Aluminum Forging Design Manual – Complete Technical Guide

December 18, 2025

Fundamentals of Aluminum Forging Design Manual Parameters

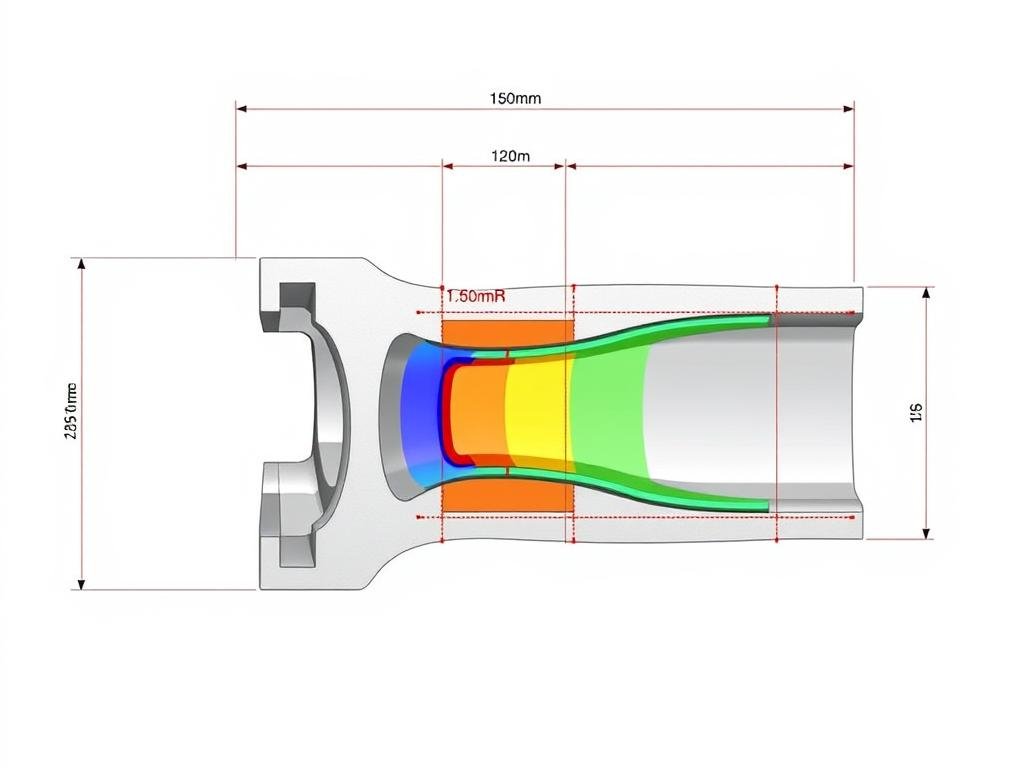

The forging process fundamentally transforms aluminum’s internal structure, creating components with superior strength-to-weight ratios and enhanced mechanical properties. Understanding the core principles outlined in this aluminum forging design manual is essential for successful implementation.

