In today’s competitive industrial landscape, finding the right manufacturing partner for your aluminum forging needs can significantly impact your project’s success. MAIKONG specializes in delivering premium aluminum forging solutions that combine exceptional strength, durability, and cost-effectiveness for US industrial applications. With our state-of-the-art facilities in GD, SZ, we offer comprehensive capabilities from design to delivery, ensuring your components meet the highest quality standards while maintaining competitive pricing.

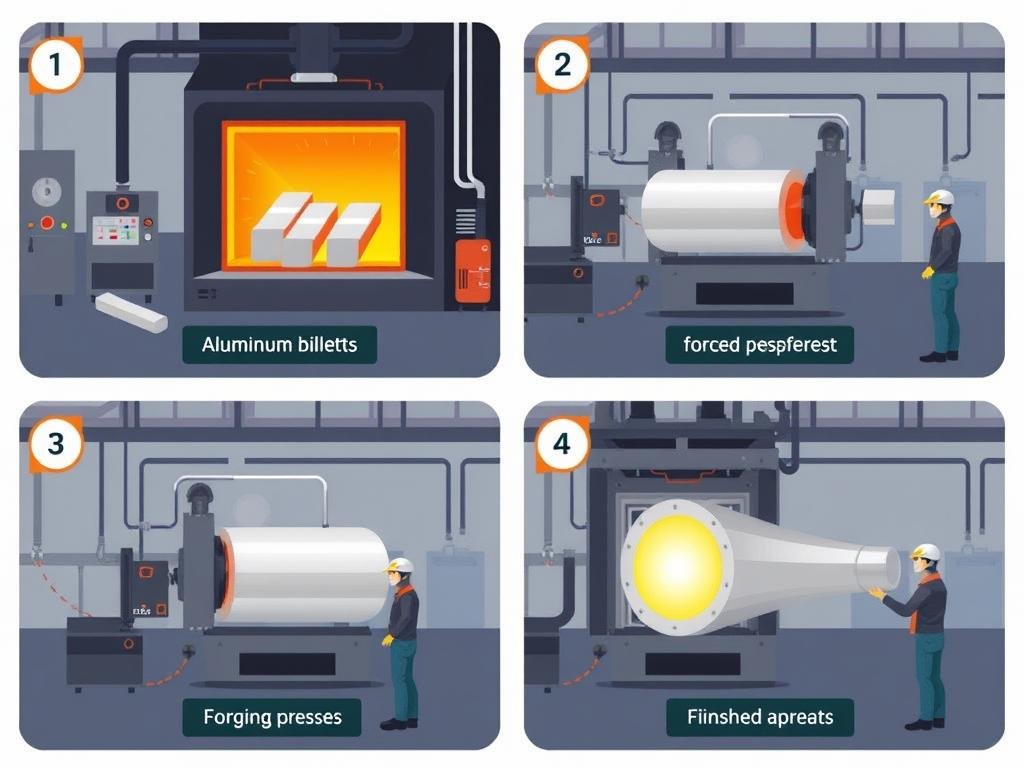

Understanding the Aluminum Forging Process

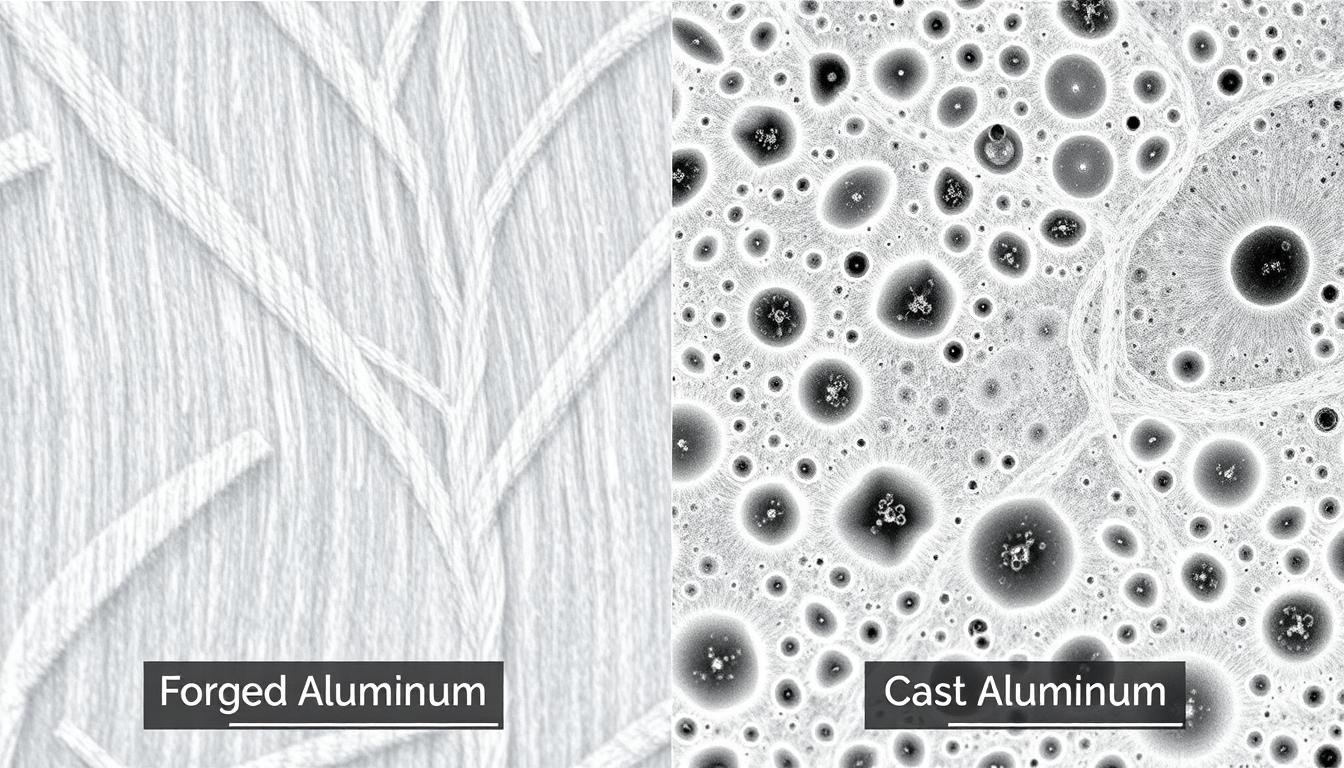

Aluminum forging is a sophisticated manufacturing process that shapes aluminum alloys through controlled pressure application. Unlike casting methods, forging aligns the metal’s grain structure, significantly enhancing mechanical properties. This results in components with superior strength-to-weight ratios, making them ideal for demanding industrial applications where performance and reliability are paramount.

The Aluminum Forging Workflow

- Material Selection: Choosing the appropriate aluminum alloy based on application requirements

- Heating: Bringing the aluminum to optimal forging temperature (700-950°F)

- Forging: Applying precise pressure to shape the material using specialized dies

- Cooling: Controlled cooling to maintain dimensional stability

- Heat Treatment: Enhancing mechanical properties through specialized heating processes

- Finishing: Precision machining and surface treatments for final specifications

Need Expert Guidance on Your Aluminum Forging Project?

Our engineering team can help determine the optimal aluminum alloy and forging process for your specific application requirements.

Request Technical Consultation

Key Benefits of Aluminum Forging for Industrial Applications

When comparing manufacturing methods for aluminum components, forging stands out for its ability to create parts with exceptional mechanical properties. MAIKONG’s advanced aluminum forging techniques deliver components that outperform cast or machined alternatives in critical applications.

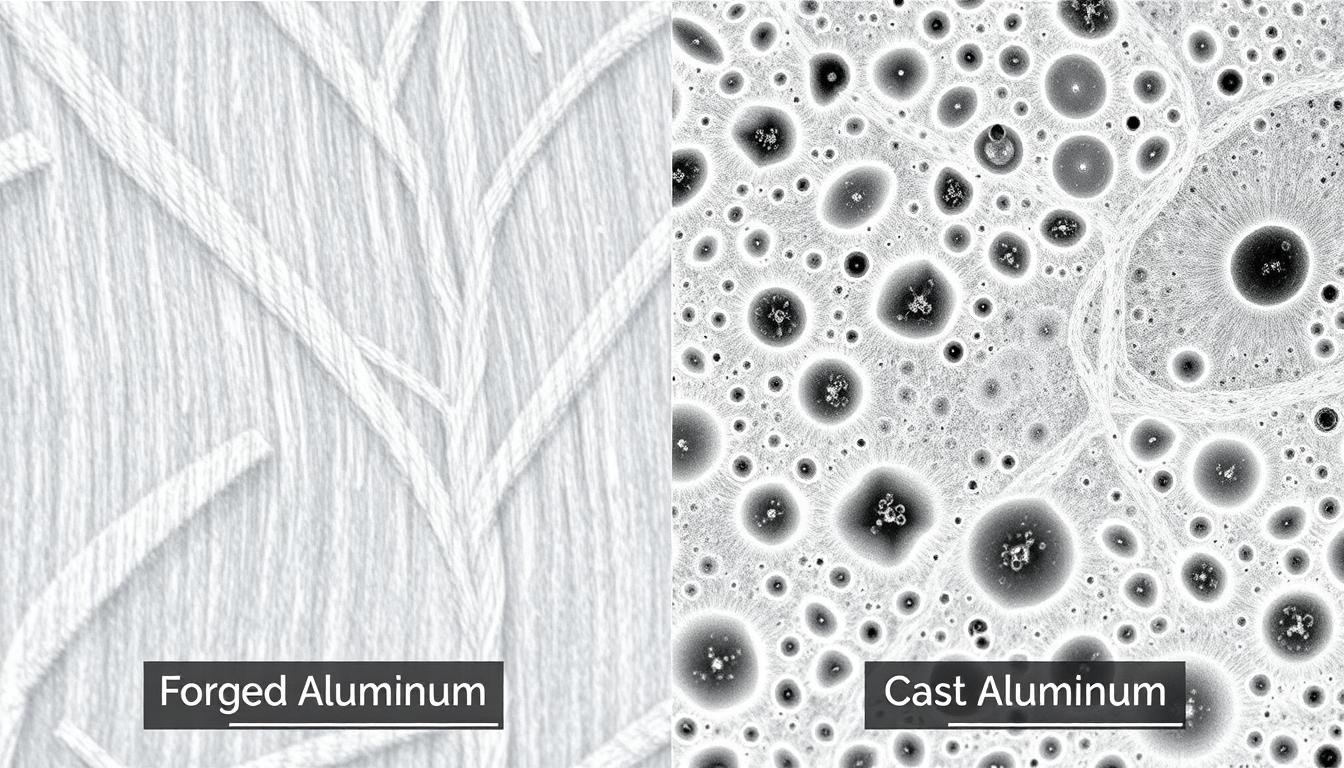

Superior Strength

Forged aluminum components feature a refined grain structure that provides up to 30% higher tensile strength compared to cast alternatives, making them ideal for load-bearing applications.

Lightweight Design

With a density one-third that of steel, aluminum forgings deliver exceptional strength-to-weight ratios, reducing overall system weight while maintaining structural integrity.

Corrosion Resistance

Aluminum’s natural oxide layer provides excellent corrosion resistance, which is further enhanced through our specialized surface treatments for extended service life in harsh environments.

Aluminum Forging vs. Casting: A Comprehensive Comparison

Understanding the differences between forging and casting is crucial when selecting the optimal manufacturing process for your aluminum components. While both methods have their place in industrial applications, aluminum forging offers distinct advantages for components where mechanical properties and reliability are critical.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Heat Treatment Response |

✅ Responsive for controlled material properties |

Less predictable response |

| Ideal Applications |

Aerospace, automotive, critical structural components |

Consumer goods, decorative items, complex shapes |

Not Sure Which Process Is Right for Your Project?

Our engineering team can analyze your requirements and recommend the optimal manufacturing approach for your specific application.

Email Our Engineering Team

MAIKONG’s Comprehensive Aluminum Forging Capabilities

At MAIKONG, we’ve developed a complete end-to-end solution for aluminum forging that ensures exceptional quality and consistency. Our state-of-the-art facility in GD, SZ houses advanced equipment and expert personnel dedicated to delivering superior forged components for US industrial applications.

Advanced Design & Analysis

Our engineering team utilizes sophisticated CAD/CAM systems with finite element analysis to optimize designs for manufacturability and performance, identifying potential issues before production begins.

Material Expertise

Our material scientists select optimal aluminum alloys based on mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness for each specific application.

Precision Tooling

We design and maintain specialized forging dies that ensure initial quality and long-term consistency, critical factors in producing high-performance aluminum components.

Advanced Forging Equipment

Our forging workshop features hydraulic presses ranging from 800 to 3,000 tons, capable of handling diverse aluminum forging specifications for components of various sizes and complexities.

Heat Treatment Expertise

Our in-house heat treatment facilities allow precise control of mechanical properties, with comprehensive statistical analysis and documentation ensuring consistent results.

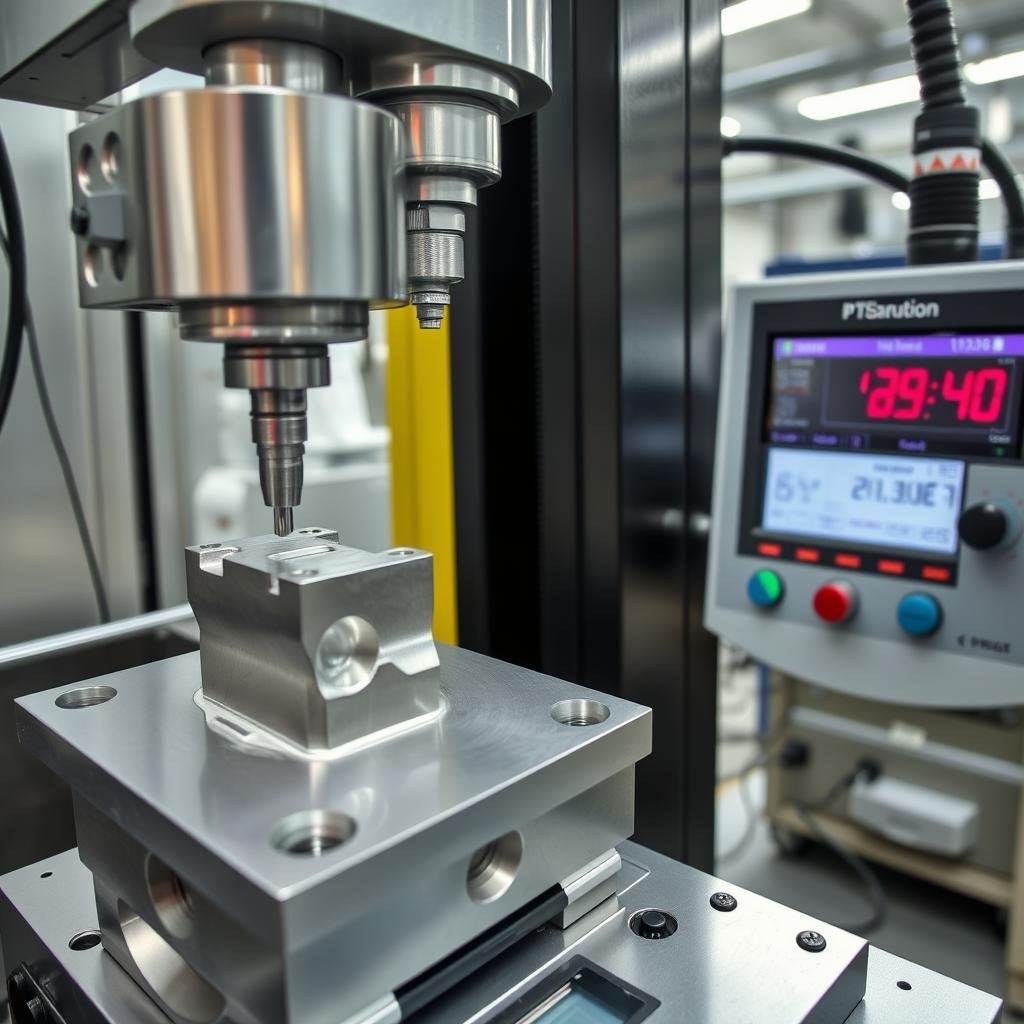

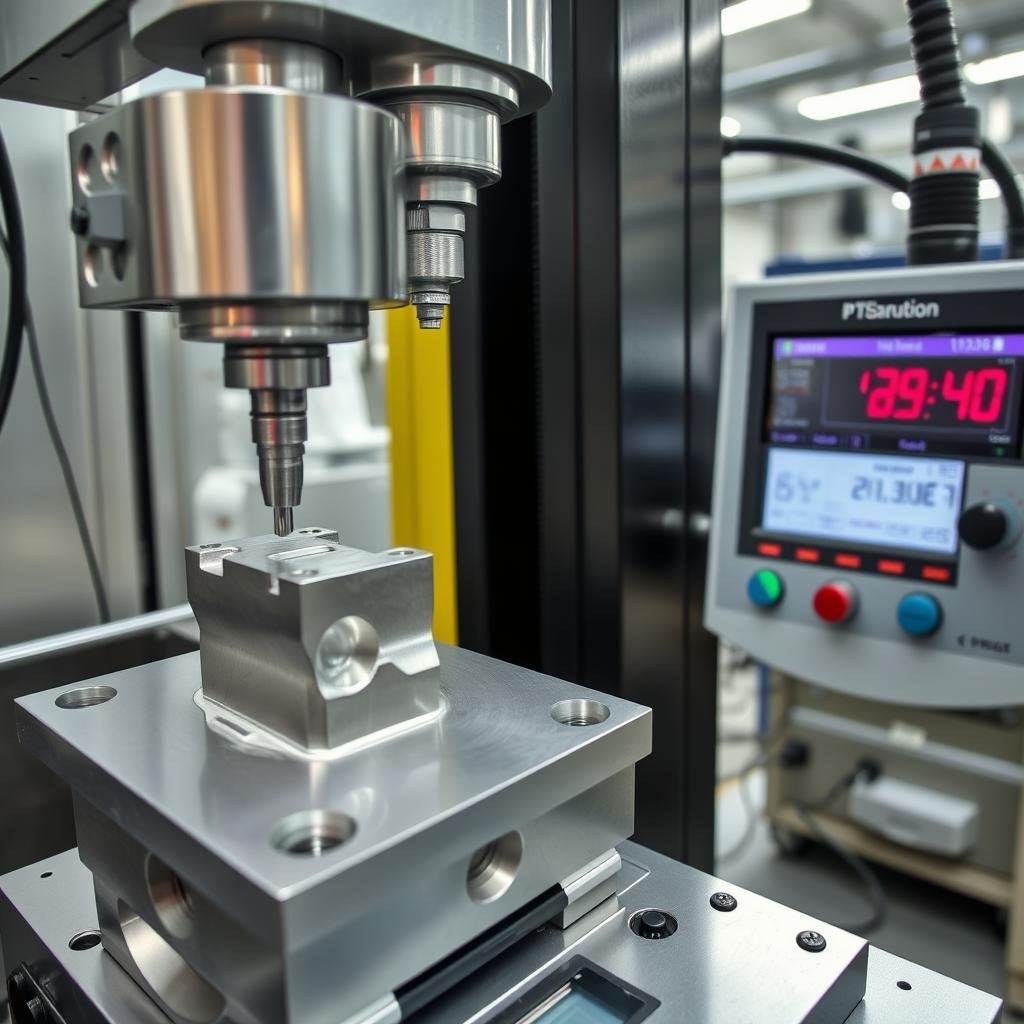

Precision CNC Machining

With over 60 CNC machines, our machining workshop handles precise and intricate operations on forged components, maintaining tight tolerances and exceptional surface finishes.

Ready to Discuss Your Aluminum Forging Requirements?

Contact our technical team today to explore how MAIKONG’s comprehensive capabilities can deliver superior aluminum components for your industrial applications.

Contact via WhatsApp

Industries Benefiting from MAIKONG’s Aluminum Forging Solutions

Our advanced aluminum forging capabilities serve diverse industrial sectors where performance, reliability, and cost-effectiveness are critical requirements. MAIKONG’s expertise extends across multiple applications, delivering components that meet the most demanding specifications.

Aerospace Applications

- Structural Components: Landing gear parts, wing attachments, and fuselage structures

- Engine Components: Compressor blades, mounting brackets, and housings

- Control Systems: Actuator components, linkages, and support structures

Automotive Industry

- Suspension Systems: Control arms, steering knuckles, and suspension links

- Powertrain Components: Connecting rods, transmission parts, and engine mounts

- Structural Elements: Chassis components, safety-critical structures

Additional Industries Served

- Defense: Weapons systems, vehicle components, and tactical equipment

- Marine: Propulsion system components, hardware, and structural elements

- Industrial Machinery: High-stress components, precision mechanisms

- Energy: Turbine components, connection systems, and support structures

“The superior strength-to-weight ratio and reliability of aluminum forged components make them indispensable in applications where failure is not an option. MAIKONG’s precision manufacturing ensures consistent quality that meets the most demanding specifications.”

– MAIKONG Engineering Team

Quality Assurance in Aluminum Forging

At MAIKONG, quality isn’t just a department—it’s a core value embedded throughout our manufacturing process. Our comprehensive quality management system ensures that every aluminum forged component meets or exceeds the specified requirements, providing our customers with complete confidence in our products.

Material Verification

Our in-house laboratory conducts comprehensive material testing, including chemical composition analysis, mechanical property verification, and microstructure examination to ensure all raw materials meet specifications.

Process Monitoring

Advanced statistical process control (SPC) techniques continuously monitor critical parameters throughout the forging process, allowing real-time adjustments to maintain optimal quality.

Comprehensive Inspection

Every component undergoes rigorous inspection using advanced measurement systems, including coordinate measuring machines (CMM), to verify dimensional accuracy and surface quality.

ISO 9001:2015 Certified: MAIKONG maintains a certified quality management system that ensures consistent processes and continuous improvement in our aluminum forging operations.

Why Choose MAIKONG for Your Aluminum Forging Needs

Selecting the right manufacturing partner for your aluminum components is a critical decision that impacts product performance, reliability, and overall project success. MAIKONG offers distinct advantages that make us the preferred choice for discerning US industrial clients.

The MAIKONG Advantage

- Comprehensive capabilities from design to delivery

- 60+ CNC machines with 100+ tons monthly processing capacity

- Advanced material laboratory with best-in-class testing

- ISO 9001:2015 certified quality management system

- Exceptional cost-effectiveness without compromising quality

- Experienced engineering team with industry-specific expertise

- Flexible production capabilities for both prototyping and high-volume manufacturing

How does MAIKONG ensure consistent quality for US customers?

Our comprehensive quality management system includes rigorous material testing, statistical process control, and 100% inspection of critical dimensions. We maintain detailed documentation and traceability throughout the manufacturing process, ensuring that every component meets the specified requirements. Our ISO 9001:2015 certification demonstrates our commitment to consistent quality and continuous improvement.

What makes MAIKONG’s aluminum forging services cost-effective?

Our strategic location in GD, SZ, combined with our efficient manufacturing processes and economies of scale, allows us to offer competitive pricing without compromising quality. We’ve optimized our workflow to minimize waste and maximize productivity, passing these savings on to our customers while maintaining the highest standards of quality and performance.

Ready to Experience the MAIKONG Difference?

Contact us today to discuss your aluminum forging requirements and discover how our comprehensive capabilities can deliver superior components for your industrial applications.

Visit Our Website

Elevate Your Industrial Projects with MAIKONG’s Aluminum Forging Expertise

Choosing the right manufacturing partner for your aluminum components is a decision that impacts product performance, reliability, and overall project success. MAIKONG combines advanced technical capabilities, comprehensive quality assurance, and exceptional cost-effectiveness to deliver superior aluminum forged components for US industrial applications.

From aerospace and automotive to defense and energy, our expertise spans diverse industries where performance and reliability are non-negotiable requirements. Our end-to-end capabilities—from design and material selection to forging, machining, and surface treatment—ensure consistent quality and performance for every component we produce.

Contact MAIKONG today to discover how our aluminum forging solutions can enhance your next industrial project with superior strength, durability, and cost-effectiveness.