Aluminum forging is a sophisticated manufacturing process that transforms aluminum alloys into high-strength, precision components through controlled pressure application. This comprehensive guide explores how aluminum forging delivers exceptional strength-to-weight ratios, superior structural integrity, and outstanding performance across multiple industries. As a leading provider of aluminum forging services, MAIKONG combines advanced technology with metallurgical expertise to create components that meet the most demanding specifications.

Understanding Aluminum Forging: Process and Principles

Aluminum forging is the process of shaping aluminum alloys under high pressure, typically at elevated temperatures, to produce components with superior mechanical properties. Unlike casting, aluminum forging aligns the metal’s grain structure, resulting in parts with exceptional strength, durability, and resistance to fatigue.

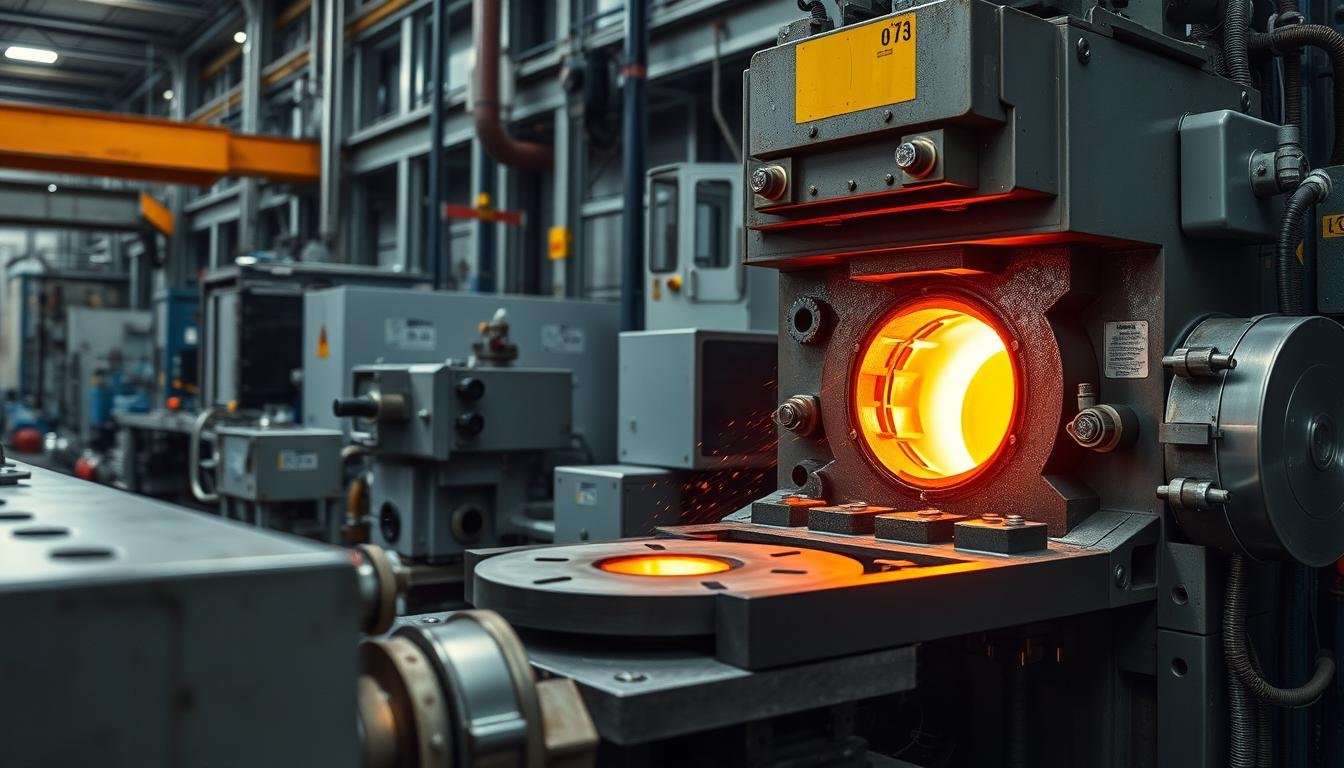

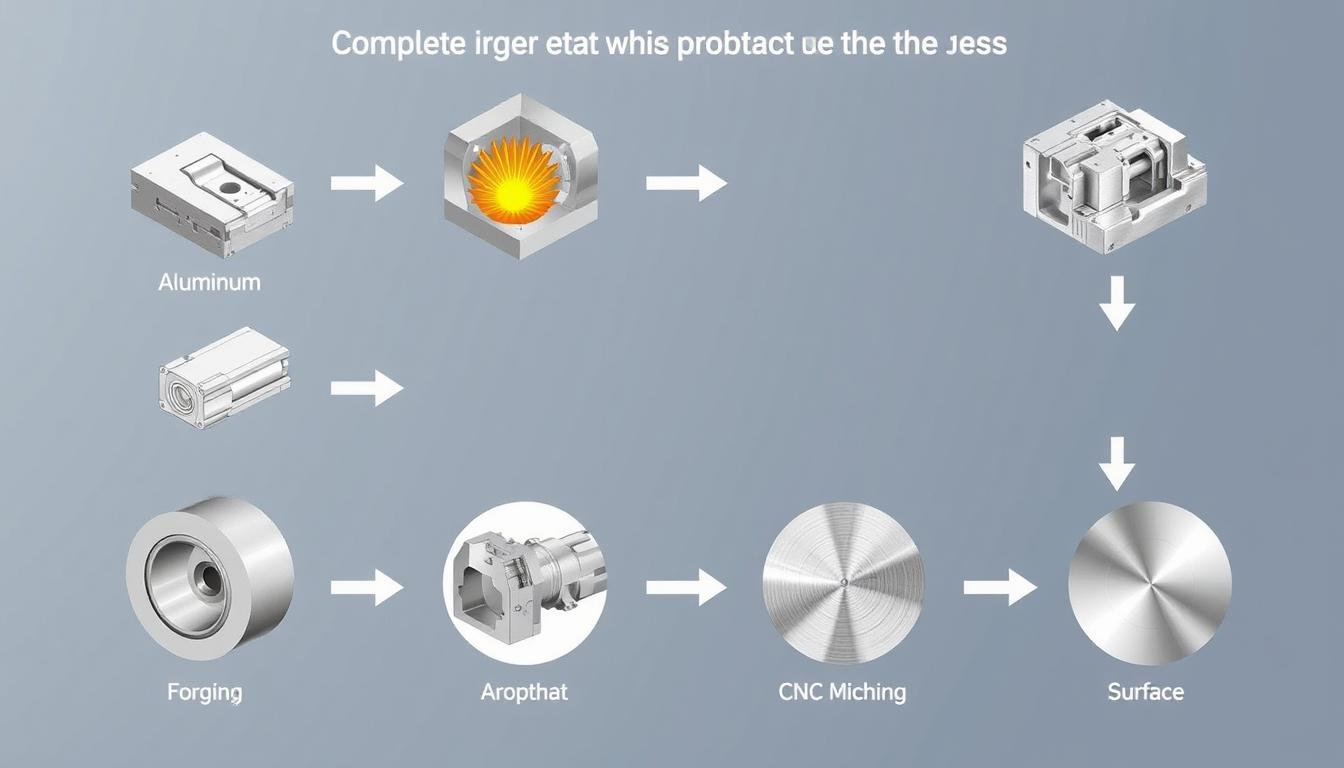

The aluminum forging process transforms raw aluminum into precision components

The Science Behind Aluminum Forging Strength

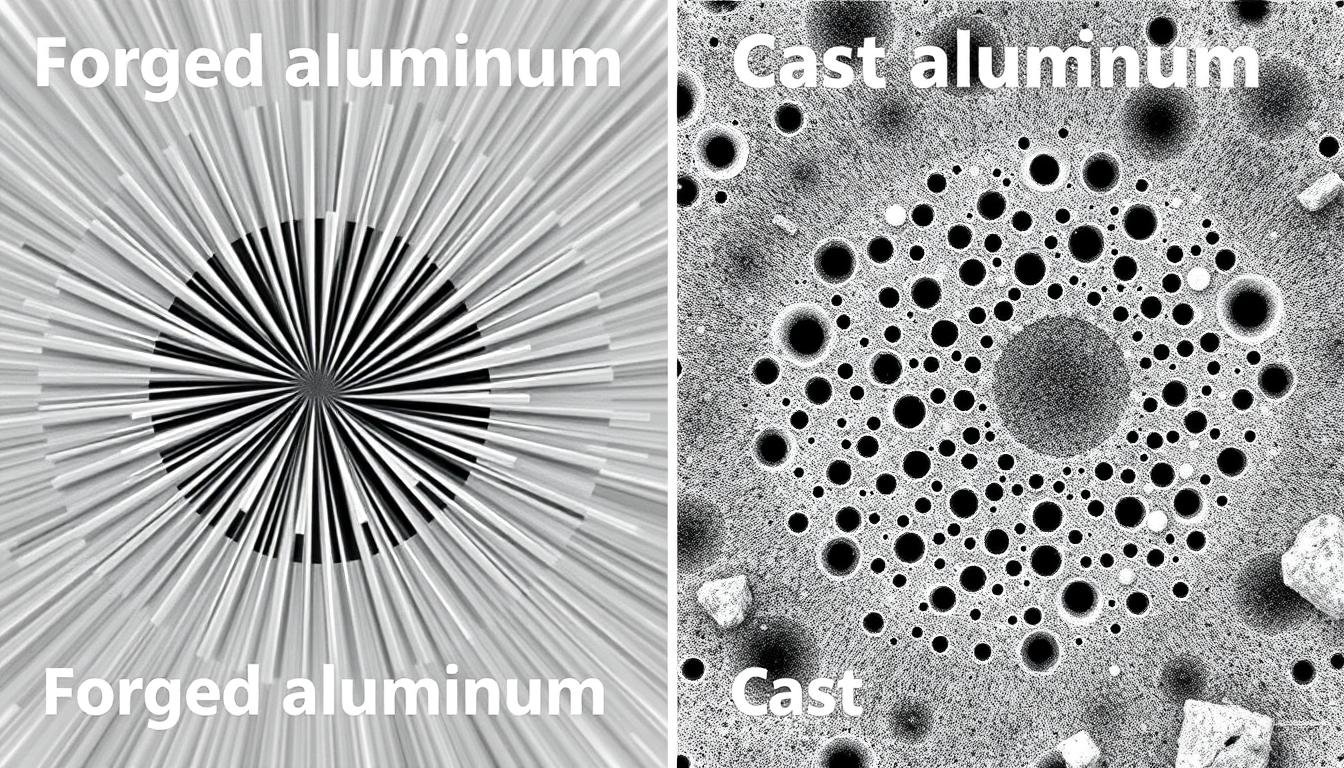