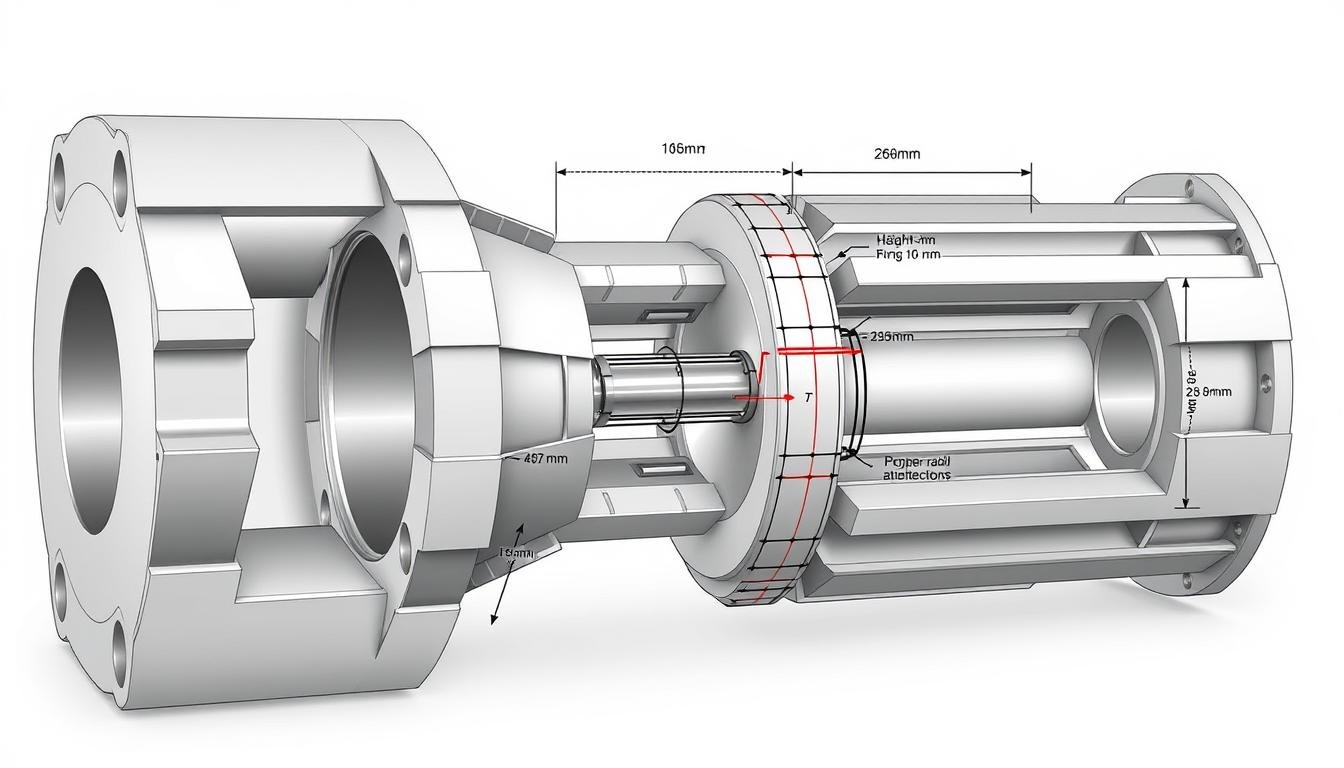

Fig 1: Optimized grain flow in properly designed aluminum forgings

Key Benefits of Properly Designed Aluminum Forgings

- Refined grain structure through controlled deformation

- Improved strength-to-weight ratio compared to cast components

- Enhanced fatigue resistance and impact toughness

- Superior mechanical properties with directional strength

- Elimination of internal voids and porosity

- Consistent material properties throughout the component

Need Expert Guidance on Your Aluminum Forging Project?

Our engineering team can help optimize your design for manufacturability and performance.

Machining Allowances in Aluminum Forging Design

Proper machining allowances are critical for successful aluminum forging design. These allowances ensure sufficient material is available for post-forging machining operations while minimizing material waste and processing time.

| Greatest Dimension (mm) | Minimum Finish Stock per Surface (mm) |

| Less than 200 | 1.6 |

| 200 to 400 | 2.4 |

| 400 to 600 | 3.2 |

| 600 to 900 | 4.0 |

| More than 900 | 4.8 |

These recommended machining allowances apply to all aluminum alloys and are related to the largest dimension of the forging. The finish allowance may be applied over the entire forging or specifically to surfaces requiring machining.

Fig 2: Visualization of machining allowances on a typical aluminum forged component

