7075 T6 aluminum forging represents the pinnacle of high-strength aluminum manufacturing. This specialized process combines the exceptional properties of 7075 aluminum alloy with the T6 tempering treatment and precision forging techniques to create components with remarkable strength-to-weight ratios. At MAIKONG, we’ve mastered this process to deliver superior quality forged components for aerospace, defense, automotive, and other demanding industries where performance cannot be compromised.

Understanding 7075 T6 Aluminum Forging Properties

Microstructure of 7075 T6 aluminum forging showing aligned grain structure. https://maikongforge.us

The exceptional performance of 7075 T6 aluminum forging stems from its unique composition and the specialized processing it undergoes. This high-strength aluminum alloy contains zinc as its primary alloying element, complemented by magnesium, copper, and chromium in carefully controlled amounts.

Composition and Mechanical Properties

| Property |

Value |

Advantage |

| Tensile Strength |

503 MPa (73,100 PSI) |

Superior load-bearing capacity |

| Yield Strength |

435 MPa (63,100 PSI) |

Excellent resistance to deformation |

| Fatigue Strength |

159 MPa (23,000 PSI) |

Enhanced durability under cyclic loading |

| Shear Strength |

331 MPa (48,000 PSI) |

Resistance to shearing forces |

| Hardness |

150 (Brinell Scale) |

Superior wear resistance |

| Machinability |

70% |

Excellent post-forging processing |

The T6 tempering process is crucial for achieving these impressive mechanical properties. This treatment involves solution heat treating, quenching, and artificial aging, which creates a uniform distribution of strengthening precipitates throughout the aluminum matrix.

The 7075 T6 Aluminum Forging Process

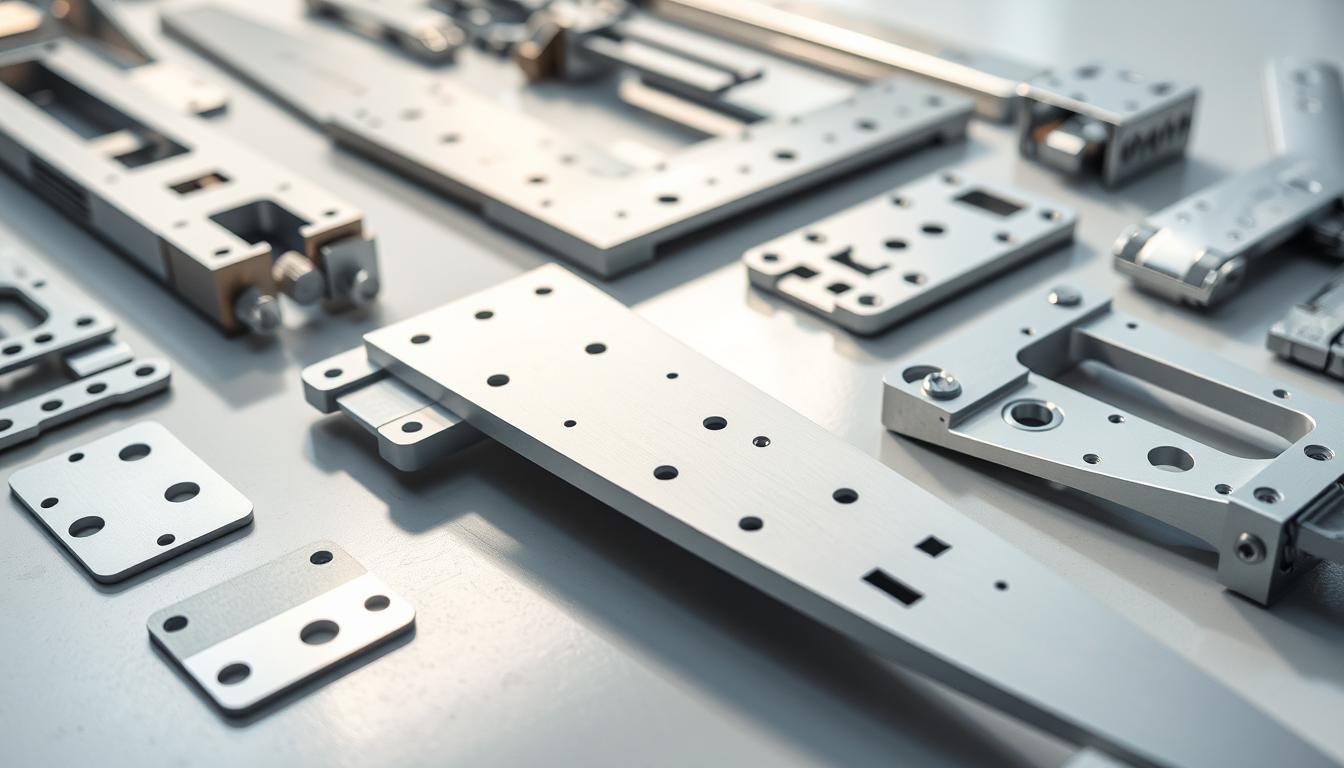

MAIKONG’s precision 7075 T6 aluminum forging process in action. https://maikongforge.us

At MAIKONG, our 7075 T6 aluminum forging process begins with selecting premium-grade 7075 aluminum billets. These are heated to optimal forging temperature before being shaped under immense pressure using our advanced hydraulic presses. This process aligns the metal’s grain structure, eliminating voids and enhancing mechanical properties.

Key Steps in Our Forging Process

- Billet Preparation: Premium 7075 aluminum is cut to precise dimensions

- Heating: Billets are heated to 750-780°F (399-416°C) for optimal plasticity

- Forging: Material is shaped under controlled pressure using custom dies

- Cooling: Controlled cooling prevents distortion and cracking

- T6 Heat Treatment: Solution heat treating, quenching, and artificial aging

- Quality Control: Comprehensive testing for dimensional accuracy and material properties

Advantages of Forging Over Other Manufacturing Methods

Forging Advantages

- Superior grain structure alignment

- Enhanced mechanical properties

- Greater strength-to-weight ratio

- Improved fatigue resistance

- Better stress distribution

- Higher impact resistance

Casting Limitations

- Potential for porosity and voids

- Lower mechanical strength

- Reduced fatigue resistance

- Inconsistent material properties

- Limited stress-bearing capacity

- Potential for internal defects

The forging process significantly enhances the inherent properties of 7075 aluminum, making it ideal for applications where failure is not an option. By aligning the grain structure and eliminating voids, forging creates components with superior strength, durability, and reliability compared to casting or machining from billet.

Applications of 7075 T6 Aluminum Forging

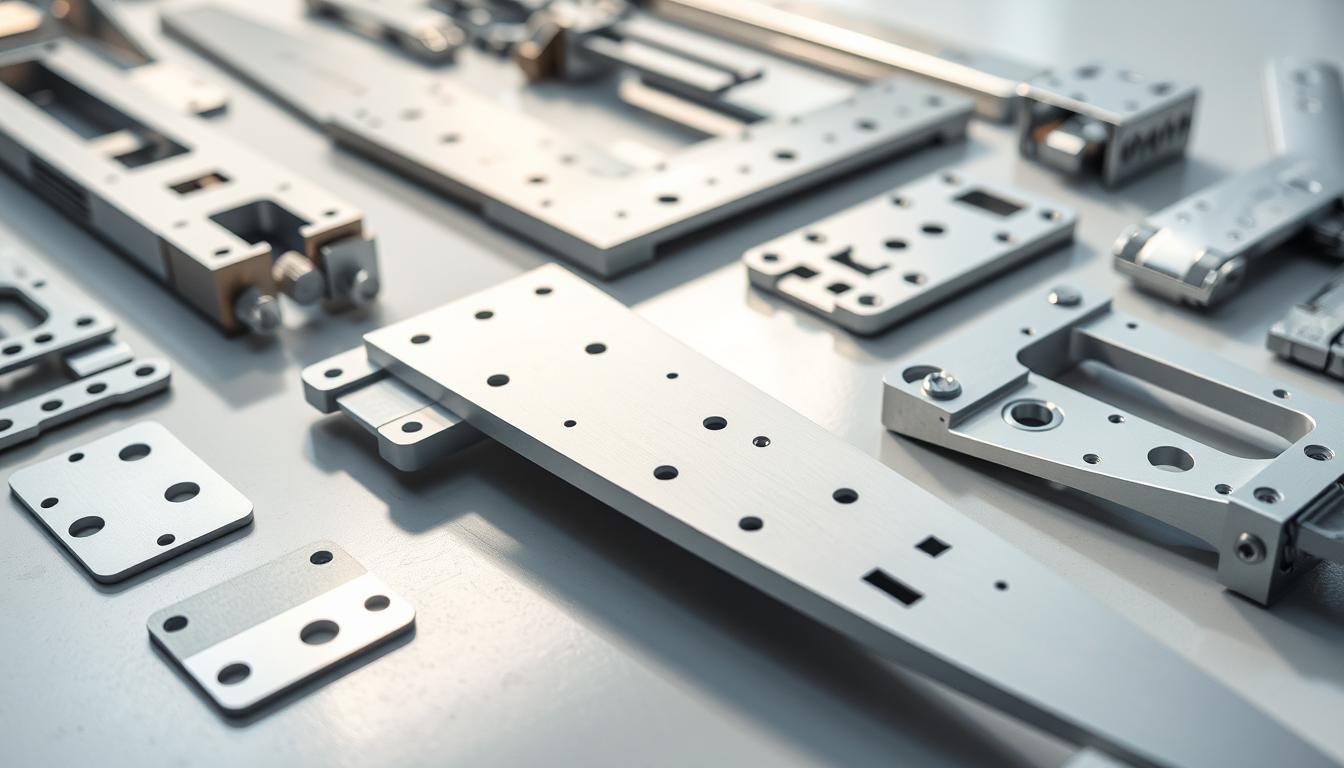

MAIKONG’s precision 7075 T6 aluminum forging components for various industries. https://maikongforge.us

The exceptional strength-to-weight ratio and superior mechanical properties of 7075 T6 aluminum forging make it the material of choice for numerous high-performance applications across multiple industries.

Aerospace and Defense

Aerospace components manufactured using 7075 T6 aluminum forging. https://maikongforge.us

In aerospace applications, 7075 T6 aluminum forging is crucial for components that must withstand extreme stresses while maintaining minimal weight. The material’s high strength-to-weight ratio makes it ideal for:

- Aircraft structural components

- Wing spars and ribs

- Landing gear components

- Fuselage frames

- Missile components

- Satellite structures

Automotive and Transportation

The automotive industry leverages 7075 T6 aluminum forging for high-performance applications where weight reduction and strength are critical:

- Suspension components

- Control arms

- Steering knuckles

- High-performance engine parts

- Racing vehicle components

- Brake calipers

Need Custom 7075 T6 Aluminum Forging?

MAIKONG specializes in custom forging solutions tailored to your exact specifications.

Get A Quick Quote

Other Industries

Sports Equipment

- Bicycle components

- Rock climbing equipment

- High-end golf club heads

- Professional racing equipment

Industrial Applications

- Heavy machinery components

- High-stress industrial parts

- Precision equipment frames

- Robotic components

Marine Applications

- High-performance boat components

- Marine hardware

- Underwater equipment

- Corrosion-resistant fittings

MAIKONG’s 7075 T6 Aluminum Forging Capabilities

MAIKONG’s state-of-the-art 7075 T6 aluminum forging facility in GD, SZ. https://maikongforge.us

At MAIKONG, we’ve invested in advanced equipment and technology to deliver superior 7075 T6 aluminum forging solutions. Our comprehensive capabilities ensure we can meet the most demanding requirements for precision, quality, and performance.