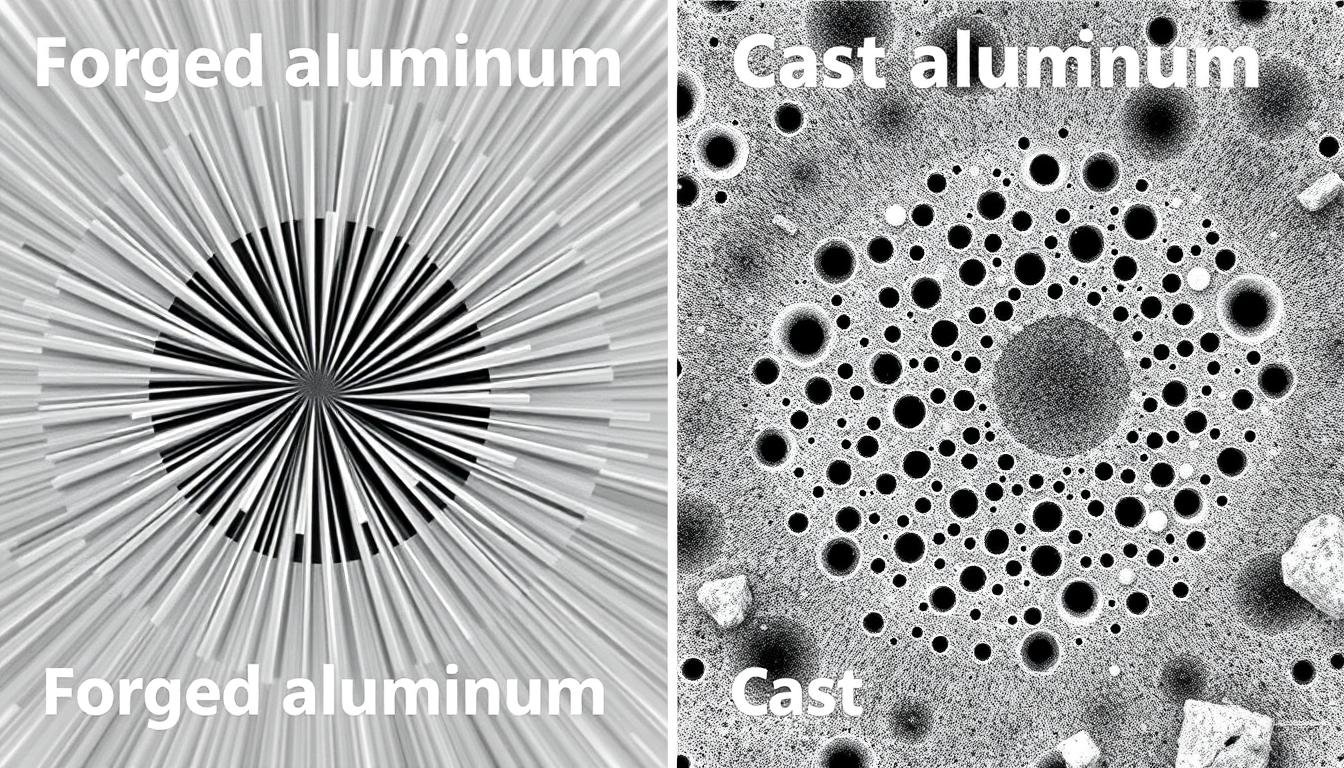

The exceptional strength of forged aluminum comes from its refined grain structure. During the aluminum forging process, pressure realigns the metal’s grain flow, eliminating porosity and creating a uniform, dense structure. This results in components with 25-30% higher strength compared to cast aluminum parts of the same dimensions.

Expert Aluminum Forging Services

MAIKONG specializes in precision aluminum forging for critical applications. Our advanced facilities in GD, SZ deliver components with superior mechanical properties and tight tolerances.

Request a Consultation

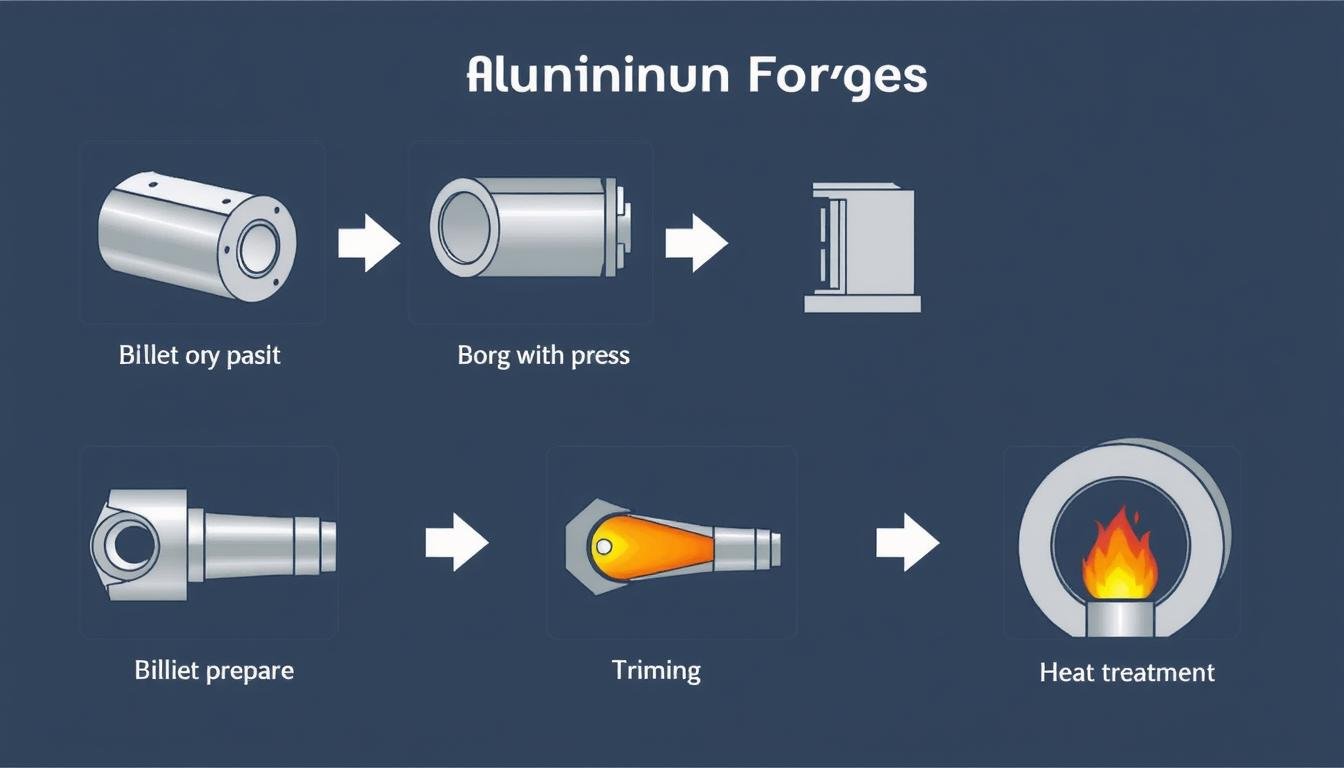

The Aluminum Forging Process: Step-by-Step

The aluminum forging process involves several critical stages, each contributing to the final component’s quality and performance characteristics. MAIKONG’s comprehensive approach ensures optimal results at every step.

1. Material Selection and Preparation

The first step in aluminum forging is selecting the appropriate aluminum alloy. Common alloys include 6061, 7075, and 2024, each offering specific properties suitable for different applications. MAIKONG’s material laboratory ensures each alloy meets precise specifications before processing.

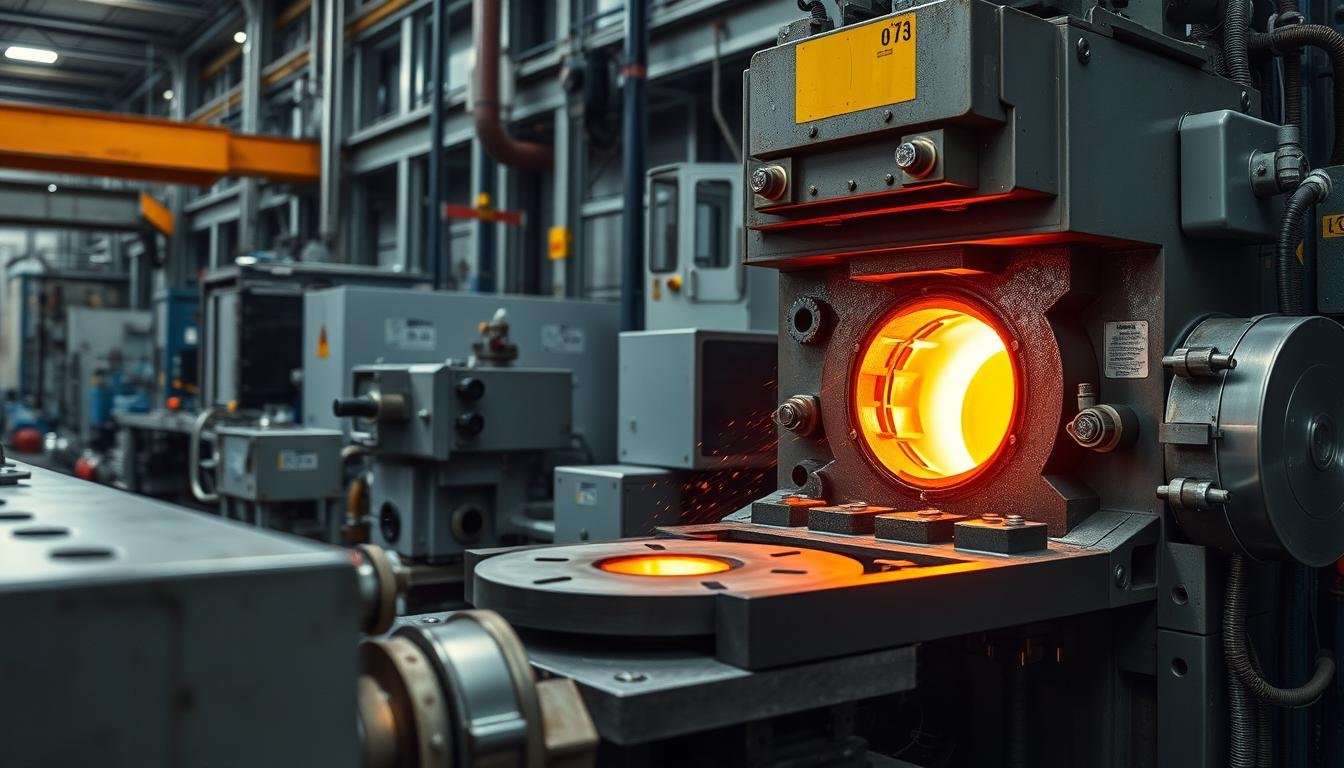

2. Heating to Optimal Forging Temperature

Aluminum requires precise temperature control during forging. The optimal aluminum forging temperature typically ranges from 700°F to 950°F (370°C to 510°C), depending on the specific alloy. This temperature range makes the aluminum malleable without risking melting or structural damage.

3. The Forging Operation

Once heated, the aluminum undergoes the actual aluminum forging operation. This can be performed using various methods:

Open Die Forging

The aluminum is compressed between flat or simply shaped dies, allowing metal flow in multiple directions. This method is ideal for larger components or lower production volumes.

Closed Die Forging

The aluminum is shaped within cavity dies that create precise geometries. This method delivers tighter tolerances and is suitable for complex shapes and higher production volumes.

4. Cooling and Heat Treatment

After forging, the aluminum components undergo controlled cooling followed by heat treatment to enhance mechanical properties. This critical step in the aluminum forging process can significantly affect strength, hardness, and durability.

5. Finishing Operations

The final steps include trimming excess material, machining to precise dimensions, and applying surface treatments. MAIKONG’s integrated CNC machining capabilities ensure forged components meet exact specifications.

Comprehensive Aluminum Forging Solutions

From design consultation to finished components, MAIKONG provides end-to-end aluminum forging services with exceptional quality control.

Contact Our Engineers

Aluminum Forging vs. Casting: A Comprehensive Comparison

When selecting a manufacturing method for aluminum components, understanding the differences between aluminum forging and casting is crucial. Each process offers distinct advantages and limitations that affect component performance, cost, and suitability for specific applications.

Microstructure comparison: Forged aluminum (left) shows dense, directional grain structure; cast aluminum (right) shows more porosity

| Comparison Criteria |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Superior strength due to dense, uniform grain structure |

Lower strength due to potential porosity and inclusions |

| Tensile Properties |

25-30% higher tensile strength and fatigue resistance |

Lower tensile strength and fatigue limits |

| Grain Structure |

Directional grain flow enhances mechanical properties |

Random grain orientation without directional benefits |

| Weight-to-Strength Ratio |

Optimal strength-to-weight ratio for lightweight applications |

Requires thicker sections for equivalent strength |

| Complex Geometries |

May require multiple operations for complex shapes |

Better suited for intricate geometries in a single operation |

| Dimensional Accuracy |

Tighter tolerances and better consistency |

Potential for dimensional variations and shrinkage |

| Surface Finish |

Superior surface quality with minimal porosity |

May require additional finishing to address surface defects |

| Ideal Applications |

Critical structural components in aerospace, automotive, defense |

Non-critical components, complex geometries, lower stress applications |

Need Help Choosing Between Aluminum Forging and Casting?

Our engineering team can help determine the optimal manufacturing process for your specific application requirements.

Email Our Technical Team

Applications and Industries for Aluminum Forging

The exceptional properties of forged aluminum make it ideal for applications where strength, weight, and reliability are critical factors. MAIKONG provides specialized aluminum forging solutions across multiple industries.

Aerospace

Aircraft structural components, landing gear parts, engine mounts, and control system components benefit from the exceptional strength-to-weight ratio of forged aluminum.

Automotive

Suspension components, steering knuckles, wheel hubs, and engine parts require the durability and fatigue resistance that only aluminum forging can provide.

Industrial Equipment

Valve bodies, fittings, structural components, and high-pressure applications rely on the superior mechanical properties of forged aluminum.

Defense

Military vehicle components, weapons systems, and tactical equipment benefit from the reliability and performance of forged aluminum parts.

Sports Equipment

Bicycle components, golf club heads, and high-performance sporting equipment leverage the strength and lightweight properties of forged aluminum.

Medical Devices

Surgical instruments, imaging equipment components, and medical device structures require the precision and reliability of forged aluminum.

Industry-Specific Aluminum Forging Solutions

MAIKONG provides specialized aluminum forging services tailored to your industry’s unique requirements and specifications.

Discuss Your Industry Needs

MAIKONG’s Advanced Aluminum Forging Capabilities

At MAIKONG, we’ve developed comprehensive aluminum forging capabilities supported by advanced technology, skilled engineers, and rigorous quality control processes. Our integrated approach ensures exceptional results from design to delivery.

MAIKONG’s state-of-the-art aluminum forging facility in GD, SZ

Comprehensive Aluminum Forging Services

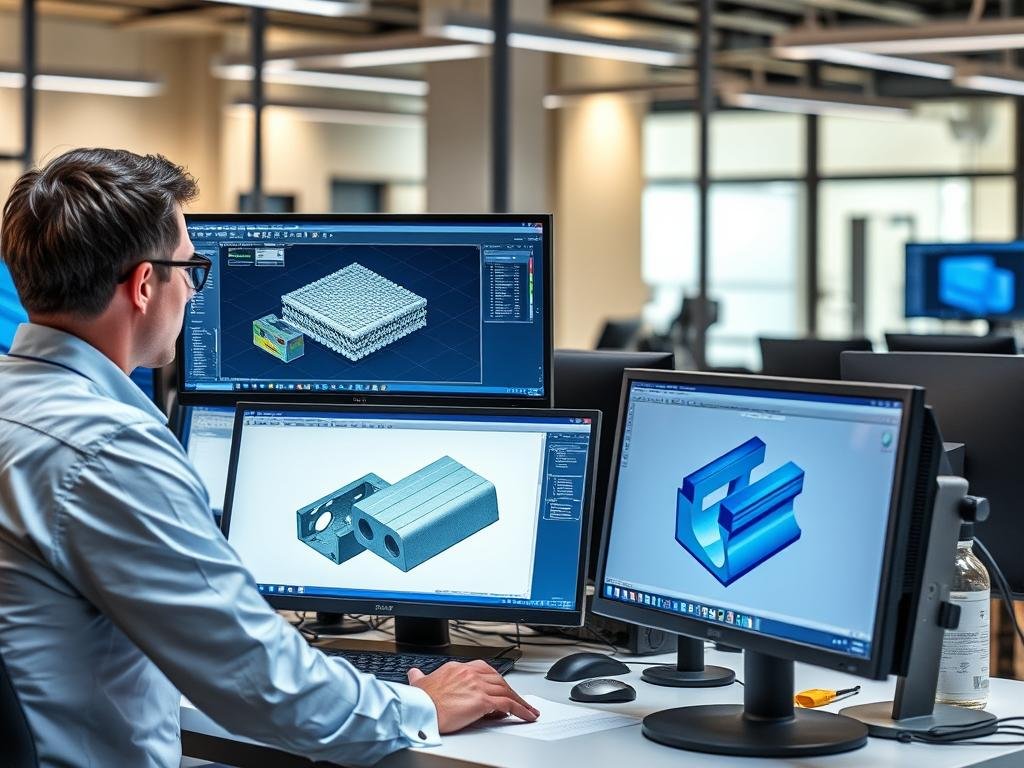

Design and Engineering

Our engineering team utilizes advanced CAD/CAM systems and finite element analysis to optimize component design for the aluminum forging process. This ensures optimal material flow, reduced stress concentrations, and enhanced performance.

Material Selection and Testing

MAIKONG’s material laboratory conducts comprehensive testing to ensure each aluminum alloy meets precise specifications. We work with a wide range of aluminum alloys including 6061, 7075, 2024, and custom formulations to meet specific application requirements.

Production Excellence

Our aluminum forging production capabilities include:

- Open and closed die forging processes

- Precision temperature control systems

- Hydraulic presses ranging from 500 to 3000 tons

- In-house heat treatment facilities

- Advanced CNC machining centers for secondary operations

- Comprehensive surface treatment options

- Rigorous quality control at every production stage

Integrated Manufacturing Approach

MAIKONG provides a complete solution from aluminum forging through finishing:

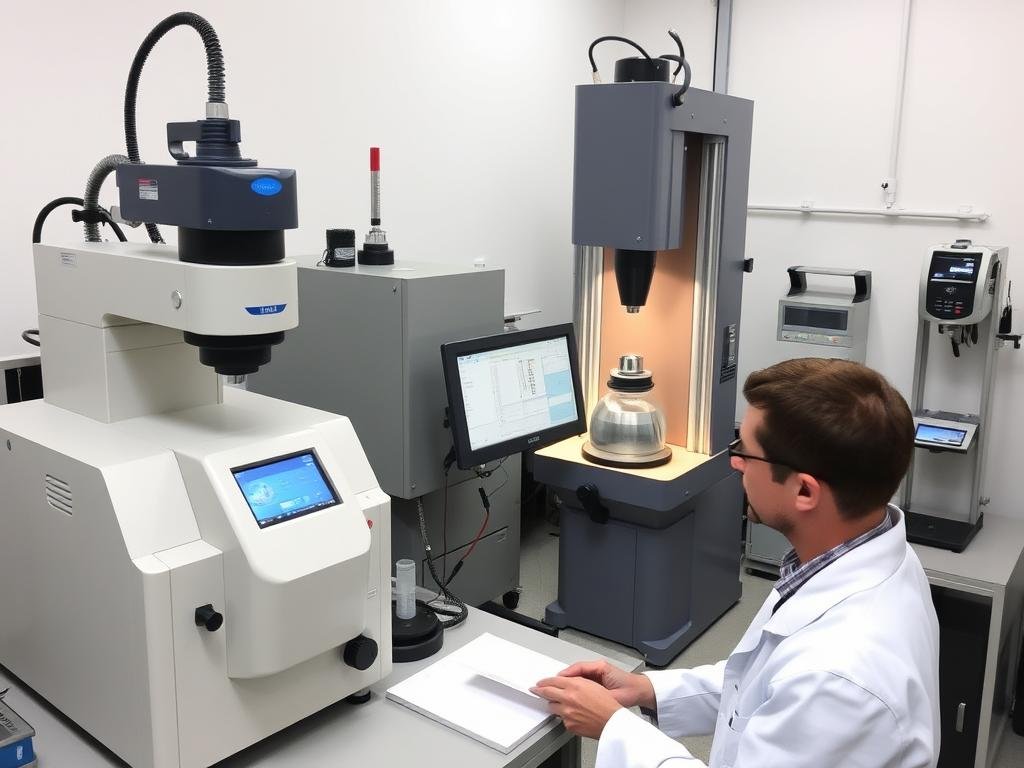

Quality Assurance in Aluminum Forging

MAIKONG maintains rigorous quality control throughout the aluminum forging process. Our ISO 9001:2015 certified quality management system ensures consistent excellence in every component we produce.

Comprehensive Testing Protocols

Our aluminum forging quality assurance includes:

Dimensional Verification

Using advanced coordinate measuring machines (CMM) and precision gauges to ensure components meet exact dimensional specifications.

Material Properties Testing

Conducting tensile testing, hardness testing, and impact testing to verify mechanical properties meet or exceed requirements.

Non-Destructive Testing

Employing ultrasonic, magnetic particle, and dye penetrant inspection to detect any internal or surface defects.

Microstructure Analysis

Examining grain structure and material composition to ensure optimal aluminum forging results.

Elevate Your Components with MAIKONG Aluminum Forging

Aluminum forging delivers unmatched strength, durability, and performance for critical components across industries. MAIKONG combines advanced technology, metallurgical expertise, and rigorous quality control to provide superior forged aluminum parts that meet the most demanding specifications. Contact us today to discuss how our comprehensive aluminum forging capabilities can benefit your next project.