Parting Line Location in Die Forging

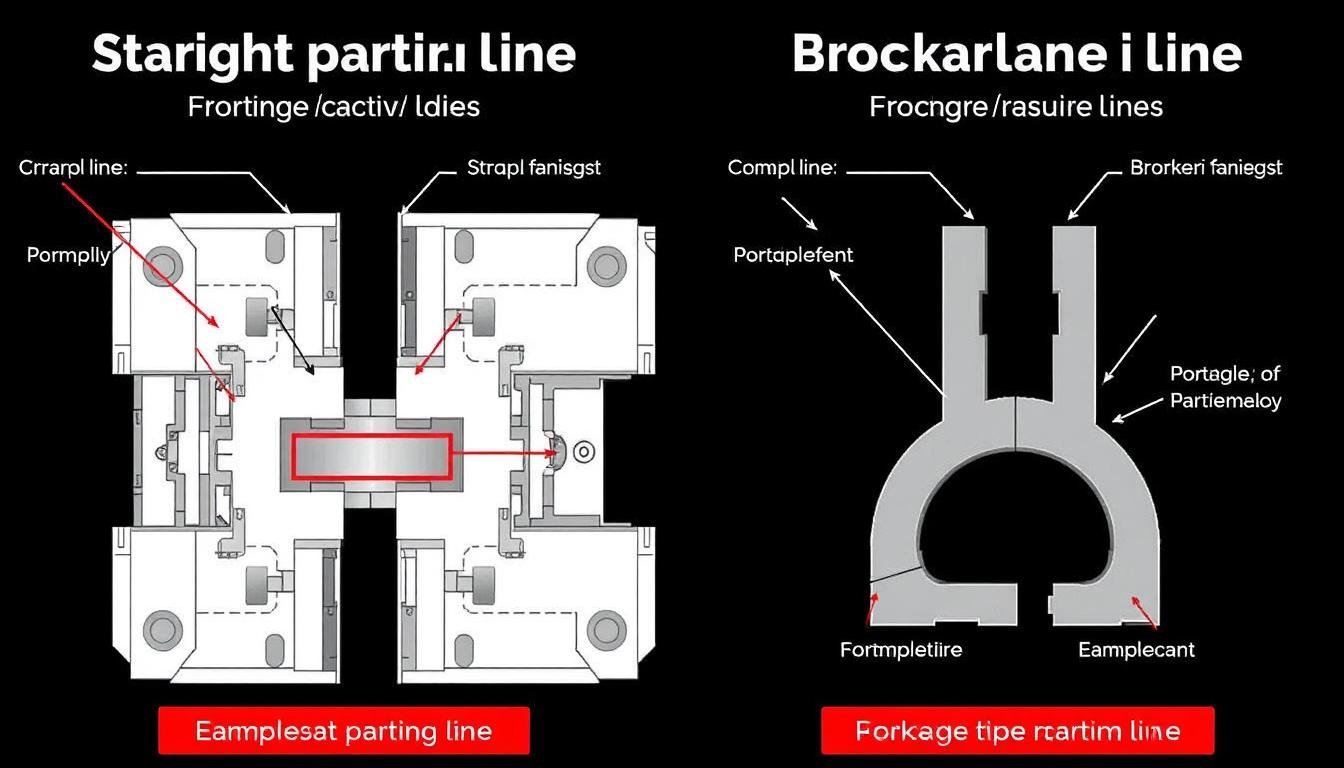

The parting line is a critical design element in closed die forging, representing where the upper and lower dies meet. Proper parting line placement significantly impacts material flow, die wear, and final part quality.

Types of Parting Lines

Straight Parting Line

A straight parting line follows the forging plane continuously, creating a single plane where the dies meet. This configuration is ideal for simpler geometries and offers easier die manufacturing and maintenance.

Broken Parting Line

A broken parting line deviates from the forging plane, allowing for more complex geometries. While more challenging to design and maintain, broken parting lines enable the creation of more intricate aluminum forgings.

Fig 3: Comparison of straight (left) and broken (right) parting lines in aluminum forging dies

Design Tip: Position the parting line along the largest cross-section of the part to facilitate material flow and easy part removal. This strategic placement minimizes flash formation and reduces the force required for forging.

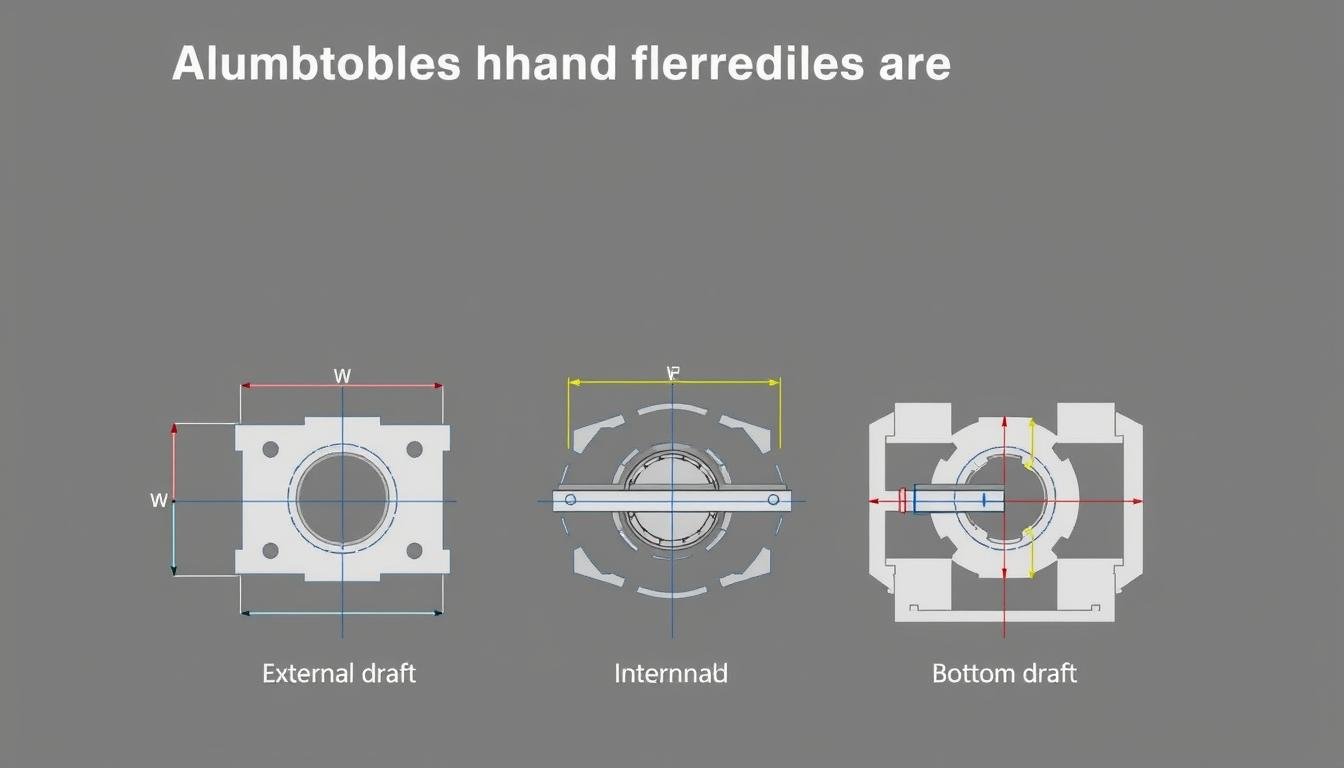

Draft Angle Requirements

Draft angles are essential for successful removal of the forged part from the die. These tapered surfaces facilitate part ejection and reduce die wear while ensuring proper material flow during the forging process.

Types of Draft Angles in Aluminum Forging

External Draft

Applied to outer surfaces perpendicular to the parting line. Typically ranges from 3° to 7° for aluminum alloys, depending on part complexity.

Internal Draft

Applied to inner surfaces perpendicular to the parting line, including pockets and cavities. Usually 1° to 2° greater than external draft to facilitate material flow.

Bottom Draft

Applied to deep recesses to promote material flow. Critical for preventing defects in complex geometries with significant depth variations.

Fig 4: Illustration of external, internal, and bottom draft angles in aluminum forging design

“Proper draft angle design is fundamental to successful aluminum forging. Insufficient draft leads to part ejection issues and excessive die wear, while excessive draft wastes material and compromises dimensional accuracy.”

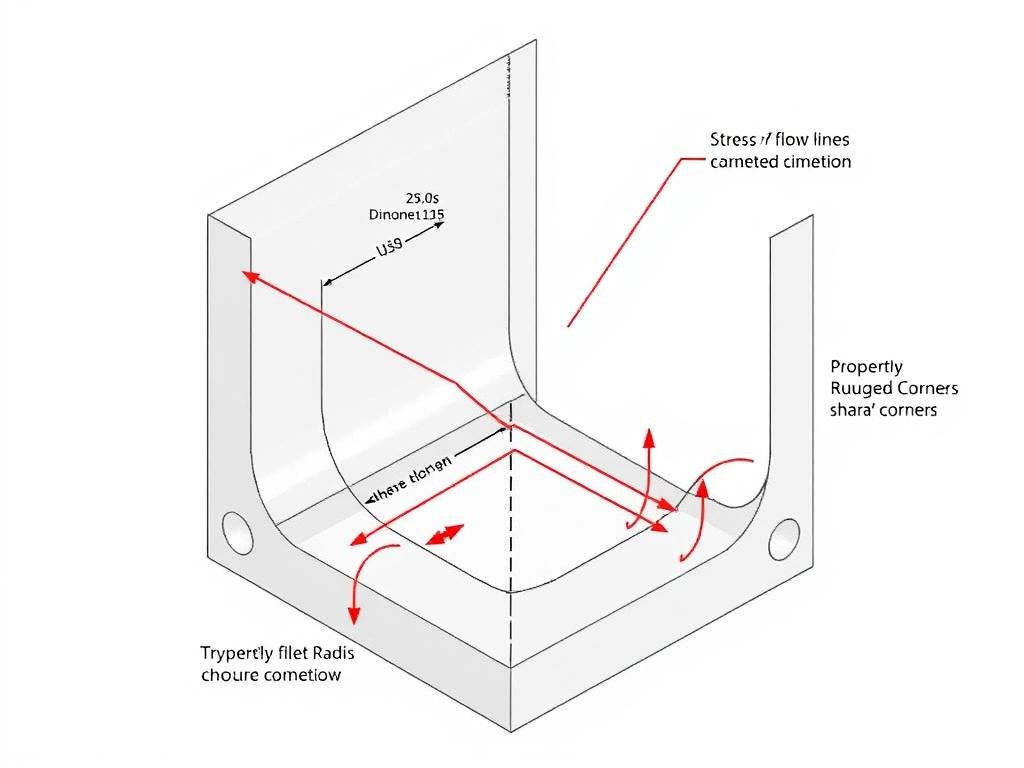

Corner and Fillet Radii Design

Proper corner and fillet radii are crucial elements in the aluminum forging design manual that significantly impact material flow, die life, and final part quality. These design features provide smooth transitions between intersecting surfaces, reducing stress concentrations and improving overall component performance.

Fig 5: Proper corner and fillet radii design showing improved material flow

Benefits of Optimized Radii Design

- Facilitates smooth material flow during forging

- Reduces die wear and extends tooling life

- Minimizes stress concentrations in the final component

- Improves grain flow around corners

- Reduces the force required for forging

- Minimizes the risk of cracking during forging

Design Recommendation: As a general rule, interior corner radii should be at least 0.5 times the adjacent wall thickness, while exterior corner radii should be at least 1.5 times the interior radius.

Optimize Your Aluminum Component Design

MAIKONG’s engineering team can review your design and recommend optimal radii for improved performance and manufacturability.

Ribs and Webs Design Guidelines

Ribs and webs are structural elements that provide strength and stability to forged aluminum components while optimizing material usage. Their proper design is essential for both manufacturability and performance.

Rib Design Parameters

Ribs are brace-like projections located either at the periphery or inside a forging. Effective rib design balances structural requirements with forging limitations:

- Height-to-thickness ratio typically limited to 6:1

- Minimum thickness of 3mm for most aluminum alloys

- Gradual transitions to adjoining sections

- Adequate draft angles (5-7° for aluminum)

- Generous radii at the base to prevent stress concentration

Web Design Parameters

Webs are thin, plate-like elements that connect ribs and other forged elements. Critical web design considerations include:

- Minimum thickness of 2.5mm for most aluminum alloys

- Uniform thickness where possible

- Avoid abrupt thickness changes

- Incorporate stiffening features for large web areas

- Consider grain flow direction for optimal strength

Fig 6: Optimal rib and web design parameters for aluminum forgings

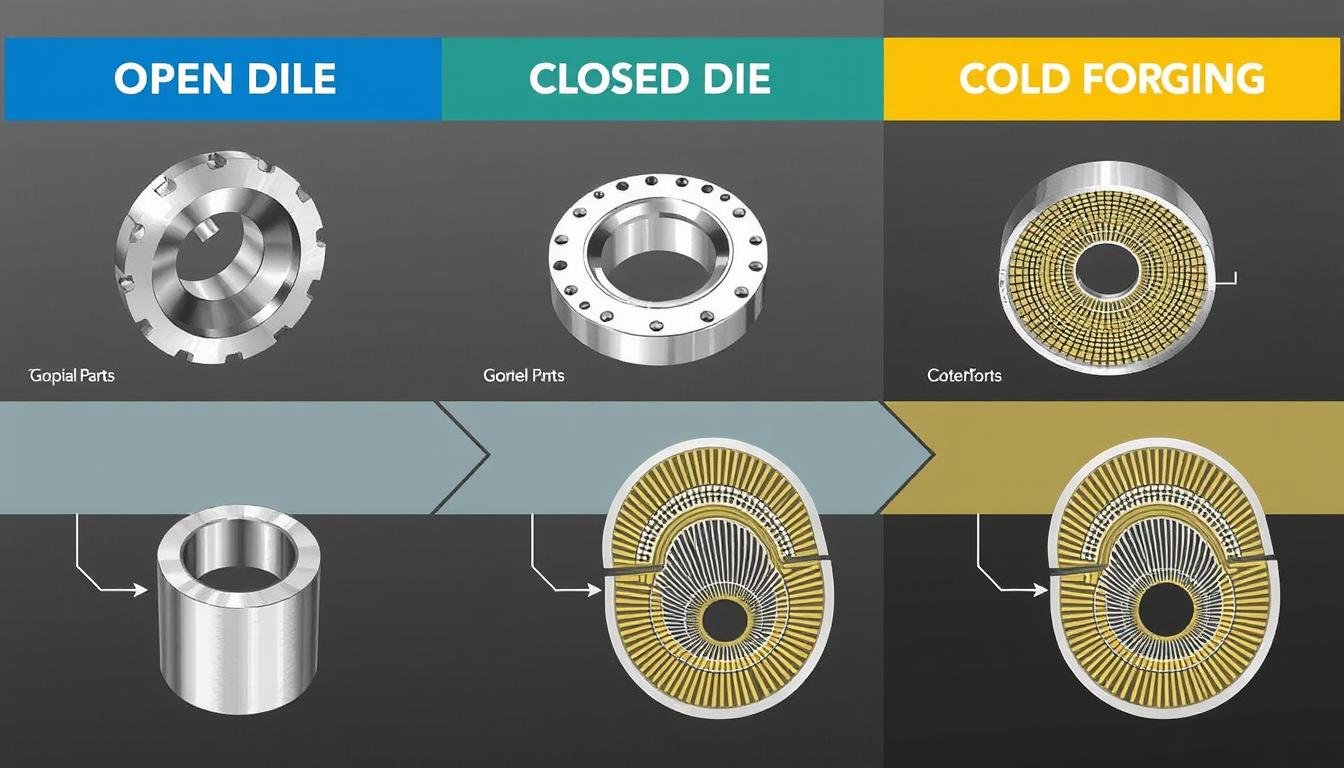

Aluminum Forging Process Selection

Selecting the appropriate forging process is a critical decision that impacts component quality, cost, and performance. Each process offers distinct advantages for specific applications and design requirements.

Open Die Forging

- Versatile process for large components

- No chargeable tooling costs

- Short lead times

- Ideal for low-volume production

- Suitable for parts up to several tons

- Requires more finish machining

Closed Die Forging

- Superior dimensional accuracy

- Excellent grain flow control

- Reduced machining requirements

- Consistent part-to-part quality

- Cost-effective for higher volumes

- Higher initial tooling investment

Cold Forging

- Excellent surface finish

- Tight dimensional tolerances

- Enhanced mechanical properties

- No scaling or decarburization

- Ideal for small, precision parts

- Limited to simpler geometries

Fig 7: Comparison of open die, closed die, and cold forging processes for aluminum

Temperature Considerations in Aluminum Forging

Temperature control is critical in aluminum forging, with different processes requiring specific temperature ranges:

| Forging Process | Temperature Range (°C) | Key Considerations |

| Hot Forging | 350-500 | Requires precise temperature control to prevent overheating |

| Warm Forging | 150-350 | Balances formability with reduced energy requirements |

| Cold Forging | 20-150 | Produces work hardening, requires annealing for complex operations |

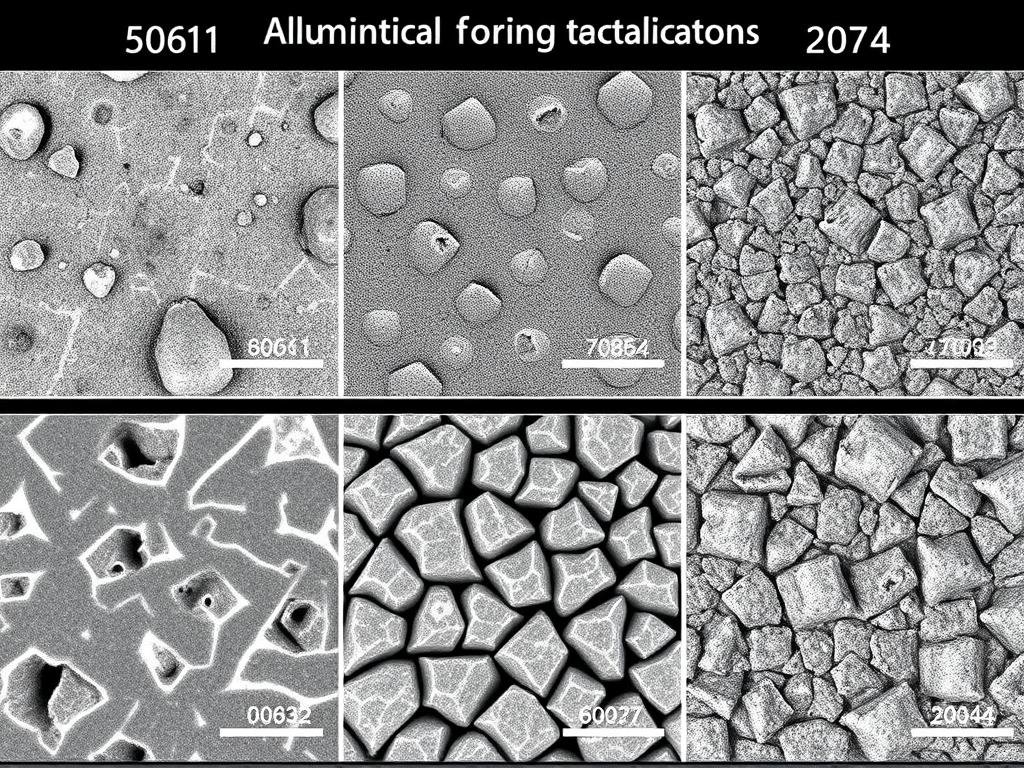

Key Aluminum Alloys for Forging

Selecting the appropriate aluminum alloy is fundamental to achieving desired mechanical properties and performance characteristics in forged components. Each alloy offers unique benefits for specific applications.

| Alloy | Key Properties | Typical Applications |

| 6061 | Excellent corrosion resistance, good weldability, medium-high strength | Structural components, aerospace parts, marine applications |

| 6063 | Superior surface finish, excellent extrudability, moderate strength | Architectural components, decorative elements, heat sinks |

| 6082 | High strength, excellent machinability, good corrosion resistance | Transportation structures, bridges, cranes, high-stress applications |

| 7075 | Very high strength, excellent fatigue resistance, good machinability | Aerospace components, defense applications, high-performance parts |

| 2014 | High strength-to-weight ratio, good machinability, moderate corrosion resistance | Aircraft fittings, wheels, structural components |

Fig 8: Microstructure comparison of common aluminum forging alloys (500x magnification)

MAIKONG Alloy Selection Expertise

Our metallurgical team provides comprehensive alloy selection guidance based on your specific application requirements, including:

- Mechanical property optimization

- Corrosion resistance assessment

- Heat treatment response analysis

- Cost-performance balance evaluation

- Environmental exposure considerations

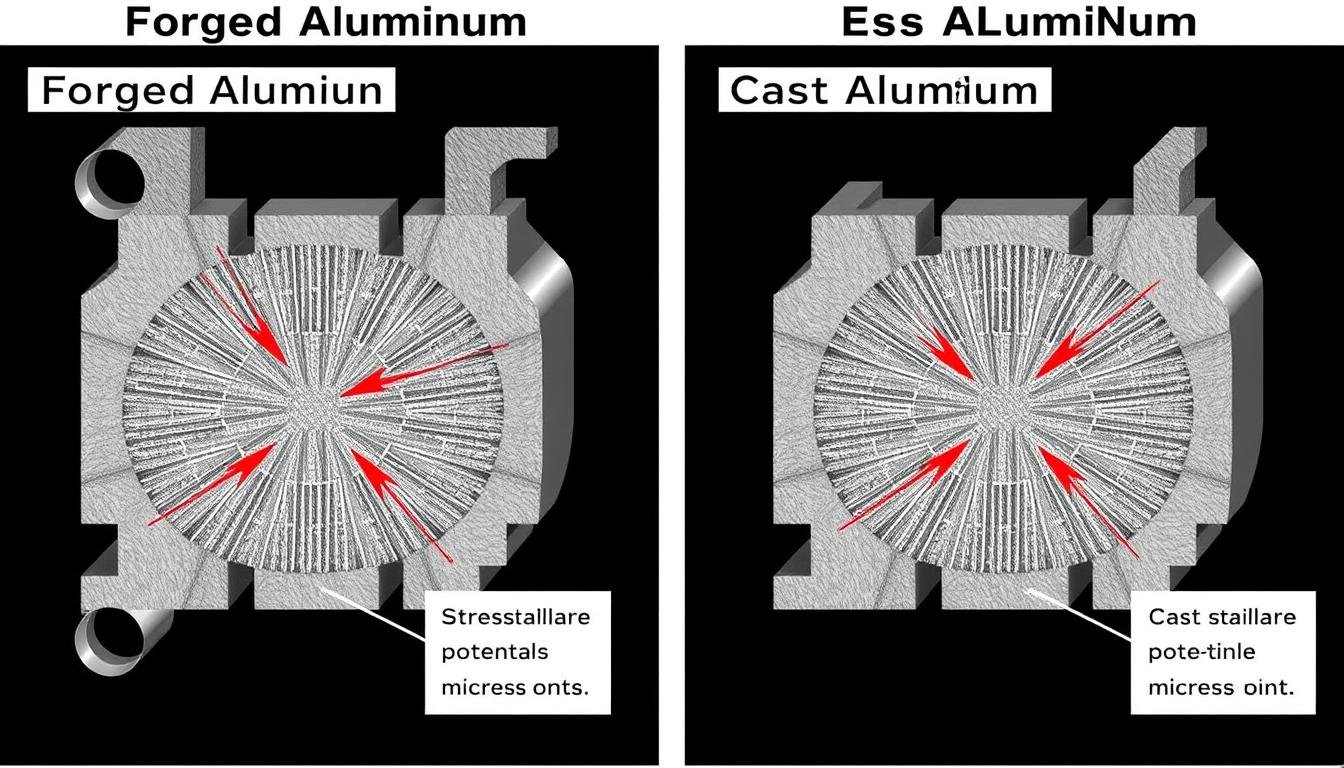

Forging vs. Casting: Comparative Analysis

Understanding the differences between forged and cast aluminum components is essential for making informed manufacturing decisions. This comparison highlights the key differentiators that impact component performance and suitability for various applications.

Fig 9: Structural comparison between forged and cast aluminum showing grain flow patterns

| Comparison Categories | Aluminum Forging | Cast Aluminum |

| Strength and Durability | Higher due to dense, uniform grain structure | Potentially lower due to air pockets and inclusions |

| Tensile Properties | Superior tensile strength and resistance | Lower tensile strength |

| Fatigue Resistance | Better resistance against fatigue failure | Potentially lower fatigue resistance |

| Complex Geometries | Require multiple steps to achieve complex shapes | Can achieve complex shapes in one session |

| Dimensional Accuracy | Better accuracy and tighter tolerances | Potential inconsistencies |

| Surface Finish | Smoother surfaces, reduced post-processing | Might require more machining due to air pockets |

Advantages of Aluminum Forging

- Superior mechanical properties

- Enhanced fatigue resistance

- Improved strength-to-weight ratio

- Directional strength capabilities

- Absence of internal porosity

- Consistent part-to-part quality

Limitations of Aluminum Forging

- Higher initial tooling costs

- Limited complexity in single operations

- Potential material waste from flash

- Size limitations compared to casting

- Higher energy requirements

- More complex process control needed

Quality Control in Aluminum Forging

Comprehensive quality control is essential throughout the aluminum forging process to ensure consistent component performance and reliability. MAIKONG implements rigorous testing and inspection protocols at each stage of production.

Fig 10: Precision dimensional inspection of aluminum forged components

Key Quality Control Procedures

Material Verification

- Chemical composition analysis

- Mechanical property testing

- Microstructure examination

- Hardness testing

Process Monitoring

- Temperature control verification

- Die alignment inspection

- Force/energy monitoring

- Lubrication system checks

Final Inspection

- Dimensional verification

- Surface quality assessment

- Non-destructive testing

- Functional testing

Fig 11: Advanced non-destructive testing of aluminum forgings at MAIKONG facility

Implementing the Aluminum Forging Design Manual Guidelines

Successful implementation of the principles outlined in this aluminum forging design manual requires a systematic approach to design, material selection, and process control. By following these guidelines, engineers and procurement specialists can achieve optimal performance, cost-efficiency, and reliability in aluminum forged components.

MAIKONG offers comprehensive aluminum forging services with industry-leading expertise in design optimization, material selection, and quality control. Our state-of-the-art facilities in GD, SZ are equipped with advanced forging equipment and staffed by experienced metallurgists and process engineers.

Ready to Optimize Your Aluminum Forging Design?

Contact MAIKONG today for expert consultation and competitive pricing on your aluminum forging projects.

Or call us directly: 8613-51090-74-01

Email: Lucy@maikongforge.us

Contact us online by Whatsapp: