In today’s competitive manufacturing landscape, selecting the right production method can significantly impact product performance, durability, and cost-effectiveness. Aluminum forging stands out as a superior manufacturing process that delivers exceptional mechanical properties and structural integrity that alternative methods simply cannot match. MAIKONG brings over two decades of specialized expertise in aluminum forging, offering unparalleled quality and precision for industries where performance and reliability are non-negotiable.

State-of-the-art aluminum forging process at MAIKONG’s GD, SZ facility

What Is Aluminum Forging and Why It Matters

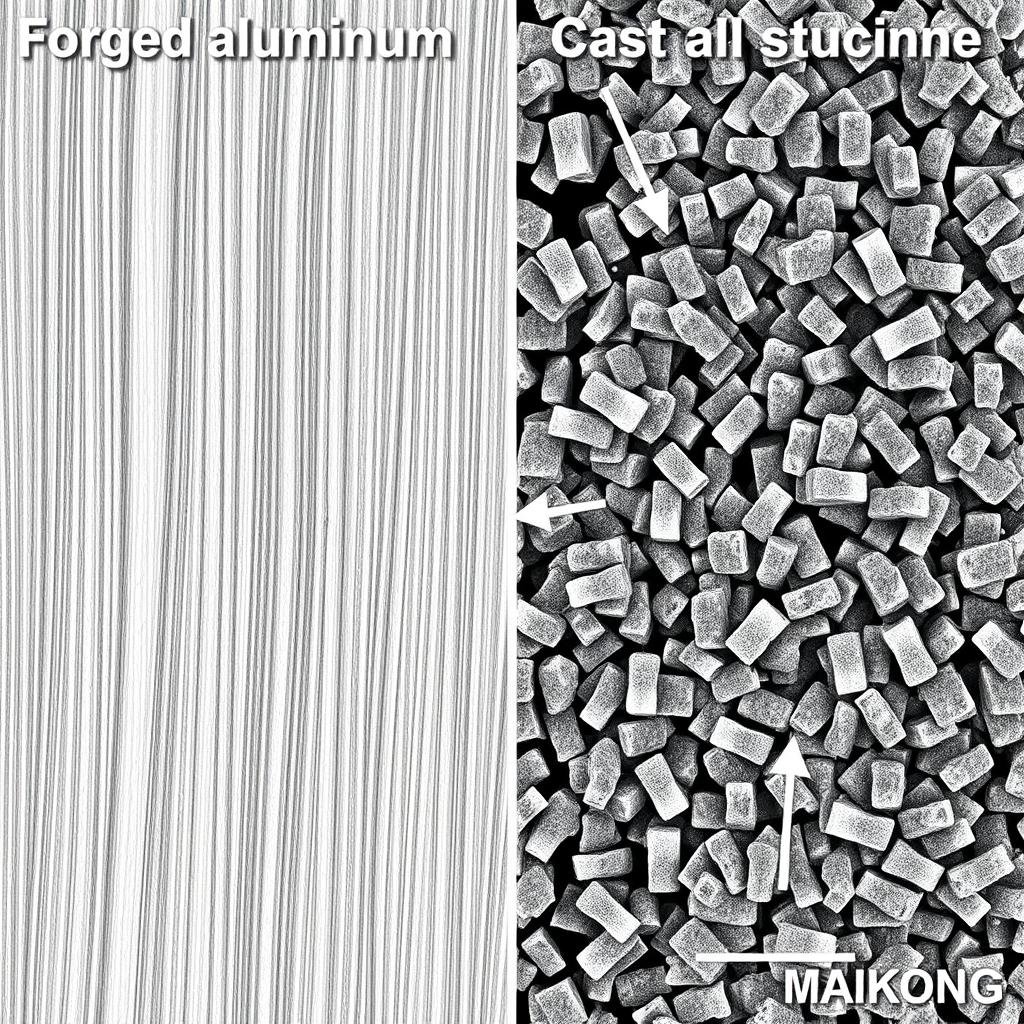

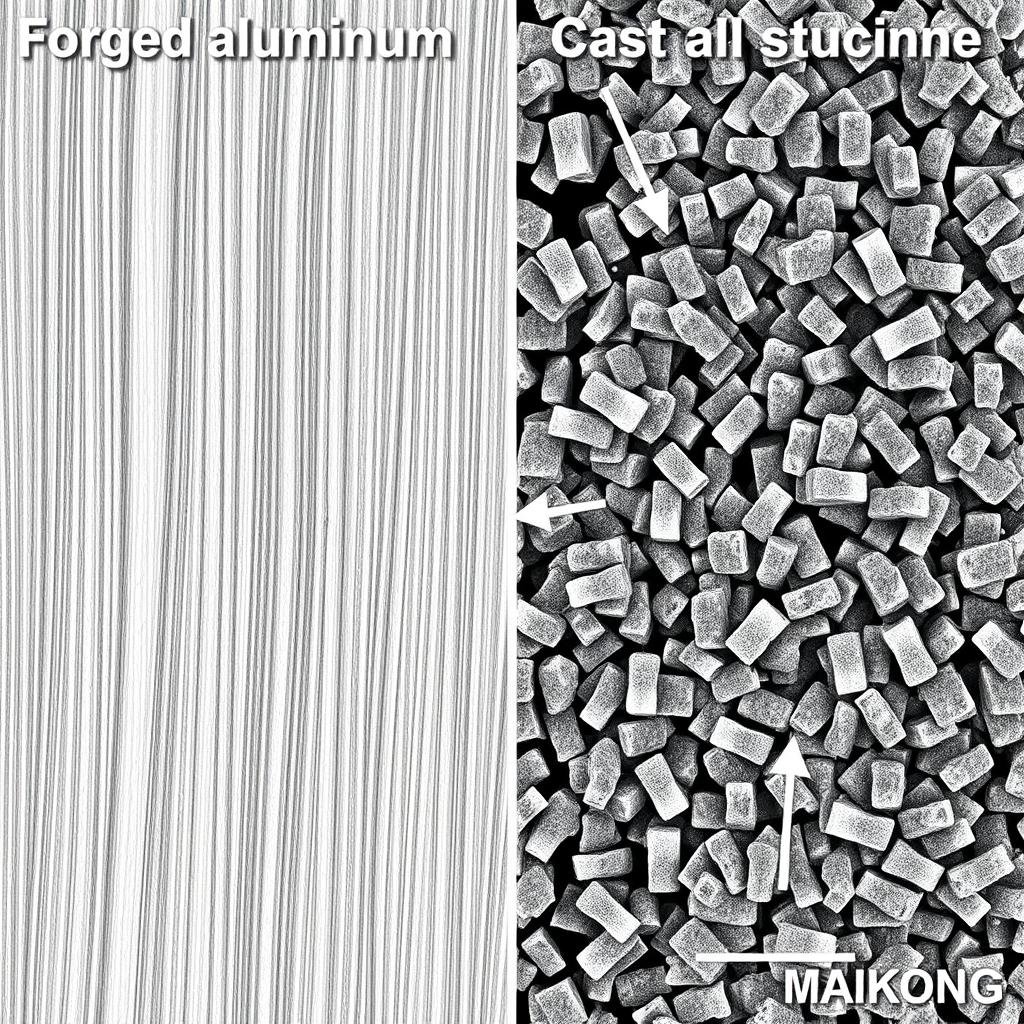

Aluminum forging is a precision manufacturing process where aluminum is shaped using compressive forces. Unlike casting or machining, forging aligns the metal’s grain structure, significantly enhancing its mechanical properties. This process creates parts with superior strength, durability, and reliability – critical factors for components used in demanding applications.

At MAIKONG, we’ve perfected the aluminum forging process through decades of specialized experience. Our state-of-the-art facility in GD, SZ houses 60+ CNC machines with a monthly production capacity exceeding 100 tons, ensuring we can meet both high-volume requirements and specialized custom orders with consistent quality.

Need Custom Aluminum Forged Parts?

Our engineering team is ready to review your specifications and provide expert guidance on the optimal forging solution for your application.

Request a Quote

Contact via WhatsApp

Superior Strength-to-Weight Ratio of Aluminum Forging

The exceptional strength-to-weight ratio achieved through aluminum forging is a game-changer for industries where weight reduction without compromising structural integrity is crucial. Through the forging process, aluminum’s internal grain structure is refined and aligned, resulting in parts that offer:

- Up to 30% higher tensile strength compared to cast aluminum

- Enhanced fatigue resistance for critical load-bearing applications

- Superior impact and shock absorption capabilities

- Exceptional performance under dynamic and cyclic loading conditions

- Reduced weight leading to improved fuel efficiency in transportation applications

Grain structure comparison: Forged aluminum (left) vs. cast aluminum (right)

For aerospace, automotive, and defense applications where every gram matters, MAIKONG’s aluminum forging solutions deliver the optimal balance of lightweight construction and structural performance. Our engineering team works closely with clients to identify the ideal aluminum alloy and forging parameters to maximize the strength-to-weight benefits for each specific application.

MAIKONG Aluminum Forging vs. Casting: A Comprehensive Comparison

| Comparison Categories |

MAIKONG Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Heat Treatment Response |

✅ Responsive for controlled material properties |

Less predictable response |

| Ideal Applications |

Aerospace, automotive, defense, high-performance components |

Consumer goods, decorative items, non-critical components |

Uncertain Which Manufacturing Method Is Right for Your Project?

Our engineering team can analyze your requirements and recommend the optimal approach for your specific application.

Email Our Engineers

Call: +86 13510907401

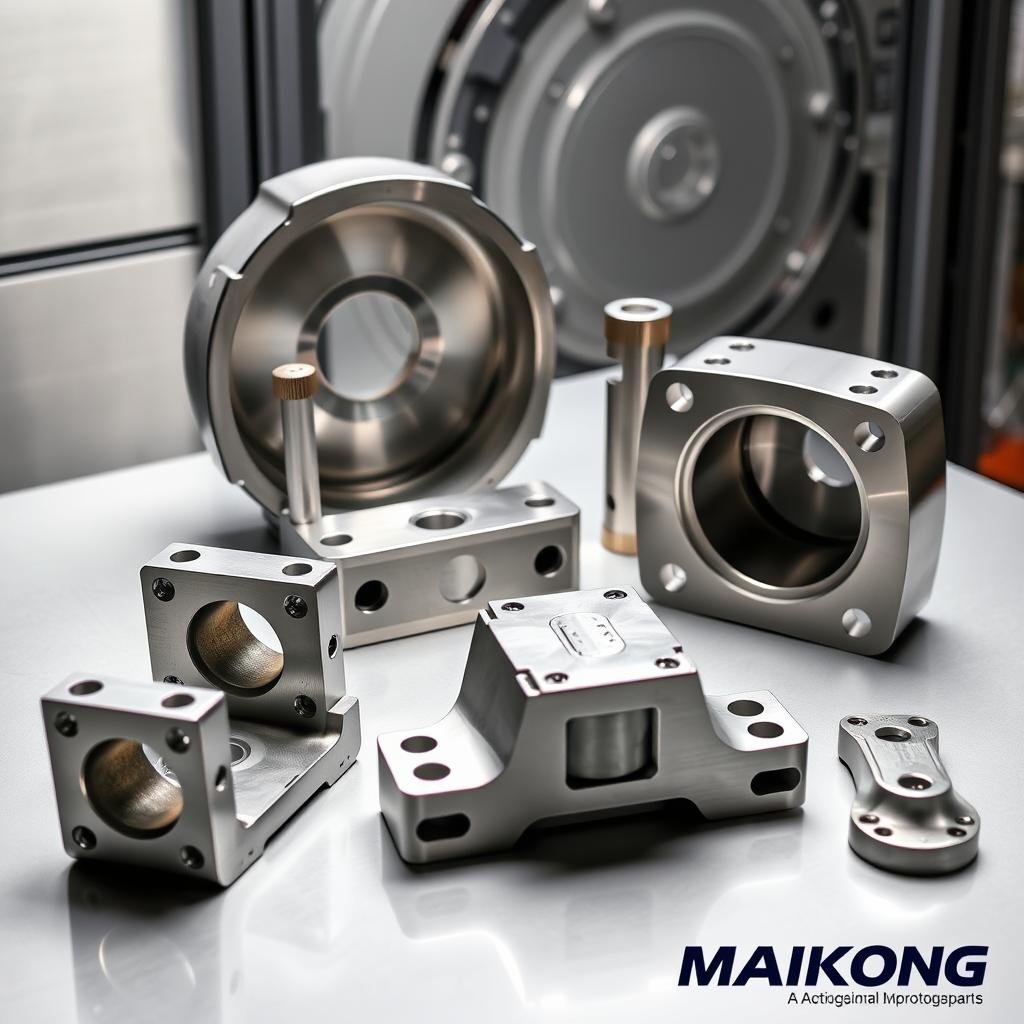

MAIKONG’s Comprehensive Aluminum Forging Services

MAIKONG’s state-of-the-art facility offers end-to-end aluminum forging solutions

At MAIKONG, we provide a complete range of aluminum forging services under one roof, eliminating the need for multiple vendors and ensuring consistent quality throughout the production process. Our comprehensive capabilities include:

Design & Engineering

- CAD/CAM optimization

- Material selection guidance

- Design for manufacturability

- FEA simulation and analysis

- Tooling design and development

Core Forging Processes

- Closed-die forging

- Open-die forging

- Precision forging

- Custom alloy processing

- Heat treatment optimization

Secondary Operations

- CNC machining

- Surface finishing

- Quality testing & inspection

- Anodizing & coating

- Assembly services

Our integrated approach ensures seamless coordination between all production stages, resulting in faster turnaround times, consistent quality, and cost efficiencies that we pass on to our customers. With MAIKONG as your aluminum forging partner, you gain access to world-class manufacturing capabilities backed by rigorous quality control and responsive customer service.

Advanced CNC Machining for Aluminum Forging

MAIKONG’s advanced CNC machining capabilities complement our aluminum forging expertise, allowing us to deliver precision-finished components that meet the most demanding specifications. Our facility houses over 60 state-of-the-art CNC machines, providing:

- CNC turning for cylindrical components with superior surface finishes

- Multi-axis CNC milling for complex prismatic shapes and flat surfaces

- Swiss-type machining for precision small parts and long shaft components

- Surface grinding for achieving tight tolerances and exceptional finishes

- Laser engraving for permanent part identification and branding

5-axis CNC machining of aluminum forging at MAIKONG’s facility

By integrating CNC machining with our aluminum forging processes, we deliver components with exceptional dimensional accuracy and surface quality. This comprehensive approach eliminates the need for multiple vendors, reducing lead times and ensuring consistent quality throughout the production process.

Need Precision CNC Machining for Your Forged Parts?

MAIKONG offers complete forging-to-finishing solutions with our advanced CNC capabilities.

Explore CNC Services

Uncompromising Quality Assurance for Aluminum Forging

Rigorous quality inspection of forged aluminum components at MAIKONG

Quality is the cornerstone of MAIKONG’s aluminum forging operations. Our comprehensive quality management system is ISO 9001:2015 certified, ensuring consistent adherence to international standards. Our quality assurance process includes:

Material Verification

- Chemical composition analysis

- Mechanical property testing

- Grain structure examination

- Alloy certification verification

- Batch traceability documentation

Production Quality Controls

- In-process dimensional inspection

- Statistical process control (SPC)

- Heat treatment verification

- Surface finish measurement

- Non-destructive testing (NDT)

Our dedicated material laboratory plays a vital role in our production process, enabling us to achieve the precise results you demand. With comprehensive testing capabilities and experienced quality engineers monitoring every stage of production, MAIKONG ensures that each aluminum forging meets or exceeds the specified requirements.

Industries Benefiting from MAIKONG Aluminum Forging

Aerospace

Our aluminum forging solutions deliver the exceptional strength-to-weight ratio and reliability required for critical aerospace applications, including structural components, engine parts, and landing gear systems.

Automotive

From suspension components to engine parts, our aluminum forging processes create lightweight, high-strength automotive components that enhance performance, improve fuel efficiency, and meet stringent safety standards.

Defense

The defense industry relies on our aluminum forging expertise for components that must perform flawlessly in the most demanding conditions, from vehicle parts to equipment mounts and structural elements.

Additional industries we serve include medical equipment, semiconductor manufacturing, marine applications, and industrial machinery. Whatever your industry, MAIKONG’s aluminum forging capabilities can be tailored to meet your specific requirements for performance, durability, and cost-effectiveness.

Aluminum Alloy Expertise for Superior Forging Results

MAIKONG’s material expertise ensures the optimal aluminum alloy selection for each forging application. Our experience with a comprehensive range of aluminum alloys allows us to recommend the ideal material based on your specific requirements for strength, corrosion resistance, machinability, and cost-effectiveness.

| Aluminum Alloy |

Key Properties |

Ideal Applications |

| 2014 |

High strength, good machinability |

Aircraft fittings, wheels, structural components |

| 2219 |

Excellent weldability, high-temperature strength |

Aerospace structures, fuel tanks, pressure vessels |

| 6061 |

Good corrosion resistance, moderate strength |

General-purpose structural components, marine applications |

| 7050 |

Very high strength, excellent fracture toughness |

Aircraft structural components, defense applications |

| 7075 |

Superior strength, good fatigue resistance |

Aerospace structures, high-stress components |

Our material laboratory conducts comprehensive testing to verify the properties of each aluminum alloy, ensuring consistent performance and quality in every forging project. This attention to material science is a key differentiator that sets MAIKONG apart from other forging providers.

MAIKONG’s advanced material testing laboratory ensures optimal aluminum forging quality

Precision Heat Treatment for Enhanced Aluminum Forging Properties

Heat treatment is a critical step in maximizing the mechanical properties of aluminum forgings. MAIKONG’s in-house heat treatment capabilities ensure precise control over this essential process, resulting in components with optimal strength, hardness, and durability.

Our comprehensive heat treatment services include:

- Solution heat treatment to dissolve alloying elements

- Quenching with precise temperature control

- Aging treatments for precipitation hardening

- Stress relieving to enhance dimensional stability

- Annealing for improved machinability

Precision-controlled heat treatment furnace at MAIKONG’s GD, SZ facility

Each heat treatment cycle is meticulously documented and verified through hardness testing and microstructure analysis, ensuring consistent results that meet or exceed industry standards. This attention to detail in the heat treatment process is essential for achieving the superior mechanical properties that make aluminum forgings the preferred choice for critical applications.

Advanced Surface Finishing for Aluminum Forgings

MAIKONG offers comprehensive surface finishing options to enhance the appearance, performance, and corrosion resistance of aluminum forgings. Our surface treatment capabilities include:

Mechanical Finishing

- Precision grinding

- Polishing to various surface roughness specifications

- Shot blasting for uniform surface texture

- Deburring and edge conditioning

- Surface preparation for subsequent treatments

Chemical Treatments

- Anodizing (Type I, II, and III)

- Chemical conversion coatings

- Passivation treatments

- Etching for specific surface characteristics

- Cleaning and degreasing processes

Coating Applications

- Powder coating in various colors

- Painting with industrial-grade finishes

- Specialized coatings for extreme environments

- Laser engraving for part identification

- Custom finishing to match specific requirements

MAIKONG’s comprehensive surface finishing capabilities for aluminum forgings

Our surface finishing processes are carefully controlled and monitored to ensure consistent results that meet your exact specifications. Whether you require a specific aesthetic appearance, enhanced corrosion protection, or special surface properties for your aluminum forgings, MAIKONG delivers superior results through our integrated surface finishing capabilities.