In today’s competitive manufacturing landscape, selecting the right production method can significantly impact your product’s performance, durability, and cost-effectiveness. Aluminum Forging Factory processes stand out as a premier solution for creating high-strength, lightweight components across numerous industries. MAIKONG has established itself as a leading provider of aluminum forging services, delivering exceptional quality and precision that outperforms alternative manufacturing methods.

MAIKONG’s state-of-the-art

Aluminum Forging Factory facility in GD, SZ

The Superior Advantages of an Aluminum Forging Factory

At MAIKONG, our advanced Aluminum Forging Factory utilizes sophisticated processes that reshape metal through controlled deformation, creating products with exceptional structural integrity. Unlike casting or machining, forging aligns the metal’s grain structure with the part’s shape, significantly enhancing mechanical properties and performance characteristics.

Unmatched Strength-to-Weight Ratio

Aluminum forgings deliver an optimal balance between structural strength and weight reduction – a critical factor in aerospace, automotive, and other high-performance applications. This balance translates to improved fuel efficiency, enhanced performance, and reduced operational costs.

Superior Structural Integrity

The forging process eliminates internal voids and porosity common in cast parts, resulting in components with consistent density and superior mechanical properties. This makes forged aluminum ideal for safety-critical applications where reliability is non-negotiable.

Experience the MAIKONG Difference

Discover how our advanced aluminum forging capabilities can enhance your product’s performance and reliability.

Request a Free Consultation

Aluminum Forging vs. Alternative Manufacturing Methods

Understanding the key differences between manufacturing processes is essential for making informed decisions about your production needs. Below, we compare aluminum forging with casting and other common manufacturing methods:

| Comparison Criteria |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Critical Applications |

✅ Ideal for structural members and load-bearing components |

Limited suitability for critical applications |

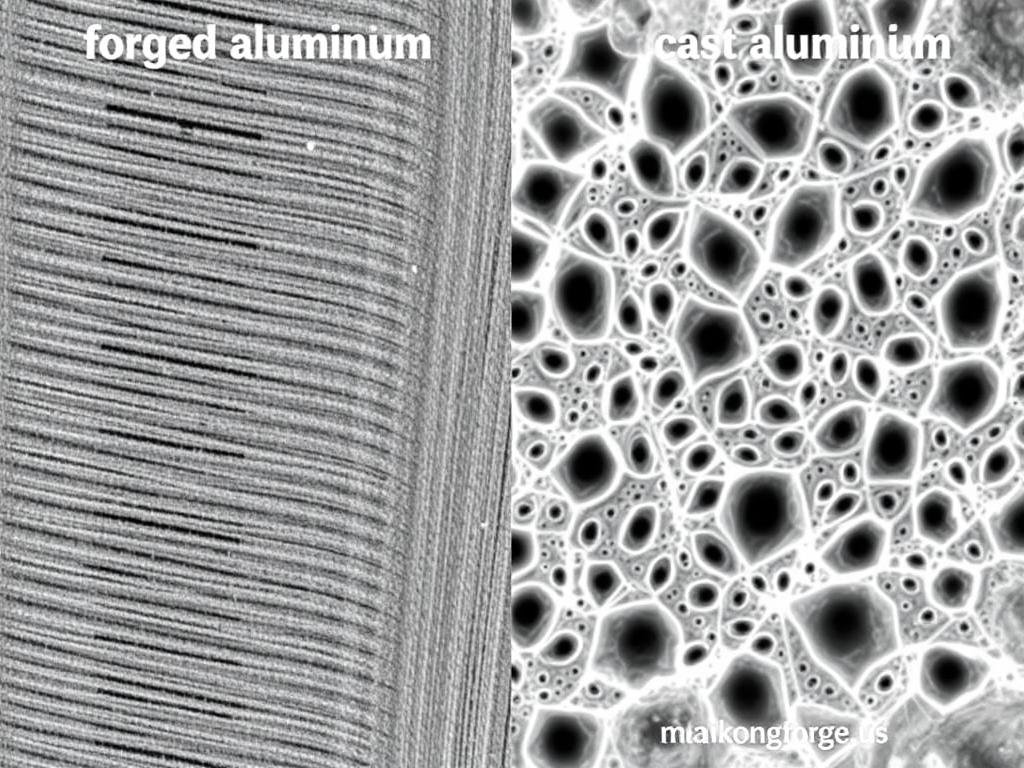

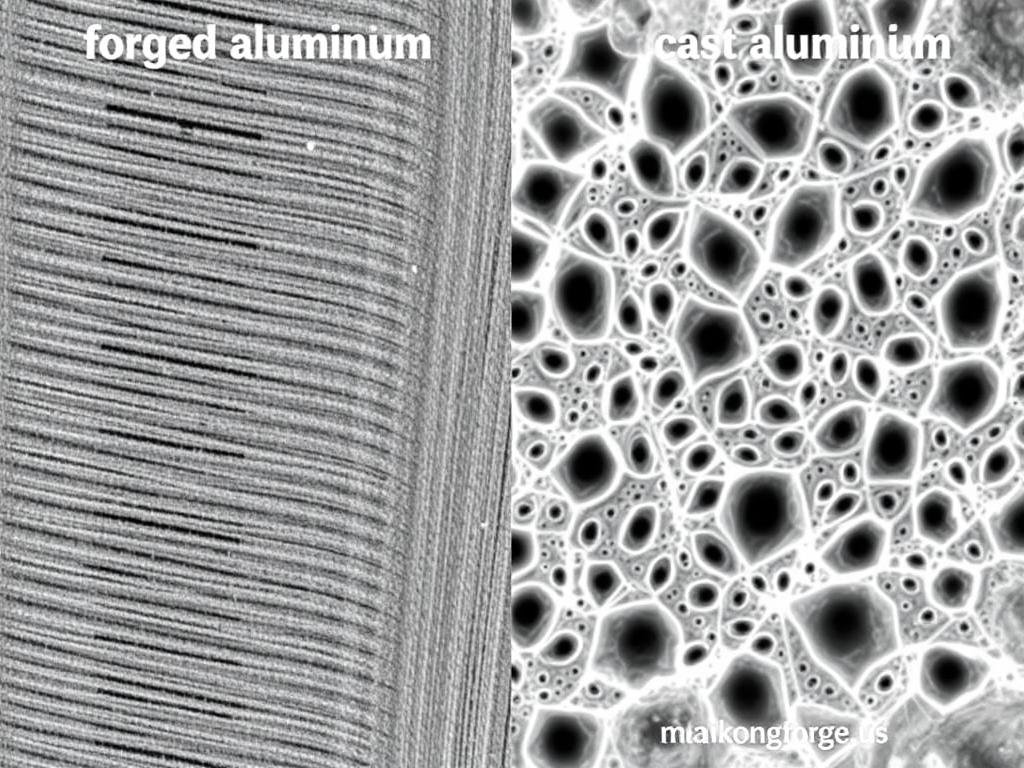

Microstructure comparison: Forged aluminum (left) shows aligned grain structure; cast aluminum (right) shows random grain pattern

The forging process fundamentally transforms aluminum’s internal structure, creating a directional grain flow that follows the contours of the part. This alignment significantly enhances mechanical properties, particularly in applications where stress resistance is critical. While casting offers advantages for complex geometries, forged components deliver superior performance in demanding environments.

The MAIKONG Aluminum Forging Factory Process

At MAIKONG, we’ve refined our aluminum forging process to deliver exceptional quality and consistency. Our comprehensive approach ensures optimal results from design through final inspection:

MAIKONG’s precision aluminum forging process ensures superior grain structure and mechanical properties

1. Design & Engineering

Our engineering team utilizes advanced CAD/CAM systems to optimize part design for the forging process. Through finite element analysis and simulation, we identify potential issues before production begins, ensuring optimal results.

2. Material Selection

We carefully select premium aluminum alloys based on your specific application requirements. Our in-house metallurgical laboratory verifies material composition and properties to ensure consistent quality.

3. Tooling Development

Precision die design is critical to successful forging. Our experienced tooling engineers create custom dies that ensure optimal metal flow and dimensional accuracy for your specific components.

4. Forging Operation

Using state-of-the-art hydraulic presses, we apply precisely controlled pressure to heated aluminum billets, forming them into the desired shape while optimizing grain structure and mechanical properties.

5. Heat Treatment

Our in-house heat treatment facilities allow precise control over material properties. Through solution treatment, quenching, and aging processes, we enhance strength, hardness, and other critical characteristics.

6. Finishing & Quality Control

Comprehensive finishing operations including precision CNC machining, surface treatments, and rigorous quality inspections ensure that every component meets exact specifications and performance requirements.

Precision Engineering at Every Step

Experience MAIKONG’s comprehensive aluminum forging capabilities for your next project.

Get A Quick Quote

Industry Applications for Aluminum Forging Factory Products

MAIKONG’s aluminum forging capabilities serve diverse industries where performance, reliability, and precision are paramount. Our specialized expertise enables us to deliver custom solutions for the most demanding applications:

Precision aerospace components forged at MAIKONG’s facility

Aerospace Applications

In aerospace, where weight reduction and structural integrity are critical, our forged aluminum components deliver exceptional performance. From structural elements to landing gear components, MAIKONG’s aerospace forgings meet the industry’s stringent quality and safety standards.

- Aircraft structural components

- Landing gear parts

- Engine mounts and brackets

- Control system components

High-performance automotive components forged from premium aluminum alloys

Automotive Excellence

The automotive industry benefits from our lightweight, high-strength aluminum forgings that enhance vehicle performance and efficiency. From suspension components to drivetrain parts, our forgings help manufacturers meet increasingly demanding performance and emissions standards.

- Suspension components

- Steering knuckles

- Connecting rods

- Wheel hubs and brackets

Industrial components forged to precise specifications for demanding applications

Industrial Applications

Industrial equipment requires components that can withstand extreme conditions while maintaining dimensional stability. Our forged aluminum parts deliver reliable performance in challenging environments, from oil and gas applications to heavy machinery.

- Valve bodies and components

- Hydraulic system parts

- Structural connectors

- High-pressure fittings

Marine and defense components engineered for extreme environments

Marine & Defense Solutions

Marine and defense applications demand components that resist corrosion while maintaining structural integrity. Our specialized aluminum alloys and forging processes create parts that perform reliably in the most challenging environments.

- Marine hardware and fittings

- Propulsion system components

- Structural brackets and mounts

- Defense equipment components

Industry-Specific Solutions

Discover how MAIKONG’s aluminum forging expertise can address your industry’s unique challenges.

Discuss Your Application

MAIKONG’s Comprehensive Aluminum Forging Factory Capabilities

As a full-service Aluminum Forging Factory, MAIKONG offers end-to-end solutions that go beyond basic forging operations. Our integrated approach ensures consistent quality and streamlined production:

MAIKONG’s integrated manufacturing facility offers complete aluminum forging solutions

Advanced Design Services

Our engineering team provides comprehensive design support, from concept development to production-ready specifications. Using advanced CAD/CAM systems and simulation tools, we optimize designs for manufacturability and performance.

Precision CNC Machining

MAIKONG’s state-of-the-art CNC machining centers complement our forging capabilities, allowing us to deliver components with precise tolerances and exceptional surface finishes. Our integrated approach ensures seamless transition from forging to final machining.

Heat Treatment Expertise

Our in-house heat treatment facilities enable precise control over material properties. Through carefully controlled thermal processes, we enhance strength, hardness, and other critical characteristics to meet your specific requirements.

Surface Treatment Options

MAIKONG offers comprehensive surface treatment services including anodizing, painting, and specialized coatings that enhance appearance, corrosion resistance, and wear properties of forged aluminum components.

Quality Assurance

Our rigorous quality control procedures include dimensional inspection, material testing, and non-destructive evaluation to ensure every component meets exact specifications. MAIKONG is committed to ISO 9001:2015 quality standards.

Logistics Support

From prototype development to high-volume production, MAIKONG provides comprehensive logistics support, ensuring timely delivery and efficient inventory management for your aluminum forging requirements.

Experience Our Full-Service Capabilities

Contact MAIKONG today to discuss your aluminum forging requirements.

Email: Lucy@maikongforge.us

Why Choose MAIKONG as Your Aluminum Forging Factory Partner

MAIKONG’s quality control specialists ensure every component meets exact specifications

The MAIKONG Advantage

- 60+ CNC machines with 100+ tons monthly processing capacity

- Comprehensive in-house capabilities from design to finishing

- Advanced metallurgical testing laboratory

- ISO 9001:2015 certified quality management system

- Competitive pricing with exceptional value

- Experienced engineering team for technical support

- Flexible production capabilities for both prototypes and high-volume orders

Customer-Focused Approach

At MAIKONG, we recognize that each client has unique requirements. Our customer-focused approach ensures that we understand your specific needs and deliver solutions that exceed expectations. From initial consultation through final delivery, our team works closely with you to ensure optimal results.

Commitment to Quality

Quality is at the core of everything we do. Our comprehensive quality management system, certified to ISO 9001:2015 standards, ensures consistent excellence in every component we produce. From material verification to final inspection, we maintain rigorous quality controls throughout the production process.

Competitive Advantage

By choosing MAIKONG as your Aluminum Forging Factory partner, you gain a significant competitive advantage. Our efficient production processes, technical expertise, and integrated capabilities deliver exceptional value, helping you bring better products to market faster and more cost-effectively.

Partner with MAIKONG Today

Experience the difference that a dedicated aluminum forging partner can make for your business.

Request a Quote

Elevate Your Products with MAIKONG’s Aluminum Forging Expertise

Choosing the right Aluminum Forging Factory is a critical decision that impacts your product’s performance, reliability, and cost-effectiveness. MAIKONG offers the comprehensive capabilities, technical expertise, and quality focus needed to deliver exceptional aluminum forgings that outperform components manufactured through alternative methods.

From aerospace and automotive applications to industrial and marine environments, our forged aluminum components provide the optimal combination of strength, weight reduction, and durability. Our integrated approach—encompassing design, forging, machining, heat treatment, and finishing—ensures consistent quality and streamlined production.

Contact MAIKONG today to discuss your aluminum forging requirements and discover how our expertise can enhance your products and streamline your supply chain. We’re actively seeking distribution partners throughout the United States to bring our cost-effective, high-quality aluminum forging solutions to more customers.

Ready to Get Started?

Contact MAIKONG today to discuss your aluminum forging requirements or distribution opportunities.

MAIKONG’s state-of-the-art Aluminum Forging Factory facility in GD, SZ

MAIKONG’s state-of-the-art Aluminum Forging Factory facility in GD, SZ