MAIKONG: Your Premier Aluminum Forging Factory for Custom Manufacturing Solutions

Welcome to MAIKONG, a leading aluminum forging factory delivering precision-engineered components for demanding applications worldwide. Based in Shenzhen, China, we combine advanced manufacturing capabilities with superior technical expertise to provide high-quality, cost-effective aluminum forging solutions for diverse industries. Our commitment to excellence has established us as a trusted partner for businesses seeking reliable metal forging services with exceptional value.

About MAIKONG: Advanced Aluminum Forging Factory

MAIKONG is a specialized forged aluminum factory headquartered in Shenzhen, China, with a state-of-the-art manufacturing facility equipped with the latest forging technology. Our expertise spans the complete spectrum of aluminum forging processes, including closed-die forging, open-die forging, and precision machining services.

Our Manufacturing Capabilities

As a premier aluminum forging alloys factory, we’ve invested in advanced production equipment that enables us to deliver exceptional quality and precision:

- Hydraulic presses ranging from 400T to 2500T

- CNC machining centers for precision finishing

- State-of-the-art heat treatment facilities

- Advanced quality control and testing equipment

- Automated production lines for high-volume manufacturing

Partner With a Leading Aluminum Forging Manufacturer

Discover how MAIKONG’s advanced manufacturing capabilities can deliver superior aluminum forged components for your specific requirements.

Request a Quote

Comprehensive Aluminum Forging Services

At MAIKONG, we offer a complete range of aluminum forging services tailored to meet the diverse needs of our global clientele. Our aluminum forging parts factory specializes in creating high-performance components with superior mechanical properties and precise dimensional accuracy.

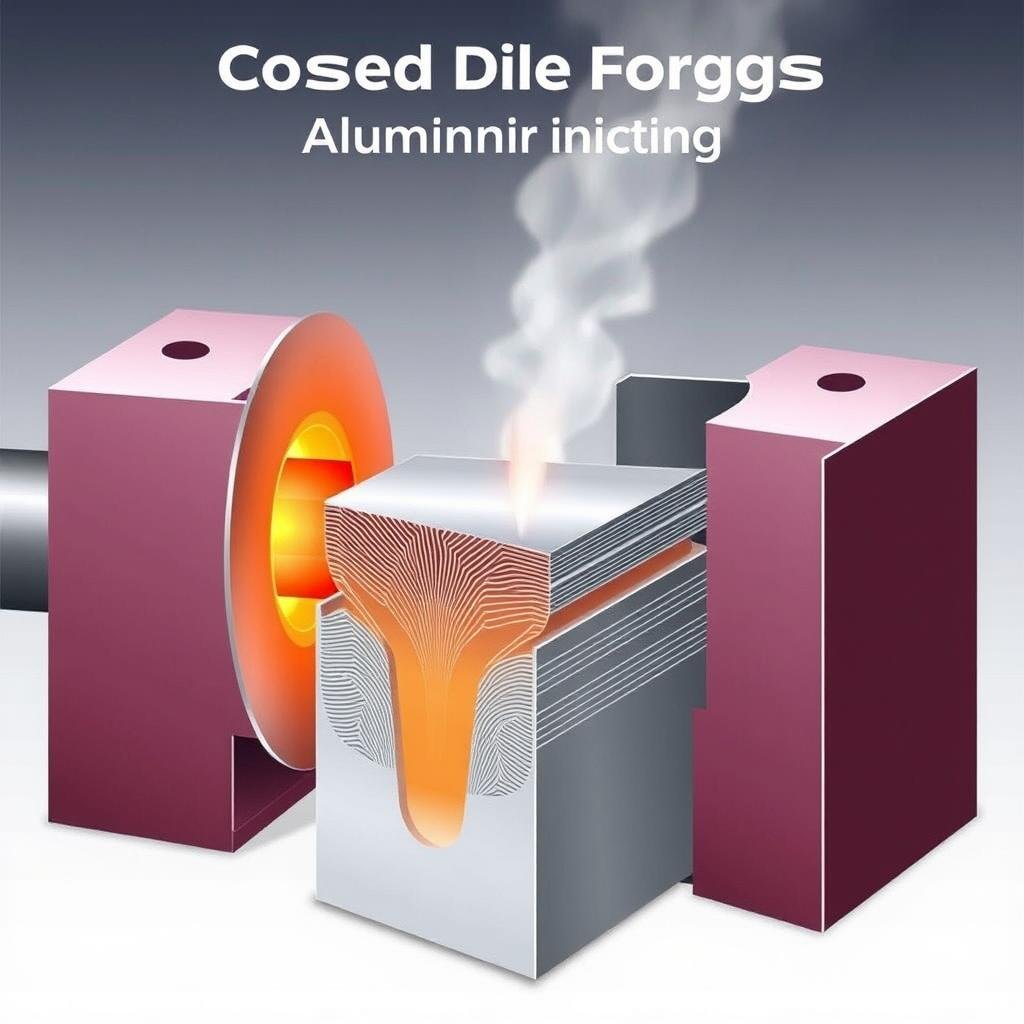

Closed Die Forging

Our closed die forging process creates complex shapes with excellent structural integrity and tight tolerances. This method is ideal for high-performance components requiring superior strength-to-weight ratios.

Open Die Forging

We excel in open die forging for larger aluminum components where material flow and grain structure optimization are critical for performance in demanding applications.

Precision Machining

Our integrated CNC machining capabilities allow us to deliver finished components with exceptional precision, completing your forged aluminum parts to exact specifications.

Aluminum Alloys We Work With

As a specialized aluminum forging alloys factory in China, we work with a comprehensive range of aluminum alloys to meet specific performance requirements:

| Alloy Series |

Key Properties |

Common Applications |

| 2000 Series (2014, 2024) |

High strength, excellent fatigue resistance |

Aerospace components, aircraft structural parts |

| 6000 Series (6061, 6082) |

Good corrosion resistance, excellent extrudability |

Automotive parts, structural components |

| 7000 Series (7075) |

Highest strength-to-weight ratio, good machinability |

Aerospace, defense, high-performance automotive |

| 5000 Series (5083) |

Excellent corrosion resistance, good weldability |

Marine applications, pressure vessels |

Our Advanced Aluminum Forging Process

At MAIKONG forged aluminum factory, we’ve refined our manufacturing processes to ensure consistent quality and exceptional performance in every component we produce. Our comprehensive forging process combines traditional expertise with modern technology.

- Material Selection: We source high-quality aluminum billets with certified composition and properties to ensure consistent performance.

- Die Design & Manufacturing: Our engineering team designs and manufactures precision dies optimized for each specific component.

- Heating: The aluminum is precisely heated to the optimal temperature for forging, ensuring proper material flow.

- Forging: Using hydraulic presses, the heated aluminum is formed under controlled pressure to create the desired shape.

- Trimming: Excess material is removed to achieve the near-net shape of the component.

- Heat Treatment: Components undergo specific heat treatment processes to enhance mechanical properties.

- Machining: Precision CNC machining operations complete the component to final dimensions and specifications.

- Quality Inspection: Rigorous testing and inspection ensure each part meets all requirements and specifications.

Quality Assurance

Our commitment to quality is embedded throughout our forging process. We maintain strict quality control procedures that include:

- Material certification and testing

- In-process inspections at critical stages

- Dimensional verification using advanced measuring equipment

- Mechanical property testing

- Surface quality inspection

- Final comprehensive quality checks

Need Technical Support for Your Aluminum Forging Project?

Our engineering team is ready to assist with technical questions and provide expert guidance for your specific requirements.

Contact Technical Support via WhatsApp

Industry Applications for Our Aluminum Forgings

As a versatile aluminum forging parts factory, MAIKONG serves diverse industries with custom-engineered components that meet specific performance requirements. Our aluminum forgings deliver exceptional strength, durability, and precision across multiple applications.

Automotive

- Suspension components

- Steering knuckles

- Engine brackets

- Transmission parts

- Forged aluminum wheels

Aerospace

- Structural components

- Landing gear parts

- Mounting brackets

- Control system components

- Engine parts

Industrial Equipment

- Valve bodies

- Hydraulic components

- Pump housings

- Structural fittings

- Machine parts

Specialized Aluminum Wheel Forging

As a specialized 17 forged aluminum wheels factory, we produce high-performance wheels that combine lightweight construction with exceptional strength and durability. Our forged aluminum rims factory capabilities include:

- Custom designs for OEM and aftermarket applications

- Sizes ranging from 15″ to 22″ diameter

- Various finishes including machined, polished, and custom coatings

- Optimized designs for weight reduction and performance

- Rigorous testing for durability and safety compliance

Looking for Custom Aluminum Forgings for Your Industry?

Contact our team to discuss your specific requirements and discover how our aluminum forging expertise can benefit your application.

Request Industry-Specific Solutions

Why Choose MAIKONG as Your Aluminum Forging Partner

As a leading brass and aluminum forging factory in China, MAIKONG offers distinct advantages that make us the preferred manufacturing partner for businesses worldwide. Our commitment to excellence extends throughout every aspect of our operation.

MAIKONG Advantages

- Advanced Manufacturing Technology: State-of-the-art equipment for superior quality and precision

- Comprehensive Capabilities: From design assistance to finished components

- Material Expertise: Specialized knowledge in aluminum alloys and their applications

- Competitive Pricing: Factory price aluminum forging with excellent value

- Quality Assurance: Rigorous testing and inspection protocols

- Technical Support: Expert engineering assistance throughout your project

- Customization: Tailored solutions for your specific requirements

- Reliable Delivery: Consistent on-time shipment performance

Quality Certifications and Standards

Our commitment to quality is backed by industry certifications and adherence to international standards:

- ISO 9001:2015 Quality Management System

- IATF 16949 Automotive Quality Management

- AS9100 Aerospace Quality Standard

- RoHS and REACH compliance

- Material certifications to international standards

Dimensional Precision and Tolerances

As a specialized forged aluminum fitting dimensions factory, we maintain exceptional precision in our manufacturing processes:

| Feature |

Standard Tolerance |

Precision Tolerance |

| Linear Dimensions |

±0.5mm |

±0.2mm |

| Diameters |

±0.3mm |

±0.1mm |

| Flatness |

0.5mm |

0.2mm |

| Concentricity |

0.4mm |

0.15mm |

Custom Aluminum Forging Solutions

At MAIKONG, we specialize in developing tailored aluminum forging solutions that address your specific requirements. Our engineering team works closely with clients to optimize designs for manufacturability, performance, and cost-effectiveness.

Design Collaboration

Our engineering team provides comprehensive design support:

- Design for manufacturability (DFM) analysis

- Material selection guidance

- 3D modeling and simulation

- Prototype development

- Performance optimization

Sample Development Process

We offer a structured approach to developing custom aluminum forgings:

- Requirement Analysis: Detailed review of specifications and performance requirements

- Design Development: Creation of optimized designs for forging

- Tool Design: Development of specialized tooling for your component

- Sample Production: Manufacturing of prototype components

- Testing and Validation: Comprehensive testing to verify performance

- Production Approval: Final verification before full production

Ready to Start Your Custom Aluminum Forging Project?

Contact our team today to discuss your requirements and receive a competitive quotation.

Request a Custom Quote