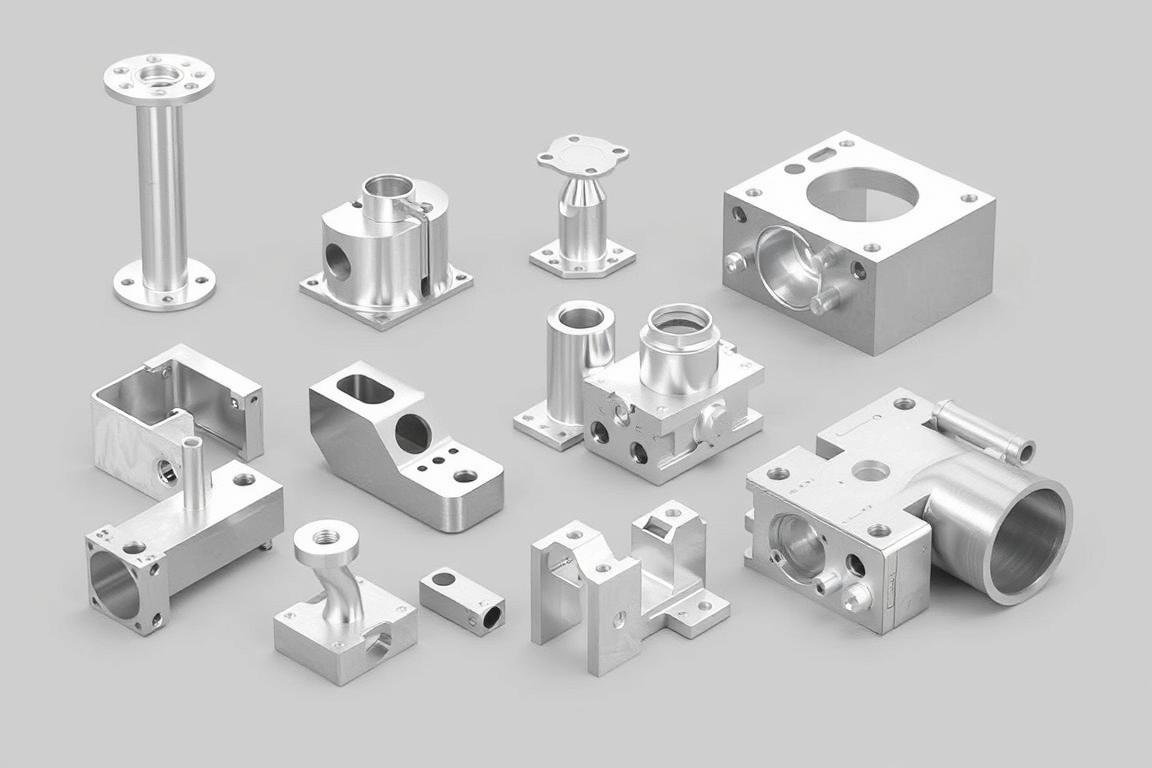

MAIKONG: Leading Among Aluminum Forging Companies for Premium B2B Solutions

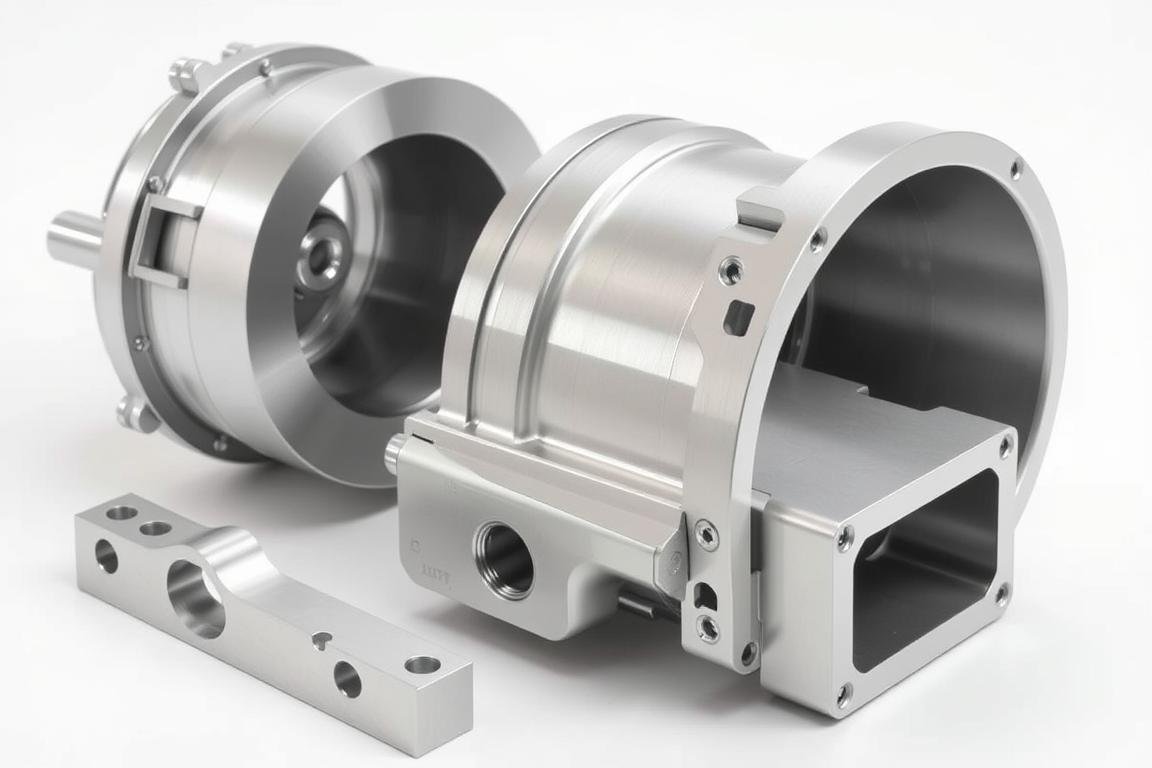

Welcome to MAIKONG, where precision meets performance in aluminum forging. As one of the most trusted aluminum forging companies in the industry, we deliver exceptional quality components that meet the exacting standards of aerospace, automotive, medical, and industrial clients worldwide. Our state-of-the-art Chinese manufacturing facilities combined with rigorous quality control processes ensure we provide superior aluminum forgings at competitive prices without compromising on quality or delivery timelines.

MAIKONG: Excellence Among Aluminum Forging Companies

Based in Shenzhen, China, MAIKONG has established itself as a premier provider among aluminum forging suppliers serving global markets. Our extensive experience in metal forging, particularly aluminum, allows us to deliver exceptional components that meet the most demanding specifications across various industries.

Our Manufacturing Advantage

MAIKONG leverages China’s advanced manufacturing infrastructure and skilled workforce to provide premium aluminum forgings at competitive prices. Our Shenzhen facility houses state-of-the-art equipment that enables us to handle projects of any complexity or volume.

Why Choose MAIKONG

- Access to China’s premier manufacturing capabilities

- Industry-leading equipment for precision forging

- Competitive pricing without compromising quality

- Comprehensive quality control systems

- Flexible production capabilities for custom projects

- Experienced engineering team for technical support

Ready to Discuss Your Project?

Our team is available to provide technical consultation and competitive quotes for your aluminum forging needs.

Request a Quote

Technical Capabilities and Quality Assurance

As one of the leading aluminum forgings manufacturers, MAIKONG offers comprehensive technical capabilities that ensure superior quality in every component we produce. Our expertise spans the entire forging process, from material selection to final inspection.

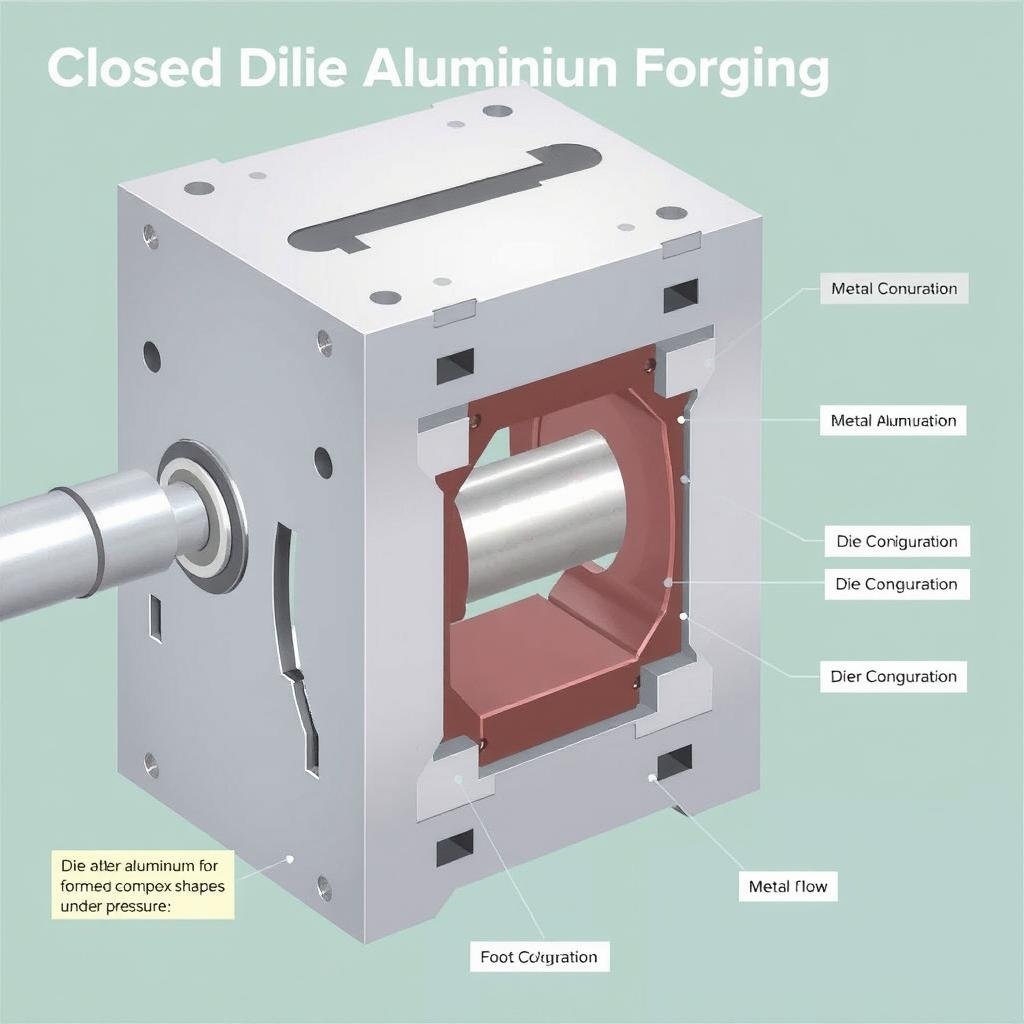

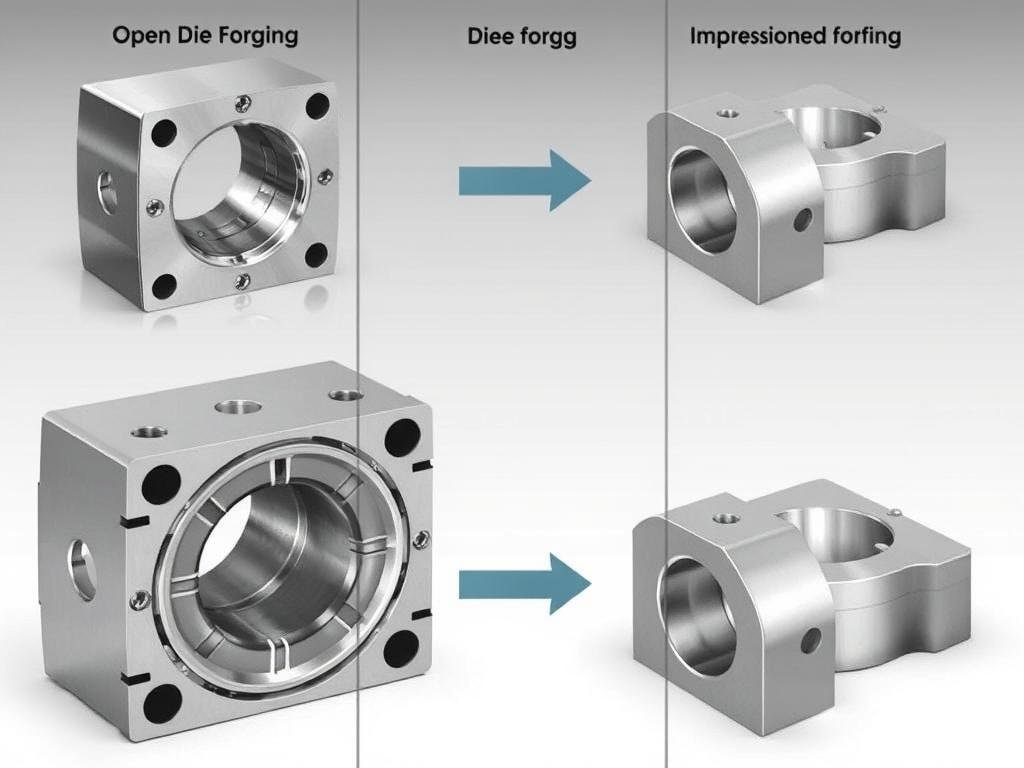

Forging Processes

- Open die forging for larger components

- Closed die forging for precision parts

- Impression die forging for complex geometries

- Hot forging for optimal material properties

Equipment Specifications

- Hydraulic presses up to 3,000 tons

- CNC machining centers for finishing

- Heat treatment furnaces for optimal properties

- Advanced testing equipment for quality verification

Quality Control

- Comprehensive material certification

- Dimensional inspection with advanced CMM

- Non-destructive testing capabilities

- Mechanical property verification

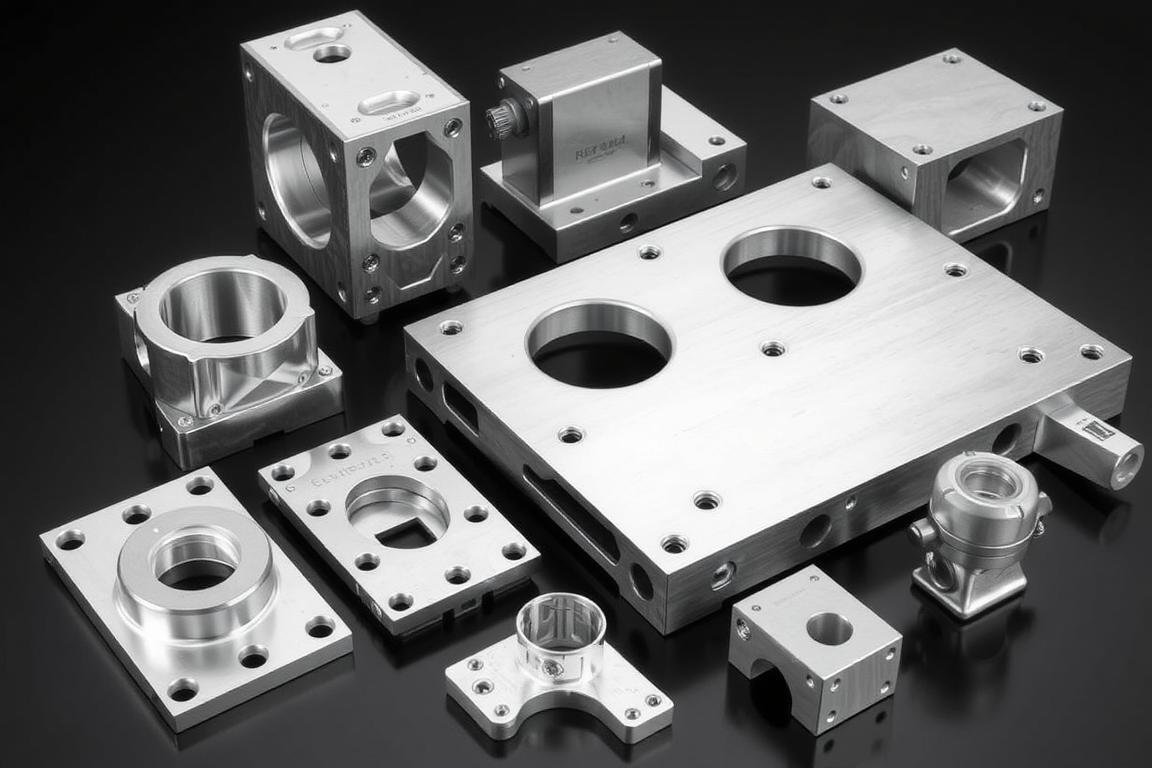

Custom Aluminum Forging Services

MAIKONG specializes in custom aluminum forging solutions tailored to your specific requirements. As versatile aluminum forging suppliers, we work closely with clients to develop components that meet exact specifications while optimizing for performance, weight, and cost.

Custom Design Support

Our engineering team collaborates with clients to optimize designs for the forging process, ensuring manufacturability while maintaining critical performance characteristics. This collaborative approach helps reduce costs and improve component performance.

4.8

Customer Satisfaction

Design Optimization

4.8/5

Production Capabilities

From prototypes to high-volume production runs, MAIKONG offers flexible manufacturing capabilities to meet diverse client needs. Our efficient production processes ensure consistent quality and timely delivery regardless of order size.

| Production Type |

Capacity |

Lead Time |

| Prototypes |

1-10 pieces |

2-3 weeks |

| Small Batch |

11-100 pieces |

3-4 weeks |

| Medium Production |

101-1,000 pieces |

4-6 weeks |

| High Volume |

1,000+ pieces |

6-8 weeks |

Material Expertise and Forging Techniques

At MAIKONG, we pride ourselves on our extensive knowledge of aluminum alloys and advanced forging techniques. Our expertise allows us to recommend the optimal material and process for your specific application requirements.

Aluminum Alloys We Work With

| Alloy |

Properties |

Common Applications |

| 6061 |

Good corrosion resistance, excellent weldability |

Structural components, frames, brackets |

| 7075 |

High strength-to-weight ratio, good fatigue resistance |

Aerospace components, high-stress parts |

| 2024 |

High strength, excellent fatigue resistance |

Aircraft structures, gears, shafts |

| 5083 |

Excellent corrosion resistance, good weldability |

Marine components, pressure vessels |

| 7050 |

High strength, excellent stress corrosion resistance |

Aircraft structural components, defense applications |

Forging Techniques

Our expertise in various forging techniques allows us to select the optimal process for each component, ensuring the best combination of mechanical properties, dimensional accuracy, and cost-effectiveness.

Heat Treatment Capabilities

MAIKONG offers comprehensive heat treatment services to optimize the mechanical properties of forged aluminum components. Our controlled processes ensure consistent results that meet or exceed industry standards.

- Solution heat treatment for maximum strength

- Precipitation hardening (aging) processes

- Stress relief treatments

- Annealing for improved machinability

- Controlled cooling for optimal properties

Material Selection Assistance

Not sure which aluminum alloy is best for your application? Our materials experts can help.

Get Expert Material Advice

Industries Served with Aluminum Forging Solutions

As versatile aluminum forging companies, MAIKONG provides specialized solutions across multiple industries, each with unique requirements and specifications. Our expertise allows us to deliver components that meet the most demanding standards in any sector.

Aerospace

We produce high-performance aluminum forgings for aircraft structural components, engine parts, and landing gear systems that meet stringent aerospace standards for strength, weight, and reliability.

- Structural components and fittings

- Engine mounts and brackets

- Landing gear components

- Control system parts

Automotive

Our automotive aluminum forgings deliver the perfect balance of strength, weight reduction, and durability for critical vehicle components in both standard and high-performance applications.

- Suspension components

- Steering knuckles and control arms

- Engine brackets and mounts

- Transmission components

Medical

We specialize in high-precision aluminum forgings for medical devices and equipment, meeting strict requirements for biocompatibility, sterilization, and dimensional accuracy.

- Surgical instrument components

- Medical device housings

- Imaging equipment parts

- Rehabilitation equipment components

Industrial Automation

Our aluminum forgings provide the strength, precision, and reliability required for industrial automation systems operating in demanding environments.

- Robotic arm components

- Actuator housings and brackets

- Conveyor system parts

- Structural support components

Defense

We deliver high-performance aluminum forgings for defense applications that meet stringent military specifications for durability, reliability, and performance in extreme conditions.

- Weapon system components

- Vehicle structural parts

- Communication equipment housings

- Tactical equipment components

Energy

Our aluminum forgings serve critical applications in the energy sector, providing durability, corrosion resistance, and reliable performance in challenging environments.

- Solar mounting systems

- Wind turbine components

- Power transmission parts

- Oil and gas equipment components

Industry-Specific Solutions

Need aluminum forgings tailored to your industry’s unique requirements? Contact our specialists today.

Discuss Industry-Specific Needs

Quality Control and Certifications

As one of the premier quality aluminum forge LLC providers, MAIKONG implements rigorous quality control processes throughout our manufacturing operations. Our commitment to quality ensures that every component we produce meets or exceeds client specifications and industry standards.

Quality Assurance Process

Our comprehensive quality assurance system covers every stage of production, from raw material inspection to final component verification. This systematic approach ensures consistent quality across all our aluminum forging products.

