Aluminum forging represents one of the most effective metal forming processes for creating high-strength, lightweight components with superior mechanical properties. At MAIKONG, we’ve mastered the art and science of transforming raw aluminum billets into precision-engineered parts that meet the most demanding specifications across industries. This comprehensive guide walks you through the entire aluminum forging journey—from material selection to finishing processes—showcasing why our approach delivers components with unmatched integrity, performance, and value.

Need Custom Aluminum Forging Solutions?

Our engineering team is ready to discuss your project requirements and provide expert recommendations.

Request a Quote

Contact via WhatsApp

What Is Aluminum Forging? Understanding the Fundamentals

Aluminum forging is a precision metal forming process that applies compressive forces to shape aluminum into specific forms with enhanced mechanical properties. Unlike casting methods that melt and pour metal into molds, forging works the metal in its solid state, creating a refined grain structure that significantly improves strength, durability, and fatigue resistance.

At MAIKONG, our aluminum forging processes leverage state-of-the-art equipment and decades of metallurgical expertise to produce components with superior integrity. Our comprehensive capabilities span from initial design consultation through final inspection, ensuring each forged part meets exact specifications.

MAIKONG’s advanced aluminum forging facility in GD, SZ

The Aluminum Forging Process: Step-by-Step Transformation

The journey from raw aluminum billet to precision-engineered component involves several critical stages. At MAIKONG, we’ve optimized each step to ensure maximum quality, consistency, and performance in the final product.

Complete aluminum forging process flow at MAIKONG

1. Design and Engineering

Every successful aluminum forging project begins with thorough design and engineering. Our team utilizes advanced CAD/CAM software to create precise models and simulations, identifying potential issues before production begins. This critical first step ensures optimal material flow, minimal waste, and components that perfectly match your specifications.

2. Material Selection

Selecting the right aluminum alloy is crucial for achieving desired mechanical properties. MAIKONG works with a wide range of aluminum grades including 2014, 2219, 6061, 7050, and 7075, each offering specific advantages for different applications. Our metallurgists help you choose the optimal alloy based on your component’s performance requirements, operating environment, and cost considerations.

| Aluminum Alloy |

Key Properties |

Common Applications |

| 2014 |

High strength, good machinability |

Aircraft fittings, wheels, structural components |

| 2219 |

Excellent weldability, high-temperature strength |

Aerospace structures, rocket components |

| 6061 |

Good corrosion resistance, medium strength |

Marine components, automotive parts |

| 7050 |

Superior strength, stress corrosion resistance |

Aircraft structural parts, defense applications |

| 7075 |

Highest strength aluminum alloy, good fatigue resistance |

Aerospace components, high-stress applications |

3. Billet Preparation

The aluminum forging process begins with carefully prepared billets cut to precise dimensions. These aluminum sections are inspected for quality and consistency before proceeding to the next stage. Proper billet preparation is essential for achieving uniform material flow during forging and minimizing defects in the final component.

4. Heating

Billets are heated to specific temperatures (typically between 750-900°F depending on the alloy) to achieve optimal plasticity for forging. MAIKONG utilizes precision-controlled furnaces that maintain exact temperatures throughout the heating process, ensuring consistent material properties and preventing overheating that could compromise the aluminum’s integrity.

Precision-controlled heating of aluminum billets at MAIKONG’s facility

5. Forging Operation

The heated aluminum is placed in specialized dies and subjected to immense pressure that reshapes the metal according to the die cavity. MAIKONG employs various aluminum forging techniques including:

Open Die Forging

The metal is compressed between flat or simply shaped dies, allowing material to flow laterally. This technique is ideal for larger, simpler shapes and custom components with minimal production runs.

Closed Die Forging

The aluminum is shaped within impression dies that completely enclose the material, creating complex geometries with tight tolerances. This method is perfect for precision components produced in higher volumes.

6. Trimming and Cleaning

After forging, excess material (flash) is removed through precision trimming operations. The components then undergo cleaning processes to remove any surface contaminants, preparing them for heat treatment or further processing.

7. Heat Treatment

Heat treatment is often essential for aluminum forging to achieve specific mechanical properties. This process may include solution treatment, quenching, and aging to optimize strength, hardness, and other characteristics. MAIKONG’s in-house heat treatment facilities ensure precise control over this critical process.

8. Finishing Operations

Depending on your requirements, forged aluminum components may undergo additional finishing processes such as machining, surface treatments, or coating applications. Our comprehensive capabilities include CNC machining, anodizing, painting, and various other finishing options to deliver components ready for immediate use.

Precision CNC machining of forged aluminum components at MAIKONG

9. Quality Inspection

Every forged component undergoes rigorous inspection using advanced measurement technologies, non-destructive testing, and when required, destructive testing of sample parts. Our ISO 9001:2015 certified quality management system ensures consistent adherence to the highest standards.

Ready to Start Your Aluminum Forging Project?

Our engineering team will help you optimize your design for manufacturability and cost-efficiency.

Email Our Team

Call/WhatsApp: 8613-51090-74-01

Advantages of Aluminum Forging Over Alternative Manufacturing Methods

Understanding the comparative benefits of aluminum forging versus other manufacturing processes helps you make informed decisions for your components. Here’s why forging often represents the optimal choice for critical applications:

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps of effort to achieve complex shape |

✅Can achieve complex shape in one session |

| Dimensional Accuracy |

✅Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅Smoother surfaces, reduced post-processing |

Might require more machining due to air pocket |

| Heat Treatment Response |

✅Responsive for controlled material properties |

Less predictable response |

| Grain Structure |

✅Directional grain flow for improved properties |

No directional grain structure |

| Weight-to-Strength Ratio |

✅High strength-to-weight ratio |

Bulkier parts may be needed |

| Critical Applications |

✅Structural Members and load-bearing capabilities |

Limited suitability for critical applications |

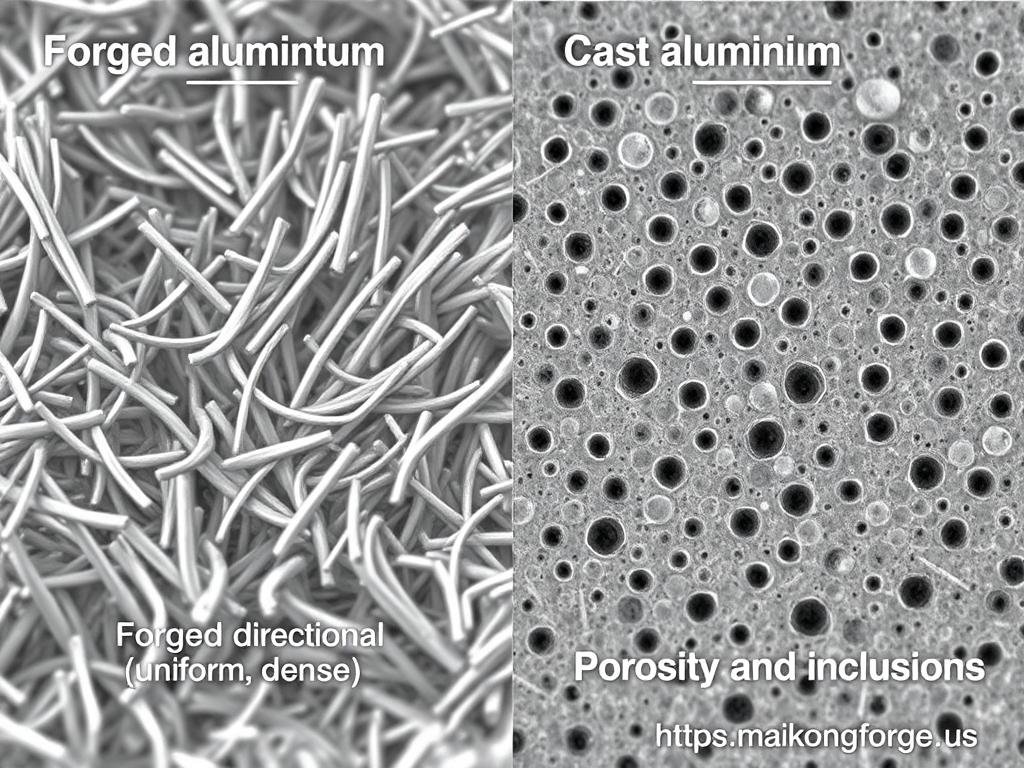

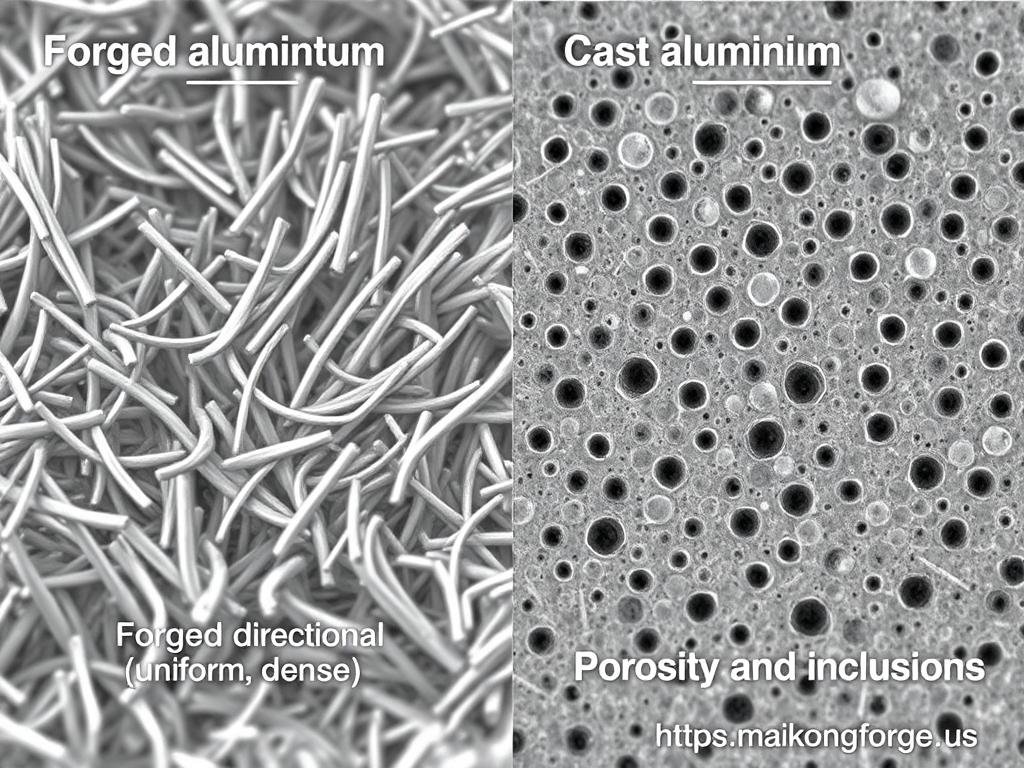

Enhanced Grain Structure and Material Integrity

The aluminum forging process fundamentally transforms the metal’s internal structure. By applying controlled pressure, we align the grain flow with the part’s geometry, eliminating the porosity and inclusions common in cast components. This results in significantly higher strength, improved ductility, and superior fatigue resistance—critical factors for components subjected to dynamic loading conditions.

Microscopic comparison showing superior grain structure of forged aluminum (left) vs. cast aluminum (right)

Optimal Strength-to-Weight Ratio

Aluminum forging creates components with an exceptional strength-to-weight ratio—a critical advantage in aerospace, automotive, and other weight-sensitive applications. The enhanced mechanical properties achieved through forging allow for thinner wall sections and lighter components without compromising structural integrity, contributing to improved fuel efficiency and performance.

Industry Applications for Aluminum Forging

MAIKONG’s aluminum forging capabilities serve diverse industries with components that meet the most demanding performance requirements. Our expertise spans multiple sectors, delivering precision-engineered parts for critical applications.

Aerospace

- Structural components

- Landing gear parts

- Engine mounts

- Control system components

Automotive

- Suspension components

- Connecting rods

- Steering knuckles

- Drivetrain components

Medical

- Surgical instruments

- Implant components

- Medical device structures

- Equipment frameworks

Defense

- Weapons components

- Tactical equipment

- Vehicle parts

- Communication hardware

Industrial

- Hydraulic components

- Valve bodies

- Pump housings

- Structural connectors

Sports & Recreation

- Bicycle components

- Golf club heads

- Climbing equipment

- Marine hardware

MAIKONG’s Comprehensive Aluminum Forging Capabilities

With over 60 CNC machines and 100+ tons of monthly metal processing capacity, MAIKONG offers end-to-end manufacturing solutions that extend far beyond basic aluminum forging. Our integrated services ensure seamless production from concept to completion.

MAIKONG’s state-of-the-art manufacturing facility in GD, SZ

Comprehensive Manufacturing Services

CNC Machining Services

Our advanced CNC machining capabilities complement our aluminum forging expertise, allowing us to perform precision secondary operations on forged components. With multi-axis machining centers, we can create complex geometries, tight tolerances, and superior surface finishes on your forged parts.

- CNC turning for cylindrical components

- CNC milling for complex prismatic shapes

- Swiss-type machining for small precision parts

- Multi-axis machining for complex geometries

Surface Treatment Options

Enhance the performance and appearance of your forged aluminum components with our comprehensive surface treatment capabilities:

- Anodizing for improved corrosion resistance

- Painting and powder coating

- Laser engraving for permanent marking

- Sand blasting for uniform surface texture

- Chemical treatments for specialized applications

Quality Assurance

MAIKONG maintains rigorous quality control throughout the aluminum forging process. Our ISO 9001:2015 certified quality management system ensures consistent adherence to the highest standards. We employ advanced inspection technologies including:

- Coordinate measuring machines (CMM) for dimensional verification

- Spectrophotometers for color and surface finish analysis

- Non-destructive testing methods including ultrasonic and penetrant testing

- Material testing for mechanical properties and composition

- Statistical process control for continuous improvement

Precision quality inspection of forged components at MAIKONG

Partner with MAIKONG for Your Aluminum Forging Needs

Experience the perfect balance of quality, cost-efficiency, and responsive service.

Contact Our Team

Call/WhatsApp: 8613-51090-74-01

Why Choose MAIKONG for Your Aluminum Forging Projects

When selecting an aluminum forging partner, capabilities, experience, and commitment to quality are paramount. MAIKONG offers a unique combination of technical expertise, manufacturing capacity, and customer-focused service that sets us apart in the industry.

Technical Excellence

- 60+ CNC machines for comprehensive machining capabilities

- 100+ tons monthly metal processing capacity

- Advanced CAD/CAM systems for optimized design

- In-house heat treatment and surface finishing

Quality Commitment

- ISO 9001:2015 certified quality management system

- Comprehensive material testing laboratory

- Statistical process control for consistent quality

- 100% inspection protocols for critical components

MAIKONG’s engineering team reviewing customer specifications

Customer-Focused Approach

- Dedicated project managers for seamless communication

- Design optimization for manufacturability and cost-efficiency

- Flexible production capabilities for both prototypes and high-volume runs

- Competitive pricing without compromising quality

- On-time delivery commitment

“At MAIKONG, we don’t just produce forged aluminum parts—we deliver comprehensive manufacturing solutions that address your complete requirements from design through delivery. Our integrated approach ensures quality, consistency, and value in every component we produce.”

– MAIKONG Engineering Team

Elevate Your Components with MAIKONG’s Aluminum Forging Expertise

Aluminum forging represents the optimal manufacturing process for components requiring superior strength, reliability, and performance. By partnering with MAIKONG, you gain access to comprehensive capabilities, technical expertise, and customer-focused service that ensure your components meet the highest standards of quality and performance.

From initial design consultation through final inspection, our team is committed to delivering forged aluminum components that exceed your expectations. Contact us today to discuss your project requirements and discover how MAIKONG can help you achieve your manufacturing goals.