In industries where performance cannot be compromised, forged 7075 T6 aluminum stands as the premier material choice for high-stress applications. This exceptional aluminum alloy combines remarkable strength-to-weight ratio with outstanding fatigue resistance, making it ideal for aerospace, defense, automotive, and high-performance sporting equipment. At MAIKONG, we specialize in precision manufacturing of forged 7075 T6 aluminum components that meet the most demanding specifications while offering cost-effective solutions for businesses across the United States.

Need Custom Forged 7075 T6 Aluminum Parts?

Our engineering team is ready to help you with your specific requirements. Get competitive pricing and expert manufacturing solutions.

Request a Quote

Contact via WhatsApp

Understanding **Forged 7075 T6 Aluminum** Properties

The exceptional performance of forged 7075 T6 aluminum comes from its unique composition and the specialized forging and heat treatment processes. This high-strength alloy contains zinc as its primary alloying element, along with magnesium, copper, and chromium, creating a material with mechanical properties that rival some steels while maintaining the lightweight benefits of aluminum.

Chemical Composition and T6 Temper Process

The 7075 aluminum alloy consists of a carefully balanced mixture of elements that contribute to its remarkable properties. The T6 designation indicates a specific heat treatment process that maximizes the material’s strength.

| Element |

Percentage (%) |

Contribution to Properties |

| Aluminum (Al) |

87.1-91.4 |

Base metal providing lightweight characteristics |

| Zinc (Zn) |

5.1-6.1 |

Primary strengthening element |

| Magnesium (Mg) |

2.1-2.9 |

Enhances strength-to-weight ratio |

| Copper (Cu) |

1.2-2.0 |

Improves tensile strength and machinability |

| Chromium (Cr) |

0.18-0.28 |

Controls grain structure and prevents corrosion |

| Other (Fe, Si, Ti, Mn) |

≤ 0.5 each |

Minor elements affecting specific properties |

The T6 tempering process involves three critical steps that transform the aluminum alloy into its high-strength state:

- Solution Heat Treatment: Heating the aluminum to approximately 990°F (530°C) to dissolve alloying elements into solid solution

- Quenching: Rapid cooling in water to prevent precipitation of elements and maintain the supersaturated state

- Artificial Aging: Controlled heating at 250-350°F (120-175°C) for 8-24 hours to form strengthening precipitates

This precise heat treatment sequence dramatically improves the yield strength from approximately 8,000 PSI to an impressive 35,000 PSI or higher, making forged 7075 T6 aluminum suitable for the most demanding applications.

Mechanical Properties of Forged 7075 T6 Aluminum

The combination of alloy composition, forging process, and T6 heat treatment results in exceptional mechanical properties that make forged 7075 T6 aluminum the material of choice for critical applications:

| Property |

Value (Imperial) |

Value (Metric) |

| Tensile Strength |

83,000 PSI |

572 MPa |

| Yield Strength |

73,000 PSI |

503 MPa |

| Fatigue Strength |

23,000 PSI |

159 MPa |

| Shear Strength |

48,000 PSI |

331 MPa |

| Hardness (Brinell) |

150 |

150 HB |

| Elongation at Break |

11% |

11% |

| Density |

0.101 lb/in³ |

2.81 g/cm³ |

Corrosion Resistance

While 7075 T6 aluminum offers moderate corrosion resistance in its natural state, it can be susceptible to stress corrosion cracking in certain environments. At MAIKONG, we apply specialized surface treatments such as anodizing, chromate conversion coating, or painting to enhance corrosion resistance for applications exposed to harsh environments.

Machinability

Despite its high strength, forged 7075 T6 aluminum offers excellent machinability with proper tooling and techniques. Our advanced CNC machining capabilities allow us to achieve tight tolerances and complex geometries while maintaining the material’s superior mechanical properties.