- Raw material certification and verification

- In-process inspection at critical stages

- Dimensional verification using advanced CMM

- Surface quality inspection

- Mechanical property testing

- Non-destructive testing when required

- Comprehensive documentation and traceability

Testing Capabilities

MAIKONG offers extensive testing capabilities to verify the quality and performance of our aluminum forgings. Our in-house testing facilities allow us to provide comprehensive documentation of component properties.

| Test Type |

Capabilities |

| Mechanical Testing |

Tensile, hardness, impact testing |

| Chemical Analysis |

Composition verification, alloy certification |

| Dimensional Inspection |

CMM, laser scanning, precision gauging |

| Non-Destructive Testing |

Ultrasonic, dye penetrant, X-ray inspection |

| Metallurgical Analysis |

Microstructure examination, grain flow analysis |

Quality Certifications

MAIKONG maintains industry-standard certifications that demonstrate our commitment to quality management and manufacturing excellence. Our quality management system ensures consistent adherence to international standards.

- ISO 9001:2015 Quality Management System

- AS9100D Aerospace Quality Management

- IATF 16949 Automotive Quality Management

Supply Chain Advantages and Logistics

MAIKONG leverages China’s robust supply chain infrastructure to deliver exceptional value to our global clients. As efficient aluminum forging suppliers, we combine manufacturing excellence with streamlined logistics to ensure timely delivery of quality components.

Supply Chain Excellence

Our integrated supply chain management ensures efficient production and delivery of aluminum forgings to clients worldwide. We maintain strong relationships with material suppliers and logistics partners to optimize every aspect of the supply chain.

- Direct access to premium aluminum suppliers

- Efficient inventory management

- Streamlined production scheduling

- Comprehensive quality control at every stage

- Flexible manufacturing capacity

Global Logistics Capabilities

MAIKONG offers comprehensive logistics solutions to ensure timely delivery of aluminum forgings to clients around the world. Our expertise in international shipping and customs procedures ensures smooth transportation of your components.

- Global shipping capabilities

- Customs documentation assistance

- Secure packaging for international transport

- Shipment tracking and status updates

- Expedited shipping options when needed

Supply Chain Consultation

Need help optimizing your aluminum component supply chain? Our experts can help.

Contact Supply Chain Team

Customer Support and Technical Assistance

At MAIKONG, we believe that exceptional customer support is as important as manufacturing excellence. Our dedicated team provides comprehensive technical assistance and responsive communication throughout your project.

Technical Support

Our engineering team offers expert technical assistance at every stage of your project, from initial design consultation to production troubleshooting. This support ensures optimal results for your aluminum forging applications.

WhatsApp Technical Support

For immediate technical assistance, connect with our engineering team via WhatsApp. Our experts are ready to answer your questions and provide solutions to technical challenges.

WhatsApp Technical Support: 0086-13510907401

Project Management

Each client is assigned a dedicated project manager who serves as your primary point of contact throughout the manufacturing process. This ensures clear communication and efficient project execution.

- Regular project status updates

- Proactive issue identification and resolution

- Transparent communication

- Milestone tracking and reporting

- Quality and delivery coordination

How quickly can you respond to technical inquiries?

Our technical team typically responds to all inquiries within 24 hours. For urgent matters, our WhatsApp support line provides immediate assistance during business hours.

Can you provide design optimization recommendations?

Yes, our engineering team regularly provides design optimization suggestions to improve manufacturability, reduce costs, and enhance performance of aluminum forged components.

Contact Our Support Team

Have questions about our aluminum forging capabilities? Our team is ready to assist you.

Why Choose MAIKONG as Your Aluminum Forging Partner

When selecting among aluminum forging companies, MAIKONG stands out for our commitment to quality, technical expertise, and customer satisfaction. Our comprehensive capabilities and customer-focused approach make us the ideal partner for your aluminum forging needs.

The MAIKONG Advantage

- Advanced manufacturing facilities in Shenzhen, China

- Comprehensive technical capabilities across all forging processes

- Extensive experience with diverse aluminum alloys

- Rigorous quality control and testing procedures

- Competitive pricing without compromising quality

- Flexible production capacity for projects of any size

- Responsive customer support and technical assistance

- Global logistics capabilities for worldwide delivery

Partner with MAIKONG for aluminum forging solutions that combine technical excellence, quality manufacturing, and exceptional value. Our team is ready to support your next project with the expertise and dedication that have made us a trusted supplier to clients worldwide.

Ready to Start Your Next Project?

Contact MAIKONG today to discuss your aluminum forging requirements and receive a competitive quote.