The US manufacturing landscape continues to evolve, seeking reliable partners who can deliver precision, quality, and value. As a leading Aluminum Forging Factory, MAIKONG brings over 30 years of expertise in forging and CNC machining technologies to meet the demanding needs of American industries. Our commitment to manufacturing excellence has positioned us as a preferred partner for companies requiring high-performance aluminum components with superior strength-to-weight ratios and exceptional durability.

The Strategic Advantage of an Aluminum Forging Factory for US Manufacturing

State-of-the-art aluminum forging process at MAIKONG’s manufacturing facility

State-of-the-art aluminum forging process at MAIKONG’s manufacturing facility

American manufacturers across aerospace, automotive, defense, and infrastructure sectors increasingly rely on specialized Aluminum Forging Factory partners to gain competitive advantages. MAIKONG’s precision forging capabilities deliver components with optimized grain structure, superior mechanical properties, and consistent quality that meet or exceed US industry standards.

Why US Industries Choose an Expert Aluminum Forging Factory

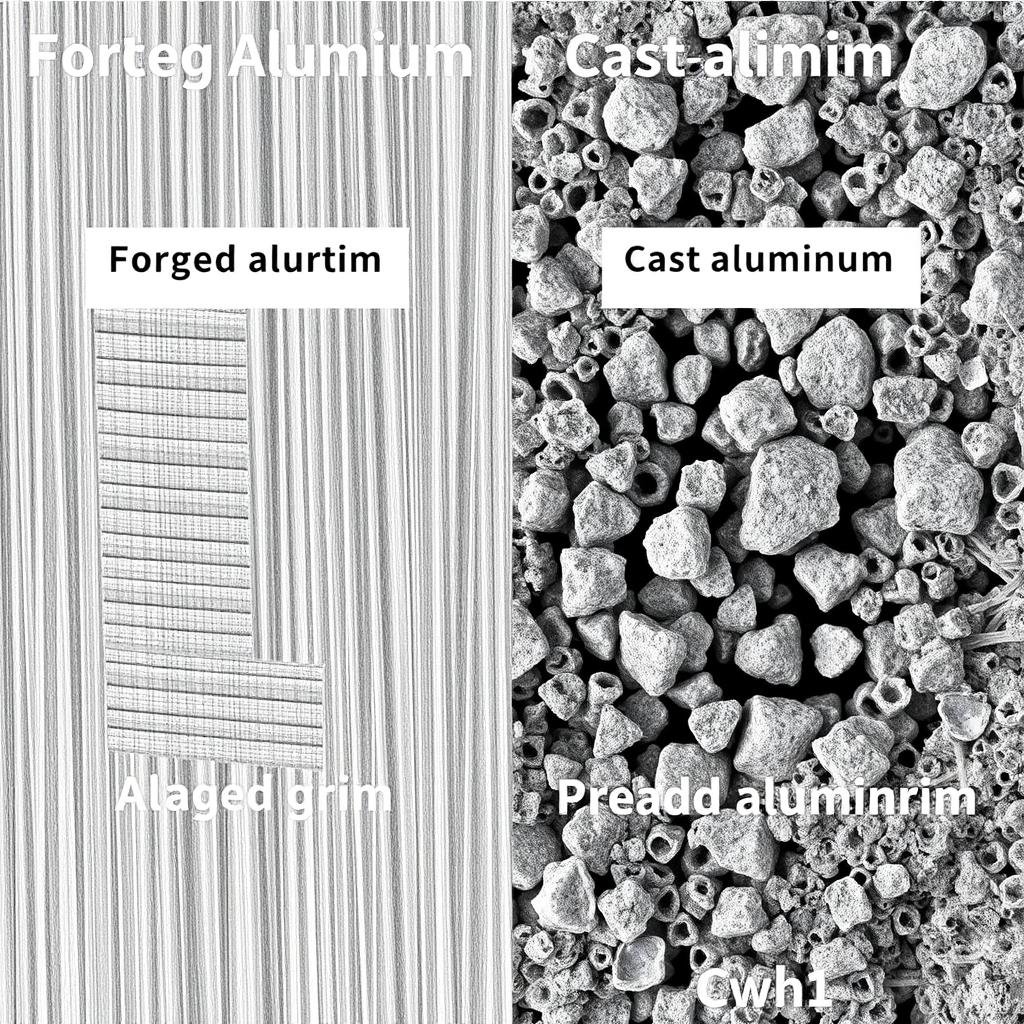

The forging process fundamentally transforms aluminum’s properties by aligning its grain structure through controlled deformation. This creates components with significantly enhanced mechanical characteristics compared to casting or machining from billet. For US manufacturers in critical industries, these advantages translate to:

- Higher strength-to-weight ratio for fuel efficiency

- Superior fatigue resistance for safety-critical applications

- Enhanced structural integrity under extreme conditions

- Improved corrosion resistance for longer service life

- Consistent quality for reliable performance

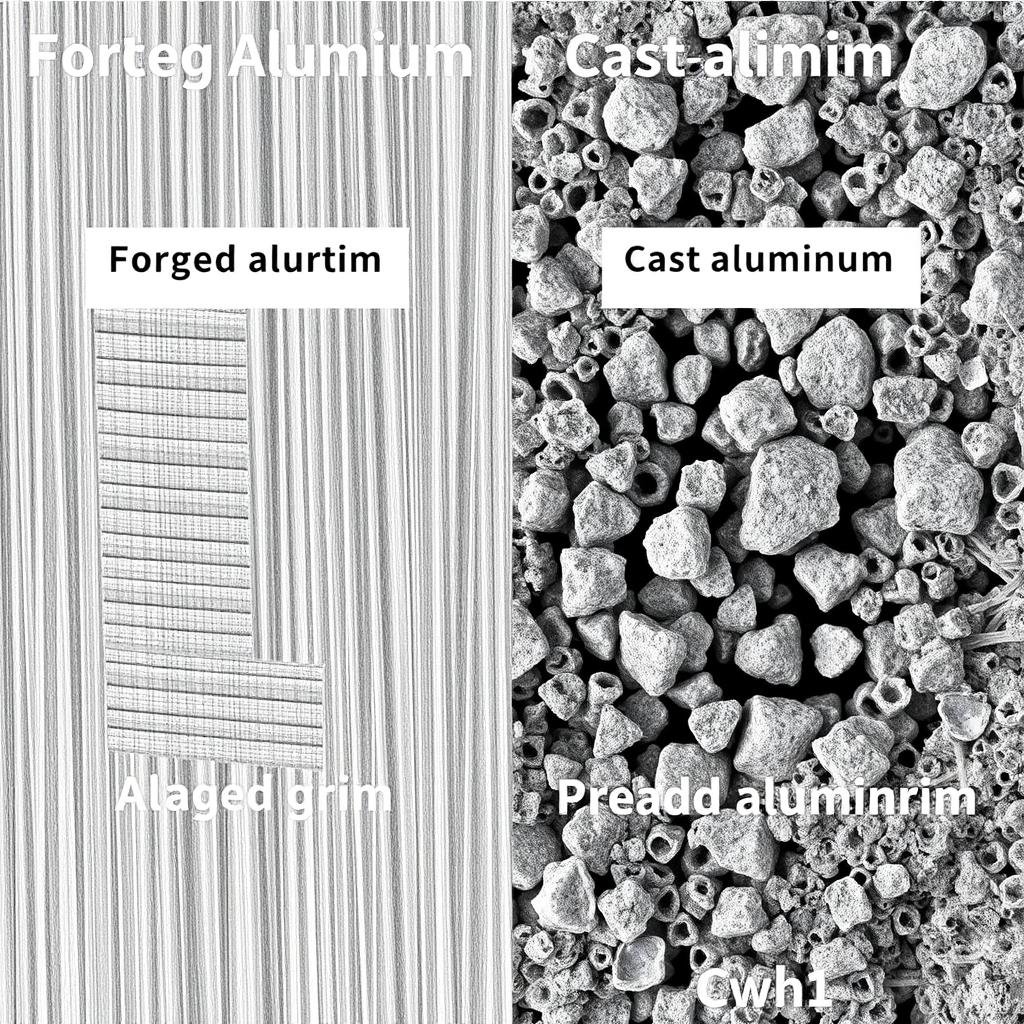

Microstructure comparison: Forged aluminum (left) vs. Cast aluminum (right)

Discover MAIKONG’s Aluminum Forging Expertise

Our team of metallurgists and engineers can help you identify the optimal aluminum alloy and forging process for your specific application.

Get Expert Consultation

Aluminum Forging vs. Casting: A Comprehensive Comparison

When evaluating manufacturing methods for aluminum components, understanding the fundamental differences between forging and casting is crucial for making informed decisions. As an experienced Aluminum Forging Factory, MAIKONG provides this detailed comparison to help US manufacturers select the optimal process for their specific requirements.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

✅ High strength-to-weight ratio |

Bulkier parts may be needed |

| Ideal Applications |

Aerospace, automotive, medical devices |

Consumer goods, simple parts, non-critical sectors |

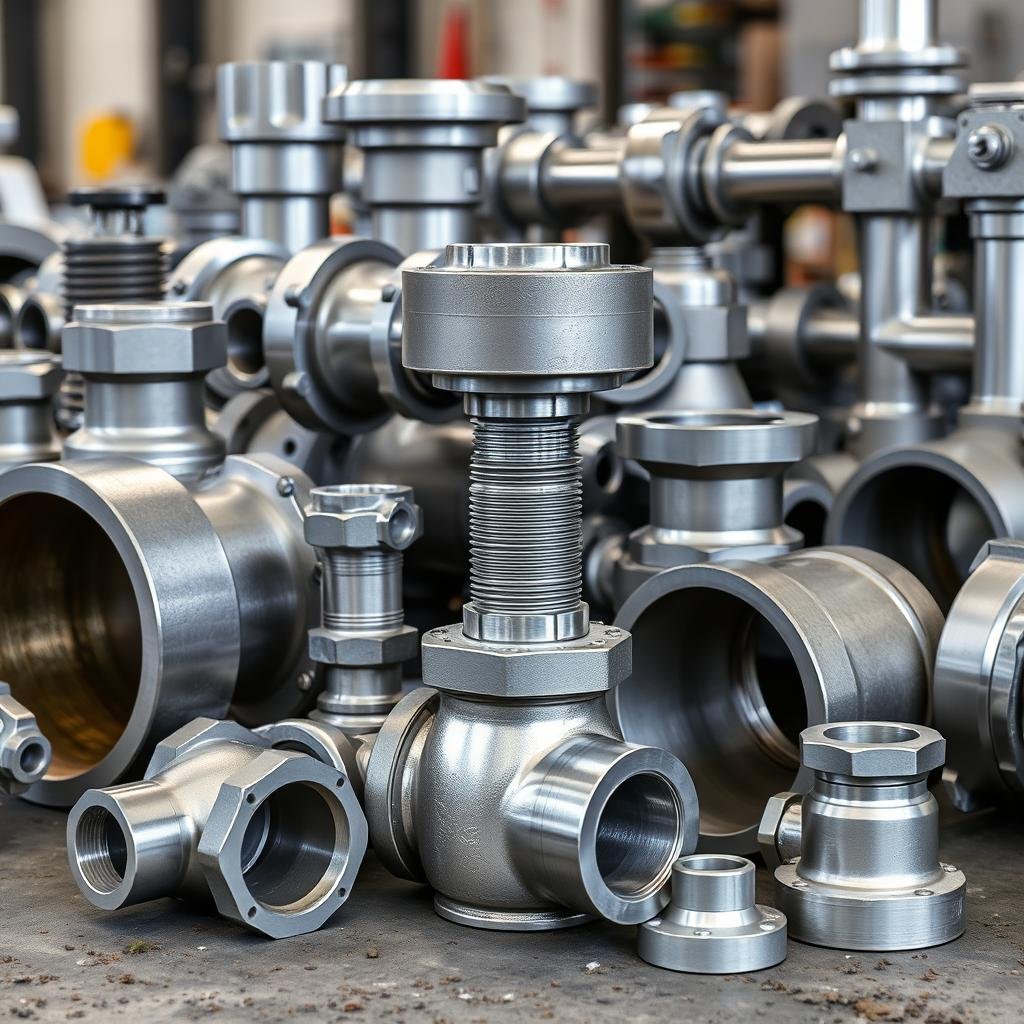

High-performance aluminum forged components manufactured by MAIKONG

MAIKONG’s Comprehensive Aluminum Forging Services

As a full-service Aluminum Forging Factory, MAIKONG delivers end-to-end solutions from initial design to finished components. Our integrated approach ensures quality control at every stage while optimizing cost-efficiency for our US clients.

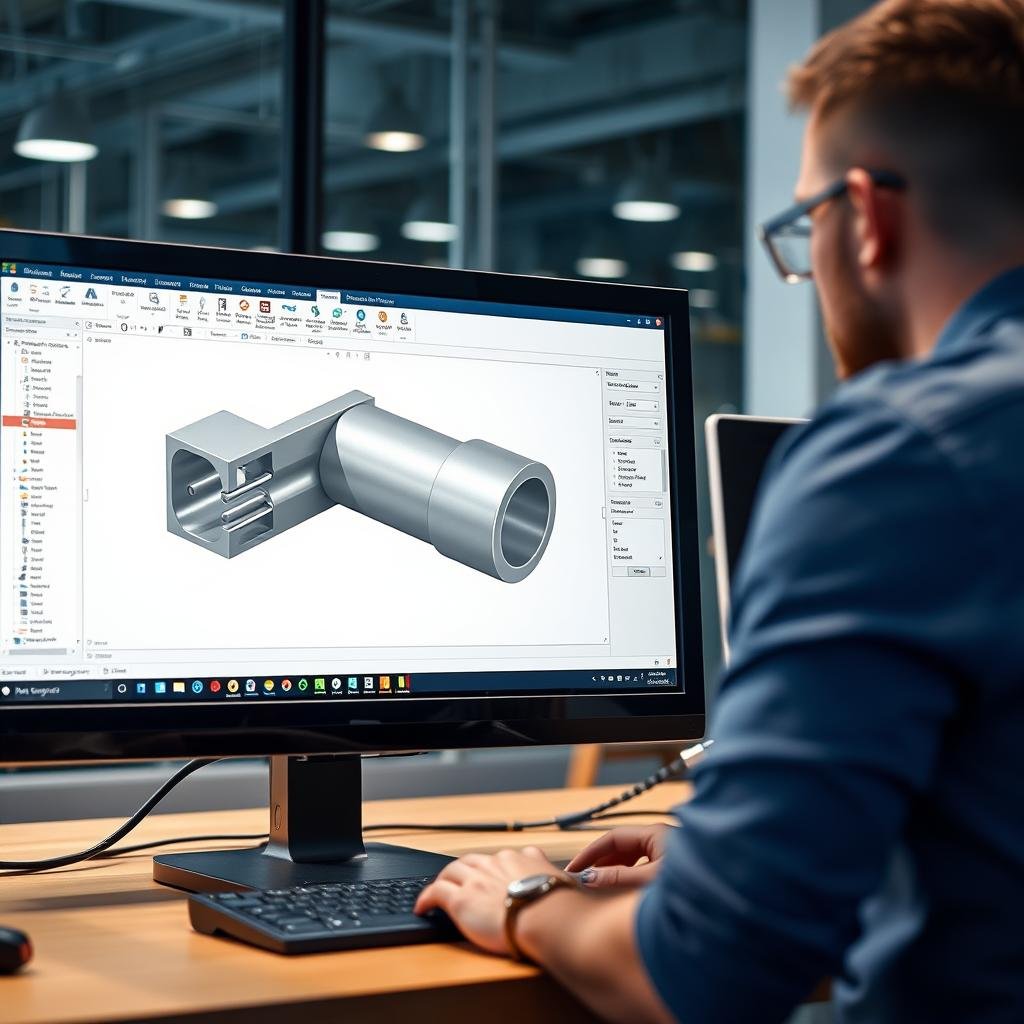

CAD/CAM Design

Our engineering team utilizes advanced analysis software to identify and mitigate potential issues early in the design process, ensuring manufacturability and performance.

Material Selection

We carefully evaluate mechanical properties, machinability, heat treatment characteristics, and cost-effectiveness to select the optimal aluminum alloy for each application.

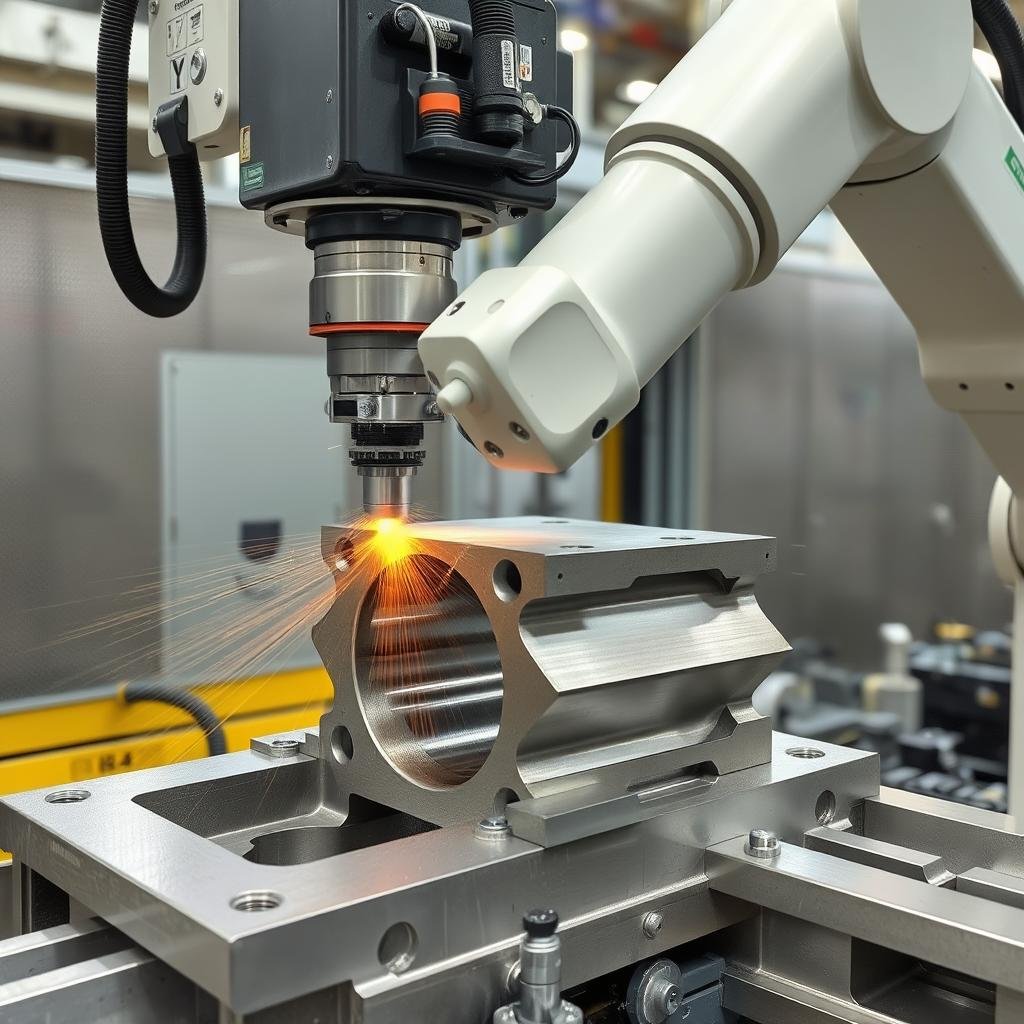

Precision Tooling

Our tooling design ensures initial quality, while regular maintenance preserves consistency—both critical factors for producing high-quality aluminum forgings.

Forging Process

Our forging workshop is equipped with state-of-the-art hydraulic presses capable of accommodating diverse aluminum forging specifications with precise control.

Heat Treatment

We conduct comprehensive statistical analysis and documentation for our in-house heat treatment processes to ensure consistent mechanical properties.

Surface Finishing

Automated grinding with specialized robots is employed to remove parting lines and achieve precise surface specifications for each component.

Ready to Optimize Your Manufacturing Process?

Contact our engineering team to discuss how our comprehensive aluminum forging services can enhance your product performance while reducing costs.

Request a Quote

Advanced CNC Machining Capabilities

MAIKONG’s state-of-the-art CNC machining center

MAIKONG complements its Aluminum Forging Factory operations with advanced CNC machining capabilities, providing a seamless transition from forged blanks to precision-finished components. With over 60 CNC machines and 100+ tons of monthly metal processing capacity, we deliver comprehensive solutions for US manufacturers.

CNC Turning Services

Our CNC turning capabilities deliver superior surface finishes for cylindrical shapes, deep holes, and machined threads. This process is ideal for creating precision components with fast turnaround times and exceptional quality.

CNC Milling Services

Our multi-axis CNC milling equipment creates complex prismatic shapes and flat surfaces with high precision. These flexible systems require no fixed tooling while maintaining extreme accuracy for diverse industrial applications.

Swiss-Type Machining

Our specialized Swiss-type machining centers excel at producing precision small parts and long shaft components. With dual spindles and multi-axis capabilities, we provide one-stop solutions with the highest level of accuracy.

Quality Assurance at Our Aluminum Forging Factory

Quality control is fundamental to MAIKONG’s operations as a premier Aluminum Forging Factory. Our comprehensive quality management system ensures that every component meets or exceeds the stringent requirements of US industries.

Our Quality Certifications

- ISO 9001:2015 certified quality management system

- Material testing and verification laboratory

- Advanced non-destructive testing capabilities

- Statistical process control implementation

- Comprehensive documentation and traceability

The advantages of our integrated production process—from raw aluminum alloys through forging, heat treatment, and CNC machining to surface treatment—allows our quality engineering staff to monitor production and ensure consistency at every stage.

Rigorous quality inspection of forged aluminum components

4.8

Overall Quality Rating

Dimensional Accuracy

4.8/5

Material Consistency

4.9/5

Industry Applications for Aluminum Forged Components

As a specialized Aluminum Forging Factory, MAIKONG serves diverse US industries with precision components that meet specific performance requirements. Our expertise spans multiple sectors where the superior properties of forged aluminum deliver critical advantages.

Aerospace

Our aerospace components deliver the exceptional strength-to-weight ratio and fatigue resistance required for flight-critical applications. From structural elements to engine components, our aluminum forgings meet rigorous industry standards.

Automotive

Automotive manufacturers rely on our forged aluminum components to reduce vehicle weight while maintaining structural integrity. Our parts contribute to improved fuel efficiency and enhanced performance in critical systems.

Defense

The defense sector demands components that perform reliably under extreme conditions. Our aluminum forgings provide the durability and precision required for military equipment, vehicles, and systems.

Medical

Medical equipment manufacturers choose our aluminum forgings for their biocompatibility, precision, and reliability. These components are essential in devices where performance directly impacts patient outcomes.

Energy

The energy sector benefits from our corrosion-resistant, high-strength aluminum components in power generation, transmission, and renewable energy applications where reliability is paramount.

Infrastructure

Infrastructure projects utilize our durable aluminum forgings for their excellent corrosion resistance and long service life in bridges, buildings, and transportation systems exposed to harsh environments.

Find the Perfect Aluminum Solution for Your Industry

Our engineering team specializes in developing custom aluminum forging solutions tailored to your industry’s specific requirements.

Discuss Your Industry Needs

Partnership Opportunities for US Distributors and Agents

MAIKONG establishing strategic partnerships with US distributors

MAIKONG is actively seeking partnerships with US distributors and agents to expand our presence in the American market. As a leading Aluminum Forging Factory with comprehensive capabilities, we offer compelling advantages for distribution partners:

Why Partner with MAIKONG

- Comprehensive product range covering multiple industries

- Competitive pricing with excellent margins for distributors

- Consistent quality that meets or exceeds US standards

- Reliable delivery schedules with flexible production capacity

- Technical support and custom engineering assistance

- Marketing and sales support for distribution partners

“Our partnership with MAIKONG has allowed us to offer our customers high-quality aluminum forged components at competitive prices. Their technical expertise and reliable delivery have made them a valuable partner for our distribution business.”

— US Distribution Partner

Become a MAIKONG Distribution Partner

Explore the benefits of representing our comprehensive aluminum forging and CNC machining capabilities in the US market.

Contact Our Partnership Team

The MAIKONG Advantage: Your Trusted Aluminum Forging Factory

As US manufacturers continue to seek reliable partners for high-performance components, MAIKONG stands ready to deliver comprehensive aluminum forging and CNC machining solutions. Our commitment to quality, innovation, and customer satisfaction has established us as a trusted partner for companies across multiple industries.

With our state-of-the-art facilities in GD, SZ, we combine advanced technology with decades of expertise to produce aluminum forged components that meet the most demanding specifications. Whether you’re seeking a manufacturing partner or distribution opportunities, MAIKONG offers the capabilities, quality, and competitive pricing to support your success in the US market.

Ready to Experience the MAIKONG Difference?

Contact our team today to discuss your aluminum forging requirements and discover how we can support your manufacturing goals.

Request a Quote Today

State-of-the-art aluminum forging process at MAIKONG’s manufacturing facility

State-of-the-art aluminum forging process at MAIKONG’s manufacturing facility