Aluminum Forging Manufacturers: MAIKONG’s Premium Metal Forging Solutions

December 22, 2025

Who is MAIKONG? Premier Aluminum Forging Manufacturers

As both producers and consumers of our customers’ products, we at MAIKONG understand the critical importance of consistency, strength, and precise weight in each forged aluminum component. Our dedicated focus on crafting superior forged parts enables us to fulfill your exact requirements for heat treating, machining, and testing with uncompromising quality.

Our advanced material laboratory plays a vital role in our production process, allowing us to achieve the precise metallurgical results you demand. Our expert team possesses a profound understanding of aluminum alloys, their properties, and their interactions, ensuring our products consistently meet the highest standards of quality and performance.

Ready to Experience MAIKONG Quality?

Discover how our aluminum forging expertise can elevate your products.

Full-Service Aluminum Forging Solutions

MAIKONG operates as a comprehensive service center for aluminum forgings, providing end-to-end solutions that maximize the advantages of forged aluminum. Through proper deformation and grain flow control, combined with material homogeneity, our forging process maximizes impact toughness, fracture resistance, and fatigue strength while ensuring consistent performance across all components.

Forged aluminum is the ideal choice for sectors where performance and safety are critical to prevent failures caused by shock, impact, cyclic loads, or vibration stresses. Our in-house secondary processing further enhances these advantages, enabling the attainment of desired mechanical properties and achieving final shape and dimensional tolerances for precision aluminum forgings.

We don’t just supply aluminum forgings; we consider how to best support the end application at each step of our one-stop forging process. Our unprecedented service center for aluminum forgings provides comprehensive technical support and solutions to our customers.

MAIKONG’s Comprehensive Aluminum Forging Service Center

CAD/CAM & Design Engineering

Our engineering team utilizes advanced analysis software to facilitate early-stage issue identification and mitigation. We collaborate closely with clients to design customized forging processes that align with specific requirements, creating tailored die designs using sophisticated computer-aided design (CAD) tools.

Material Science & Selection

It is imperative to thoroughly consider the mechanical properties, machining capabilities, heat treatment characteristics, and cost-effectiveness of aluminum alloy selection. Our material experts help you choose the optimal aluminum alloy for your specific application needs, ensuring the perfect balance of performance and value.

Precision Tooling & Die Design

Our tooling design ensures initial quality, while regular maintenance preserves consistency—both critical for producing high-quality forgings. MAIKONG’s expert toolmakers create precision dies that maximize material flow and minimize waste, resulting in near-net-shape components that require minimal machining.

The Forging Process

Our forging workshop is equipped to accommodate diverse aluminum forging specifications. Using hydraulic presses and specialized equipment, we transform aluminum billets into precision components with superior grain structure and mechanical properties that cannot be achieved through casting or machining alone.

In-House Heat Treatment

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment processes. This critical step enhances the mechanical properties of aluminum forgings, ensuring they meet or exceed industry specifications for strength, hardness, and durability.

CNC Machining & Finishing

Our machining workshop is equipped with state-of-the-art CNC machines capable of precise and intricate forging machining operations. This allows us to transform near-net-shape forgings into finished components with exact dimensions and superior surface finishes.

Surface Treatment & Coating

Surface treatment plays a vital role in manufacturing by enhancing the appearance, performance, and competitiveness of products. We offer comprehensive finishing options including anodizing, painting, laser engraving, and sand blasting—all with rigorous quality control to ensure consistent results.

Rigorous Quality Assurance

Quality control procedures are essential to ensure that forged components meet stringent standards. Our quality management system monitors every aspect of production, from raw material verification to final inspection, ensuring consistent excellence in every component we produce.

+86 13-5109-0701Contact our aluminum forging experts today!

Why Choose Forging? The MAIKONG Advantage

Aluminum Forging and its Optimal Strength-to-Weight Ratio

Strength-to-weight ratio is a fundamental engineering principle that addresses the balance between material strength and weight—an essential consideration in industries prioritizing performance, efficiency, and safety. Aluminum, recognized for its lightweight properties and robust mechanical characteristics, is enhanced through forging, refining its internal grain structure for enhanced resilience and strength.

This makes aluminum forgings from MAIKONG the optimal choice for withstanding both static and dynamic loads. With an optimal strength-to-weight ratio, our forgings showcase engineering excellence—a combination of material science, metallurgy, and precision manufacturing that reshapes possibilities across industries.

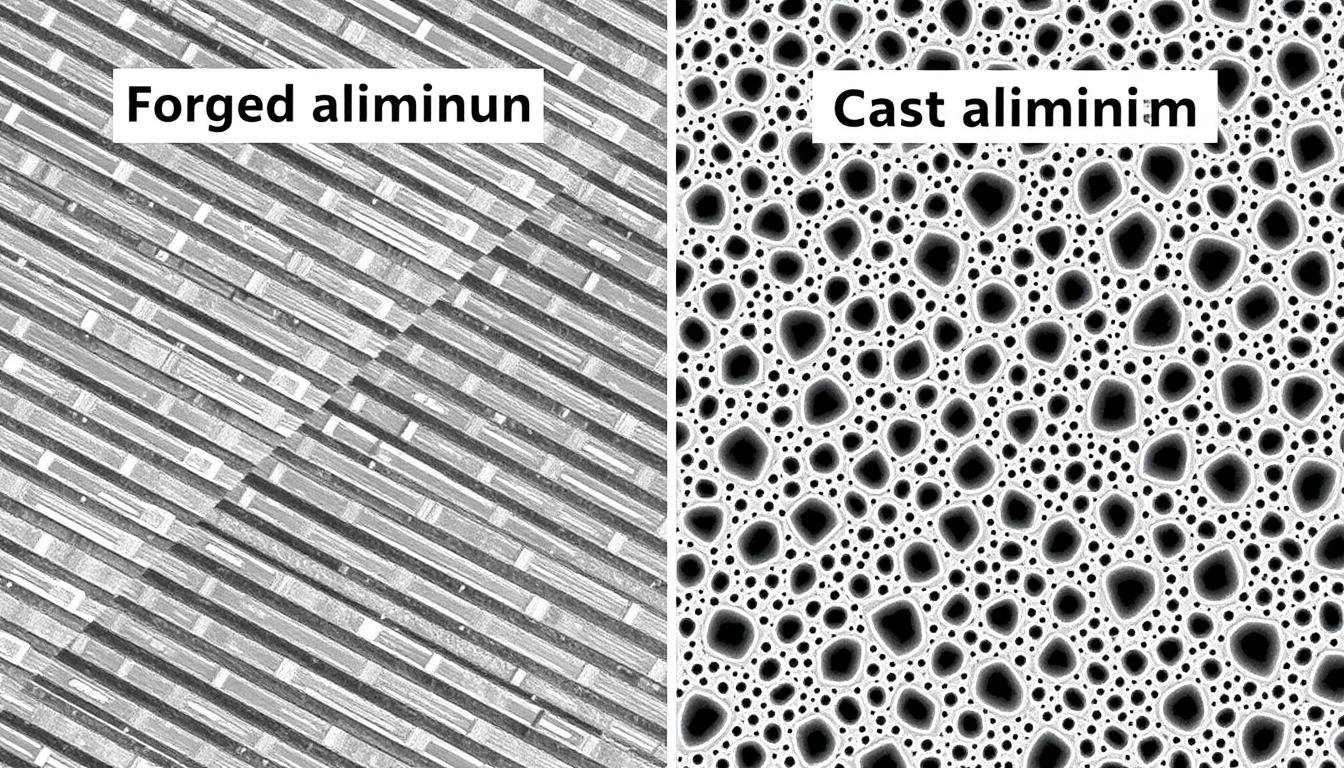

The Advantage of Aluminum Forging over Casting Aluminum

| Comparison Categories | Aluminum Forging | Casting Aluminum |

| Strength and Durability | ✅ Higher due to dense, uniform grain structure | Potentially lower due to air pockets and inclusions |

| Tensile Properties | ✅ Superior tensile strength and resistance | Lower tensile strength |

| Fatigue Resistance | ✅ Better resistance against fatigue failure | Potentially lower fatigue resistance |

| Complex Geometries | Require multiple steps to achieve complex shapes | ✅ Can achieve complex shapes in one session |

| Dimensional Accuracy | ✅ Better accuracy and tighter tolerances | Potential inconsistencies |

| Surface Finish | ✅ Smoother surfaces, reduced post-processing | Might require more machining due to air pockets |

| Ideal Applications | Aerospace, automotive, high-stress components | Consumer goods, decorative items, non-critical parts |

Ready to Upgrade to Superior Forged Components?

Experience the MAIKONG difference in quality, strength, and performance.

MAIKONG’s Manufacturing Prowess

MAIKONG’s state-of-the-art manufacturing facility, located in the heart of GD, SZ, houses a comprehensive range of well-maintained forging equipment. Our strategic location presents significant logistical advantages, facilitating efficient receipt of raw materials and prompt dispatch of finished components to our partners worldwide.

Our suite of machinery, encompassing hydraulic forging presses, uniform heat treatment furnaces, and precision-driven CNC machines, assures both the quality and volume of our production. The factory layout is meticulously planned to foster optimal efficiency, with production lines engineered to minimize waste and expedite the manufacturing process.

Quality Certifications

MAIKONG proudly maintains ISO 9001:2015 certification, demonstrating our commitment to quality management systems and continuous improvement. Our rigorous quality control processes ensure consistent excellence in every component we produce.

Sustainable Manufacturing

Every aspect of our operation, from the configuration of our production floors to the maintenance of our machinery, is informed by our commitment to efficiency, quality, and sustainability. This pragmatic approach allows MAIKONG to deliver reliable, quality aluminum forgings while minimizing our environmental footprint.

Beyond Aluminum Forging: MAIKONG’s Full Capabilities

As leading aluminum forging manufacturers, MAIKONG offers a comprehensive range of metal fabrication services to meet all your manufacturing needs. Our vertically integrated approach allows us to provide complete solutions from design to delivery.

CNC Machining Services

Our advanced CNC machining capabilities include turning, milling, and Swiss-type machining for precision components. With 60+ CNC machines, we provide 100+ tons of metal processing capacity monthly.

- CNC Turning Services

- CNC Milling Services

- Swiss-Type Machining

- Multi-Axis Machining

Steel Forging Services

MAIKONG supports programs requiring custom steel forging in both low- and high-volume quantities. We work with carbon steel, alloy steel, and tool steel grades, producing near-net-shape parts with excellent mechanical properties.

- Carbon Steel Forgings

- Alloy Steel Forgings

- Tool Steel Forgings

- Custom Steel Components

Brass Extrusion Services

Our brass extrusion capabilities deliver high-quality custom components with excellent corrosion resistance and conductivity. Perfect for electrical, plumbing, architectural, and decorative applications.

- Custom Brass Profiles

- Precision Extrusions

- Complex Cross-Sections

- Finishing Services

Partner with MAIKONG: Your Premier Aluminum Forging Manufacturers

MAIKONG is actively seeking agents and partners across the United States to represent our high-quality, cost-effective aluminum forging and metal fabrication services. With our comprehensive capabilities, state-of-the-art facilities, and commitment to excellence, we offer unmatched value in the metal manufacturing industry.

Why choose MAIKONG as your aluminum forging partner?

MAIKONG combines advanced manufacturing capabilities, rigorous quality control, and competitive pricing to deliver superior aluminum forgings. Our comprehensive services from design to delivery ensure seamless project execution, while our experienced team provides expert technical support throughout the process.

What industries do MAIKONG’s aluminum forgings serve?

Our precision aluminum forgings are used across numerous industries including aerospace, automotive, defense, marine, industrial machinery, sports equipment, and medical devices. Any application requiring high strength-to-weight ratio, excellent corrosion resistance, and superior mechanical properties can benefit from our aluminum forging expertise.

How does MAIKONG ensure consistent quality?

MAIKONG maintains ISO 9001:2015 certification and implements rigorous quality management systems throughout our production process. From material verification to final inspection, every step is carefully monitored and documented to ensure consistent excellence in every component we produce.

Ready to Experience the MAIKONG Difference?

Contact us today to discuss your aluminum forging needs or partnership opportunities.

Email: Lucy@maikongforge.us | Website: maikongforge.us

Contact us online by Whatsapp: