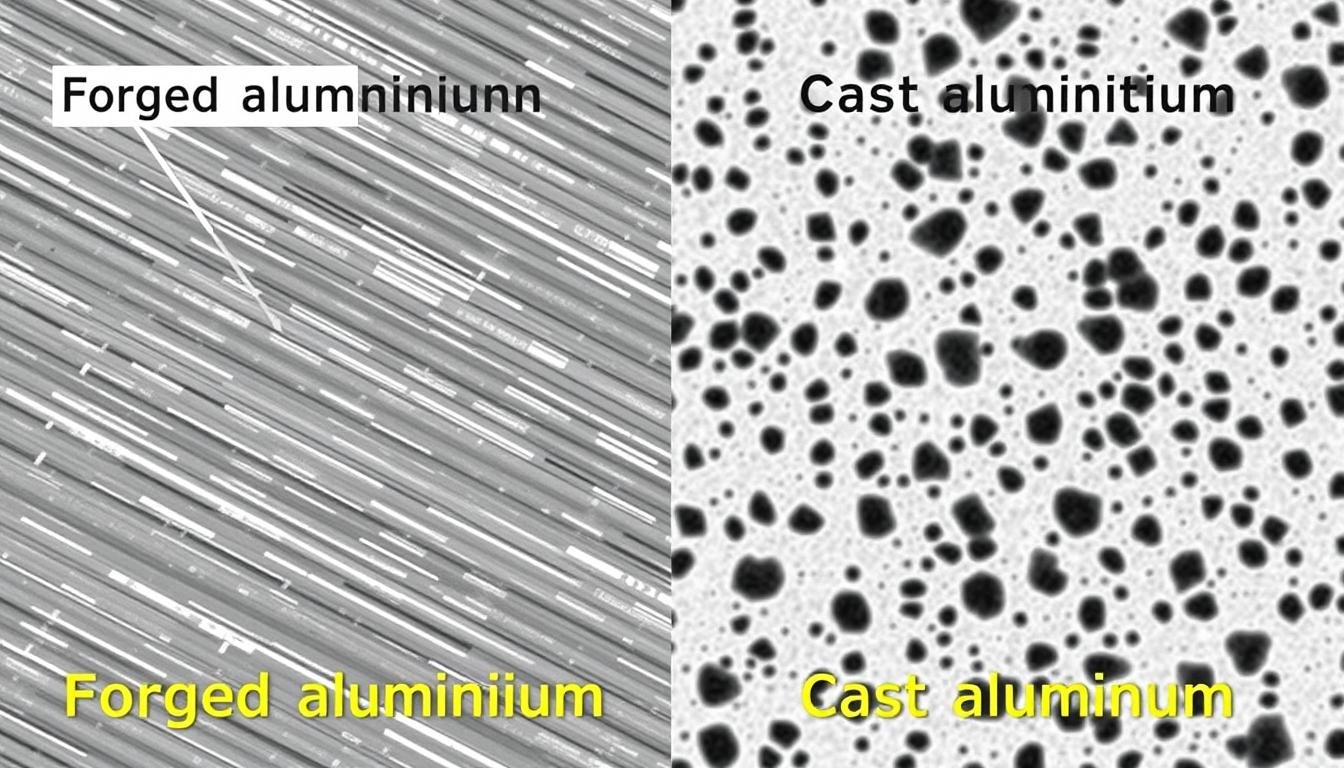

Forged Aluminum vs. Cast Aluminum: A Critical Comparison

Understanding the differences between forging and casting is essential for industrial buyers seeking optimal performance and value:

Microstructure comparison: Forged aluminum (left) shows aligned grain structure vs. cast aluminum (right)

Advantages of Forged Aluminum

- Superior strength due to dense, uniform grain structure

- Enhanced fatigue resistance and durability

- Better dimensional accuracy and tighter tolerances

- Improved mechanical properties through grain alignment

- Higher resistance to impact and stress

Limitations of Forged Aluminum

- Higher initial tooling costs

- More challenging for complex geometries

- Typically requires more machining steps

- Limited to certain shape capabilities

- Higher energy consumption in production

Need Expert Guidance on Alloy Selection?

Our materials engineers can help determine the optimal aluminum alloy for your specific application requirements.

Get Expert Consultation

Aluminum Forging Processes and Their Impact on Material Properties

The forging method significantly influences the final properties of aluminum components. Understanding these processes helps industrial buyers make informed decisions:

Open Die Forging

Also called smith forging, this process shapes aluminum between flat dies that don’t completely enclose the metal. Ideal for large, simple components with excellent mechanical properties.

- Best for: Large components, simple geometries

- Strength characteristics: Excellent directional strength

- Typical industries: Heavy equipment, infrastructure

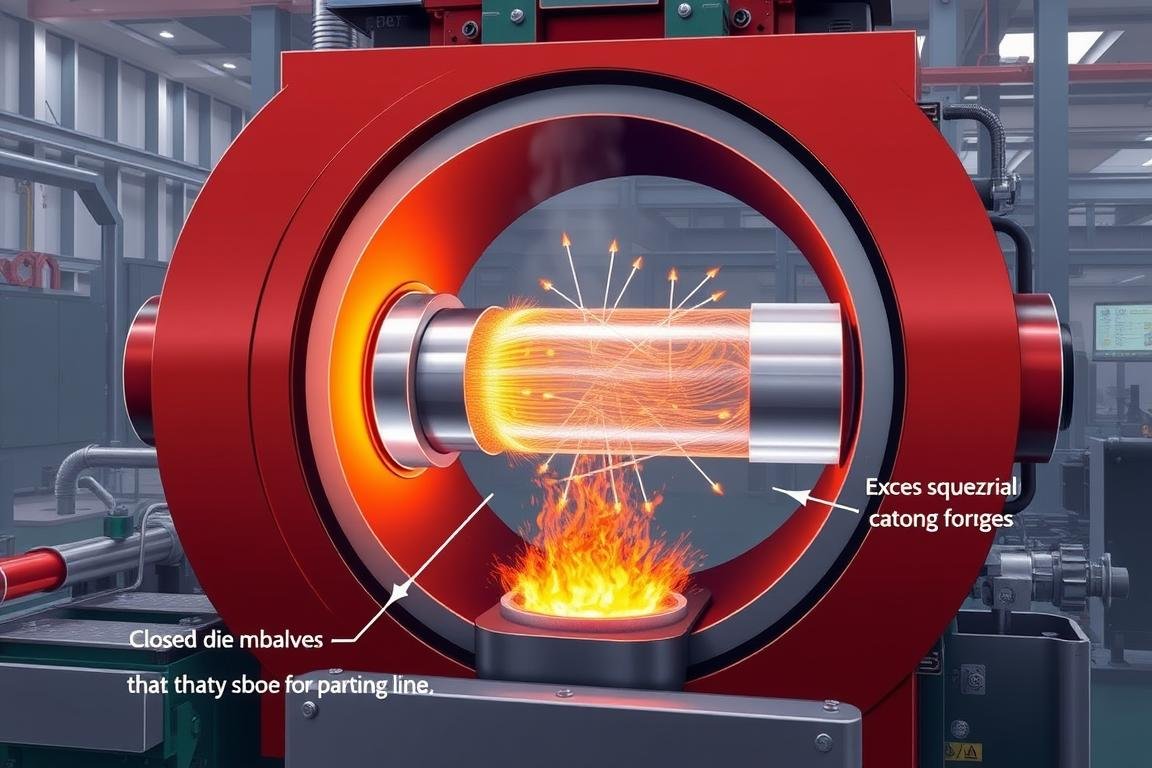

Closed Die Forging

Also called impression die forging, this method shapes aluminum between matching dies that completely enclose the metal, creating precise, complex shapes.

- Best for: Complex geometries, precision components

- Strength characteristics: Uniform properties, excellent grain flow

- Typical industries: Aerospace, automotive, precision machinery

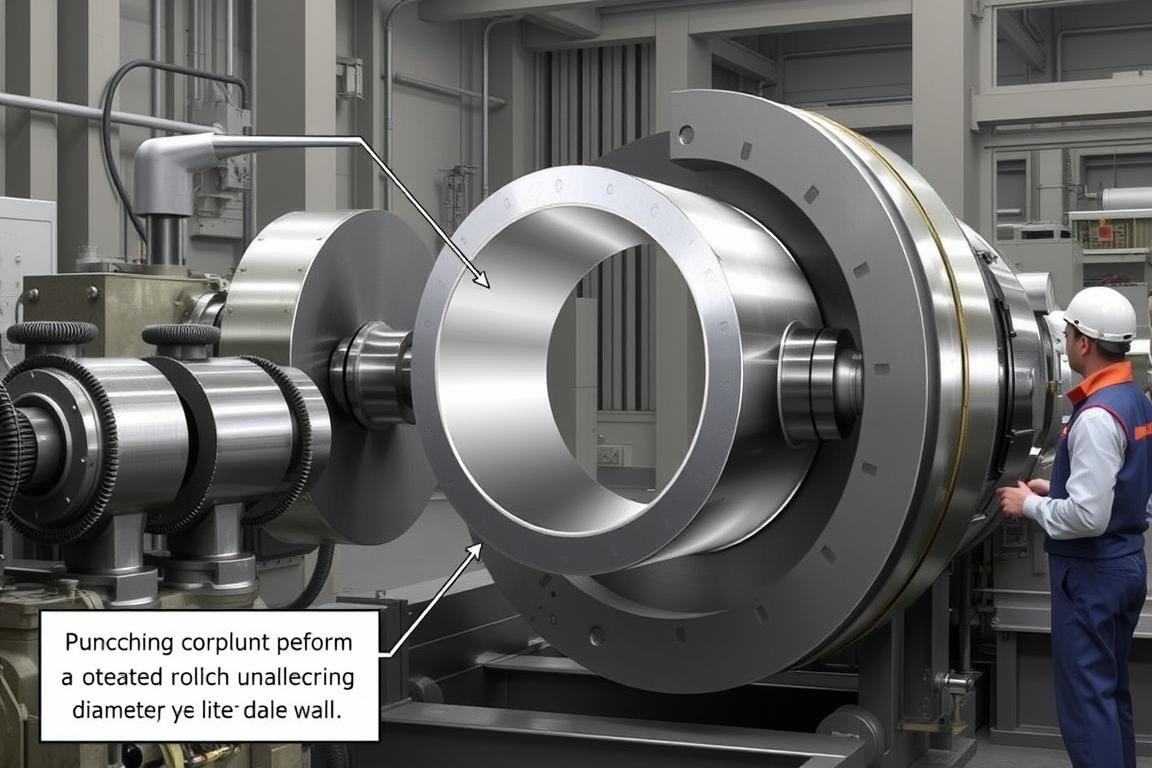

Rolled Ring Forging

Specialized process that creates seamless rings by punching a hole in a round billet and then rolling to increase diameter and reduce wall thickness.

- Best for: Seamless rings, flanges, bearings

- Strength characteristics: Circumferential grain flow, excellent radial strength

- Typical industries: Aerospace, energy, industrial machinery

Heat Treatment: Optimizing Aluminum Alloy Properties

Heat treatment is crucial for developing optimal mechanical properties in aluminum forgings. Different treatments yield specific property profiles:

Precision heat treatment furnaces at MAIKONG’s manufacturing facility

| Heat Treatment |

Process Description |

Effect on Properties |

Typical Applications |

| T6 Temper |

Solution heat treatment followed by artificial aging |

Maximizes strength and hardness |

High-stress components, aerospace parts |

| T4 Temper |

Solution heat treatment followed by natural aging |

Good balance of strength and formability |

Automotive components, structural parts |

| Annealing |

Heating to specific temperature and slow cooling |

Increases ductility, reduces hardness |

Parts requiring additional forming after forging |

| Stress Relief |

Low-temperature heating to reduce internal stresses |

Improves dimensional stability |

Precision components, machined parts |

“Proper heat treatment is not just a manufacturing step—it’s a critical process that determines the performance and lifespan of aluminum forged components in industrial applications.”

– MAIKONG Technical Director

Industry-Specific Applications of Aluminum Forging Alloys

Different industries have unique requirements for Aluminum Forging Alloys for Industrial Buyers. Here’s how specific sectors leverage aluminum’s properties:

Aerospace & Defense

Aerospace applications demand the highest performance from aluminum forgings, with critical requirements for strength-to-weight ratio, fatigue resistance, and reliability.

- Common alloys: 7075, 7050, 2024

- Typical components: Structural frames, landing gear parts, engine mounts

- Key requirements: Exceptional strength, fatigue resistance, crack tolerance

Automotive & Transportation

Automotive manufacturers increasingly turn to aluminum forgings to reduce vehicle weight, improve fuel efficiency, and enhance performance while maintaining safety standards.

- Common alloys: 6061, 6082, 2014

- Typical components: Suspension parts, engine components, structural elements

- Key requirements: Weight reduction, durability, cost-effectiveness

Energy & Industrial Equipment

The energy sector relies on aluminum forgings for components that must withstand extreme conditions, corrosive environments, and continuous operation.

- Common alloys: 5083, 6061, 7075

- Typical components: Valve bodies, pump components, structural elements

- Key requirements: Corrosion resistance, thermal conductivity, reliability

Industry-Specific Forging Solutions

MAIKONG specializes in custom aluminum forging solutions tailored to your industry’s specific requirements.

Discuss Your Industry Needs

Quality Assurance and Testing for Aluminum Forgings

Rigorous testing ensures that aluminum forgings meet the demanding requirements of industrial applications:

MAIKONG’s state-of-the-art testing laboratory ensures consistent quality and performance

Mechanical Testing

- Tensile strength testing

- Yield strength verification

- Hardness testing

- Impact resistance evaluation

- Fatigue life assessment

Metallurgical Analysis

- Microstructure examination

- Grain flow analysis

- Chemical composition verification

- Heat treatment validation

- Inclusion assessment

Dimensional Inspection

- Coordinate measuring machine (CMM)

- Laser scanning

- Optical comparators

- Gauge verification

- Geometric dimensioning and tolerancing

MAIKONG Quality Commitment: Every aluminum forging undergoes comprehensive testing to ensure it meets or exceeds industry standards and customer specifications. Our ISO 9001:2015 certified quality management system guarantees consistent quality across all production runs.

MAIKONG’s Advanced Aluminum Forging Capabilities

With over 60 CNC machines and 100+ tons of monthly metal processing capacity, MAIKONG offers comprehensive aluminum forging and machining solutions:

MAIKONG’s state-of-the-art forging and CNC machining facility in GD, SZ

Forging Capabilities

- Open die forging up to 500 tons

- Closed die forging with precision tolerances

- Rolled ring forging capabilities

- Custom die design and fabrication

- Specialized aluminum alloy expertise

CNC Machining Services

- Multi-axis CNC milling

- Precision CNC turning

- Swiss-type machining for small parts

- Surface grinding and finishing

- Laser engraving capabilities

Additional Services

- Heat treatment and stress relief

- Surface treatments and anodizing

- Non-destructive testing

- Assembly and sub-assembly

- Custom packaging and logistics

Success Stories: Aluminum Forging Solutions in Action

Aerospace Component Weight Reduction

An aerospace manufacturer needed to reduce component weight while maintaining structural integrity. MAIKONG developed a custom 7075-T6 aluminum forging solution that:

- Reduced weight by 32% compared to previous steel component

- Maintained all strength and durability requirements

- Improved fuel efficiency in the final aircraft

- Passed all FAA certification requirements

Automotive Suspension Component Optimization

A leading automotive manufacturer sought to improve performance and durability of suspension components. MAIKONG’s solution included:

- Custom 6061-T6 aluminum forging with optimized grain flow

- Integrated design that eliminated multiple assembly points

- 25% weight reduction while increasing strength by 15%

- Extended service life and improved vehicle handling

Procurement Guide: Selecting the Right Aluminum Forging Partner

When sourcing Aluminum Forging Alloys for Industrial Buyers, choosing the right manufacturing partner is as important as selecting the correct alloy. Consider these key factors:

Critical Selection Factors

Technical Expertise

9.5/10

Quality Management System

9.0/10

Manufacturing Capabilities

8.5/10

Industry Experience

8.0/10

Cost Competitiveness

7.5/10

Questions to Ask Potential Suppliers

What quality certifications do you maintain?

Look for ISO 9001:2015 certification at minimum. Industry-specific certifications like AS9100 for aerospace or IATF 16949 for automotive provide additional assurance.

What testing capabilities do you offer in-house?

Comprehensive testing capabilities ensure consistent quality. Ask about mechanical testing, metallurgical analysis, and dimensional inspection methods.

Can you provide examples of similar projects?

Experience with similar components or industries indicates capability to meet your specific requirements. Request case studies or examples relevant to your application.

What is your typical lead time for prototypes and production runs?

Understanding lead times helps with project planning. Evaluate if the supplier can meet your timeline requirements for both initial samples and full production.

Conclusion: Making Informed Decisions on Aluminum Forging Alloys

Selecting the right Aluminum Forging Alloys for Industrial Buyers requires careful consideration of application requirements, material properties, and manufacturing processes. By partnering with an experienced aluminum forging specialist like MAIKONG, industrial buyers can ensure optimal performance, cost-effectiveness, and reliability in their components.

Our comprehensive capabilities in aluminum forging, CNC machining, and secondary operations provide a complete solution for your manufacturing needs. Contact MAIKONG today to discuss how our expertise can benefit your next project.

Different aluminum alloy grades used in industrial forging applications at MAIKONG’s facility

Different aluminum alloy grades used in industrial forging applications at MAIKONG’s facility