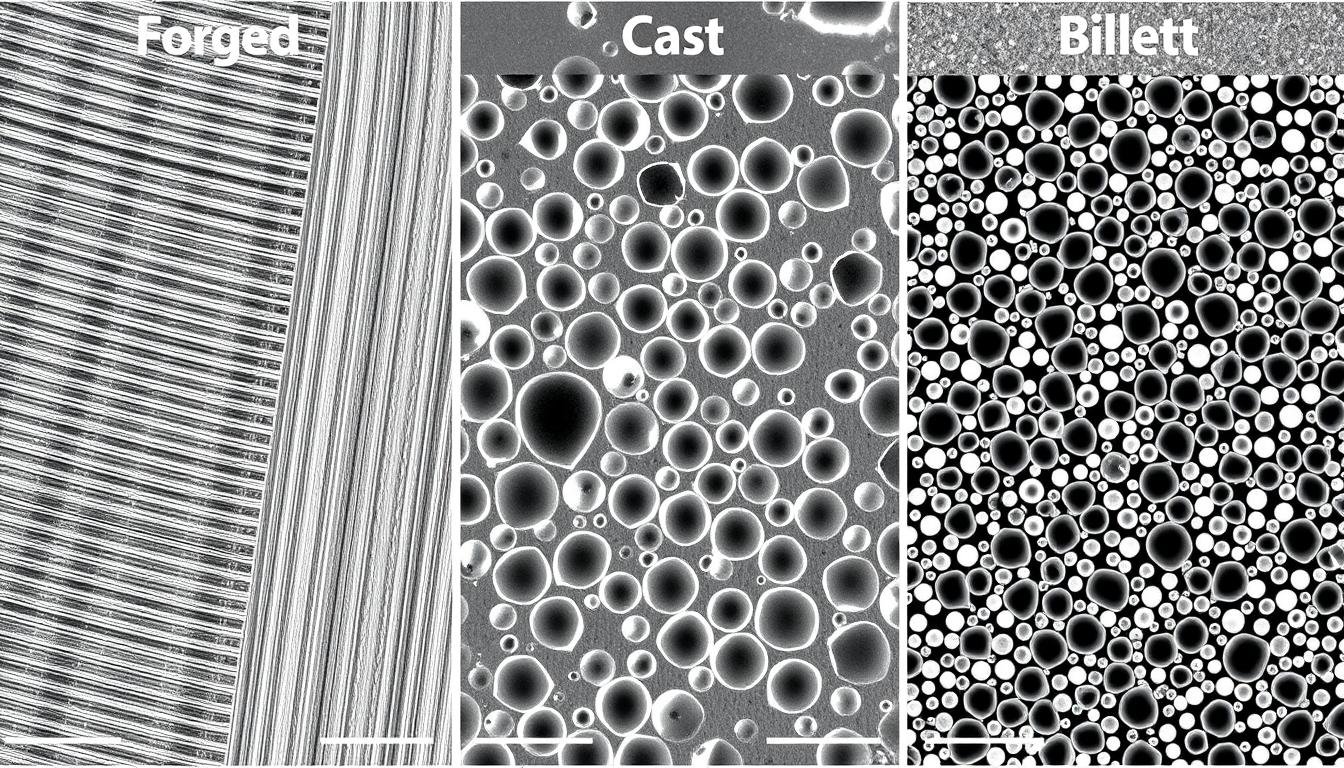

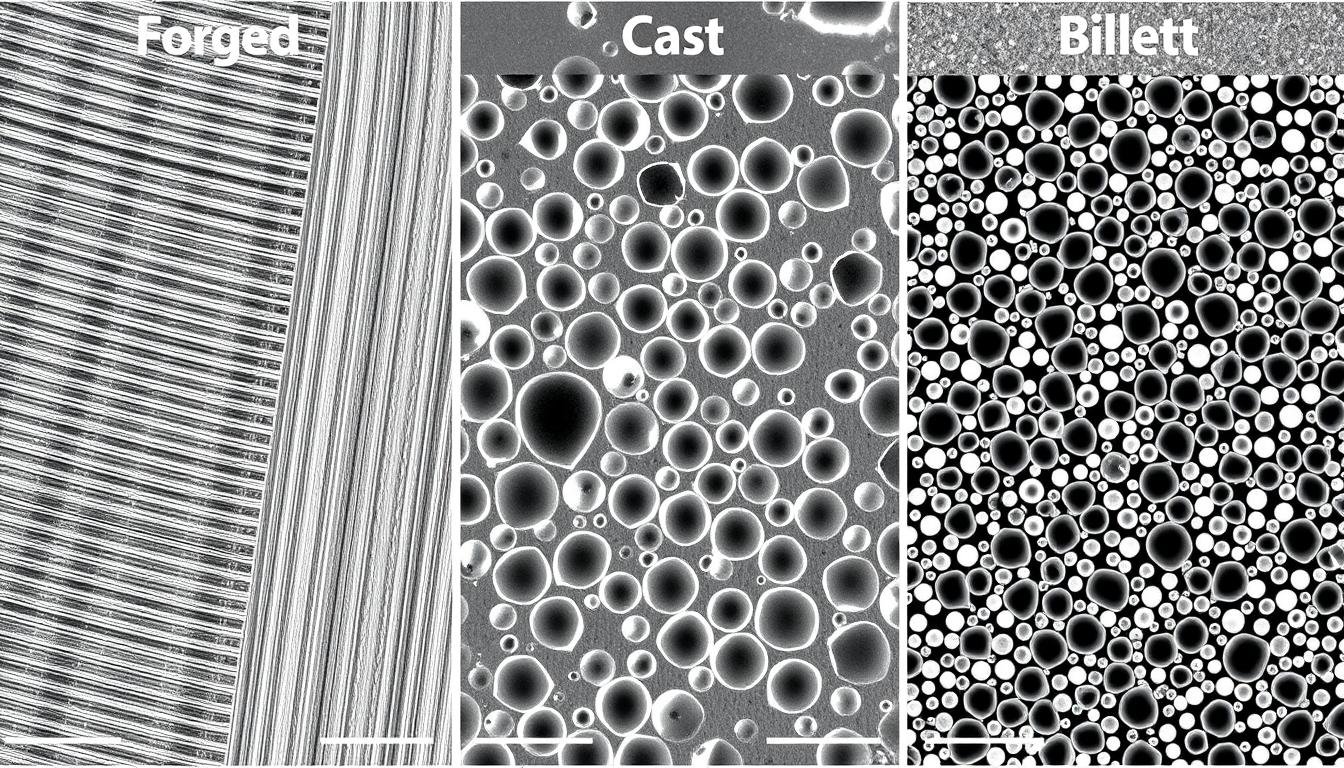

Advantages of **Forged 7075 T6 Aluminum** vs. Other Manufacturing Methods

The forging process offers significant advantages over other manufacturing methods such as casting or machining from billet. When aluminum is forged, it undergoes controlled deformation under high pressure, which aligns the grain structure and eliminates porosity, resulting in superior mechanical properties.

Forged 7075 T6 Aluminum

- Superior strength due to aligned grain structure

- Enhanced fatigue resistance (20-30% higher)

- Improved impact toughness

- Elimination of internal porosity

- Higher strength-to-weight ratio

- Better stress distribution under load

- Enhanced fracture toughness

Cast Aluminum

- Lower strength due to random grain structure

- Potential for internal porosity and defects

- Reduced fatigue resistance

- Lower impact resistance

- Less predictable mechanical properties

- More susceptible to stress concentration

- Limited applications in high-stress environments

Machined Billet

- Good strength but interrupted grain flow

- Higher material waste (up to 80%)

- More expensive for complex shapes

- Longer production time

- Limited size by available stock

- Inconsistent properties across different directions

- Higher energy consumption in production

Need Expert Guidance on Material Selection?

Our engineering team can help you determine the best manufacturing method for your specific application requirements.

Consult Our Engineers

Or call us directly: 8613-51090-74-01

Applications of **Forged 7075 T6 Aluminum**

The exceptional combination of high strength, good machinability, and relatively light weight makes forged 7075 T6 aluminum ideal for a wide range of demanding applications across multiple industries.

Aerospace

- Aircraft structural components

- Wing spars and ribs

- Fuselage frames

- Landing gear components

- Engine mounts and brackets

Automotive

- Suspension components

- Control arms and knuckles

- High-performance connecting rods

- Wheel hubs and spindles

- Brake calipers

Defense & Military

- Weapon components

- Armor mounting systems

- Tactical equipment

- Vehicle structural parts

- Communication equipment housings

Sports Equipment

- Bicycle components

- Rock climbing equipment

- Racing components

- Golf club heads

- High-end fishing reels

Industrial Machinery

- Hydraulic components

- High-pressure valve bodies

- Precision tooling fixtures

- Robotic arm components

- High-stress structural parts

Medical Equipment

- Surgical instrument frames

- Imaging equipment components

- Medical device housings

- Rehabilitation equipment

- Laboratory equipment structures

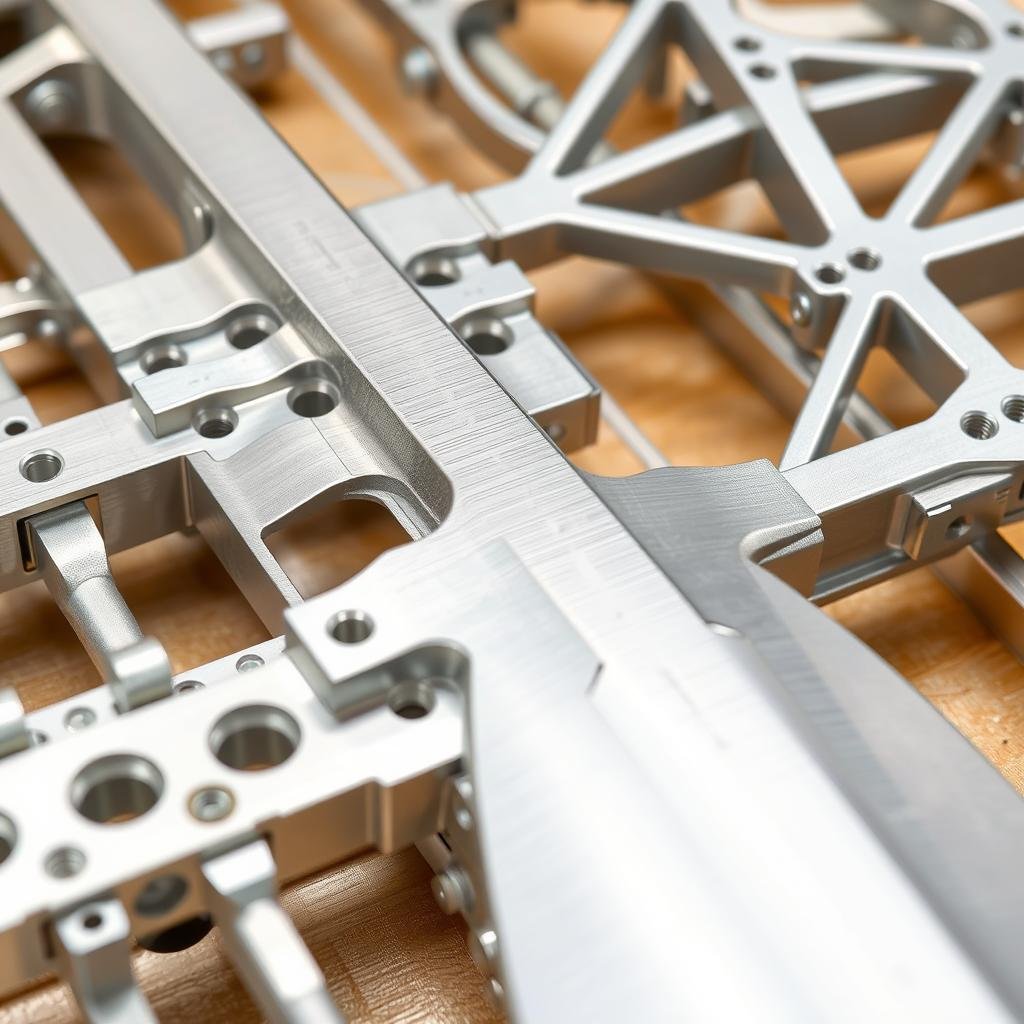

MAIKONG’s **Forged 7075 T6 Aluminum** Manufacturing Process

At MAIKONG, we have developed a comprehensive manufacturing process that ensures the highest quality forged 7075 T6 aluminum components. Our state-of-the-art facility in GD, SZ is equipped with advanced forging presses, heat treatment furnaces, and CNC machining centers to deliver precision parts that meet the most demanding specifications.

- Design and EngineeringOur process begins with collaborative design and engineering. Using advanced CAD/CAM software and finite element analysis, we optimize component design for both performance and manufacturability. This stage includes material selection, process planning, and tooling design.

- Material Selection and TestingWe source premium 7075 aluminum alloy from certified suppliers and verify its composition in our material laboratory. Each batch undergoes rigorous testing to ensure it meets chemical composition requirements before entering our production process.

- Forging Die Design and FabricationOur tooling engineers design and fabricate custom forging dies that ensure optimal grain flow and material distribution. These precision tools are manufactured from high-grade tool steel and undergo regular maintenance to maintain dimensional accuracy.

- Forging ProcessThe aluminum is heated to the optimal forging temperature (typically 750-900°F or 400-480°C) and then shaped under high pressure using our hydraulic forging presses. This process aligns the grain structure and eliminates porosity, resulting in superior mechanical properties.

- Heat TreatmentAfter forging, components undergo the T6 heat treatment process, including solution heat treatment, quenching, and artificial aging. Our computer-controlled furnaces ensure precise temperature control throughout the process to achieve optimal mechanical properties.

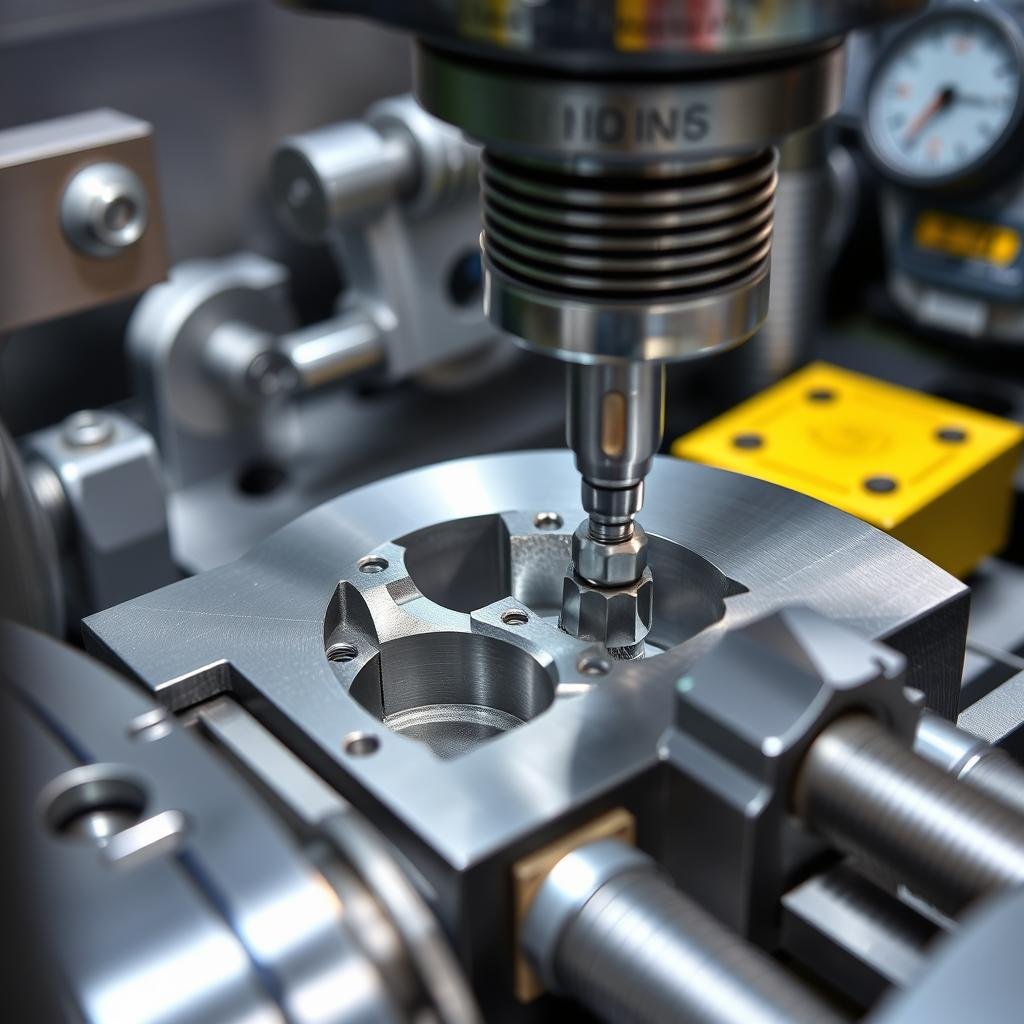

- CNC MachiningWith our fleet of 60+ CNC machines providing over 100 tons of monthly processing capacity, we perform precision machining operations to achieve final dimensions and features. Our advanced multi-axis machining centers can handle complex geometries with tight tolerances.

- Surface TreatmentDepending on application requirements, we apply various surface treatments to enhance corrosion resistance, appearance, or specific performance characteristics. Options include anodizing, chromate conversion coating, painting, and other specialized treatments.

- Quality ControlThroughout the entire process, our comprehensive quality control system ensures that every component meets or exceeds specifications. We utilize advanced inspection equipment including CMM, ultrasonic testing, and hardness testing to verify dimensional accuracy and material properties.

Ready to Start Your Custom Forging Project?

Contact our team today to discuss your specific requirements and discover how MAIKONG can deliver high-quality forged 7075 T6 aluminum components at competitive prices.

Get a Custom Quote

Email Our Team

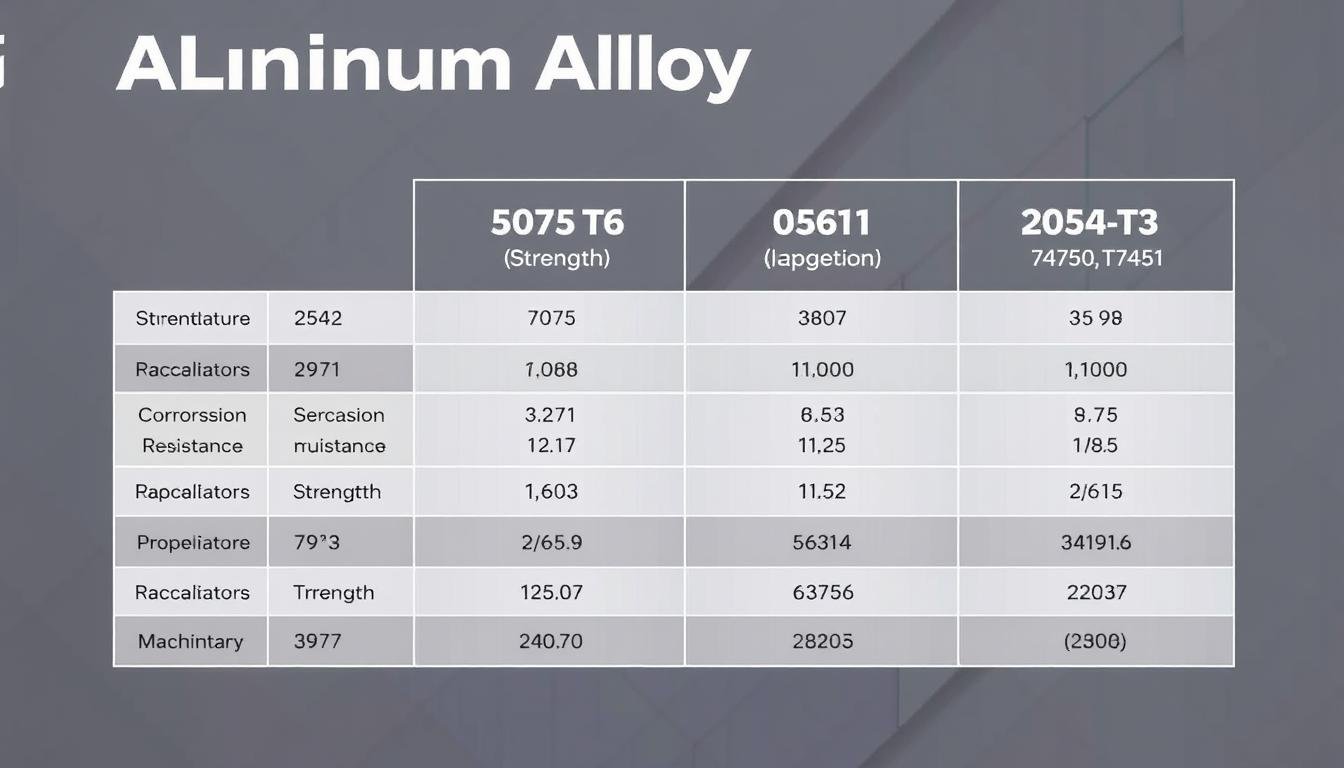

**Forged 7075 T6 Aluminum** vs. Other Aluminum Alloys

While forged 7075 T6 aluminum offers exceptional strength and performance, other aluminum alloys may be more suitable for specific applications. Understanding the differences between these materials helps in selecting the optimal alloy for your requirements.

| Property |

7075-T6 (Forged) |

6061-T6 |

2024-T3 |

7050-T7451 |

| Tensile Strength (MPa) |

572 |

310 |

483 |

510 |

| Yield Strength (MPa) |

503 |

276 |

345 |

455 |

| Elongation (%) |

11 |

12 |

18 |

10 |

| Corrosion Resistance |

Moderate |

Excellent |

Fair |

Good |

| Machinability |

Good |

Excellent |

Good |

Good |

| Weldability |

Poor |

Excellent |

Fair |

Poor |

| Cost |

Higher |

Lower |

Moderate |

High |

| Primary Applications |

Aerospace, defense, high-stress components |

General-purpose structural, marine applications |

Aircraft structures, truck wheels |

Aircraft bulkheads, aerospace structures |

When to Choose Forged 7075 T6 Aluminum

Ideal Applications

- High-stress structural components

- Safety-critical parts

- Applications requiring maximum strength-to-weight ratio

- Components subject to fatigue loading

- Parts requiring excellent machinability and high strength

Consider Alternatives When

- Weldability is required

- Superior corrosion resistance is needed without surface treatment

- Cost is a primary concern

- Complex forming operations are required

- Applications involve exposure to temperatures above 250°F (120°C)

MAIKONG’s Comprehensive Manufacturing Services

Beyond our expertise in forged 7075 T6 aluminum, MAIKONG offers a complete range of metal manufacturing services to meet diverse customer needs. Our integrated capabilities allow us to provide end-to-end solutions from design to finished components.

Aluminum Forging Services

We specialize in precision aluminum forging for various alloys including 7075, 6061, 2024, and others. Our advanced forging equipment can handle components ranging from small precision parts to large structural elements.

CNC Machining Services

With over 60 CNC machines and 100+ tons of monthly processing capacity, we offer precision CNC milling, turning, and multi-axis machining for complex components with tight tolerances.

Steel Forging Services

Our steel forging capabilities include carbon steel, alloy steel, and stainless steel components for automotive, industrial, and construction applications requiring high strength and durability.

Brass Extrusion Services

We provide custom brass extrusion services for electrical components, plumbing fixtures, architectural elements, and decorative applications requiring excellent conductivity and corrosion resistance.

Custom Metal Parts

Our comprehensive manufacturing capabilities allow us to produce custom metal parts for diverse applications across industries, combining different materials and processes to meet specific requirements.

Precision Machining

Our precision machining services deliver components with tight tolerances and excellent surface finishes for applications where dimensional accuracy and consistency are critical.

Why Choose MAIKONG for **Forged 7075 T6 Aluminum** Components

MAIKONG has established itself as a leading manufacturer of high-quality forged aluminum components, offering a unique combination of technical expertise, manufacturing capabilities, and customer service that sets us apart from competitors.

- Comprehensive Manufacturing Capabilities – From design assistance to finished components, our integrated services streamline your supply chain and ensure consistent quality.

- Technical Expertise – Our engineering team has extensive experience in aluminum forging and precision machining, providing valuable insights to optimize your component design.

- Advanced Equipment – Our state-of-the-art facility features the latest forging presses, CNC machines, and inspection equipment to deliver superior quality components.

- Quality Assurance – Our rigorous quality control procedures and ISO 9001 certification ensure that every component meets or exceeds specifications.

- Cost-Effective Solutions – Our efficient manufacturing processes and strategic location allow us to offer competitive pricing without compromising quality.

- Responsive Customer Service – Our dedicated team provides prompt communication and personalized attention to meet your specific requirements.

- Global Shipping Capabilities – We offer reliable shipping solutions to customers worldwide, with particular expertise in serving the United States market.

4.8

Customer Satisfaction

Frequently Asked Questions About **Forged 7075 T6 Aluminum**

What makes forged 7075 T6 aluminum superior to other aluminum alloys?

Forged 7075 T6 aluminum offers an exceptional combination of high strength, good machinability, and relatively light weight. The forging process aligns the grain structure and eliminates porosity, while the T6 heat treatment maximizes strength through controlled precipitation hardening. This results in mechanical properties that rival some steels while maintaining the weight advantage of aluminum.

