Aluminum forging represents a critical manufacturing process that transforms raw aluminum into high-strength, lightweight components through controlled deformation. The strategic manipulation of aluminum under precise temperature and pressure conditions creates products with superior mechanical properties that serve countless industries. This comprehensive guide explores the fundamental principles, techniques, and applications of aluminum forging processes, highlighting how MAIKONG’s expertise delivers exceptional quality and performance across diverse industrial sectors.

Aluminum Forging and Optimal Strength-to-Weight Ratio

The strength-to-weight ratio represents a fundamental engineering principle that balances material strength against weight—a critical consideration in industries where performance, efficiency, and safety are paramount. Aluminum, inherently lightweight yet mechanically robust, undergoes significant enhancement through aluminum forging processes.

During forging, aluminum’s internal grain structure is refined and aligned, creating a more resilient and stronger material. This transformation makes forged aluminum components the optimal choice for applications that must withstand both static and dynamic loads while maintaining minimal weight.

Key Strength Advantages

- Superior tensile strength compared to cast aluminum

- Enhanced fatigue resistance for cyclical loading applications

- Improved impact resistance and toughness

- Excellent strength retention at elevated temperatures

- Consistent mechanical properties throughout the component

Weight Reduction Benefits

- 20-40% lighter than comparable steel components

- Reduced energy consumption in transportation applications

- Lower inertial forces in moving components

- Easier handling and installation

- Reduced shipping and logistics costs

Need Expert Guidance on Material Selection?

Our metallurgists can help you determine the optimal aluminum alloy for your specific application requirements.

