Aluminum Alloy Forgings: Superior Strength and Performance

December 4, 2025

Why Choose MAIKONG for Aluminum Alloy Forgings

When you partner with MAIKONG for your aluminum alloy forgings, you gain access to decades of specialized expertise and state-of-the-art manufacturing capabilities. Our comprehensive approach ensures superior quality at competitive prices, making us the preferred choice for discerning clients worldwide.

Superior Metallurgical Properties

Our forging processes align the grain structure of aluminum alloys, significantly enhancing strength, fatigue resistance, and overall mechanical properties compared to cast or machined components.

Precision Engineering

With advanced CAD/CAM technology and precision tooling, we deliver aluminum alloy forgings with exceptional dimensional accuracy and consistency across production runs.

Comprehensive Quality Control

Every forging undergoes rigorous inspection using state-of-the-art equipment, ensuring compliance with international standards and your specific requirements.

Cost-Effective Solutions

Our efficient production processes and strategic location in GD, SZ allow us to offer competitive pricing without compromising on quality or delivery timelines.

Ready to Elevate Your Components with Premium Forgings?

Our engineering team is standing by to discuss your specific requirements and provide expert guidance.

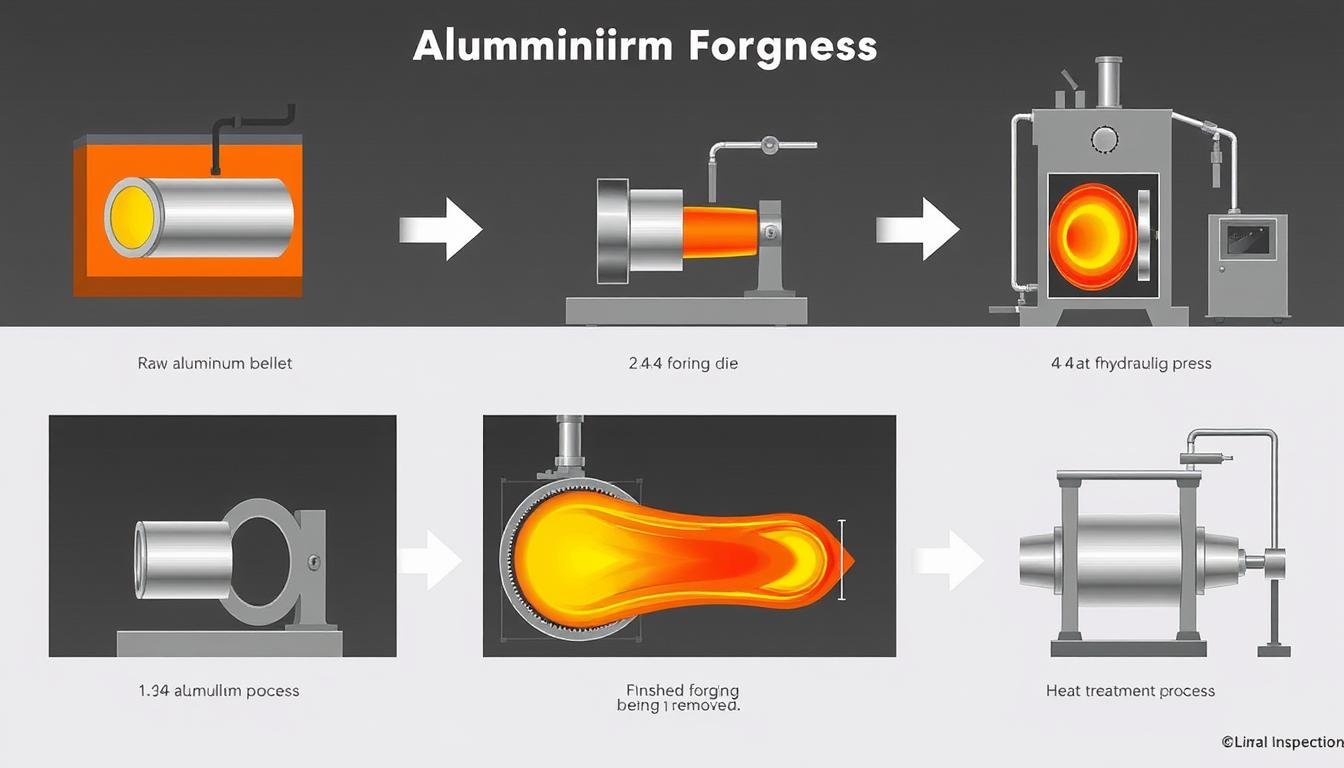

The MAIKONG Aluminum Alloy Forging Process

At MAIKONG, we’ve refined our forging process to ensure optimal material properties and dimensional precision for every component we produce. Our comprehensive approach to aluminum alloy forgings encompasses every stage from initial design to final inspection.

Our Comprehensive Forging Workflow

- Material Selection – We carefully select the optimal aluminum alloy based on your application requirements, considering factors like strength, corrosion resistance, and machinability.

- Engineering & Design – Our engineering team utilizes advanced CAD/CAM software to optimize component design for the forging process, ensuring optimal grain flow and mechanical properties.

- Die Design & Fabrication – Precision tooling is created specifically for your component, with careful attention to draft angles, radii, and parting lines.

- Heating – Aluminum billets are heated to precise temperatures in controlled furnaces to achieve optimal plasticity for forging.

- Forging Operation – Using hydraulic presses ranging from 800 to 8,000 tons, we apply controlled pressure to form the aluminum into the desired shape.

- Trimming & Cleaning – Excess material (flash) is precisely removed, and the forging undergoes cleaning to prepare for heat treatment.

- Heat Treatment – Specialized thermal processing enhances mechanical properties to meet specific requirements.

- Quality Inspection – Comprehensive testing including dimensional verification, ultrasonic testing, and mechanical property validation ensures compliance with specifications.

Need Technical Guidance?

Our metallurgical experts can help you select the optimal aluminum alloy and forging process for your specific application.

Types of Aluminum Alloy Forgings We Offer

MAIKONG specializes in various forging techniques to meet diverse application requirements. Each method offers distinct advantages for different component designs and performance specifications.

| Forging Type | Description | Ideal Applications | Size Capabilities |

| Open Die Forgings | Formed between flat or simply shaped dies, allowing material to flow laterally during compression | Large structural components, shafts, discs, rings | Up to 5000kg with dimensions up to 4000mm |

| Closed Die Forgings | Formed in dies containing impressions of the final part shape, providing precise dimensions | Complex components requiring tight tolerances and excellent mechanical properties | Up to 100kg with dimensions up to 1000mm |

| Rolled Ring Forgings | Seamless rings created through specialized rolling processes | Bearings, flanges, gears, aerospace components | Diameters from 100mm to 2000mm |

| Precision Forgings | Near-net-shape components requiring minimal machining | High-performance parts for aerospace and automotive applications | Up to 50kg with tight tolerances |

Unsure Which Forging Type Is Right for Your Application?

Our engineering team can analyze your requirements and recommend the optimal forging process.

Aluminum Alloys for Superior Forging Performance

The selection of the appropriate aluminum alloy is critical to achieving the desired mechanical properties and performance characteristics in forged components. At MAIKONG, we work with a comprehensive range of aluminum alloys to meet diverse application requirements.

Common Aluminum Alloys for Forging Applications

| Alloy Series | Key Properties | Typical Applications |

| 2XXX Series (2014, 2024, 2219) | High strength, excellent fatigue resistance, good machinability | Aerospace structural components, aircraft fittings, missile parts |

| 6XXX Series (6061, 6063, 6082) | Good corrosion resistance, excellent extrudability, moderate strength | Automotive components, architectural applications, marine hardware |

| 7XXX Series (7050, 7075, 7175) | Highest strength aluminum alloys, good stress corrosion resistance | Critical aerospace components, high-stress structural parts |

| 5XXX Series (5083, 5086) | Excellent corrosion resistance, good weldability, moderate strength | Marine applications, cryogenic equipment, pressure vessels |

Our metallurgical expertise allows us to recommend the optimal alloy for your specific application requirements, considering factors such as strength, weight, corrosion resistance, and cost-effectiveness.

Need Help Selecting the Right Aluminum Alloy?

Our materials experts can guide you through the selection process based on your performance requirements.

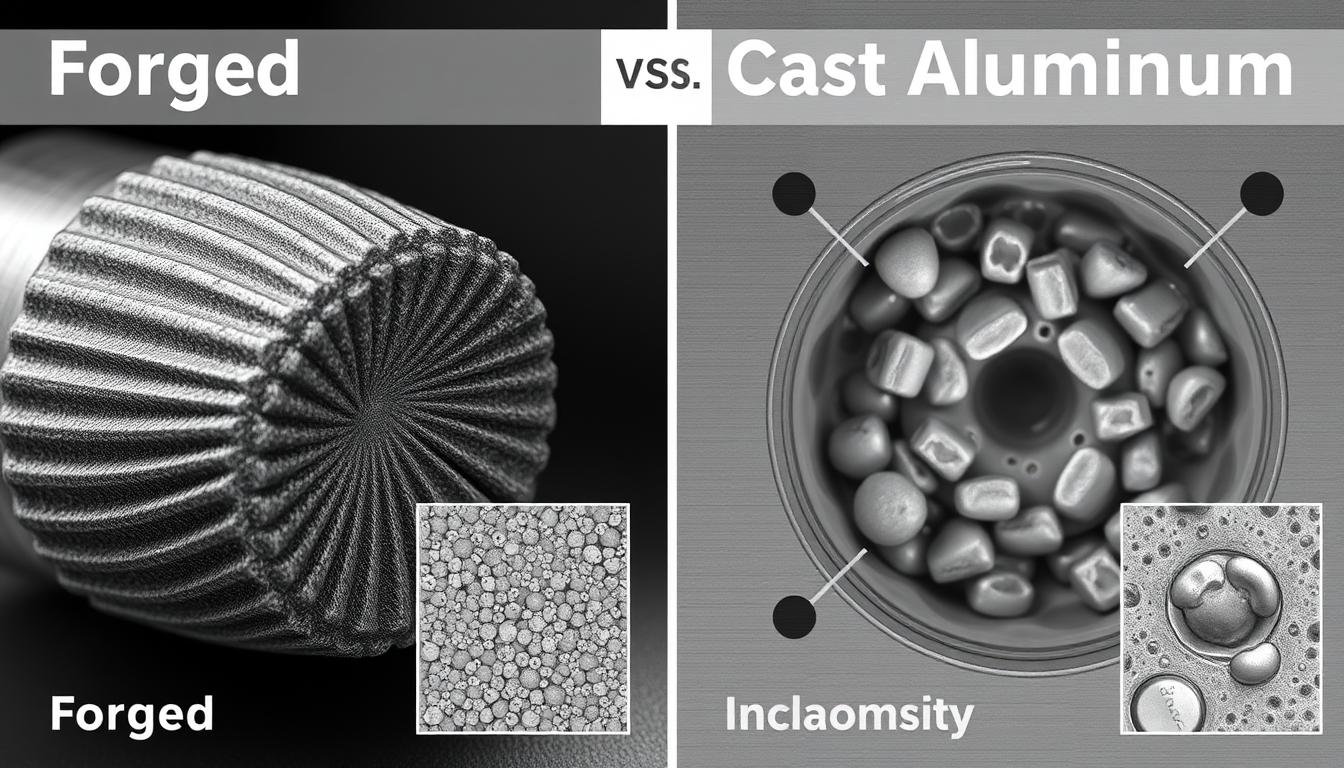

Aluminum Forging vs. Casting: Making the Right Choice

Understanding the differences between forged and cast aluminum components is essential for making informed manufacturing decisions. While both processes have their place in metal forming, aluminum alloy forgings offer distinct advantages for applications where mechanical properties and reliability are paramount.

Comparative Analysis: Forging vs. Casting

| Property | Aluminum Forgings | Aluminum Castings |

| Mechanical Strength | Superior strength due to refined, aligned grain structure | Lower strength with potential for porosity and inclusions |

| Fatigue Resistance | Excellent resistance to cyclic loading and stress | More susceptible to fatigue failure |

| Structural Integrity | Consistent, dense material structure without voids | Potential for internal defects and porosity |

| Dimensional Complexity | Limited to moderately complex geometries | Capable of highly complex, intricate shapes |

| Weight-to-Strength Ratio | Optimal efficiency with higher strength at lower weight | Requires thicker sections for equivalent strength |

| Surface Finish | Excellent with minimal post-processing | May require extensive finishing to address porosity |

| Production Volume | Economical for medium to high volumes | Suitable for both low and high volumes |

For critical applications where performance and reliability are essential, aluminum alloy forgings provide superior mechanical properties and consistency. Our engineering team can help you determine whether forging or casting is more appropriate for your specific component requirements.

Industries and Applications for Aluminum Alloy Forgings

The exceptional properties of aluminum alloy forgings make them ideal for a wide range of demanding applications across multiple industries. At MAIKONG, we serve diverse sectors with customized forging solutions tailored to specific performance requirements.

Aerospace

- Structural components

- Landing gear parts

- Engine mounts

- Control system components

- Bulkheads and frames

Automotive

- Suspension components

- Steering knuckles

- Connecting rods

- Wheel hubs

- Drivetrain components

Industrial

- Hydraulic components

- Valve bodies

- Structural connectors

- Gears and sprockets

- Pressure vessels

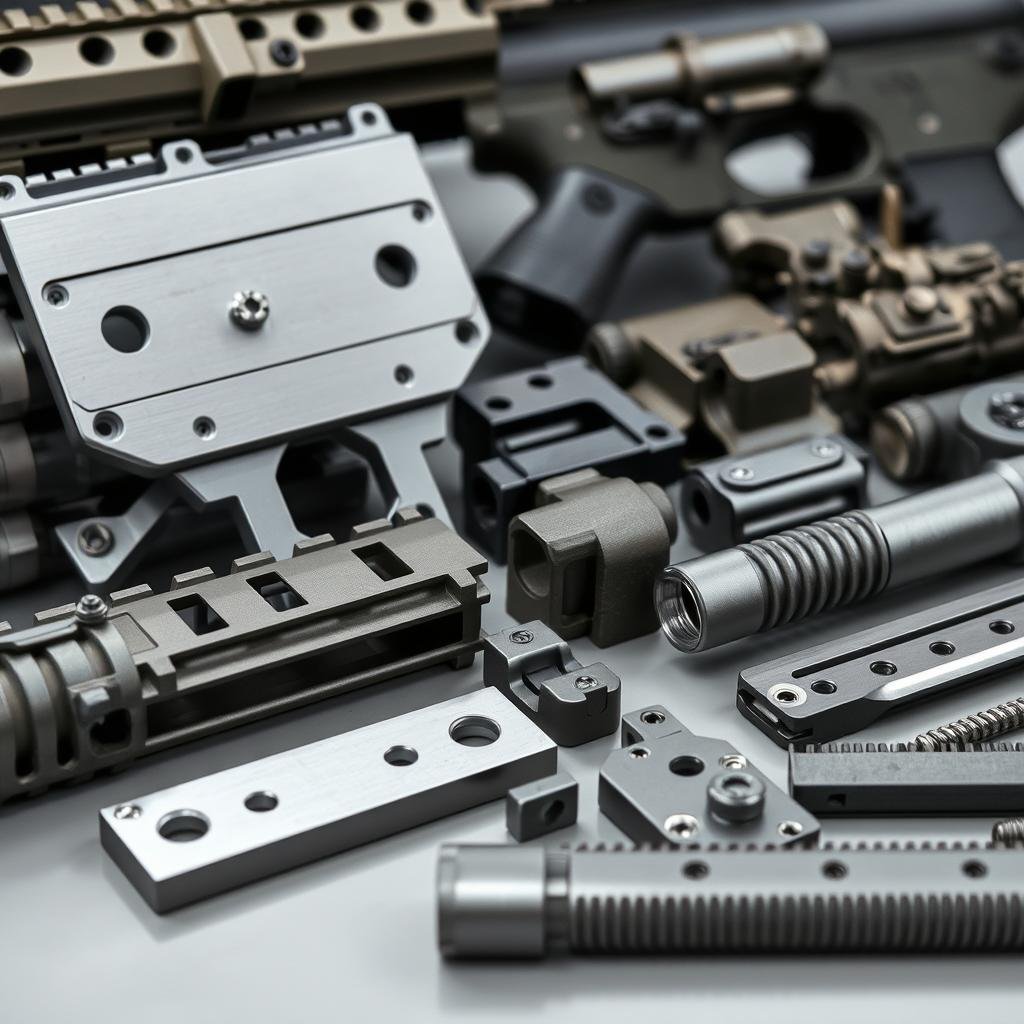

Defense

- Weapons systems

- Vehicle components

- Communication equipment

- Tactical hardware

- Structural elements

Marine

- Propeller components

- Deck hardware

- Structural fittings

- Engine components

- Navigation equipment housings

Energy

- Wind turbine components

- Solar mounting systems

- Hydroelectric equipment

- Power transmission parts

- Oil and gas components

Working on a Specialized Application?

Our engineering team can develop custom forging solutions tailored to your unique requirements.

MAIKONG’s Advanced Manufacturing Capabilities

Our state-of-the-art facility in GD, SZ is equipped with advanced forging equipment and comprehensive in-house capabilities that enable us to deliver exceptional quality aluminum alloy forgings with optimal efficiency.

Our Comprehensive Manufacturing Infrastructure

| Equipment/Capability | Specifications | Benefits |

| Hydraulic Forging Presses | 800 to 8,000 ton capacity | Enables production of both small precision components and large structural parts |

| Heat Treatment Furnaces | Computer-controlled with ±3°C precision | Ensures consistent mechanical properties across production runs |

| CNC Machining Centers | 3, 4, and 5-axis capabilities | Provides precision finishing and secondary operations |

| Quality Testing Equipment | Ultrasonic, X-ray, mechanical testing | Ensures compliance with stringent quality standards |

| Surface Treatment | Anodizing, painting, coating capabilities | Enhances corrosion resistance and aesthetic appearance |

| CAD/CAM Systems | Advanced simulation and modeling software | Optimizes design and manufacturing processes |

Quality Assurance and Certifications

At MAIKONG, quality is built into every step of our manufacturing process. Our comprehensive quality management system ensures consistent excellence in all the aluminum alloy forgings we produce.

- ISO 9001:2015 certified quality management system

- AS9100D certification for aerospace applications

- IATF 16949 compliance for automotive components

- 100% inspection of critical dimensions and properties

- Full material traceability and lot control

- Comprehensive documentation and certification

Ready to Experience MAIKONG Quality?

Contact us today to discuss your aluminum forging requirements and discover the MAIKONG difference.

Comprehensive CNC Machining and Value-Added Services

Beyond our core expertise in aluminum alloy forgings, MAIKONG offers a complete range of value-added services to provide turnkey solutions for your manufacturing needs.

CNC Machining Excellence

Our advanced CNC machining capabilities complement our forging expertise, allowing us to deliver precision-finished components ready for assembly.

CNC Turning Services

Precision turning of cylindrical components with superior surface finishes and tight tolerances. Ideal for shafts, bushings, and rotational parts.

CNC Milling Services

Multi-axis milling capabilities for complex geometries and precise features. Perfect for structural components and parts with intricate details.

Swiss-Type Machining

Specialized machining for small, precise components with exceptional accuracy and surface quality. Ideal for small, complex parts.

Additional Value-Added Services

- Heat Treatment – Specialized thermal processing to enhance mechanical properties

- Surface Treatments – Anodizing, painting, and coating for improved corrosion resistance and aesthetics

- Assembly – Integration of components into sub-assemblies or finished products

- Testing & Certification – Comprehensive quality validation and documentation

- Prototyping – Rapid development of sample components for validation

- Engineering Support – Design optimization for manufacturability and performance

- Logistics Management – Efficient delivery solutions worldwide

- Inventory Programs – Just-in-time delivery and stock management

One-Stop Manufacturing Solution

From forging to finishing, MAIKONG delivers complete manufacturing solutions to streamline your supply chain.

Partner with MAIKONG for Premium Aluminum Alloy Forgings

When you choose MAIKONG for your aluminum alloy forgings, you gain a dedicated manufacturing partner committed to your success. Our combination of technical expertise, advanced capabilities, and customer-focused approach ensures exceptional results for even the most demanding applications.

With competitive pricing, exceptional quality, and responsive service, MAIKONG is your ideal partner for aluminum forging projects of any scale. We’re currently expanding our presence in the United States and seeking distribution partners nationwide.

Ready to Discuss Your Project?

Contact our team today to explore how MAIKONG can support your manufacturing needs with premium aluminum alloy forgings and comprehensive machining services.

Email: Lucy@maikongforge.us

MAIKONG – Delivering precision aluminum alloy forgings with superior strength, performance, and value. Contact us today to experience the difference of working with a true forging specialist.

Contact us online by Whatsapp: