Aluminum forging is a sophisticated metal forming process that shapes aluminum alloys using compressive forces to create high-strength, lightweight components with superior mechanical properties. For US businesses seeking reliable manufacturing partners, understanding the advantages of aluminum forging can significantly impact product performance, durability, and cost-effectiveness. MAIKONG brings decades of expertise in precision aluminum forging to deliver exceptional quality parts with optimal strength-to-weight ratios for aerospace, automotive, defense, and other demanding industries.

The Aluminum Forging Process Explained

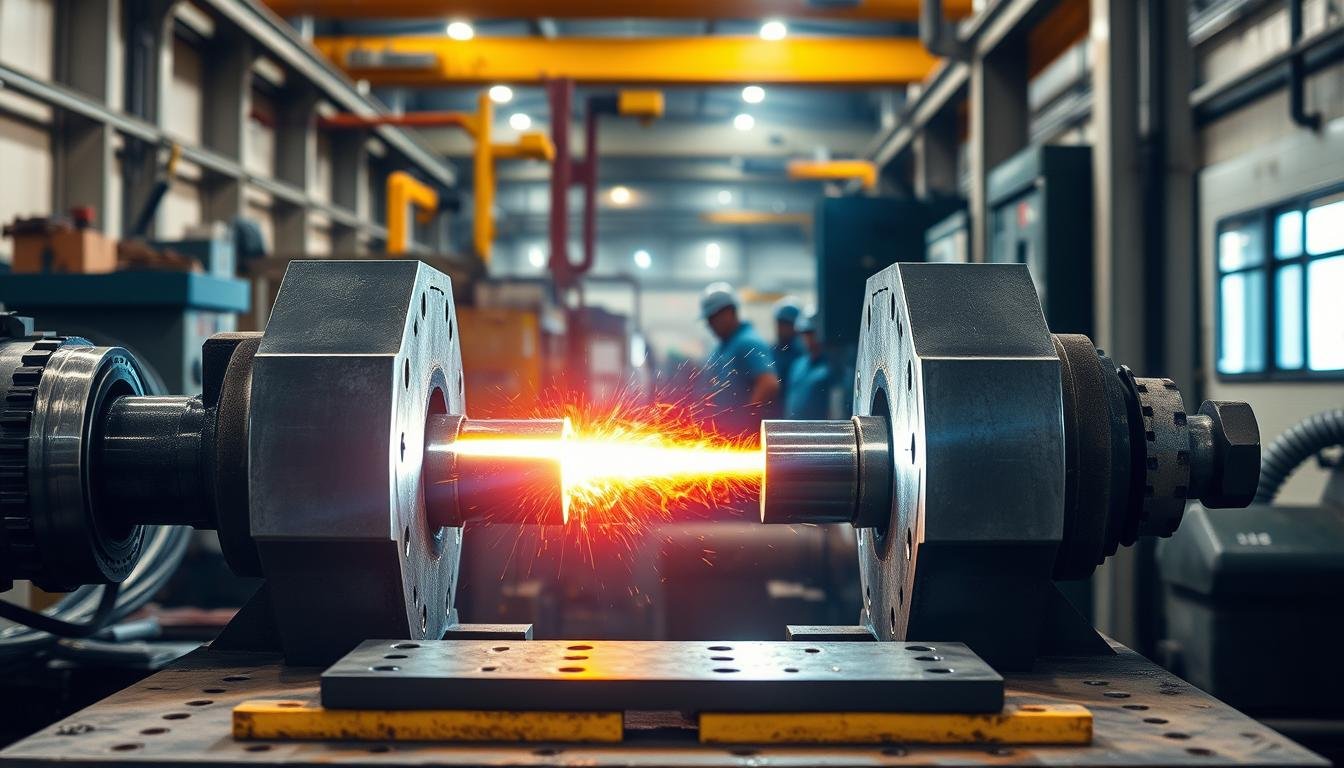

Aluminum forging is a precision manufacturing technique where aluminum is heated to specific temperatures and then shaped under controlled pressure between dies. This process fundamentally alters the metal’s grain structure, creating parts with exceptional strength, durability, and performance characteristics that surpass cast or machined components.

Key Steps in the Aluminum Forging Process

- Material selection and preparation of aluminum billets

- Heating aluminum to optimal forging temperature (typically 750-950°F)

- Positioning in forging dies designed for specific part geometry

- Application of precisely controlled pressure to shape the metal

- Controlled cooling to maintain desired material properties

- Secondary operations including trimming, heat treatment, and finishing

Types of Aluminum Forging Techniques

- Closed-die forging: Creates complex shapes with tight tolerances

- Open-die forging: Ideal for larger, simpler shapes with less tooling cost

- Impression-die forging: Produces precise, near-net shapes

- Cold forging: Performed at room temperature for specific applications

- Warm forging: Conducted at intermediate temperatures

- Hot forging: Most common method for aluminum alloys

Why Choose Aluminum Forging for Your Manufacturing Needs

Advantages of Aluminum Forging

- Superior strength-to-weight ratio compared to other manufacturing methods

- Enhanced mechanical properties through optimized grain structure

- Excellent fatigue resistance and durability under stress

- Consistent material properties throughout the part

- Natural corrosion resistance for extended product life

- Improved impact and shock resistance

- Ability to create complex geometries with high precision

- Excellent thermal and electrical conductivity

- 100% recyclable material for sustainability

Limitations to Consider

- Higher initial tooling costs compared to casting

- Size limitations based on available equipment

- More complex shapes may require multiple forging steps

- Not economical for very small production runs

- Some design constraints compared to casting processes

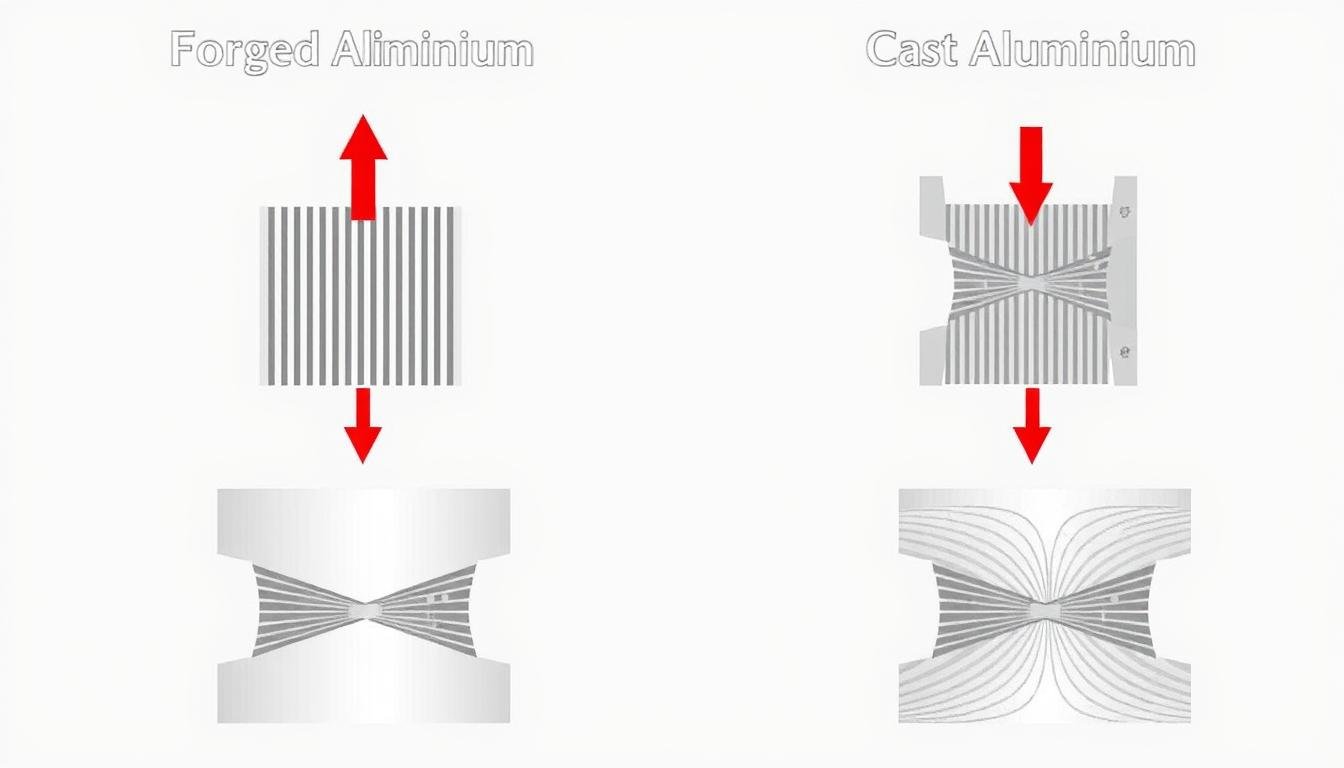

The Optimal Strength-to-Weight Ratio of Aluminum Forging

The exceptional strength-to-weight ratio achieved through aluminum forging is a critical advantage for weight-sensitive applications. This fundamental engineering principle balances material strength against weight—essential for industries prioritizing performance, efficiency, and safety. The forging process aligns and refines aluminum’s internal grain structure, dramatically enhancing its resilience and strength while maintaining its lightweight characteristics.

At MAIKONG, we leverage this principle to create components that withstand both static and dynamic loads with minimal weight penalties. Our aluminum forging expertise showcases engineering excellence through a sophisticated combination of material science, metallurgy, and precision manufacturing—embodying efficiency and performance that reshapes possibilities across industries.

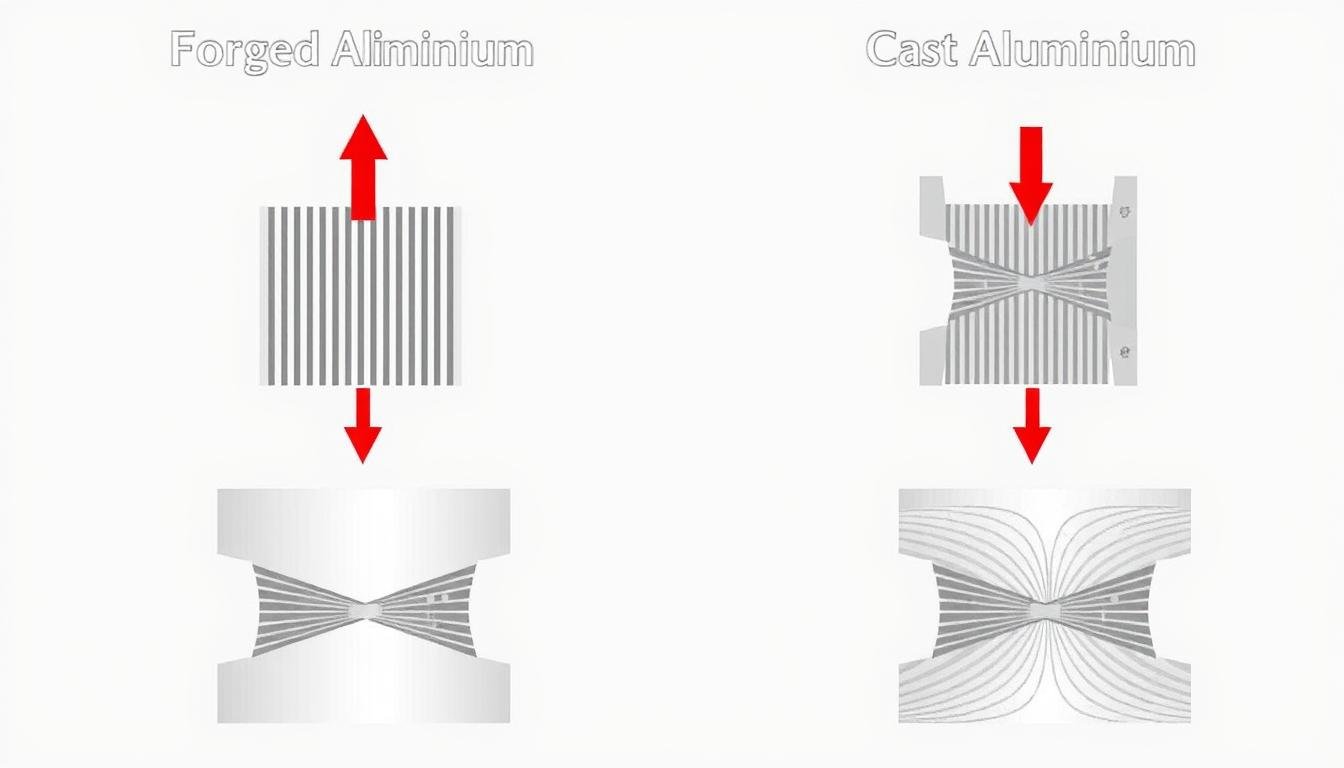

Aluminum Forging vs. Casting: A Comprehensive Comparison

Understanding the differences between aluminum forging and casting is crucial for selecting the optimal manufacturing process for your specific application requirements. The following comparison highlights key differences in mechanical properties, production considerations, and suitable applications.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Heat Treatment Response |

✅ Responsive for controlled material properties |

Less predictable response |

| Grain Structure |

✅ Directional grain flow for improved properties |

No directional grain structure |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed |

| Resistance to Corrosion |

✅ Improved due to denser structure |

Naturally forming oxide layer for resistance |

| Engineering Consistency |

✅ Controlled material characteristics |

Variability in material properties |

Not Sure Which Process Is Right for Your Project?

Our engineering team can analyze your requirements and recommend the optimal manufacturing approach.

Request a Free Consultation

Industries Benefiting from Aluminum Forging

The exceptional properties of forged aluminum make it the material of choice across numerous industries where performance, safety, and reliability are paramount. MAIKONG’s aluminum forging expertise serves diverse sectors with customized solutions.

Aerospace

The aerospace industry relies heavily on aluminum forging for critical components where failure is not an option. Forged aluminum parts offer the perfect balance of lightweight construction and exceptional strength for:

- Aircraft structural components

- Engine mounts and housings

- Landing gear components

- Fuel system parts

- Control surface mechanisms

Automotive

The automotive sector benefits from aluminum forging through improved vehicle performance, fuel efficiency, and safety. Common applications include:

- Suspension components

- Steering knuckles

- Connecting rods

- Wheel hubs and pistons

- Drivetrain components

- Performance vehicle parts

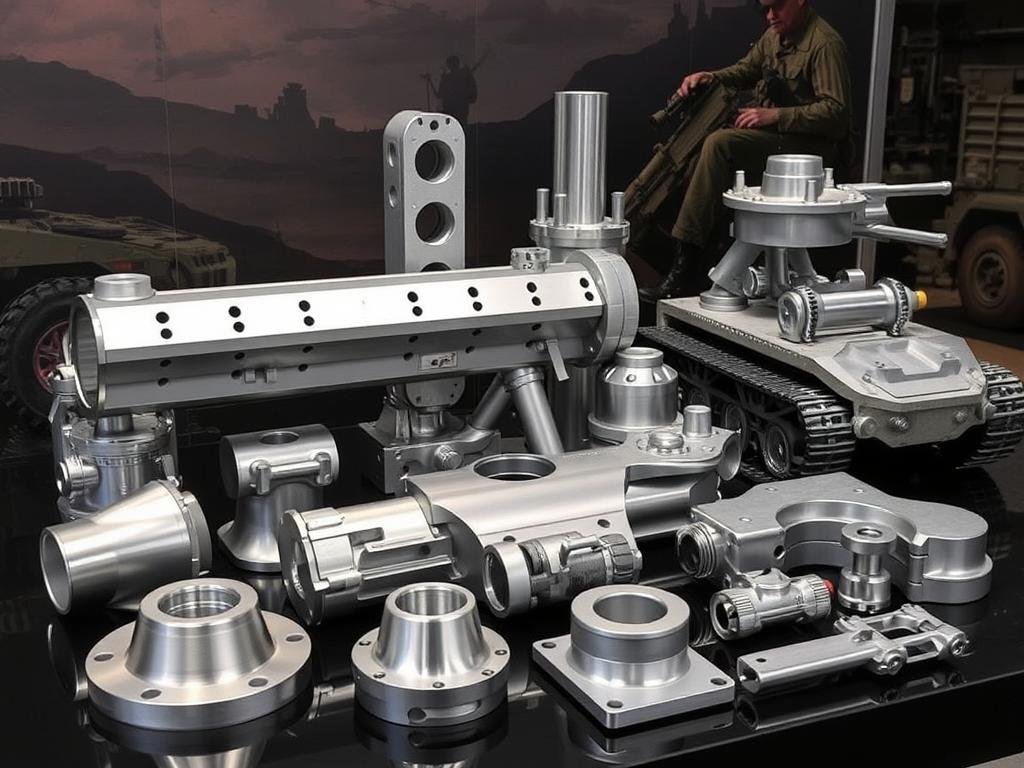

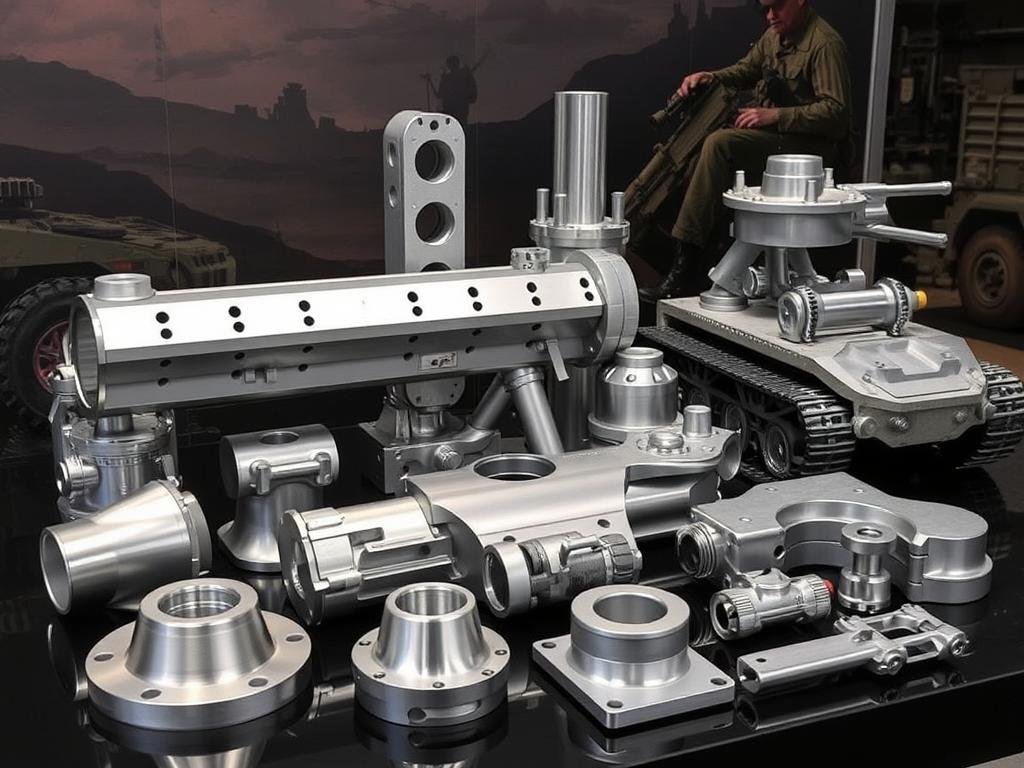

Defense & Military

Military and defense applications demand the highest standards of reliability and performance that aluminum forging provides:

- Weapons systems components

- Military vehicle parts

- Naval equipment components

- Tactical equipment housings

- Communication system structures

- Unmanned vehicle components

Medical Equipment

The medical industry utilizes forged aluminum for equipment requiring precision, cleanliness, and reliability:

- Surgical instrument components

- Imaging equipment structures

- Hospital bed mechanisms

- Medical device housings

- Rehabilitation equipment

Sports & Recreation

Sporting goods benefit from the lightweight strength of forged aluminum:

- High-performance bicycle components

- Golf club heads

- Tennis racket frames

- Mountain climbing equipment

- Marine equipment components

Industrial Equipment

Industrial applications leverage forged aluminum’s durability and corrosion resistance:

- Hydraulic system components

- Valve bodies and fittings

- Pump components

- Pressure vessels

- Material handling equipment

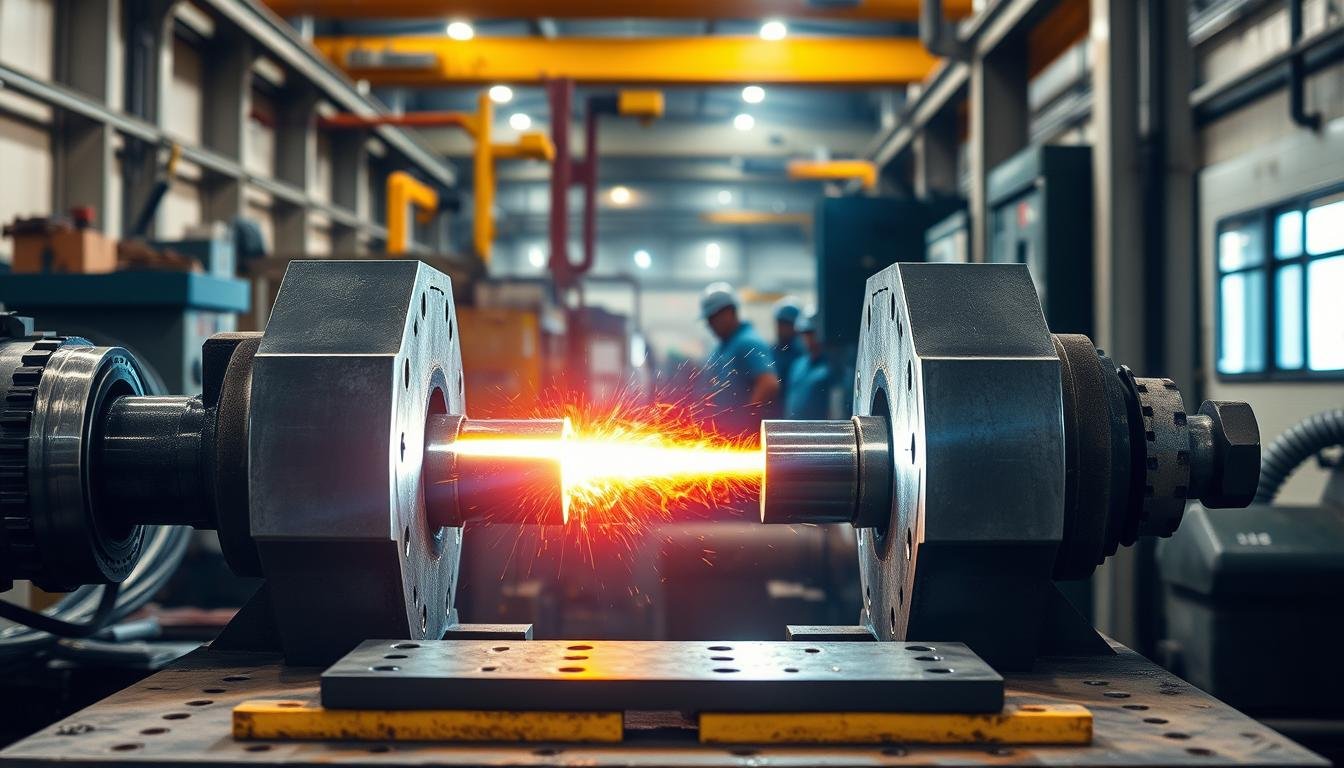

MAIKONG’s Comprehensive Aluminum Forging Capabilities

At MAIKONG, we offer end-to-end aluminum forging solutions from initial design consultation through final finishing and quality assurance. Our state-of-the-art facility in GD, SZ is equipped with 60+ CNC machines providing 100+ tons of metal processing capacity monthly, ensuring we can meet your most demanding requirements.

Design & Engineering

- CAD/CAM Integration: Advanced analysis software for early-stage issue identification

- Material Selection: Expert guidance on aluminum alloy selection based on mechanical properties, machinability, and cost-effectiveness

- Tooling Design: Precision die design ensuring initial quality and consistency

- Process Optimization: Finite element analysis to simulate and perfect the forging process

Production Capabilities

- Forging Workshop: Advanced equipment accommodating diverse specifications

- Heat Treatment: In-house capabilities with comprehensive statistical analysis

- Precision Grinding: Automated robot grinding for parting line removal

- CNC Machining: State-of-the-art machines for precise secondary operations

- Surface Treatment: Comprehensive finishing options enhancing appearance and performance

Quality Assurance

- ISO 9001:2015 Certified: Rigorous quality management system

- Material Testing: Comprehensive laboratory for material verification

- Dimensional Inspection: Advanced measurement equipment for precise tolerance verification

- Non-Destructive Testing: Multiple methods to ensure internal integrity

- Documentation: Complete traceability and certification

Common Aluminum Alloys for Forging Applications

Selecting the right aluminum alloy is crucial for achieving optimal performance in your forged components. MAIKONG offers expertise in working with a wide range of aluminum alloys, each with specific properties suited to different applications.

| Alloy |

Key Properties |

Common Applications |

| 2014 |

High strength, good machinability, moderate corrosion resistance |

Aircraft fittings, wheels, structural components |

| 2024 |

High strength-to-weight ratio, excellent fatigue resistance |

Aircraft structures, truck wheels, transportation parts |

| 2219 |

Good weldability, maintains strength at high temperatures |

Aerospace structures, fuel tanks, high-temperature applications |

| 6061 |

Good corrosion resistance, excellent formability, medium strength |

Marine fittings, transportation components, structural parts |

| 7050 |

Very high strength, excellent stress corrosion resistance |

Aerospace structural parts, defense applications |

| 7075 |

One of the highest strength aluminum alloys, good fatigue resistance |

Aircraft structures, defense equipment, high-stress components |

Our metallurgical expertise allows us to recommend the optimal alloy for your specific application requirements, balancing mechanical properties, corrosion resistance, weight considerations, and cost-effectiveness.

