What is forged aluminium? Forged aluminium is aluminum that has been shaped under immense pressure and controlled temperature to create components with superior strength, durability, and grain structure. Unlike cast aluminum, the forging process aligns the metal’s grain flow with the part’s contours, significantly enhancing mechanical properties and eliminating internal defects. This comprehensive guide explores the forging process, benefits, applications, and why MAIKONG’s aluminum forging services deliver exceptional quality for demanding industries.

Forged aluminum components showcasing the superior finish and structural integrity achieved through the forging process

Forged aluminum components showcasing the superior finish and structural integrity achieved through the forging process

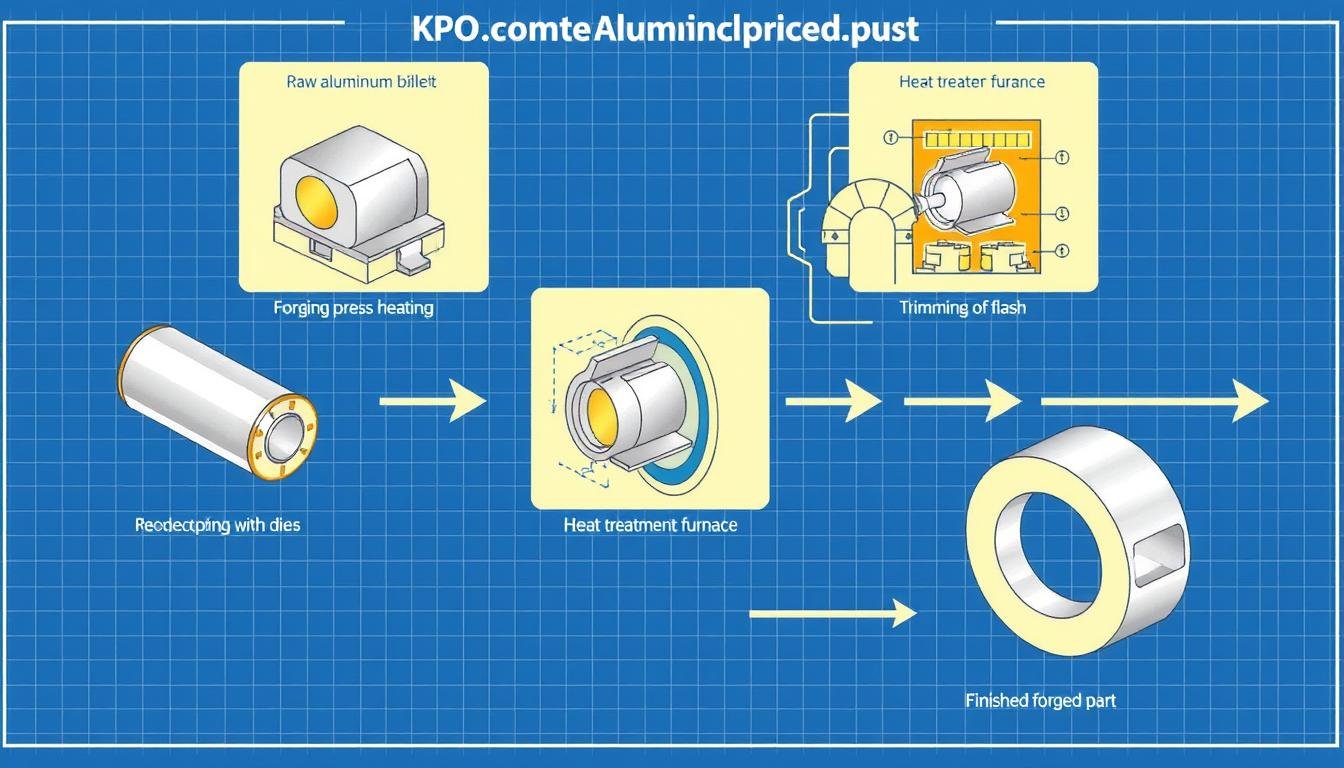

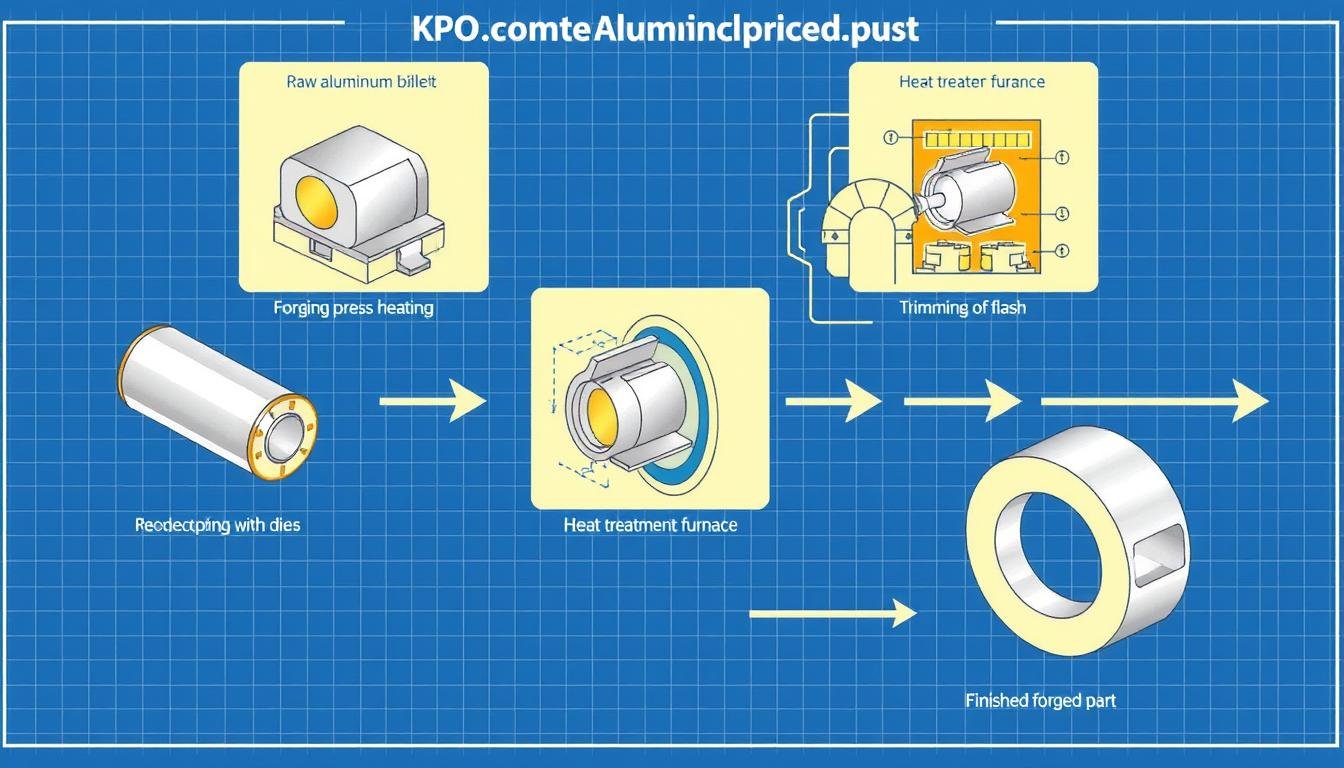

The Forging Process: How What is Forged Aluminium Becomes Reality

The aluminum forging process transforms raw aluminum alloys into high-performance components through controlled deformation. Understanding this process is essential to appreciating why forged aluminum delivers superior performance compared to other manufacturing methods.

The complete aluminum forging process from raw billet to finished component

Key Stages in the Aluminum Forging Process

- Billet Preparation: Raw aluminum alloy is cut to the appropriate size and weight for the desired component.

- Heating: The billet is heated to a specific temperature (typically 750-950°F depending on the alloy) to increase plasticity.

- Forging: The heated aluminum is placed between dies and subjected to immense pressure, forcing it to conform to the die shape.

- Trimming: Excess material (flash) is removed from the forged part.

- Heat Treatment: The component undergoes controlled heating and cooling to achieve desired mechanical properties.

- Finishing: Final machining, surface treatments, and quality inspections complete the process.

Types of Aluminum Forging Processes

Open-Die Forging

Material is compressed between flat or simply shaped dies that don’t completely enclose it. Ideal for large, simple shapes with excellent mechanical properties.

Closed-Die Forging

Material is shaped within cavity dies that impart a specific shape. Provides better dimensional control and is suitable for complex geometries.

Precision Forging

Advanced process that creates near-net-shape components with minimal need for secondary machining. Offers tight tolerances and excellent material properties.

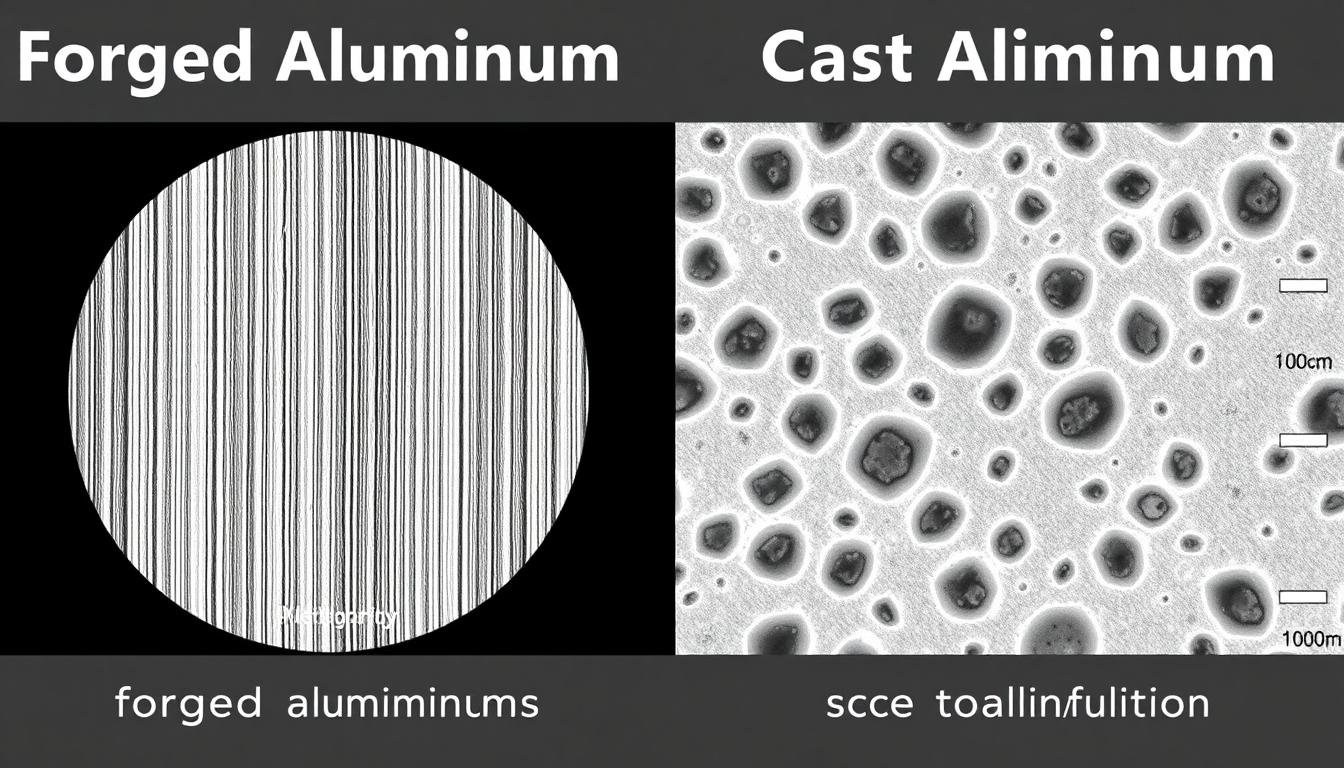

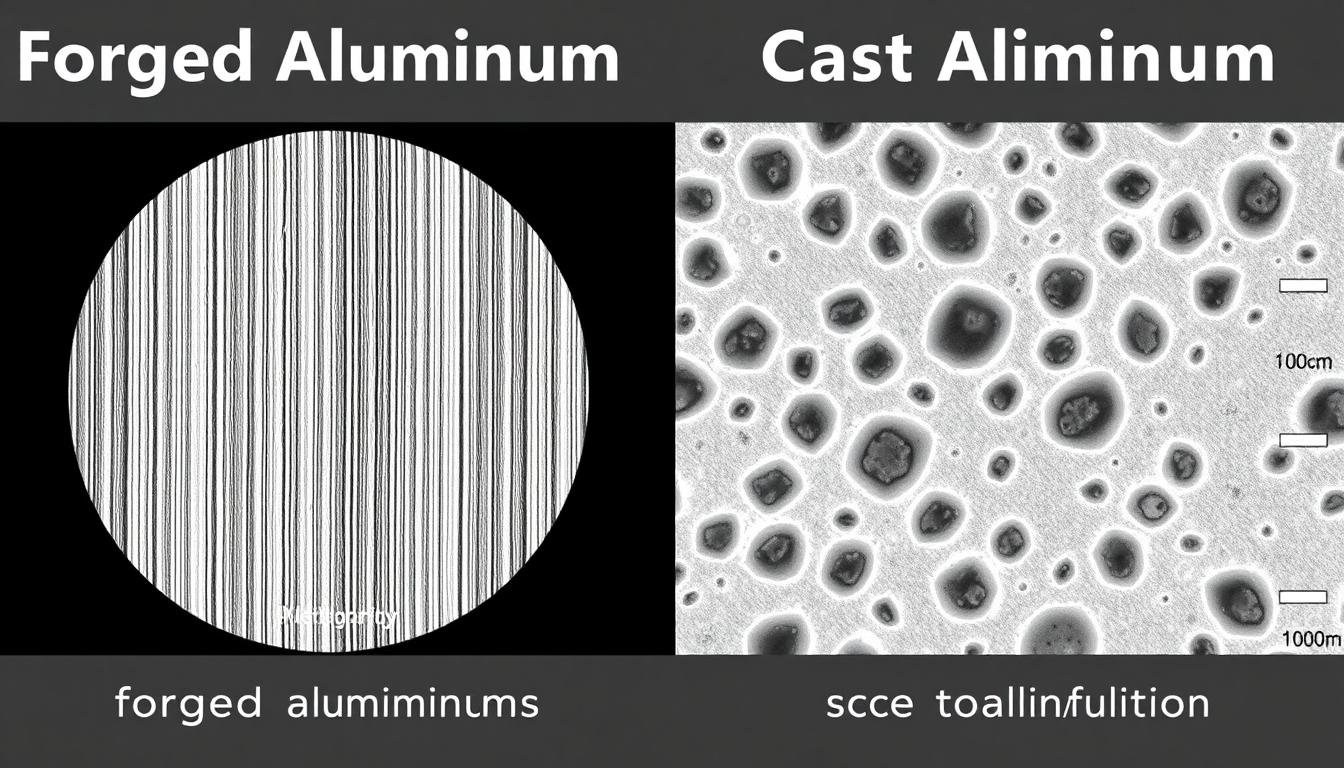

Forged Aluminium vs. Cast Aluminum: Understanding the Critical Differences

When considering aluminum manufacturing methods, the choice between forging and casting significantly impacts component performance, durability, and application suitability. Let’s examine the key differences to understand why forged aluminium is preferred for critical applications.

| Characteristic |

Forged Aluminium |

Cast Aluminum |

| Grain Structure |

Directional, refined, and aligned with part contours |

Random, coarse, non-directional |

| Mechanical Strength |

Superior (20-100% stronger than casting) |

Moderate to good |

| Fatigue Resistance |

Excellent |

Fair to good |

| Internal Defects |

Minimal to none |

Potential porosity and inclusions |

| Density |

High (minimal porosity) |

Lower (potential voids) |

| Design Complexity |

Moderate (limited by die constraints) |

High (complex shapes possible) |

| Production Volume |

Low to high |

Medium to high |

| Cost |

Higher initial tooling, better long-term value |

Lower initial cost, higher lifetime cost |

Microscopic comparison of forged aluminum (left) vs. cast aluminum (right) showing the superior grain structure of forged components

Need Help Choosing Between Forged and Cast Aluminum?

Our engineering team can help determine the optimal manufacturing process for your specific application requirements.

Get Expert Advice

Aluminum Alloys for Forging: Selecting the Right Material

Not all aluminum alloys are created equal when it comes to forging. The choice of alloy significantly impacts the mechanical properties, corrosion resistance, and overall performance of the final component. At MAIKONG, we work with a wide range of aluminum alloys to meet specific application requirements.

Various aluminum alloy billets prepared for the forging process, each offering unique properties

Common Aluminum Alloy Series for Forging

2xxx Series (Al-Cu)

Examples: 2014, 2024, 2219

Properties: High strength, excellent fatigue resistance, good machinability

Applications: Aerospace structural components, military equipment

6xxx Series (Al-Mg-Si)

Examples: 6061, 6082

Properties: Good strength, excellent corrosion resistance, superior formability

Applications: Automotive parts, structural components, marine applications

7xxx Series (Al-Zn)

Examples: 7075, 7050

Properties: Highest strength aluminum alloys, good fatigue resistance

Applications: Critical aerospace components, high-performance automotive parts

Alloy Selection Considerations

- Mechanical Requirements: Strength, hardness, and fatigue resistance needed for the application

- Environmental Factors: Exposure to corrosive environments, temperature extremes

- Manufacturing Considerations: Forgeability, machinability, heat treatment response

- Cost Constraints: Material cost, processing requirements, volume production

- Regulatory Requirements: Industry standards, certifications, traceability

Benefits of Forged Aluminium Components

The unique combination of material properties and manufacturing process makes forged aluminium the preferred choice for critical applications across numerous industries. Understanding these benefits helps engineers and procurement professionals make informed decisions about component manufacturing.

Lightweight forged aluminum automotive components demonstrating the exceptional strength-to-weight ratio

Mechanical Advantages

- Superior Strength-to-Weight Ratio: Forged aluminum offers exceptional strength while maintaining aluminum’s lightweight characteristics

- Enhanced Fatigue Resistance: The aligned grain structure significantly improves resistance to cyclic loading

- Improved Impact Resistance: Better ability to absorb energy without failure

- Consistent Performance: Uniform mechanical properties throughout the component

- Excellent Dimensional Stability: Maintains shape under thermal and mechanical stress

Production and Economic Benefits

- Reduced Material Waste: Near-net-shape capabilities minimize machining requirements

- Lower Lifetime Costs: Longer service life and reduced maintenance needs

- Improved Safety Margins: Higher mechanical properties allow for more conservative design

- Predictable Performance: Consistent properties reduce variation in production

- Versatile Manufacturing: Compatible with various secondary operations

Ready to Experience the Benefits of Forged Aluminum?

Contact MAIKONG today to discuss your project requirements and discover how our forging expertise can enhance your components.

Request a Quote

Applications of Forged Aluminium Across Industries

The exceptional properties of forged aluminium make it ideal for a wide range of applications where performance, reliability, and weight are critical factors. MAIKONG provides forged aluminum components for diverse industries, each with unique requirements and specifications.

Diverse applications of forged aluminum components across multiple industries

Aerospace

- Structural components

- Landing gear parts

- Engine components

- Turbine blades

- Control systems

Automotive

- Suspension components

- Connecting rods

- Wheel hubs

- Steering knuckles

- Transmission parts

Industrial

- Hydraulic components

- Valves and fittings

- Pressure vessels

- Structural connectors

- Heavy machinery parts

Sports & Recreation

- Bicycle components

- Golf club heads

- Climbing equipment

- Marine hardware

- High-performance equipment

Defense

- Weapons components

- Armor systems

- Vehicle parts

- Communication equipment

- Tactical gear

Medical

- Surgical instruments

- Equipment components

- Prosthetic devices

- Imaging system parts

- Laboratory equipment

MAIKONG’s Aluminum Forging Capabilities

At MAIKONG, we offer comprehensive aluminum forging services backed by advanced equipment, technical expertise, and rigorous quality control. Our state-of-the-art facility in GD, SZ provides end-to-end solutions from design to finished components.

MAIKONG’s state-of-the-art aluminum forging facility in GD, SZ

Our Comprehensive Forging Services

Design & Engineering

- CAD/CAM design assistance

- Finite Element Analysis (FEA)

- Material selection consultation

- Process optimization

- Prototype development

Manufacturing

- Open-die forging

- Closed-die forging

- Precision forging

- Heat treatment

- Surface finishing

Quality Assurance

- Material certification

- Dimensional inspection

- Non-destructive testing

- Mechanical property testing

- Full documentation packages

Equipment and Capacity

Forging Equipment

- Hydraulic presses (500-2000 tons)

- Precision die systems

- Automated handling equipment

- Heat treatment furnaces

- Surface preparation systems

CNC Machining Capabilities

- 60+ CNC machines

- 3, 4, and 5-axis machining centers

- CNC turning centers

- Swiss-type precision machining

- 100+ tons monthly capacity

Discover MAIKONG’s Full-Service Aluminum Forging Solutions

From design assistance to finished components, we provide comprehensive forging services tailored to your specific requirements.

Explore Our Services

Quality Control in Forged Aluminium Production

Quality is at the core of MAIKONG’s manufacturing philosophy. Our comprehensive quality control system ensures that every forged aluminium component meets or exceeds customer specifications and industry standards.

Precision quality control inspection of forged aluminum components at MAIKONG’s facility

Our Quality Assurance Process

- Material Verification: Chemical composition and mechanical property testing of incoming materials

- Process Monitoring: Continuous monitoring of critical parameters during forging

- Heat Treatment Validation: Verification of proper thermal processing through hardness testing

- Dimensional Inspection: Precision measurement using coordinate measuring machines (CMM)

- Non-Destructive Testing: Ultrasonic, magnetic particle, and dye penetrant inspection as required

- Mechanical Testing: Tensile, impact, and fatigue testing of production samples

- Surface Quality Inspection: Visual and automated inspection of surface finish

- Final Verification: Comprehensive inspection before shipping

Certifications and Standards

MAIKONG maintains ISO 9001:2015 certification and adheres to international standards for aluminum forging. Our quality management system ensures consistent quality, traceability, and documentation for every component we produce.

MAIKONG’s quality certifications and comprehensive documentation ensure traceability and compliance

Why Choose MAIKONG for Your Forged Aluminium Needs

MAIKONG offers a unique combination of technical expertise, manufacturing capabilities, and customer service that sets us apart as a premier provider of forged aluminium components. Our commitment to quality, innovation, and customer satisfaction makes us the ideal partner for your manufacturing needs.

MAIKONG’s engineering team collaborating with customers to develop optimal forging solutions

Technical Excellence

- Experienced engineering team

- Advanced design capabilities

- Material expertise

- Process optimization

- Continuous innovation

Manufacturing Advantages

- State-of-the-art equipment

- Comprehensive in-house capabilities

- High production capacity

- Flexible batch sizes

- Competitive pricing

Customer Focus

- Responsive communication

- Collaborative approach

- On-time delivery

- Complete documentation

- Long-term partnership

“At MAIKONG, we don’t just manufacture forged aluminum components – we engineer solutions that help our customers succeed. Our comprehensive approach from design to delivery ensures that every part meets the highest standards of quality and performance.”