Forging Equipment

Our facility in GD, SZ houses state-of-the-art forging equipment capable of handling a wide range of part sizes and complexities:

- 5,500-Ton Hydraulic Press

- 4,100-Ton Screw Press

- 2,100-Ton Mechanical Press

- 1,600-Ton Precision Press

- Custom-designed forging dies

CNC Machining Capabilities

Precision CNC machining of 7075 T6 aluminum forging components. https://maikongforge.us

With over 60 CNC machines and 100+ tons of metal processing capacity per month, MAIKONG offers comprehensive post-forging machining services:

CNC Turning

- Precision cylindrical components

- Deep hole drilling

- Thread machining

- Superior surface finishes

CNC Milling

- Complex prismatic shapes

- Multi-axis machining

- Precision flat surfaces

- Intricate feature creation

Swiss-Type Machining

- Small precision parts

- Long shaft components

- Multi-axis capabilities

- One-stop manufacturing

Become a US Distributor

MAIKONG is seeking distributors across the United States for our high-quality 7075 T6 aluminum forging products. Join our team and represent a leader in precision metal forging.

Partner With Us

Quality Control for 7075 T6 Aluminum Forging

Rigorous quality testing of 7075 T6 aluminum forging components at MAIKONG. https://maikongforge.us

At MAIKONG, quality is built into every step of our 7075 T6 aluminum forging process. Our comprehensive quality control system ensures that every component meets or exceeds the most stringent industry standards.

Testing and Verification

- Material Verification: Spectroscopic analysis confirms exact alloy composition

- Mechanical Testing: Tensile, yield, and hardness testing verify material properties

- Dimensional Inspection: Precision measurement ensures exact specifications

- Non-Destructive Testing: Ultrasonic and penetrant testing detect internal flaws

- Microstructure Analysis: Confirms proper grain structure and alignment

- Heat Treatment Verification: Ensures proper T6 temper properties

Our in-house materials laboratory enables us to perform comprehensive testing and verification, ensuring that every 7075 T6 aluminum forging component meets the exact specifications required for your application.

MAIKONG’s advanced materials testing laboratory. https://maikongforge.us

Certifications and Standards

MAIKONG maintains rigorous quality management systems and holds key industry certifications:

- ISO 9001:2015 Quality Management System

- Aerospace AS9100 compliance capabilities

- IATF 16949 automotive quality standards

- Full material traceability and documentation

Why Choose MAIKONG for 7075 T6 Aluminum Forging

MAIKONG’s expert engineering team developing 7075 T6 aluminum forging solutions. https://maikongforge.us

Partnering with MAIKONG for your 7075 T6 aluminum forging needs offers numerous advantages that help you achieve superior quality, cost efficiency, and reliable performance.

Technical Expertise

- Specialized knowledge in aluminum metallurgy

- Advanced forging process optimization

- Custom solution development

- Material selection guidance

Manufacturing Excellence

- State-of-the-art equipment

- 60+ CNC machines

- 100+ tons monthly capacity

- Comprehensive in-house capabilities

Customer Benefits

- Competitive pricing

- Consistent quality

- Reliable delivery

- Responsive customer service

Conclusion

Precision 7075 T6 aluminum forging components by MAIKONG. https://maikongforge.us

7075 T6 aluminum forging represents the pinnacle of aluminum manufacturing technology, offering unmatched strength-to-weight ratio and performance characteristics for the most demanding applications. At MAIKONG, we combine advanced equipment, technical expertise, and rigorous quality control to deliver superior forged components that meet the highest industry standards.

Whether you need aerospace components, automotive parts, or industrial equipment, our comprehensive capabilities in 7075 T6 aluminum forging and precision CNC machining ensure that we can meet your exact requirements with competitive pricing and reliable delivery.

Contact MAIKONG today to discuss your 7075 T6 aluminum forging needs and discover how our expertise can contribute to the success of your projects.

Start Your Project Today

Ready to experience the MAIKONG difference? Contact us now for a consultation and quote.

Get A Quick Quote