Request Material Consultation

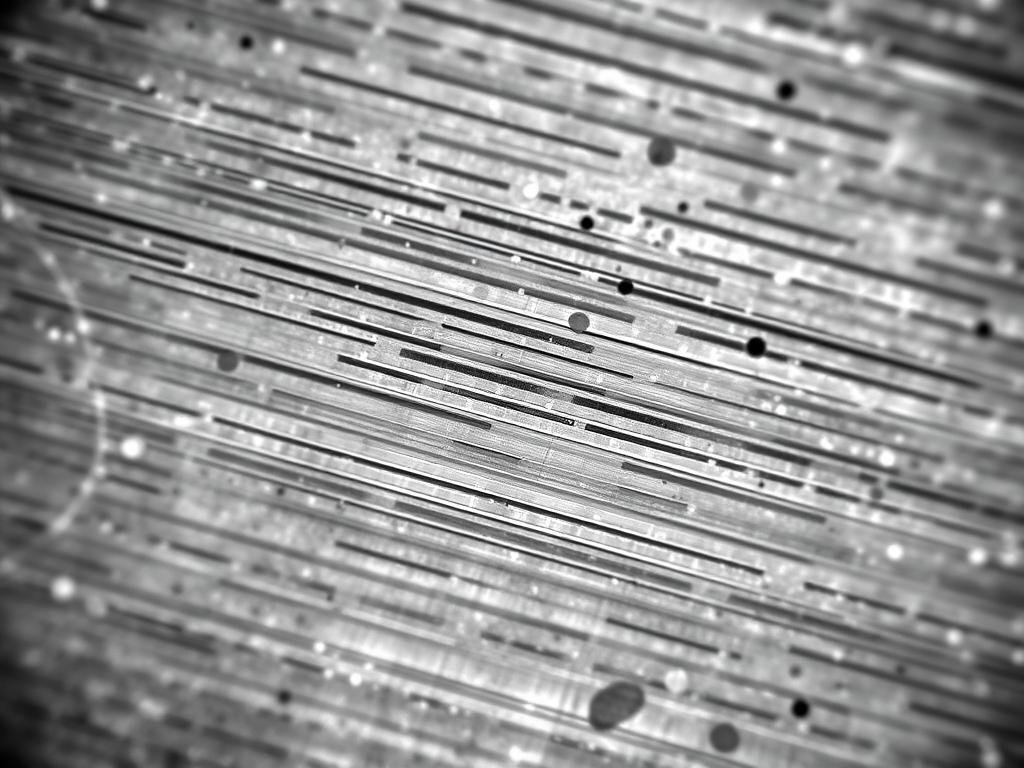

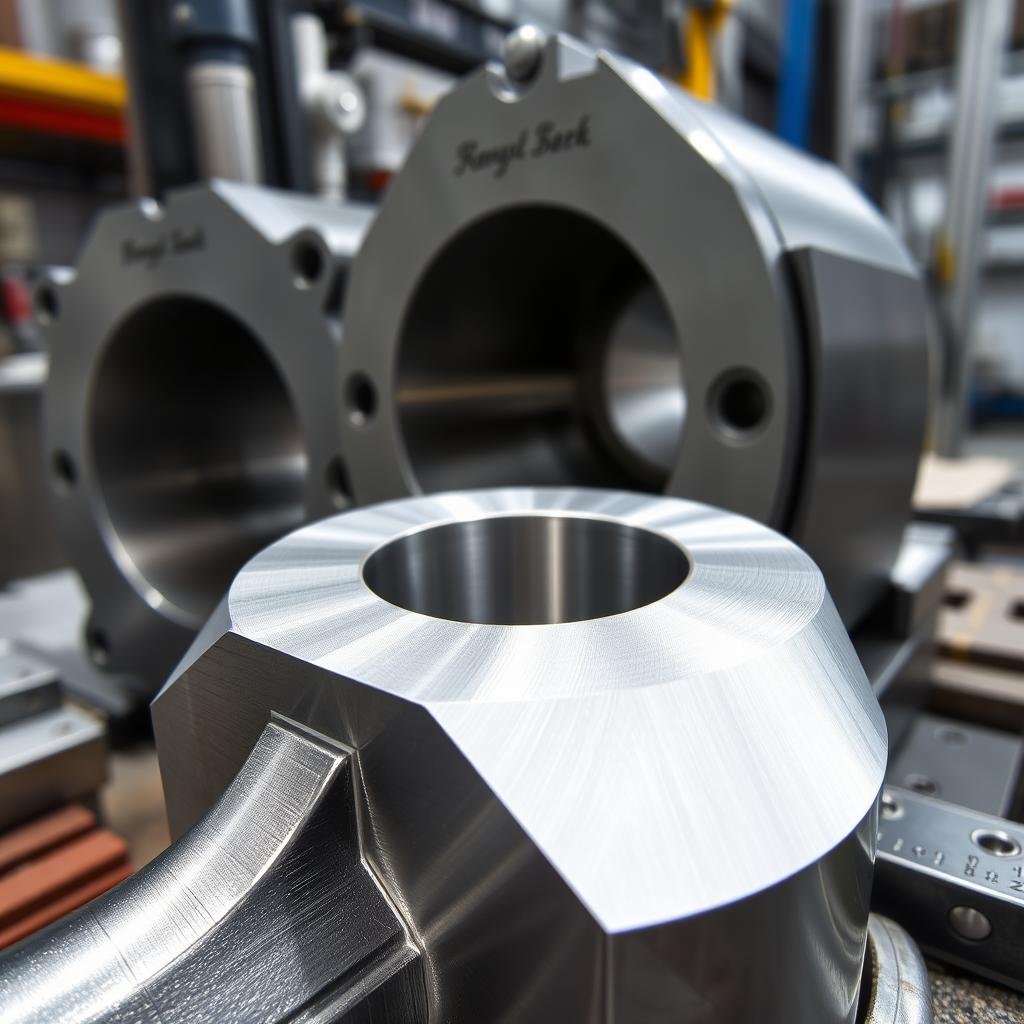

Grain Structure Alignment Through Aluminum Forging Processes

One of the most significant advantages of aluminum forging processes is the deliberate alignment of the material’s grain structure. Unlike casting or machining from stock, forging creates a directional grain flow that follows the contours of the part, significantly enhancing mechanical properties.

How Forging Aligns Grain Structure

During the forging process, aluminum undergoes plastic deformation as it’s compressed between dies. This deformation causes the metal’s crystalline structure to elongate and align in the direction of material flow. The result is a fibrous grain structure that provides superior strength, particularly in the directions most critical to the part’s function.

| Property |

Effect of Grain Alignment |

Performance Improvement |

| Tensile Strength |

Fibers aligned in direction of stress |

25-30% increase over cast aluminum |

| Fatigue Resistance |

Reduced crack propagation paths |

Up to 200% improvement in fatigue life |

| Impact Toughness |

Enhanced energy absorption |

50-75% higher impact resistance |

| Stress Corrosion |

Fewer transverse grain boundaries |

Significantly improved resistance |

At MAIKONG, our engineers carefully analyze each component’s stress patterns to design forging processes that optimize grain flow for maximum performance. This attention to metallurgical detail is what separates premium forged components from standard manufactured parts.

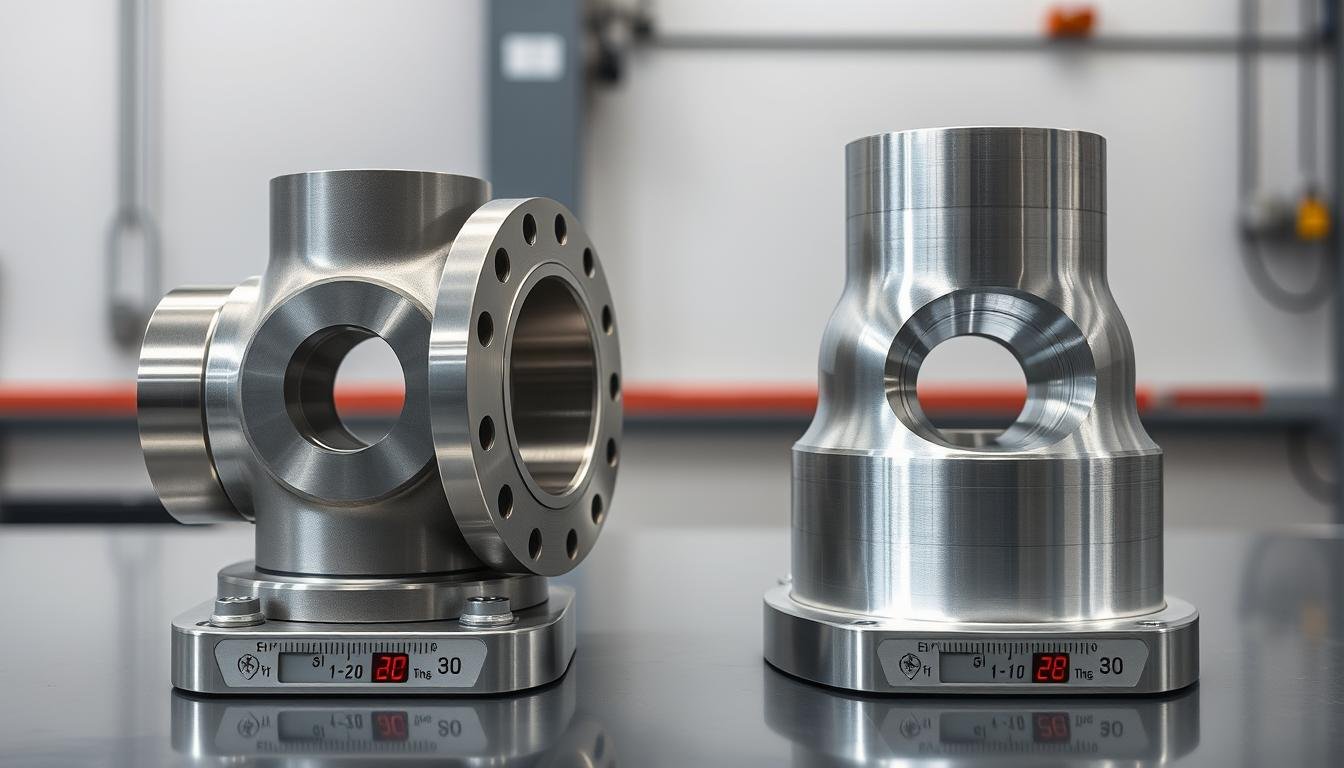

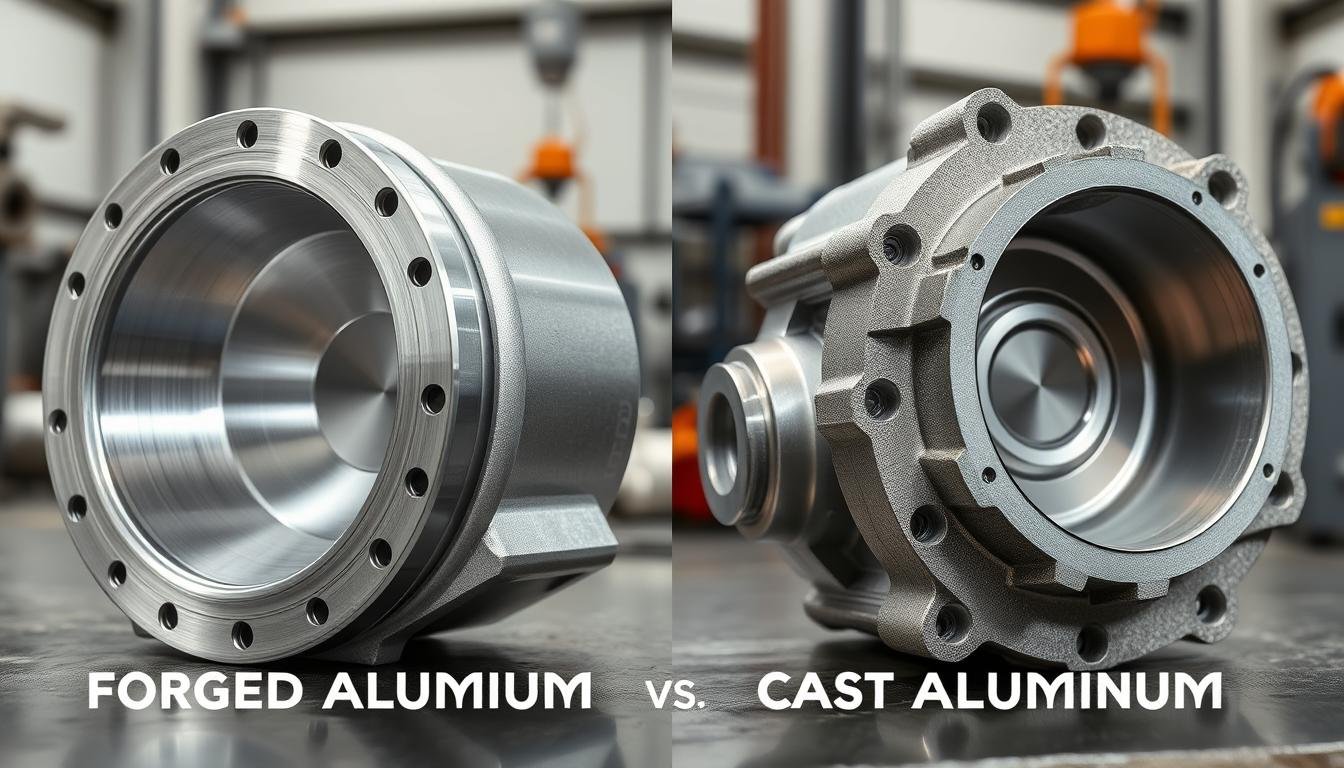

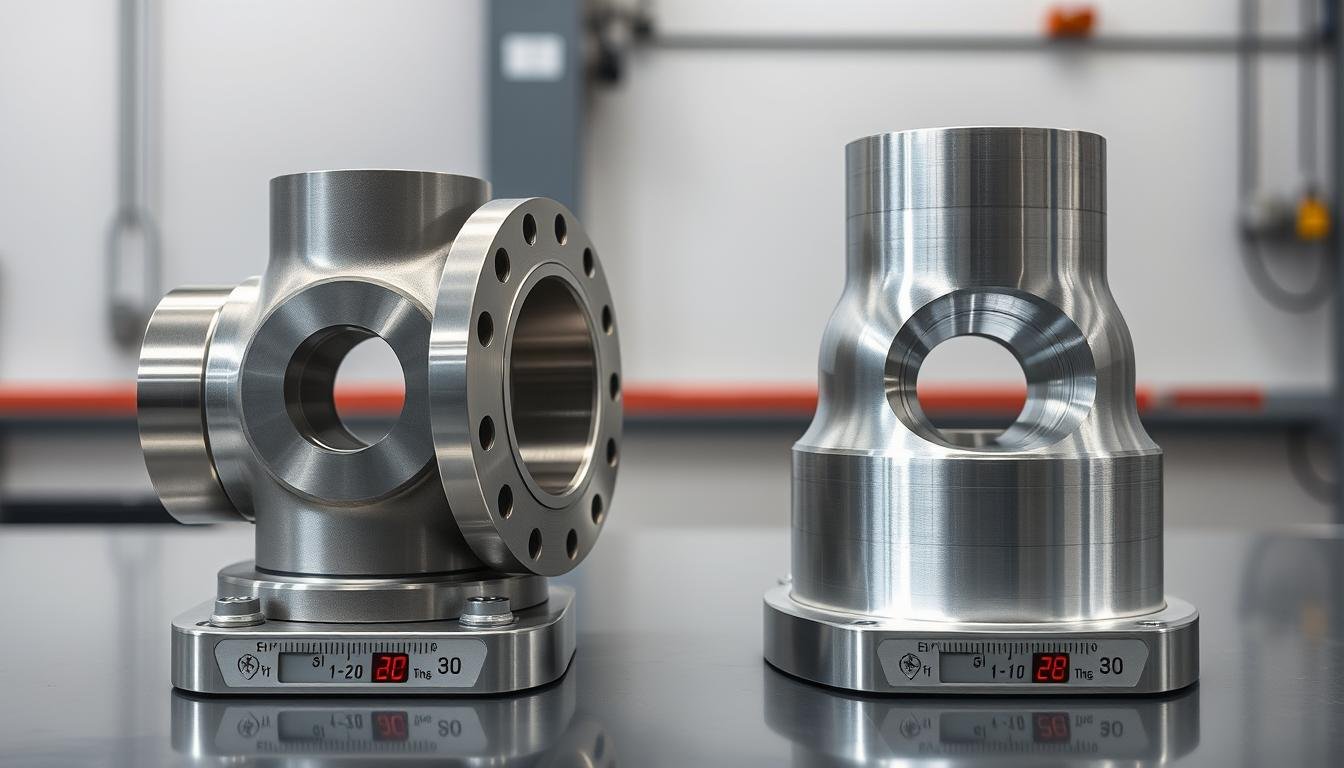

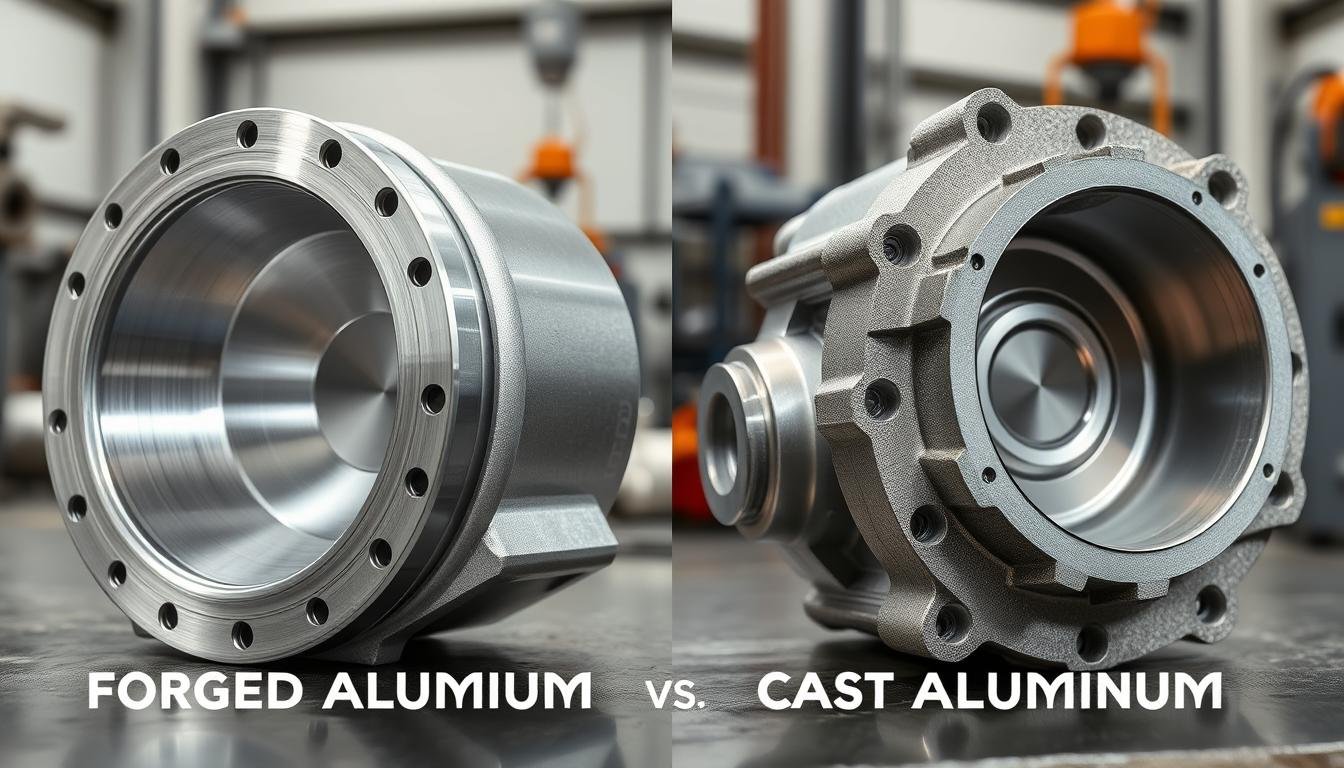

Aluminum Forging vs. Casting: A Comprehensive Comparison

When selecting a manufacturing method for aluminum components, understanding the fundamental differences between forging and casting is crucial. While both processes create aluminum parts, they result in products with significantly different properties and performance characteristics.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

Can achieve complex shapes in one session |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Heat Treatment Response |

Responsive for controlled material properties |

Less predictable response |

| Ideal Applications |

Structural components, safety-critical parts |

Decorative items, non-load bearing components |

While casting offers advantages for certain applications, forging is the superior choice for components where mechanical performance, reliability, and safety are paramount. MAIKONG specializes in high-performance aluminum forgings that deliver exceptional strength, durability, and consistency.

Types of Aluminum Forging Processes

Aluminum forging processes encompass a variety of techniques, each offering distinct advantages for specific applications. At MAIKONG, we employ multiple forging methods to deliver optimal results based on component requirements, production volume, and performance specifications.

Open Die Forging

In open die forging, aluminum is shaped between flat or simply shaped dies that don’t completely enclose the workpiece. This process is ideal for:

- Large components with simple geometries

- Low to medium production volumes

- Parts requiring excellent mechanical properties

- Components with weight exceeding 100kg

Closed Die Forging

Closed die forging utilizes dies that completely enclose the aluminum, creating complex shapes with excellent precision. Benefits include:

- Complex geometries with tight tolerances

- Excellent grain flow orientation

- Reduced material waste

- Ideal for medium to high production volumes

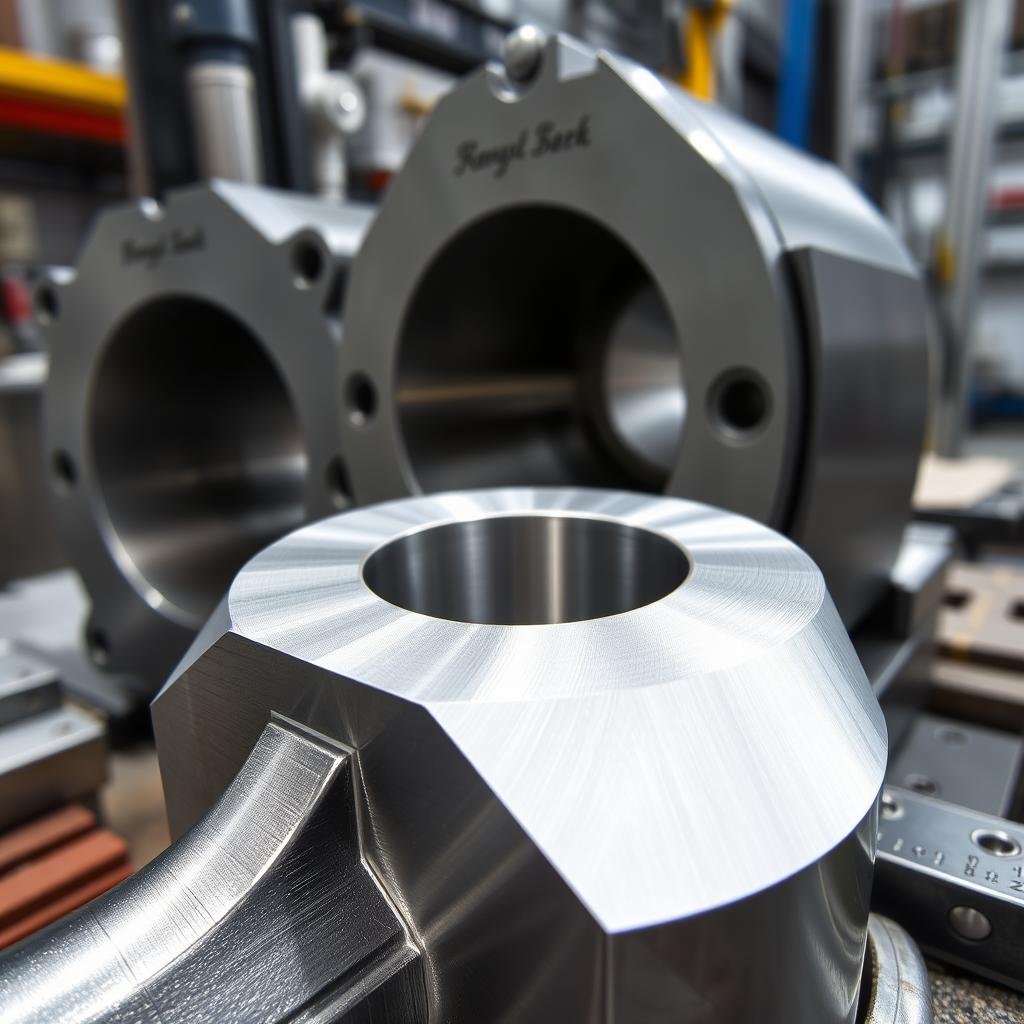

Precision Forging

Precision forging creates near-net shape components that require minimal machining. Key advantages include:

- Tight dimensional tolerances (±0.2mm)

- Reduced machining costs

- Excellent surface finish

- Material savings up to 30%

Not Sure Which Forging Process Is Right For Your Project?

Our engineering team can analyze your requirements and recommend the optimal forging process for your specific application.

Get Expert Process Recommendation

Aluminum Alloys Commonly Used in Forging

The selection of the appropriate aluminum alloy is crucial to achieving the desired mechanical properties, corrosion resistance, and performance characteristics in forged components. MAIKONG works with a wide range of aluminum alloys, each offering specific advantages for different applications.

| Alloy Series |

Common Alloys |

Key Properties |

Typical Applications |

| 2xxx Series |

2014, 2024, 2219 |

High strength, good fatigue resistance, moderate corrosion resistance |

Aerospace structural components, aircraft fittings, missile parts |

| 6xxx Series |

6061, 6063, 6082 |

Good strength, excellent corrosion resistance, good formability, weldability |

Automotive components, structural parts, marine applications |

| 7xxx Series |

7050, 7075, 7175 |

Very high strength, good stress corrosion resistance, moderate toughness |

Aerospace structures, defense applications, high-stress components |

| 5xxx Series |

5052, 5083, 5086 |

Moderate strength, excellent corrosion resistance, good weldability |

Marine components, pressure vessels, cryogenic applications |

Alloy Selection Considerations

When selecting an aluminum alloy for forging, MAIKONG engineers consider multiple factors to ensure optimal performance:

- Required mechanical properties (strength, hardness, ductility)

- Service environment (temperature, corrosive conditions)

- Fatigue resistance requirements

- Weight constraints

- Post-forging operations (machining, welding, anodizing)

- Heat treatment response

- Cost considerations

- Regulatory and specification requirements

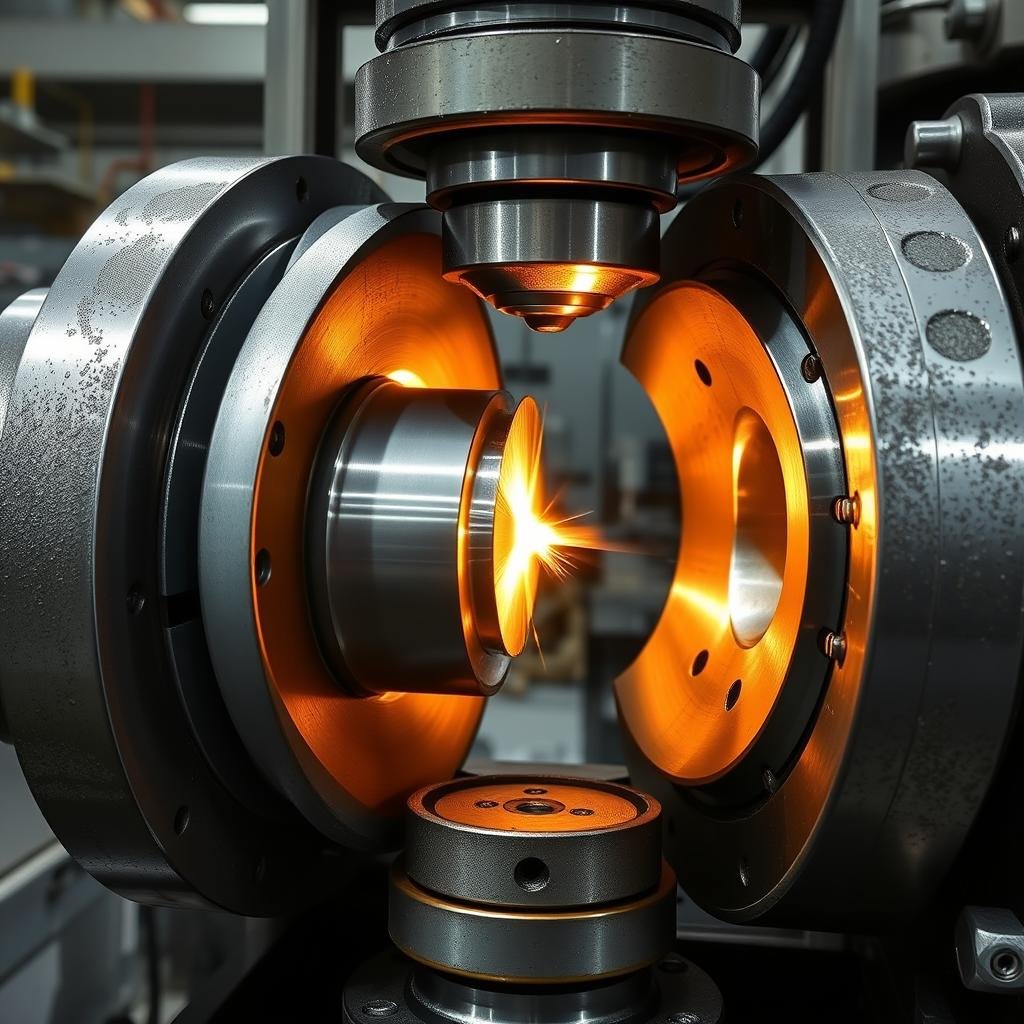

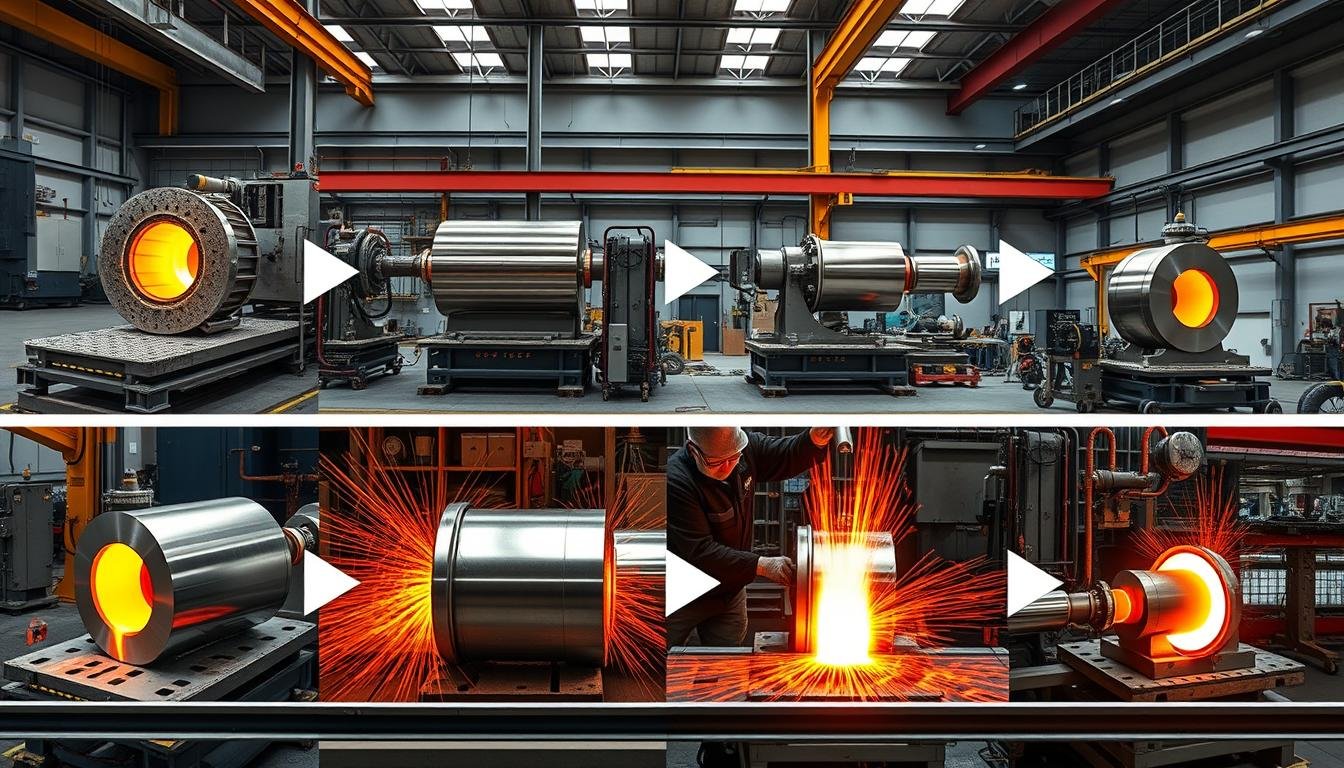

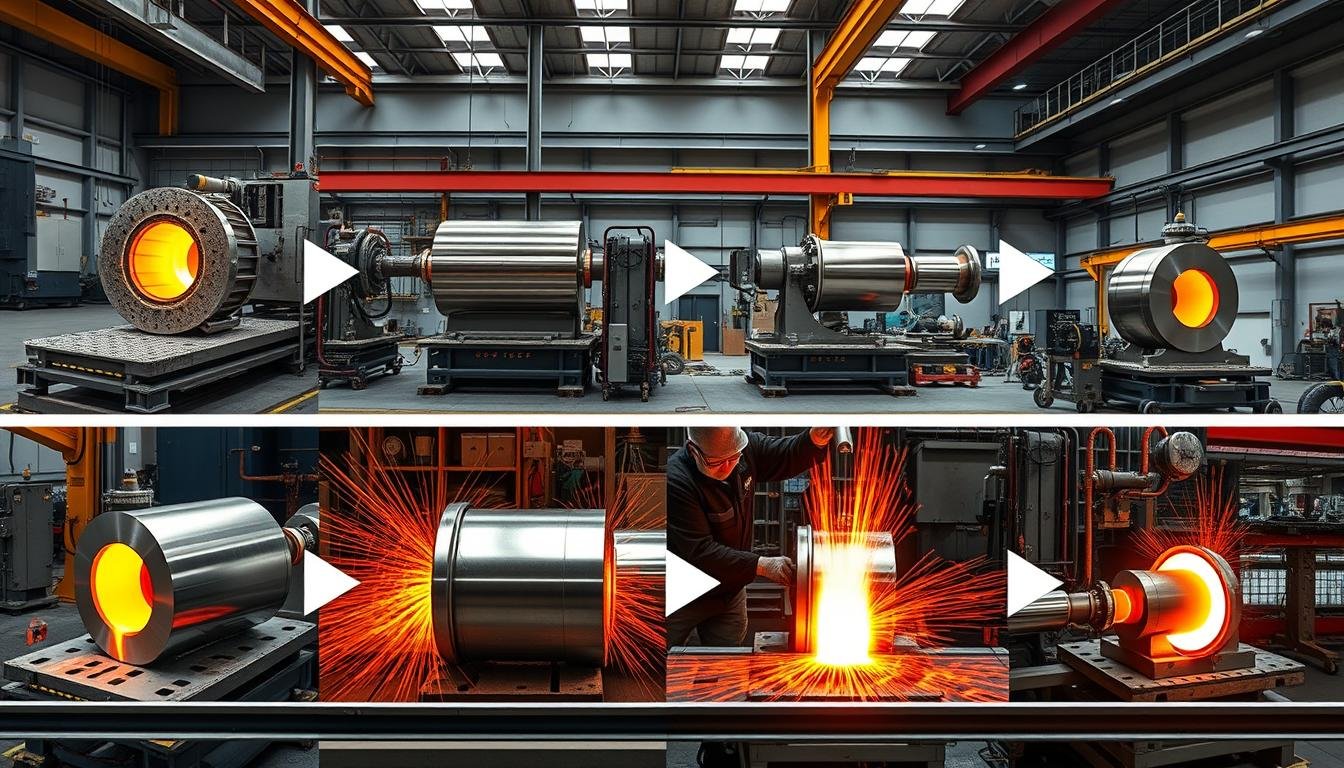

The Aluminum Forging Processes Explained

Understanding the complete aluminum forging workflow is essential for appreciating the craftsmanship and precision that goes into creating high-performance components. At MAIKONG, our aluminum forging processes follow a systematic approach to ensure consistent quality and exceptional mechanical properties.

Pre-Forging Preparation

Before the actual forging begins, several critical preparatory steps ensure optimal results:

- Material Selection: Choosing the appropriate aluminum alloy based on application requirements

- Billet Preparation: Cutting raw material to the required size and weight

- Heating: Raising the aluminum to the optimal forging temperature (typically 400-500°C) to enhance formability

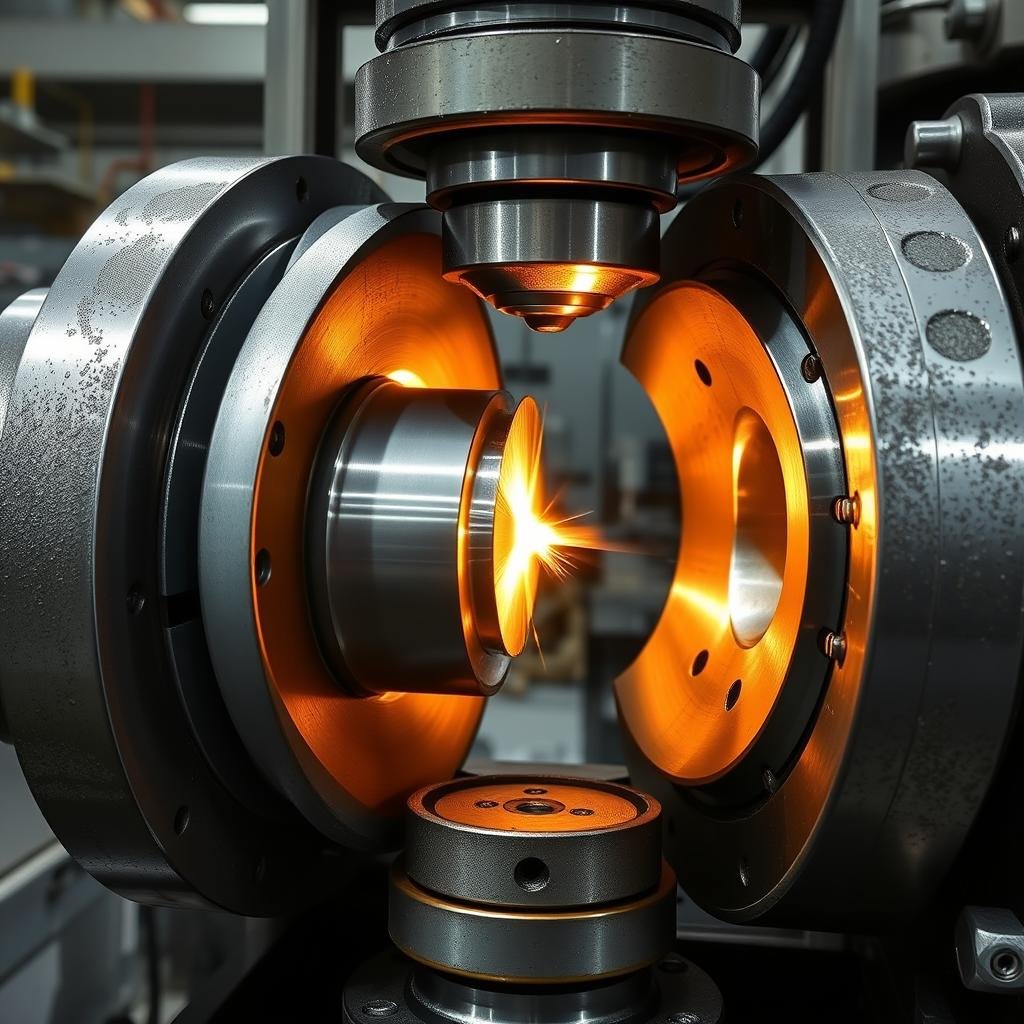

Core Forging Operations

The actual forging process involves several carefully controlled steps:

- Die Preparation: Preheating and lubricating the forging dies to prevent sticking and premature wear

- Initial Forming: Placing the heated aluminum in the die cavity and applying initial pressure

- Final Forming: Applying full forging pressure to completely form the part

- Trimming: Removing excess material (flash) from the forged component

Post-Forging Operations

After the basic shape is formed, several additional processes enhance the component’s properties and finish:

- Heat Treatment: Solution treatment, quenching, and aging to optimize mechanical properties

- Straightening: Correcting any distortion that may have occurred during forging or heat treatment

- Machining: Adding precision features and achieving final dimensions

- Surface Treatment: Applying finishes such as anodizing, painting, or other protective coatings

- Inspection: Conducting dimensional, visual, and non-destructive testing to ensure quality

Ready to Start Your Aluminum Forging Project?

Contact our team to discuss your requirements and receive a competitive quote for your custom aluminum forgings.

Get A Quick Quote

MAIKONG’s Advanced Aluminum Forging Capabilities

With over 60 CNC machines and a monthly metal processing capacity exceeding 100 tons, MAIKONG stands as a leader in aluminum forging and precision machining. Our comprehensive capabilities enable us to deliver exceptional quality and value across diverse applications.

CAD/CAM Integration

Our advanced CAD/CAM systems enable precise design and simulation of forging processes before production begins. This approach allows us to:

- Identify potential issues early in the design phase

- Optimize material flow during forging

- Reduce development time and costs

- Ensure consistent quality across production runs

Material Testing Laboratory

Our in-house material laboratory ensures that all raw materials and finished components meet exact specifications:

- Chemical composition analysis

- Mechanical property testing

- Microstructure examination

- Hardness testing

- Corrosion resistance evaluation

Heat Treatment Facilities

Comprehensive heat treatment capabilities allow us to optimize the mechanical properties of forged aluminum components:

- Solution heat treatment

- Controlled quenching

- Precipitation hardening (aging)

- Stress relieving

- Statistical process control for consistent results

CNC Machining Services

Our extensive CNC machining capabilities complement our forging operations, providing complete solutions from raw material to finished components:

CNC Turning Services

Ideal for creating precise cylindrical shapes with superior surface finishes, our CNC turning capabilities deliver exceptional accuracy for components requiring:

- Deep holes and bores

- Machined threads

- Complex cylindrical profiles

- Tight tolerances (±0.01mm)

CNC Milling Services

Our multi-axis CNC milling machines create complex prismatic shapes and flat surfaces with exceptional precision:

- 3-axis, 4-axis, and 5-axis machining

- Complex pocket milling

- Contour machining

- Surface profiling

Quality Control in Aluminum Forging Processes

Quality assurance is integrated into every stage of our aluminum forging processes. MAIKONG’s comprehensive quality management system, certified to ISO 9001:2015 standards, ensures consistent excellence in all our products.

Inspection Methods

We employ multiple inspection techniques to verify component quality:

- Dimensional Inspection: Using coordinate measuring machines (CMM) and precision gauges to verify dimensional accuracy

- Visual Inspection: Examining surface quality and identifying potential defects

- Non-Destructive Testing: Including ultrasonic, dye penetrant, and magnetic particle inspection to detect internal and surface defects

- Mechanical Testing: Conducting tensile, hardness, and impact tests to verify mechanical properties

- Chemical Analysis: Verifying material composition and ensuring proper alloy selection

Statistical Process Control

We implement rigorous statistical process control (SPC) methods to monitor and continuously improve our forging processes:

- Real-time process monitoring and data collection

- Trend analysis to identify potential issues before they affect quality

- Process capability studies to ensure consistent quality

- Root cause analysis using 5 Whys and other advanced statistical techniques

MAIKONG Quality Commitment: Our quality management system incorporates 6S, PDCA, and lean production principles to ensure consistent excellence in every component we produce. We’re not satisfied until you are.

Industrial Applications of Aluminum Forgings

Aluminum forgings play a critical role across numerous industries where performance, reliability, and weight reduction are essential. MAIKONG’s expertise spans diverse applications, delivering custom solutions for the most demanding environments.

Aerospace Applications

- Structural components and fittings

- Landing gear components

- Engine mounts and brackets

- Control system components

- Bulkheads and frames

Automotive Applications

- Suspension components

- Steering knuckles

- Connecting rods

- Wheel hubs and carriers

- Transmission components

Industrial Applications

- Valve bodies and components

- Pump housings and impellers

- Structural connectors

- Pressure vessels

- Heavy equipment components

Additional Application Sectors

Marine Applications

- Propeller components

- Structural fittings

- Hardware for corrosive environments

- Underwater equipment housings

Defense Applications

- Weapons systems components

- Armored vehicle parts

- Missile components

- Naval equipment

Become a US Distributor for MAIKONG

We’re seeking distribution partners across the United States for our high-quality aluminum forgings and precision machined components.

Partner With Us

Conclusion

Aluminum forging processes represent a critical manufacturing technology that delivers superior mechanical properties, reliability, and performance across numerous industries. By combining controlled deformation with precise temperature management and expert metallurgical knowledge, forging creates aluminum components with exceptional strength-to-weight ratios and directional grain structures optimized for specific loading conditions.

At MAIKONG, we leverage decades of experience, advanced equipment, and rigorous quality control to deliver world-class aluminum forgings that meet the most demanding specifications. Whether you require aerospace-grade components, automotive parts, or industrial hardware, our comprehensive capabilities provide complete solutions from design to delivery.

Contact us today to learn how our aluminum forging expertise can support your manufacturing needs with cost-effective, high-performance components that deliver exceptional value.