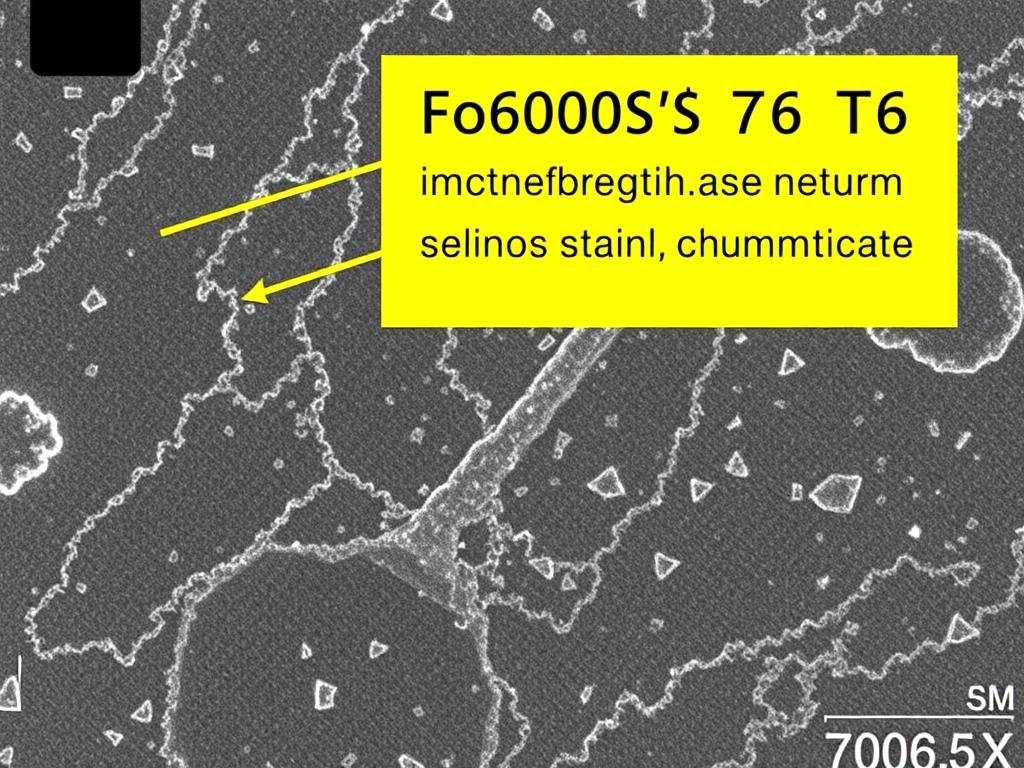

How does the forging process improve the properties of 7075 aluminum?

The forging process significantly enhances the mechanical properties of 7075 aluminum through several mechanisms:

- Grain flow alignment that follows the component’s geometry, improving directional strength

- Elimination of internal porosity and defects that could serve as stress concentration points

- Refinement of the microstructure, resulting in improved toughness and fatigue resistance

- More uniform distribution of alloying elements, enhancing overall performance

These improvements make forged components superior to those manufactured through casting or machining from billet for high-stress applications.

What is the T6 tempering process for 7075 aluminum?

The T6 tempering process for 7075 aluminum involves three main steps:

- Solution Heat Treatment: Heating the aluminum to approximately 990°F (530°C) to dissolve alloying elements into a solid solution

- Quenching: Rapid cooling in water to prevent precipitation of elements and maintain the supersaturated state

- Artificial Aging: Controlled heating at 250-350°F (120-175°C) for 8-24 hours to form strengthening precipitates

This process dramatically improves the yield strength from approximately 8,000 PSI to an impressive 35,000 PSI or higher, making it suitable for demanding applications.

What are the limitations of forged 7075 T6 aluminum?

Despite its exceptional properties, forged 7075 T6 aluminum does have some limitations:

- Poor weldability due to its high zinc content, which can lead to cracking in the heat-affected zone

- Susceptibility to stress corrosion cracking in certain environments without proper surface treatment

- Reduced strength at elevated temperatures (above 250°F or 120°C)

- Higher cost compared to more common alloys like 6061

- More challenging to form using conventional methods due to its high strength

These limitations should be considered when selecting materials for specific applications.

How does MAIKONG ensure the quality of forged 7075 T6 aluminum components?

MAIKONG implements a comprehensive quality assurance system throughout the manufacturing process:

- Material verification and testing before production to ensure proper composition

- Controlled forging parameters monitored by advanced systems

- Precise heat treatment with computer-controlled furnaces and temperature monitoring

- Comprehensive dimensional inspection using coordinate measuring machines (CMM)

- Mechanical property testing including hardness, tensile strength, and yield strength

- Non-destructive testing such as ultrasonic inspection to detect internal defects

- Surface quality inspection and treatment verification

- ISO 9001 certified quality management system governing all processes

This multi-layered approach ensures that every component meets or exceeds specifications and performs reliably in its intended application.