Comprehensive Metal Manufacturing Services at MAIKONG

Beyond our core aluminum forging capabilities, MAIKONG offers a complete range of metal manufacturing services to meet all your production needs. Our integrated approach ensures consistency, quality control, and efficient project management from concept to completion.

CNC Machining Services

- CNC Turning: Precision manufacturing of cylindrical shapes with superior surface finishes

- CNC Milling: Complex prismatic shapes and flat surfaces for diverse applications

- Swiss-Type Machining: Specialized precision for small parts and long shaft components

- Multi-Axis Machining: Advanced capabilities for complex geometries

Additional Forging Capabilities

- Steel Forging: Carbon, alloy, and tool steel forgings for high-strength applications

- Brass Forging: Precision brass components with excellent electrical properties

- Custom Metal Parts: Specialized components to exact specifications

- Precision Machining: Tight-tolerance secondary operations

Value-Added Services

- Heat Treatment: Optimizing mechanical properties for specific applications

- Surface Finishing: Anodizing, painting, laser engraving, and sand blasting

- Quality Testing: Comprehensive material and dimensional verification

- Prototyping: Rapid development of sample parts before full production

- Contract Manufacturing: Complete production management

Seeking US Agents Nationwide

MAIKONG is currently expanding our presence in the United States and seeking qualified sales representatives and agents across the country. If you have experience in industrial sales and manufacturing, we offer competitive commission structures and comprehensive product training.

Interested? Contact us at Lucy@maikongforge.us for more information.

Why Choose MAIKONG for Your Aluminum Forging Needs

Our Commitment to Excellence

- Manufacturing Expertise: Decades of experience in precision metal forging and machining

- Production Capacity: 60+ CNC machines with 100+ tons monthly processing capability

- Quality Assurance: ISO 9001:2015 certified with comprehensive testing facilities

- Cost-Effectiveness: Competitive pricing without compromising quality

- Technical Support: Expert engineering assistance throughout your project

- On-Time Delivery: Reliable logistics and project management

- Material Expertise: In-depth knowledge of aluminum alloys and their applications

- Comprehensive Services: One-stop solution from design to finished parts

Frequently Asked Questions About Aluminum Forging

What minimum and maximum sizes can MAIKONG produce for aluminum forged parts?

MAIKONG can produce aluminum forged parts ranging from small components weighing just a few ounces to larger parts up to 25 pounds. Our equipment accommodates various dimensions, but please contact us with your specific requirements for confirmation.

What is the typical lead time for aluminum forged parts?

Lead times vary based on part complexity, quantity, and current production schedule. Typical lead times range from 4-8 weeks for new projects including tooling development, and 2-4 weeks for repeat orders. We offer expedited services for urgent requirements when possible.

How does MAIKONG ensure quality for overseas production?

Our ISO 9001:2015 certified quality management system ensures consistent quality across all production. We implement rigorous inspection protocols, material testing, and dimensional verification. Additionally, we provide comprehensive documentation and can accommodate third-party inspection when required.

Can MAIKONG help with design optimization for aluminum forged parts?

Yes, our engineering team specializes in design for manufacturability (DFM) and can provide valuable input to optimize your designs for the forging process. This collaboration often results in cost savings, improved performance, and enhanced producibility.

Experience the MAIKONG Difference in Aluminum Forging

MAIKONG brings together decades of manufacturing expertise, state-of-the-art equipment, and a commitment to quality that ensures your aluminum forged components meet the highest standards of performance and reliability. Our comprehensive approach—from initial design consultation through final inspection—provides a seamless experience that saves you time, reduces costs, and delivers superior results.

Whether you’re in aerospace, automotive, defense, or any industry requiring high-performance metal components, our team is ready to support your manufacturing needs with precision aluminum forging services and expert technical guidance.