– MAIKONG Engineering Team

Frequently Asked Questions About Forged Aluminium

Our customers often have questions about forged aluminium and our manufacturing processes. Here are answers to some of the most common inquiries we receive.

What makes forged aluminum stronger than cast aluminum?

Forged aluminum is stronger than cast aluminum due to three primary factors: 1) The forging process creates a refined, dense grain structure with minimal porosity; 2) The directional grain flow follows the contours of the part, concentrating strength where needed; and 3) The mechanical working during forging eliminates internal defects that can serve as stress concentration points. These factors combine to provide superior tensile strength, fatigue resistance, and impact toughness compared to cast aluminum.

What aluminum alloys are best for forging?

The best aluminum alloys for forging depend on the specific application requirements. The most commonly forged aluminum alloys include:

- 2xxx series (Al-Cu): Such as 2014 and 2024, offering high strength and good machinability

- 6xxx series (Al-Mg-Si): Including 6061 and 6082, providing a good balance of strength, corrosion resistance, and formability

- 7xxx series (Al-Zn): Like 7075, delivering the highest strength among aluminum alloys

At MAIKONG, we help customers select the optimal alloy based on mechanical requirements, environmental conditions, manufacturing considerations, and cost constraints.

What is the difference between forged aluminum and extruded aluminum?

Forged aluminum and extruded aluminum differ in their manufacturing processes and resulting properties:

- Forging: Involves compressive force to shape heated aluminum between dies, creating components with superior strength, refined grain structure, and directional properties

- Extrusion: Involves pushing heated aluminum through a die to create long profiles with consistent cross-sections, offering good strength in the longitudinal direction but less control over grain structure

Forging is typically used for discrete, high-strength components with complex 3D geometries, while extrusion is ideal for long, uniform cross-section products like profiles, tubes, and bars.

What are the limitations of aluminum forging?

While aluminum forging offers many advantages, it does have some limitations:

- Geometric Complexity: Very complex shapes with deep recesses or thin sections can be challenging to forge

- Tooling Costs: Initial die costs can be high, especially for low-volume production

- Size Limitations: Very large components may require specialized equipment

- Minimum Order Quantities: May not be economical for extremely small production runs

At MAIKONG, we work closely with customers to overcome these limitations through innovative design approaches, optimized tooling, and efficient production planning.

How does MAIKONG ensure the quality of forged aluminum components?

MAIKONG ensures the quality of forged aluminum components through a comprehensive quality management system that includes:

- Rigorous material testing and certification

- Process parameter monitoring and control

- In-process inspections at critical stages

- Advanced dimensional measurement using CMM technology

- Non-destructive testing as required by specifications

- Mechanical property verification

- Final inspection and documentation

Our ISO 9001:2015 certified quality system provides traceability throughout the manufacturing process, ensuring consistent quality and reliability.

Conclusion: The Superior Choice for Critical Applications

What is forged aluminium? It’s more than just a manufacturing process – it’s a commitment to superior quality, performance, and reliability. The unique combination of refined grain structure, directional strength, and enhanced mechanical properties makes forged aluminum the material of choice for critical applications across numerous industries.

At MAIKONG, we leverage our extensive expertise in aluminum forging to deliver components that meet the most demanding requirements. From aerospace and automotive to industrial and defense applications, our comprehensive capabilities ensure that every forged aluminum part we produce delivers exceptional performance and value.

Contact us today to discover how MAIKONG’s aluminum forging services can help you achieve your manufacturing goals with precision-engineered components that exceed expectations.

Forged aluminum components showcasing the superior finish and structural integrity achieved through the forging process

Forged aluminum components showcasing the superior finish and structural integrity achieved through the forging process