For procurement managers navigating the complex world of metal manufacturing, understanding aluminum forging terminology is essential for making informed sourcing decisions. This comprehensive guide breaks down the critical concepts, processes, and benefits of aluminum forging, equipping you with the knowledge to evaluate suppliers and secure high-quality components for your manufacturing needs. As global supply chains evolve, partnering with experienced aluminum forging specialists like MAIKONG ensures you receive superior products with optimal strength-to-weight ratios and exceptional performance characteristics.

Understanding Aluminum Forging: Fundamental Concepts

At its core, aluminum forging is a metal forming process that shapes aluminum into precise forms by applying compressive forces. Unlike casting, which involves pouring molten metal into molds, forging manipulates solid metal through controlled deformation, resulting in components with superior mechanical properties.

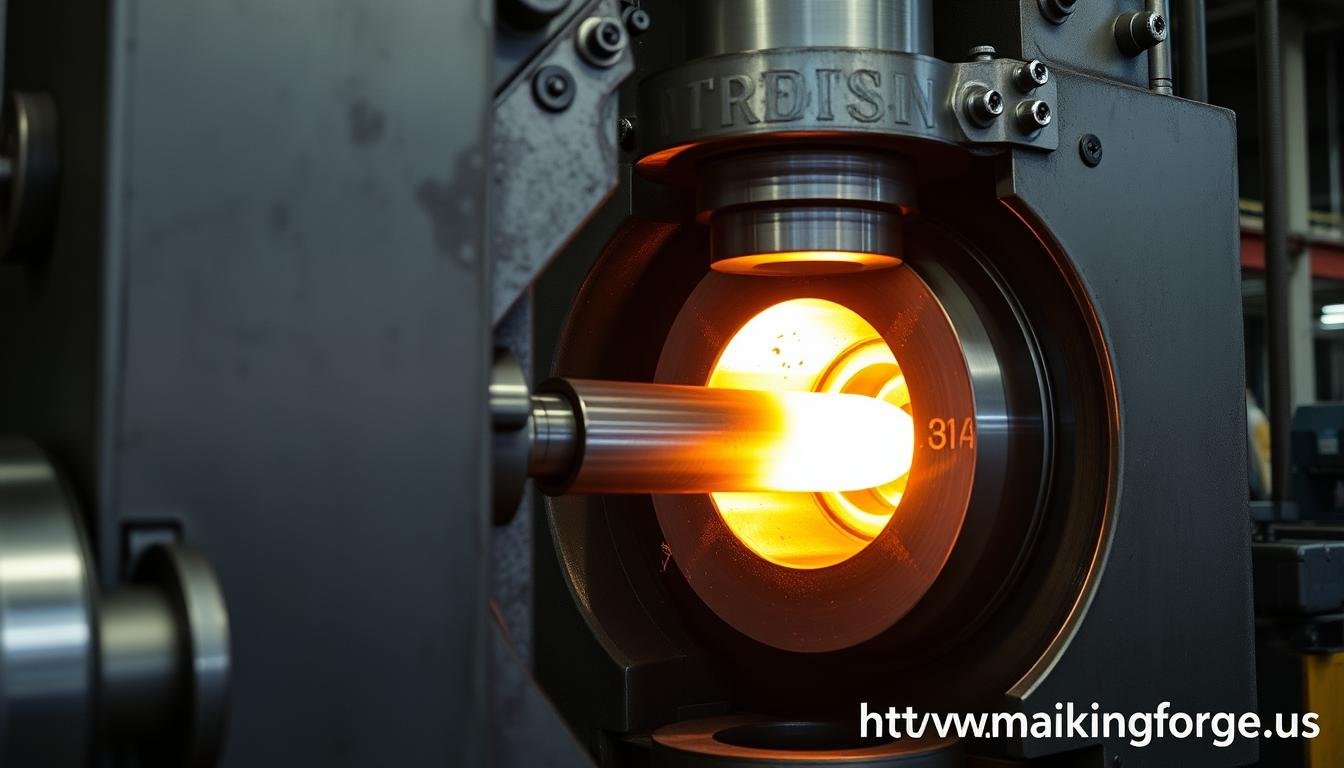

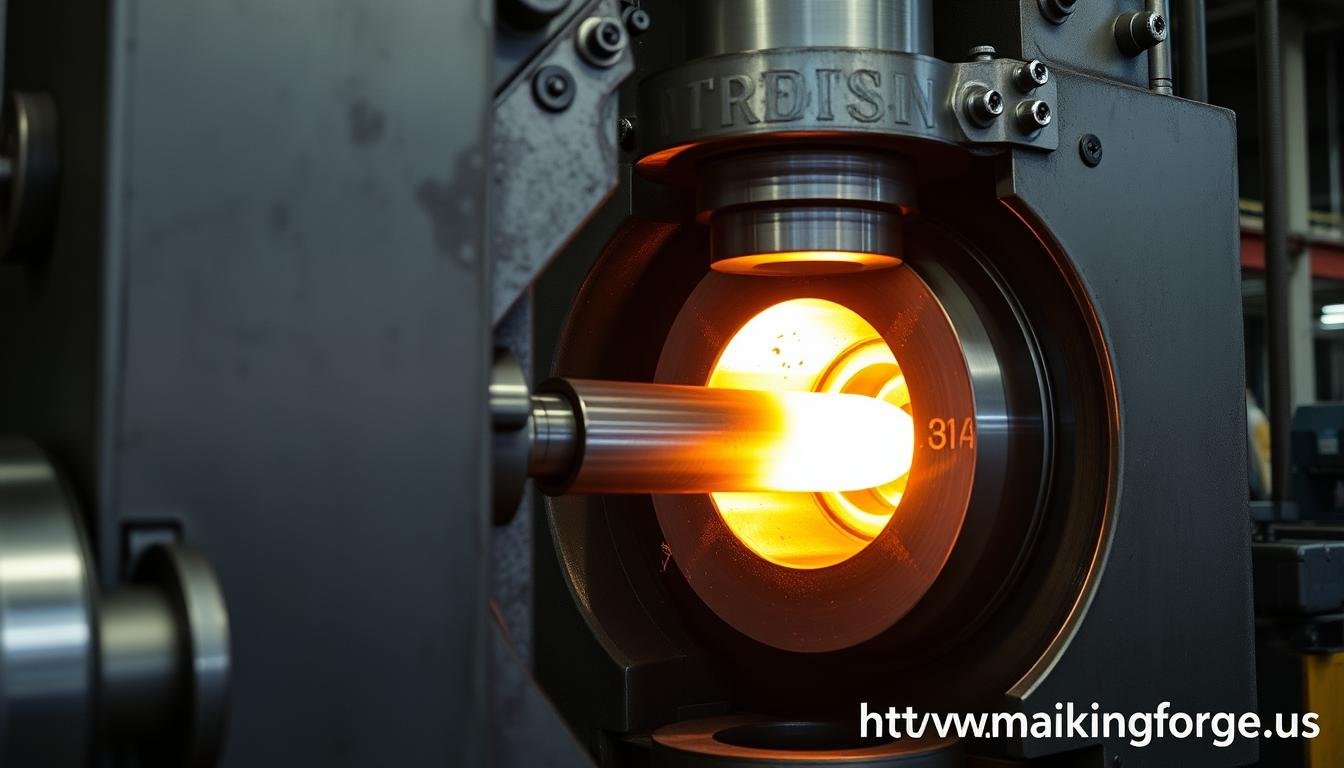

Industrial

aluminum forging process at MAIKONG’s state-of-the-art facility in GD, SZ

The Aluminum Forging Process: Step-by-Step

- Material Selection: Choosing the appropriate aluminum alloy based on desired mechanical properties and application requirements.

- Billet Preparation: Cutting aluminum stock to the required dimensions and cleaning to remove contaminants.

- Heating: Raising the aluminum to forging temperature (typically 700°F to 950°F) to increase malleability.

- Forging Operation: Applying pressure using hydraulic presses or hammers to shape the heated aluminum.

- Cooling: Controlled cooling to prevent thermal shock and maintain dimensional stability.

- Heat Treatment: Enhancing mechanical properties through solution treatment, quenching, and aging.

- Finishing: Secondary operations including machining, grinding, and surface treatments.

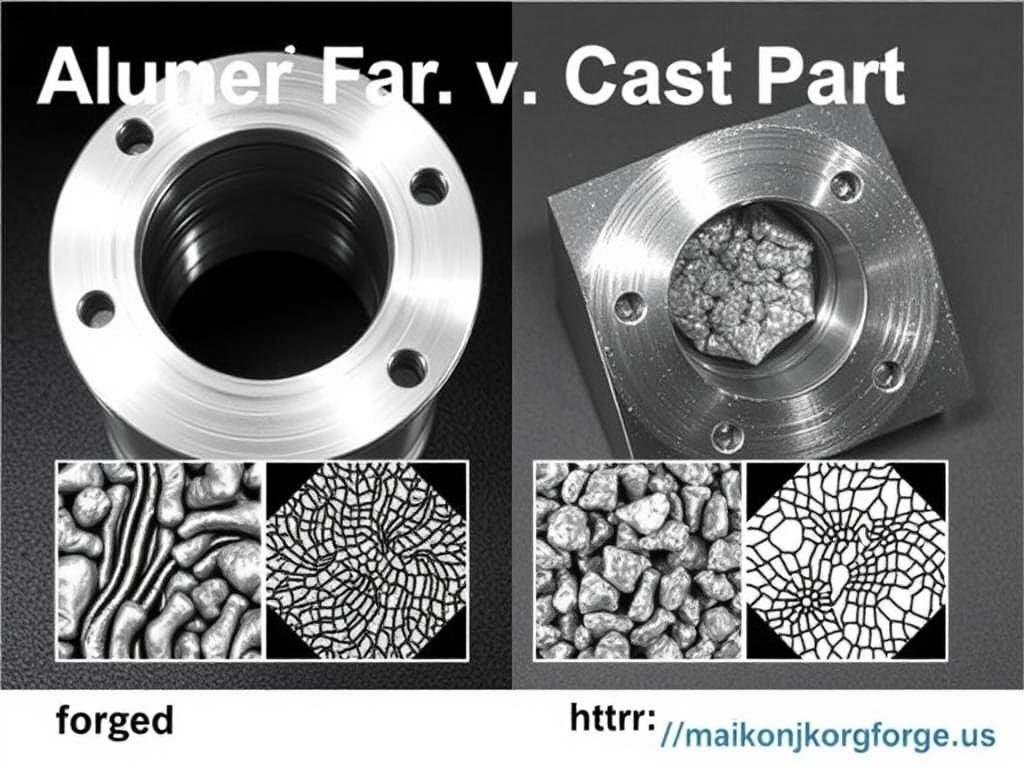

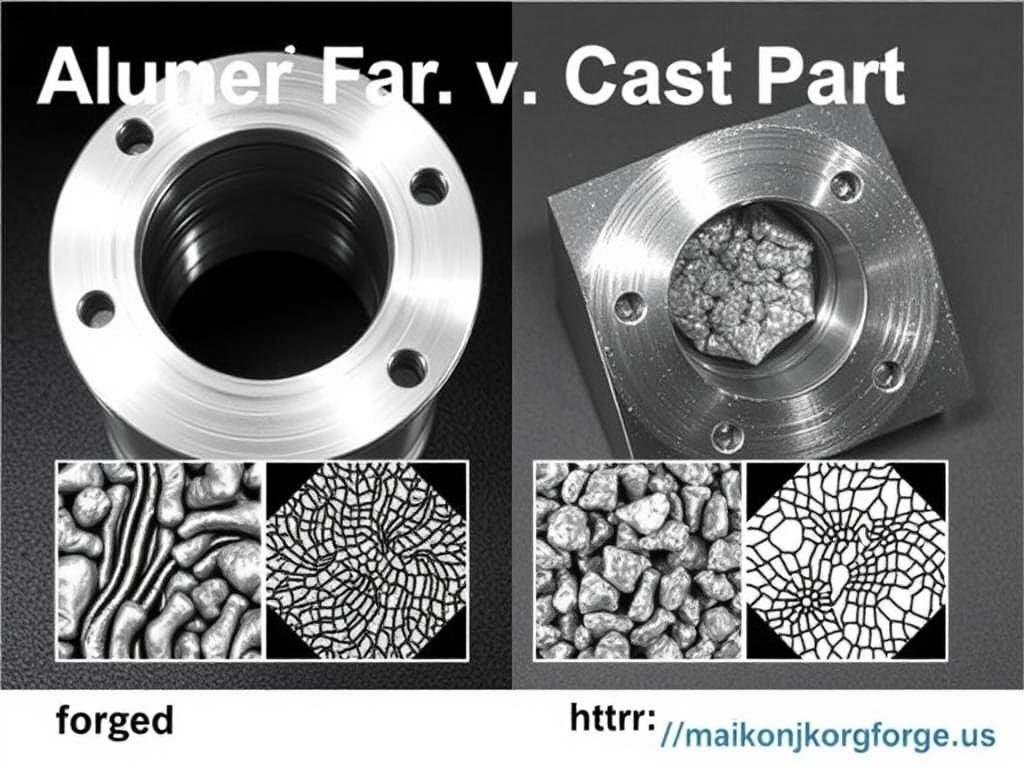

Advantages of Aluminum Forging Over Casting

When evaluating manufacturing processes for aluminum components, procurement managers must understand the distinct advantages that aluminum forging offers compared to casting methods.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Grain Structure |

✅ Directional grain flow for improved properties |

No directional grain structure |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed |

Microscopic comparison of grain structure: Forged aluminum (left) vs. Cast aluminum (right)

Optimal Strength-to-Weight Ratio in Aluminum Forging

The strength-to-weight ratio is a critical factor for procurement managers evaluating materials for weight-sensitive applications. Aluminum forging creates components with exceptional strength while maintaining aluminum’s inherent lightweight properties.

How Aluminum Forging Enhances Strength

The forging process refines aluminum’s grain structure by aligning it along the direction of metal flow. This directional grain structure significantly improves mechanical properties, particularly in the direction of the greatest stress. Unlike cast aluminum, which has a random grain structure, forged aluminum exhibits superior:

- Tensile strength

- Yield strength

- Fatigue resistance

- Impact toughness

- Structural integrity

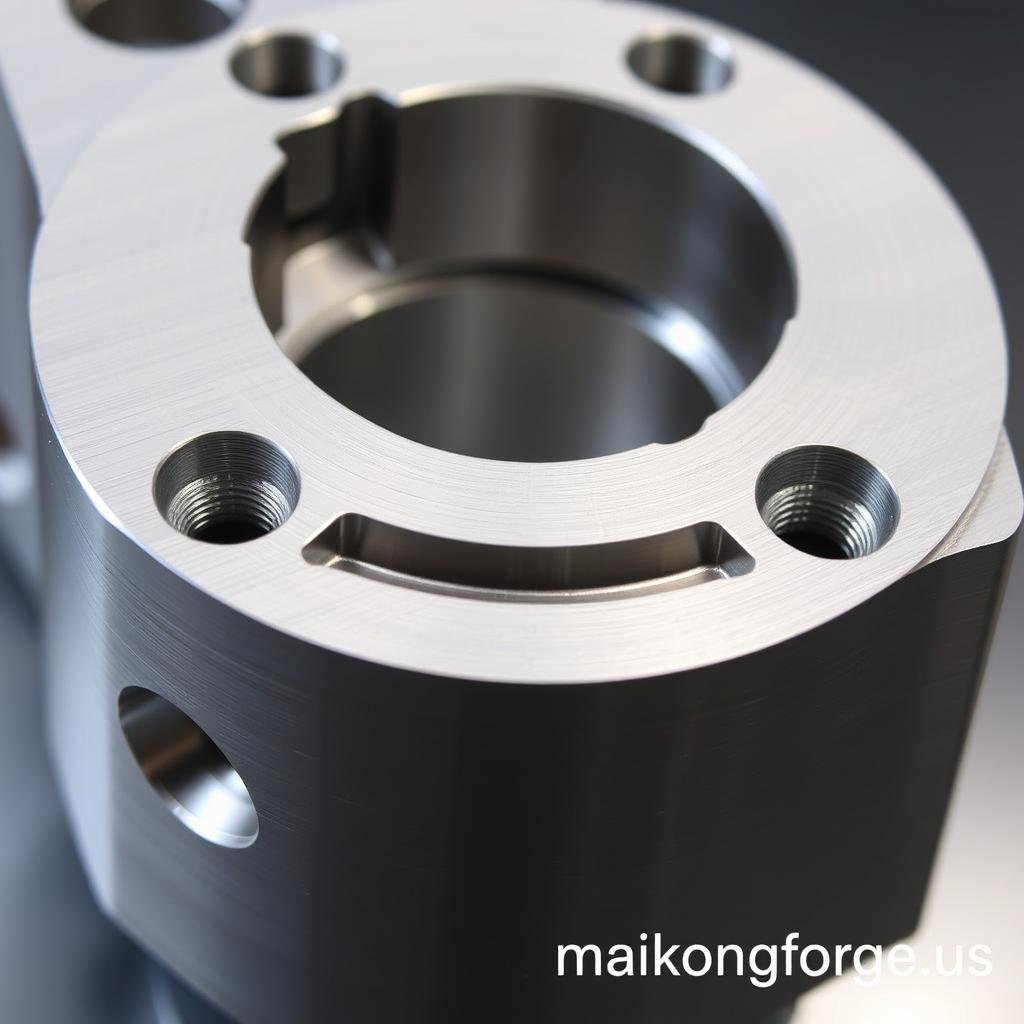

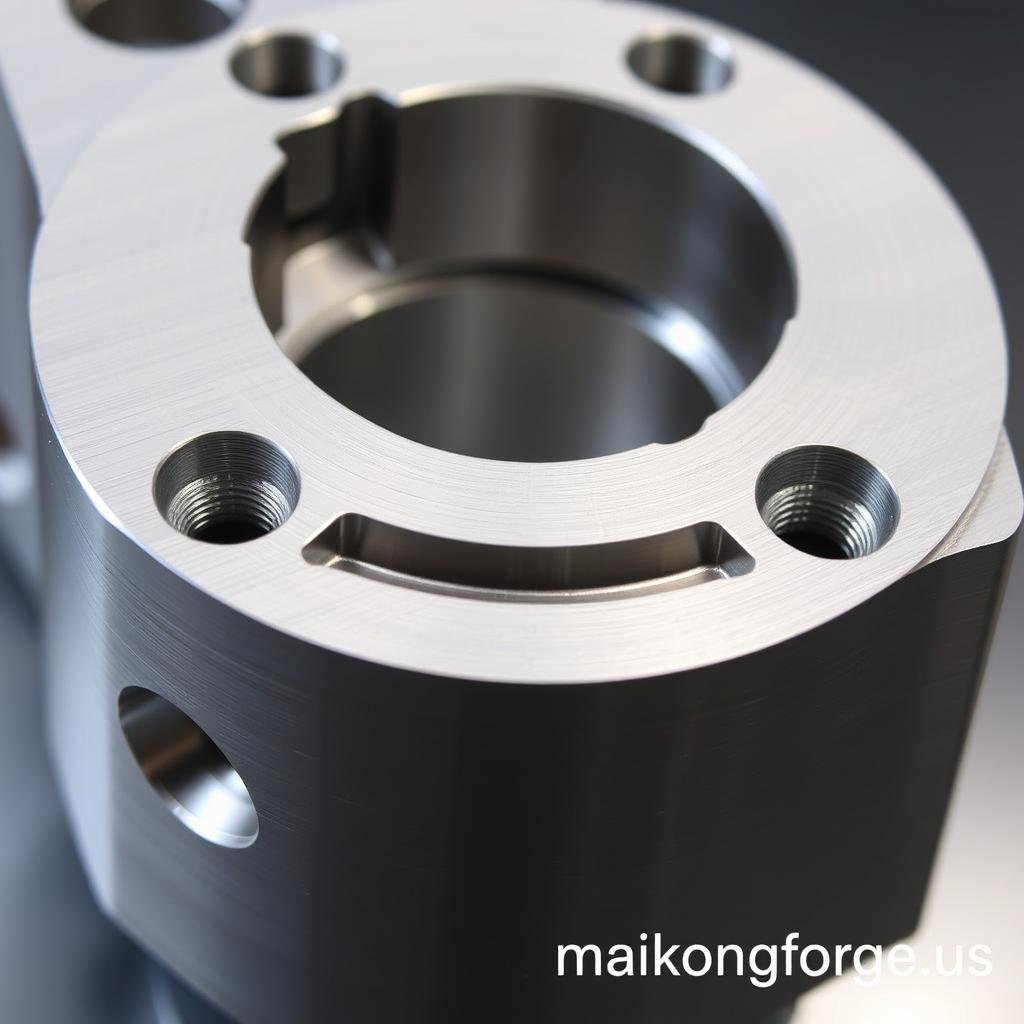

Precision aerospace component forged from aluminum alloy at MAIKONG

Experience Superior Strength-to-Weight Ratio

MAIKONG’s advanced aluminum forging processes deliver components with optimal strength-to-weight ratios for your most demanding applications. Our engineering team can help you select the ideal aluminum alloy and forging process for your specific requirements.

Get Expert Consultation

Essential Aluminum Alloys for Forging Applications

Selecting the appropriate aluminum alloy is crucial for achieving desired mechanical properties in forged components. MAIKONG specializes in forging a wide range of aluminum alloys to meet diverse application requirements.

| Alloy Series |

Common Alloys |

Key Properties |

Typical Applications |

| 1000 Series |

1100 |

Excellent corrosion resistance, high thermal conductivity |

Heat exchangers, chemical equipment |

| 2000 Series |

2014, 2024, 2219, 2618 |

High strength, good fatigue resistance |

Aerospace structural components, aircraft fittings |

| 5000 Series |

5052, 5083, 5086, 5456 |

Good corrosion resistance, moderate strength |

Marine components, pressure vessels |

| 6000 Series |

6061, 6063 |

Good formability, weldability, corrosion resistance |

Structural components, architectural applications |

| 7000 Series |

7050, 7075, 7175 |

Highest strength aluminum alloys |

Aerospace, defense, high-stress applications |

Selection of premium aluminum alloys at MAIKONG’s forging facility in GD, SZ

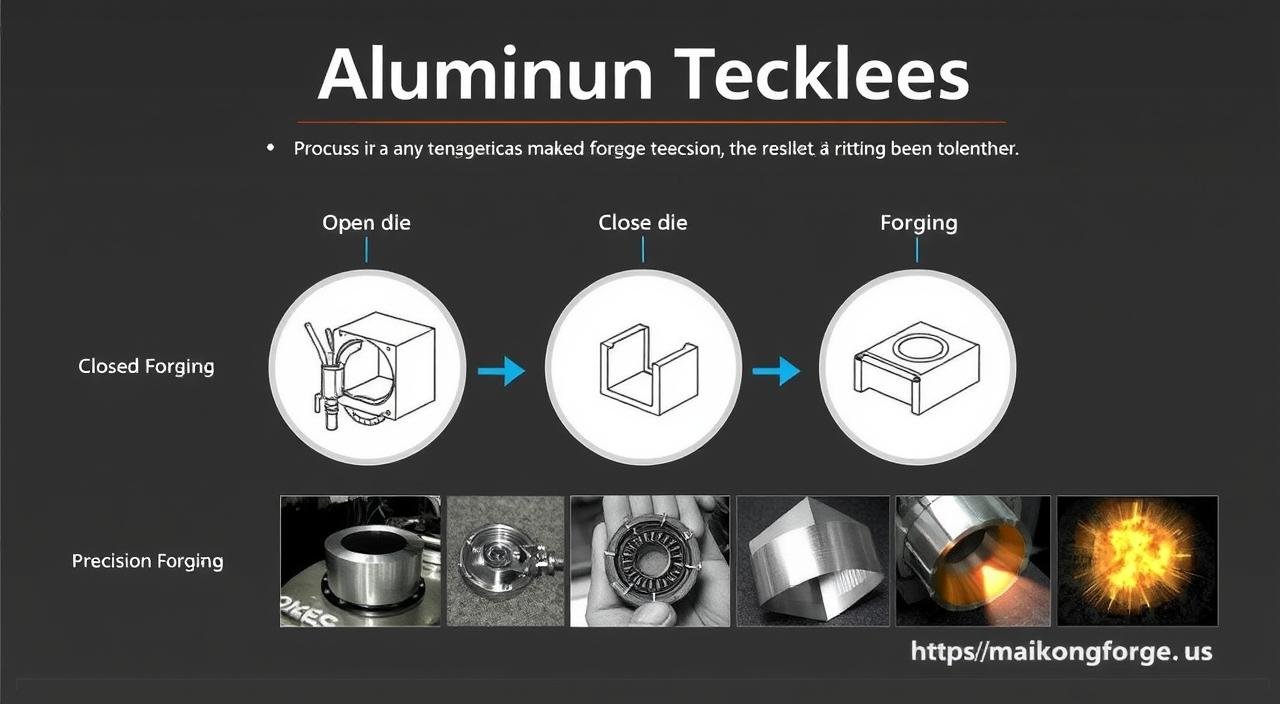

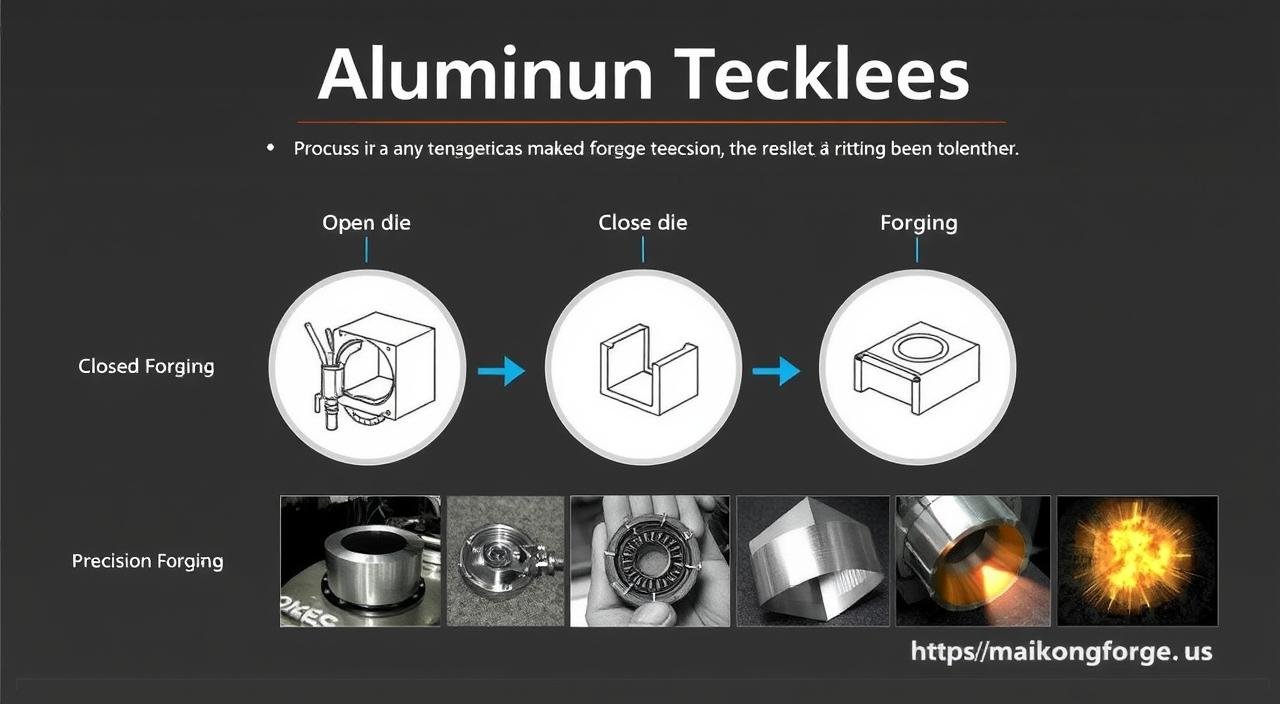

Aluminum Forging Techniques: Key Terminology

Understanding the various aluminum forging techniques is essential for procurement managers to specify the most appropriate manufacturing method for their components.

Open Die Forging

Also known as free forging, this process involves shaping aluminum between flat or simply shaped dies. The metal flows freely except where contacted by the dies.

- Ideal for large, simple shapes

- Lower tooling costs

- Greater flexibility in dimensions

- Suitable for low-volume production

Closed Die Forging

Also called impression die forging, this technique shapes aluminum by forcing it into a die cavity that contains the negative impression of the desired part.

- Produces complex geometries

- Excellent dimensional accuracy

- Minimal material waste

- Optimal for high-volume production

Precision Forging

An advanced forging technique that produces near-net-shape components with minimal need for secondary machining operations.

- Tight tolerances (±0.005″)

- Reduced machining costs

- Excellent surface finish

- Material and energy savings

Comparison of aluminum forging techniques utilized at MAIKONG’s manufacturing facility

Heat Treatment in Aluminum Forging: Critical Terminology

Heat treatment is an essential process that enhances the mechanical properties of forged aluminum components. Understanding heat treatment terminology is crucial for specifying the correct treatment for your application requirements.

Common Heat Treatment Processes

- Solution Heat Treatment: Heating aluminum to a specific temperature to dissolve alloying elements into solid solution.

- Quenching: Rapid cooling to maintain the solid solution formed during solution treatment.

- Aging: Controlled precipitation of alloying elements to achieve desired strength properties.

- Annealing: Heating and slow cooling to reduce hardness, increase ductility, and relieve internal stresses.

- Stress Relief: Moderate heating to reduce residual stresses without significantly affecting mechanical properties.

State-of-the-art heat treatment furnace at MAIKONG’s GD, SZ facility

Temper Designations in Aluminum Forging

Temper designations indicate the condition of aluminum alloys after heat treatment and provide critical information about their mechanical properties.

| Temper |

Description |

Typical Applications |

| F |

As fabricated – No special control over thermal conditions |

Non-critical applications where mechanical properties are not specified |

| O |

Annealed – Lowest strength, highest ductility condition |

Components requiring extensive forming or bending |

| T4 |

Solution heat treated and naturally aged |

Parts requiring good formability with moderate strength |

| T6 |

Solution heat treated and artificially aged |

High-strength structural components for aerospace and automotive |

| T7 |

Solution heat treated and stabilized (overaged) |

Components requiring dimensional stability and stress corrosion resistance |

Quality Assurance in Aluminum Forging

For procurement managers, understanding quality assurance terminology and standards is essential for ensuring that forged aluminum components meet specified requirements and perform reliably in their intended applications.

Comprehensive quality inspection at MAIKONG’s state-of-the-art testing laboratory

Testing Methods for Aluminum Forging

Non-Destructive Testing

- Ultrasonic Testing: Detects internal flaws using high-frequency sound waves.

- Dye Penetrant Inspection: Reveals surface discontinuities through liquid penetrants.

- Eddy Current Testing: Identifies surface and near-surface defects using electromagnetic induction.

- X-ray Radiography: Provides images of internal structures to detect voids or inclusions.

Destructive Testing

- Tensile Testing: Measures strength, ductility, and elastic properties.

- Hardness Testing: Determines resistance to indentation.

- Impact Testing: Evaluates toughness and energy absorption.

- Metallographic Examination: Analyzes microstructure and grain flow.

Ensure Consistent Quality with MAIKONG

MAIKONG’s ISO 9001:2015 certified quality management system ensures that every aluminum forged component meets your exact specifications. Our comprehensive testing capabilities provide complete documentation and traceability for your critical applications.

Discuss Your Quality Requirements

MAIKONG’s Comprehensive Aluminum Forging Capabilities

MAIKONG offers end-to-end aluminum forging solutions with advanced capabilities across the entire manufacturing process. Our state-of-the-art facility in GD, SZ is equipped with 60+ CNC machines providing 100+ tons of metal processing capacity per month.

MAIKONG’s advanced manufacturing facility in GD, SZ

Design & Engineering

- CAD/CAM capabilities

- Finite Element Analysis

- Design for Manufacturability

- Material selection expertise

- Tooling design optimization

Manufacturing

- Open die forging

- Closed die forging

- Precision forging

- In-house heat treatment

- CNC machining services

Quality & Finishing

- Surface treatments

- Anodizing capabilities

- Comprehensive testing

- ISO 9001:2015 certified

- Full documentation

CNC Machining Services for Aluminum Forging

MAIKONG complements our forging capabilities with comprehensive CNC machining services to deliver finished components ready for installation:

- CNC Turning: Precision manufacturing of cylindrical shapes with superior surface finishes.

- CNC Milling: Complex prismatic shapes and flat surfaces for a variety of industrial products.

- CNC SWISS Type Machining: Specialized precision for small parts and long shaft components.

- Multi-Axis Machining: Advanced capabilities for complex geometries and features.

Precision CNC machining of forged aluminum component

Industries and Applications for Aluminum Forging

MAIKONG’s aluminum forged components serve critical applications across multiple industries where performance, reliability, and safety are paramount.

Aerospace Components

Aerospace Components

Automotive Applications

Automotive Applications

Defense Industry

Defense Industry

| Industry |

Common Applications |

Key Requirements |

| Aerospace |

Structural components, landing gear parts, engine mounts |

High strength-to-weight ratio, fatigue resistance, precision |

| Automotive |

Suspension components, engine parts, transmission housings |

Durability, weight reduction, cost-effectiveness |

| Defense |

Weapon systems, vehicle components, equipment housings |

Reliability, impact resistance, precision tolerances |

| Marine |

Propeller components, structural fittings, hardware |

Corrosion resistance, strength, reliability |

| Medical |

Surgical instruments, equipment components, implant tools |

Precision, biocompatibility, sterilization capability |

Mastering Aluminum Forging Terminology for Procurement Success

Armed with this comprehensive understanding of aluminum forging terminology, US procurement managers can make more informed decisions when sourcing high-performance components. MAIKONG’s expertise in aluminum forging, combined with our full-service capabilities including CNC machining, heat treatment, and surface finishing, ensures that your components meet the highest standards of quality and performance.

With 60+ CNC machines, 100+ tons monthly capacity, and ISO 9001:2015 certification, MAIKONG delivers exceptional value through our commitment to quality, innovation, and customer satisfaction. Contact us today to experience the MAIKONG difference in aluminum forging.

Industrial aluminum forging process at MAIKONG’s state-of-the-art facility in GD, SZ

Industrial aluminum forging process at MAIKONG’s state-of-the-art facility in GD, SZ

Aerospace Components

Aerospace Components Automotive Applications

Automotive Applications Defense Industry

Defense Industry