In industries where performance cannot be compromised, 7075 aluminum forgings deliver exceptional strength, durability, and reliability. These precision-engineered components combine the lightweight properties of aluminum with steel-like strength, making them ideal for aerospace, defense, automotive, and high-end manufacturing applications where failure is not an option.MAIKONG specializes in custom 7075 aluminum forgings that meet the most demanding specifications while offering competitive pricing and global delivery capabilities. Our advanced manufacturing processes ensure optimal grain flow, superior mechanical properties, and consistent quality that exceeds industry standards.

Superior Properties of 7075 Aluminum Forgings

The exceptional mechanical properties of 7075 aluminum alloy make it one of the most sought-after materials for high-stress applications. When combined with precision forging techniques, these properties are further enhanced, creating components that deliver outstanding performance in the most demanding environments.

| Property |

7075-T6 |

7075-T73 |

7075-T7352 |

| Tensile Strength (MPa) |

510-538 |

505 |

462-538 |

| Yield Strength (MPa) |

434-476 |

435 |

372-462 |

| Elongation (%) |

5-8 |

13 |

3-9 |

| Brinell Hardness |

150 |

130 |

135-145 |

| Fatigue Resistance |

Excellent |

Very Good |

Superior |

| Corrosion Resistance |

Moderate |

Excellent |

Excellent |

Chemical Composition of 7075 Aluminum Alloy

The precise chemical composition of 7075 aluminum alloy contributes to its exceptional performance characteristics. MAIKONG ensures strict adherence to these compositional requirements for consistent quality in all our 7075 aluminum forgings.

| Element |

Minimum (%) |

Maximum (%) |

| Zinc (Zn) |

5.1 |

6.1 |

| Magnesium (Mg) |

2.1 |

2.9 |

| Copper (Cu) |

1.2 |

2.0 |

| Chromium (Cr) |

0.18 |

0.28 |

| Silicon (Si) |

– |

0.40 |

| Iron (Fe) |

– |

0.50 |

| Manganese (Mn) |

– |

0.30 |

| Titanium (Ti) |

– |

0.20 |

Need Custom 7075 Aluminum Forgings?

Our engineering team can help you select the optimal temper and specifications for your application requirements.

Get a Quote

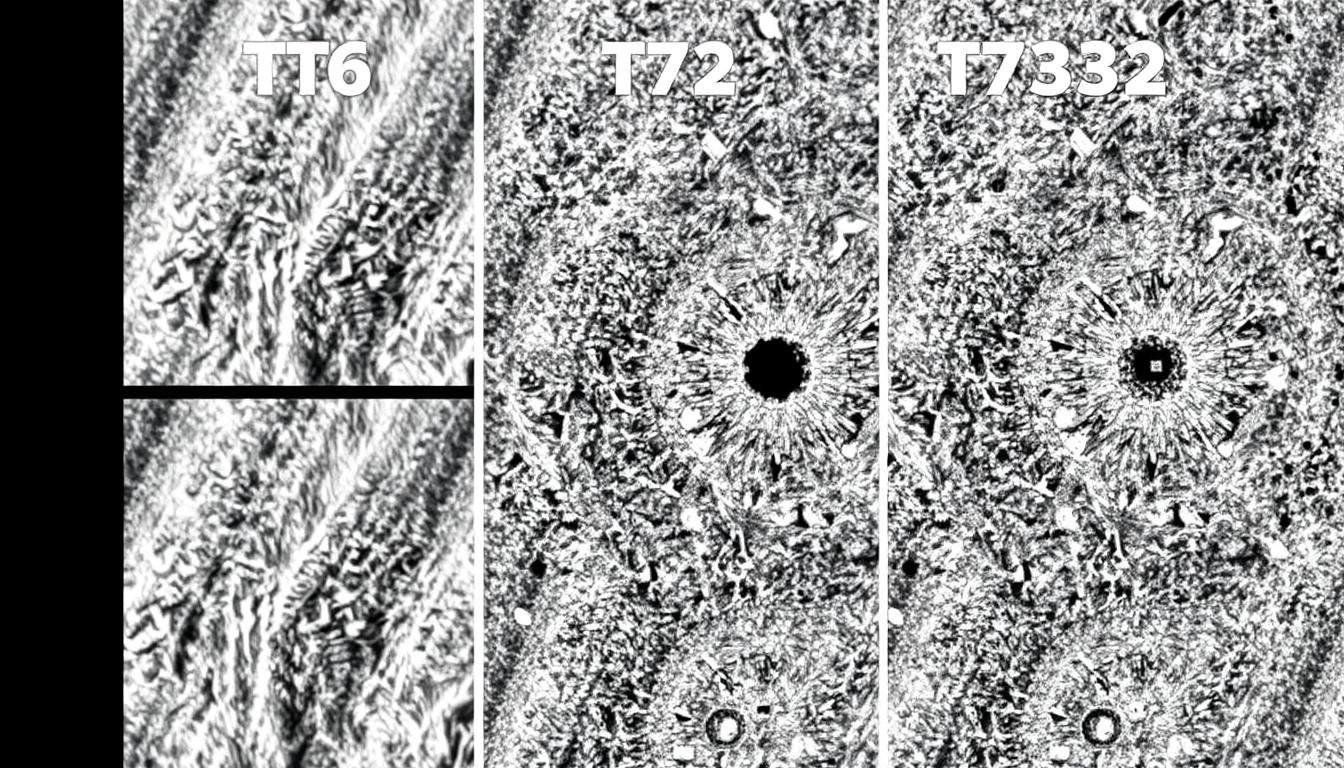

Available Tempers for 7075 Aluminum Forgings

The performance characteristics of 7075 aluminum can be precisely tailored through different heat treatment processes. MAIKONG offers a complete range of temper options to meet your specific application requirements:

7075-T6 Aluminum Forgings

Maximum Strength

Solution heat treated and artificially aged to achieve peak strength properties. Ideal for high-load applications where maximum strength is the primary requirement.

Standards: ASTM B247, AMS 4126, AMS-A-22771

Applications: Landing gear components, structural frames, precision mold bases

7075-T73 Aluminum Forgings

Corrosion Resistance

Overaged treatment that provides excellent stress corrosion cracking resistance with slightly reduced strength compared to T6. Ideal for humid or marine environments.

Standards: ASTM B247, AMS 4131

Applications: Wing joints, missile casings, ship structures, high-speed rail components

7075-T7352 Aluminum Forgings

Balanced Performance

Enhanced version of T73 with additional treatments to improve fracture toughness while maintaining excellent corrosion resistance. Perfect for critical applications requiring balanced properties.

Standards: AMS 4141, AMS 4147

Applications: Aircraft landing gear, offshore platforms, crane arms, mining machinery

Selecting the Right Temper for Your Application

- Need maximum strength? Choose T6 or T652

- Need corrosion resistance? Choose T73 or T7352

- Need balanced strength and corrosion resistance? Choose T74

- Military/Aerospace grade applications? Choose T7452

Not Sure Which Temper Is Right for Your Application?

Our metallurgical experts can help you select the optimal 7075 aluminum temper for your specific requirements.

Contact via WhatsApp

Email Our Team

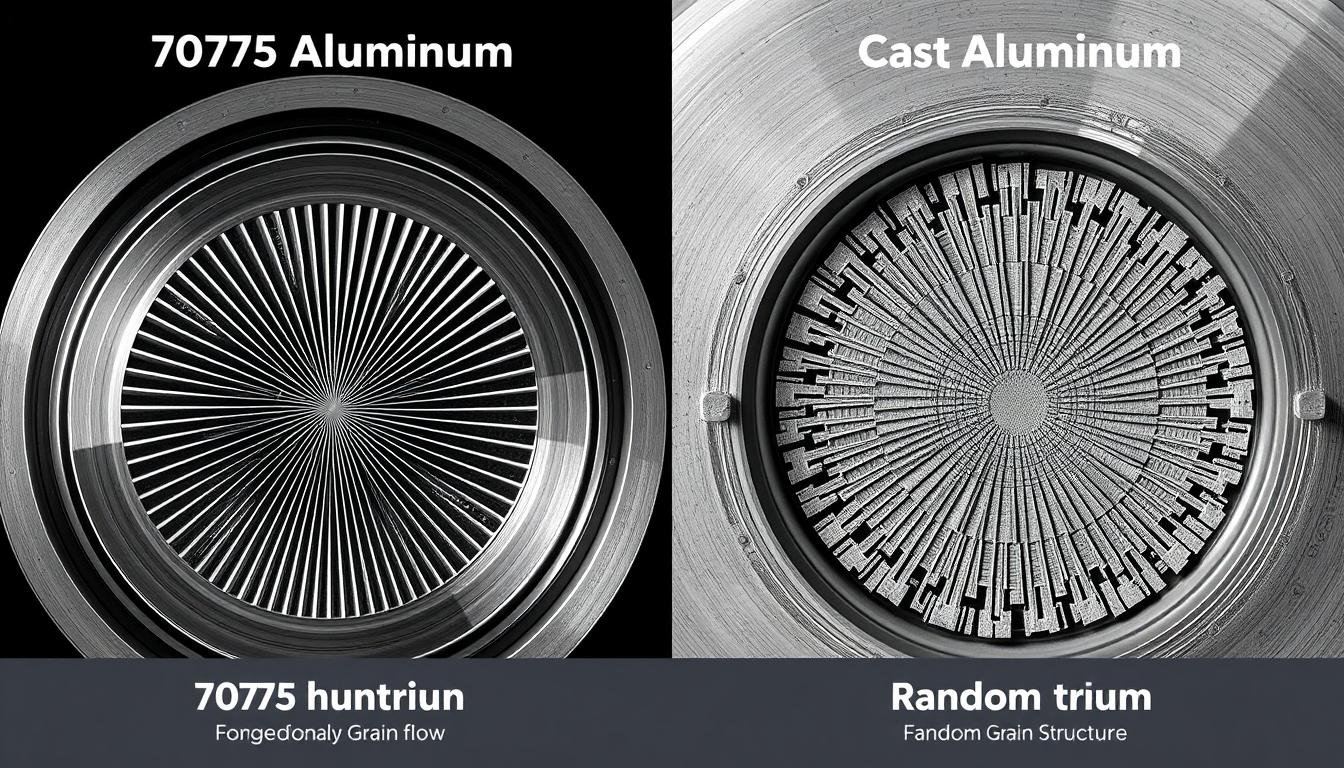

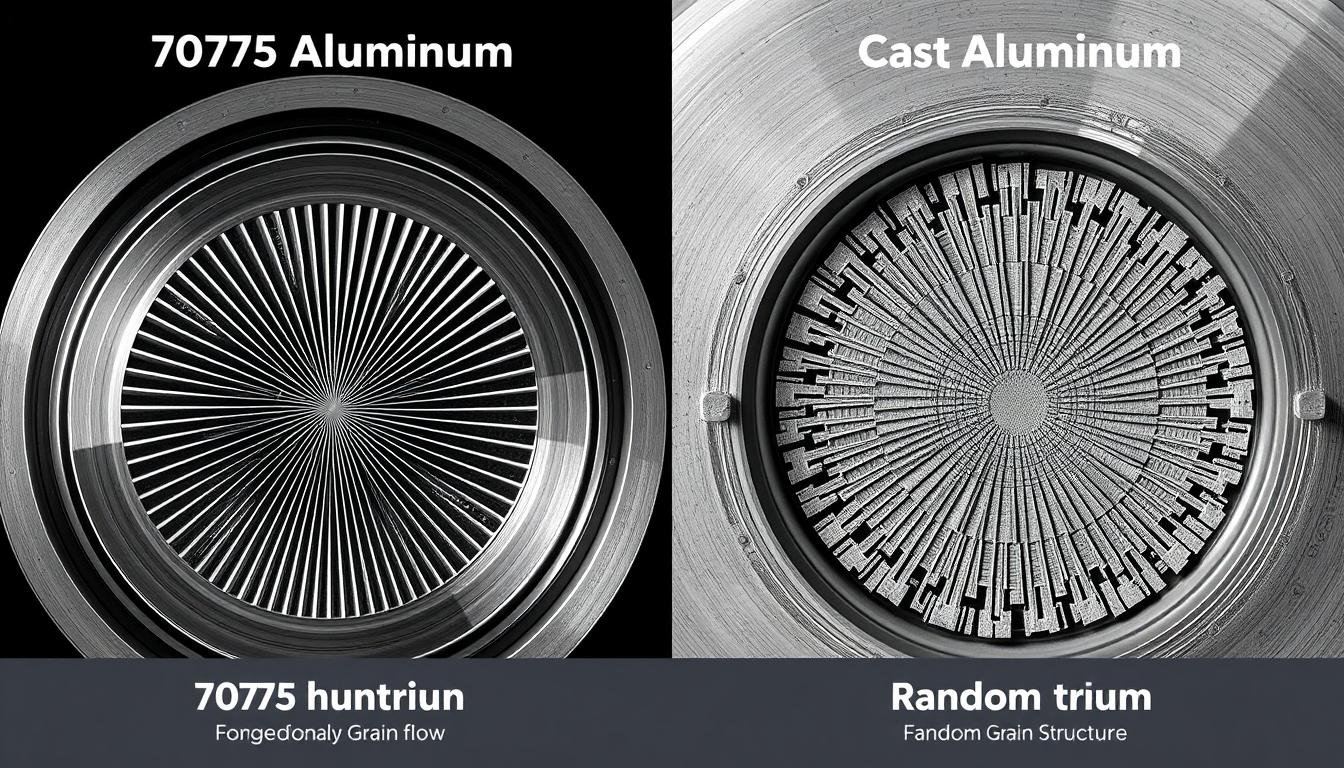

Why Choose Forged 7075 Aluminum Over Cast Aluminum

The forging process fundamentally transforms the mechanical properties of 7075 aluminum, creating components with superior performance characteristics compared to cast alternatives. Understanding these differences is crucial when selecting the optimal manufacturing process for critical applications.

| Comparison Categories |

7075 Aluminum Forgings |

Cast Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

✅ Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

✅ Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Complex Geometries |

Require multiple steps to achieve complex shapes |

✅ Can achieve complex shapes in one session |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

✅ Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

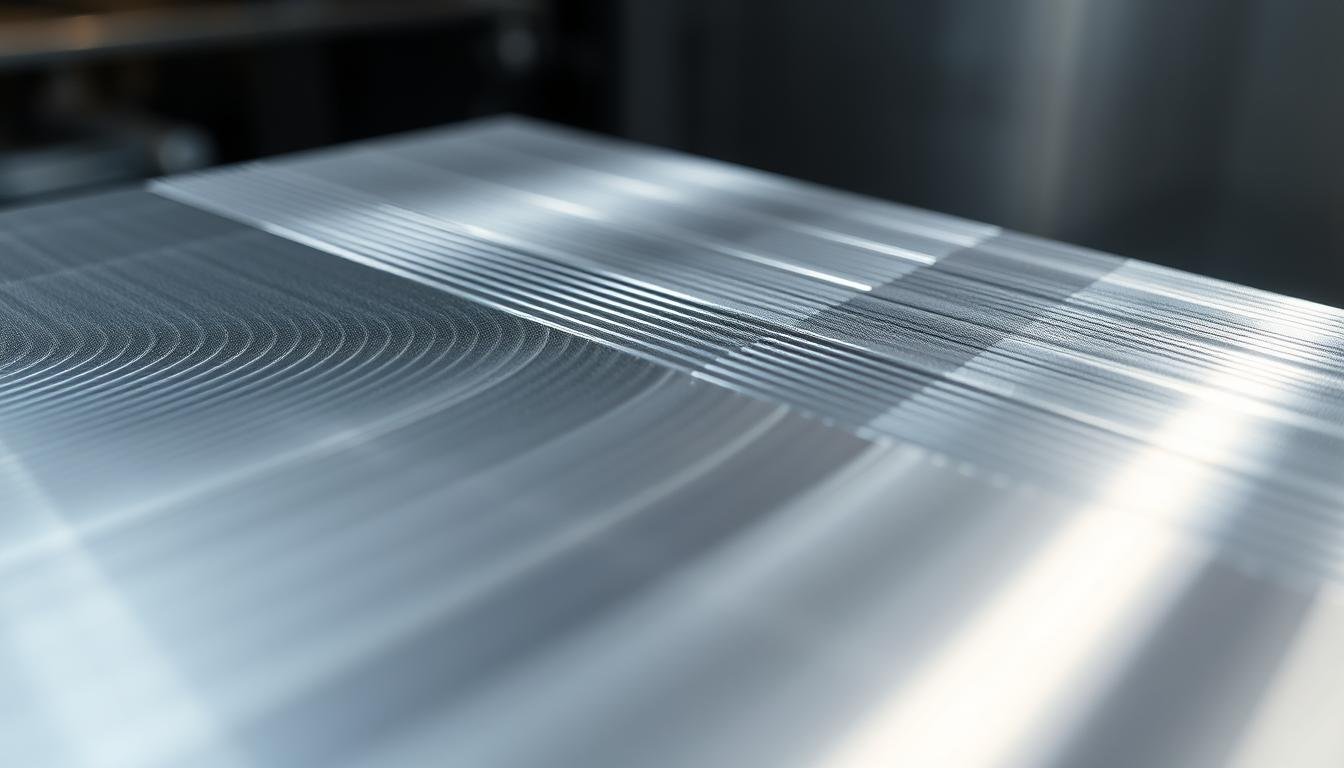

| Grain Structure |

✅ Directional grain flow for improved properties |

No directional grain structure |

| Critical Applications |

✅ Structural members and load-bearing capabilities |

Limited suitability for critical applications |

Optimal Strength-to-Weight Ratio in 7075 Aluminum Forgings

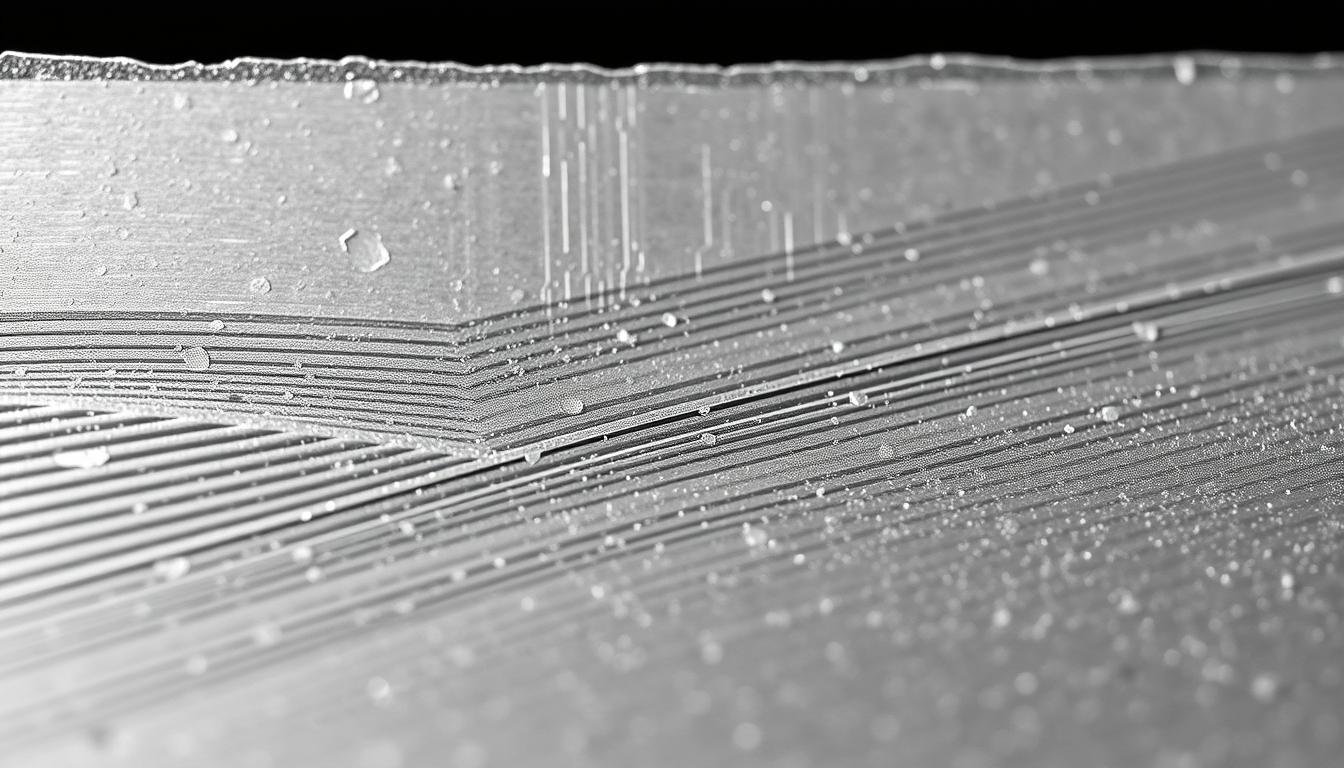

The forging process aligns the grain structure of 7075 aluminum, significantly enhancing its mechanical properties. This directional grain flow creates components with exceptional strength-to-weight ratios that are ideal for applications where both performance and weight savings are critical.

Advantages of 7075 Aluminum Forgings

- Superior strength-to-weight ratio

- Enhanced fatigue resistance

- Improved impact toughness

- Better dimensional stability

- Higher reliability in critical applications

- Consistent mechanical properties

- Excellent machinability for secondary operations

Limitations to Consider

- Higher initial tooling costs

- Geometric complexity limitations

- Minimum order quantities may apply

- Longer lead times for custom tooling

- Higher unit cost for low-volume production

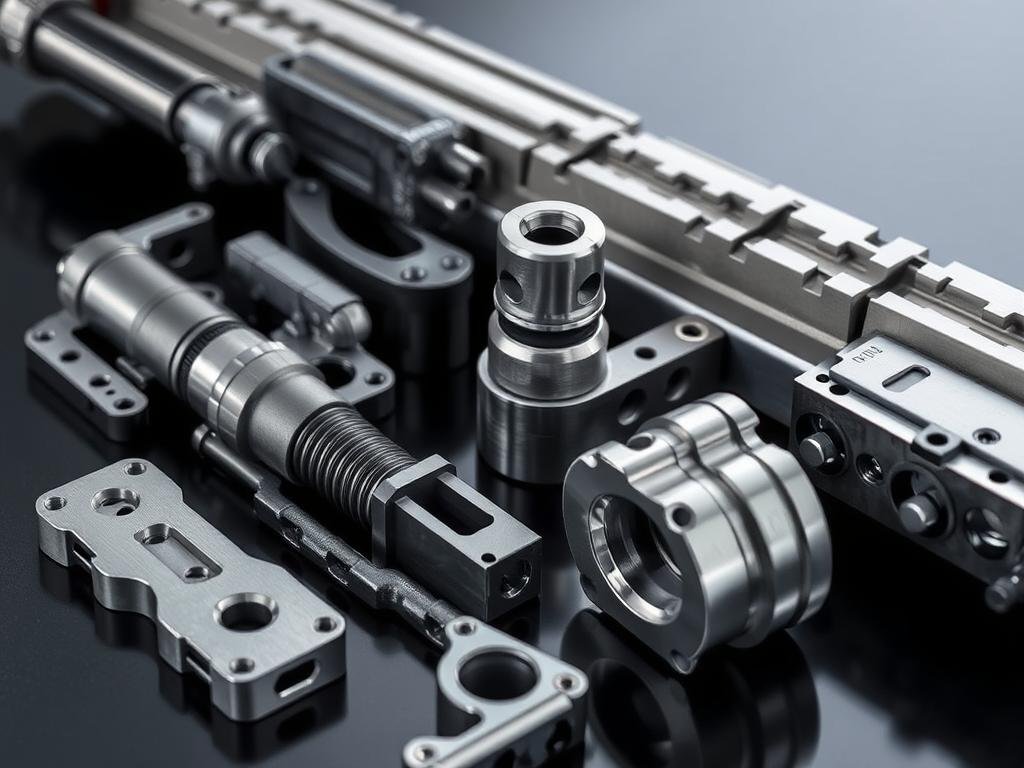

Industry Applications for 7075 Aluminum Forgings

The exceptional mechanical properties of 7075 aluminum forgings make them ideal for a wide range of demanding applications across multiple industries. MAIKONG specializes in producing custom forgings tailored to the specific requirements of these diverse sectors.

Aerospace Applications

- Aircraft structural components

- Landing gear parts

- Wing attachment fittings

- Bulkheads and frames

- Missile components

- Satellite structural elements

Automotive Applications

- High-performance suspension components

- Racing car chassis parts

- Engine mounts and brackets

- Drivetrain components

- Structural reinforcements

- Brake system components

Defense Applications

- Armor components

- Weapon mounting systems

- Tactical equipment parts

- Military vehicle components

- Naval equipment structures

- Communication system housings

Industrial Applications

- High-pressure hydraulic components

- Industrial robot parts

- Precision machinery components

- Heavy equipment structural elements

- Manufacturing tooling and fixtures

- High-stress mechanical components

Marine Applications

- Propulsion system components

- Structural marine fittings

- Offshore platform elements

- High-performance boat parts

- Underwater equipment housings

- Corrosion-resistant marine hardware

Sports & Recreation

- High-performance bicycle components

- Racing equipment parts

- Professional climbing hardware

- Competition-grade sporting equipment

- Motorsport components

- Marine recreational equipment

Custom 7075 Aluminum Forgings for Your Industry

Whatever your application, MAIKONG can deliver custom 7075 aluminum forgings that meet your exact specifications and performance requirements.

Request Application-Specific Quote

MAIKONG’s Manufacturing Capabilities for 7075 Aluminum Forgings

At MAIKONG, we offer comprehensive manufacturing solutions for 7075 aluminum forgings from initial design through final delivery. Our state-of-the-art facility in GD, SZ is equipped with advanced forging equipment and precision machining capabilities to produce components that meet the most demanding specifications.

Our Comprehensive Production Process

- Design & EngineeringOur engineering team works closely with clients to optimize designs for manufacturability, performance, and cost-efficiency using advanced CAD/CAM systems and simulation tools.

- Material Selection & TestingWe source only premium-grade 7075 aluminum alloy that undergoes rigorous testing to ensure chemical composition and mechanical properties meet all applicable standards.

- Precision ForgingOur hydraulic forging presses (ranging from 800 to 3000 tons) create components with optimized grain flow and superior mechanical properties through carefully controlled deformation processes.

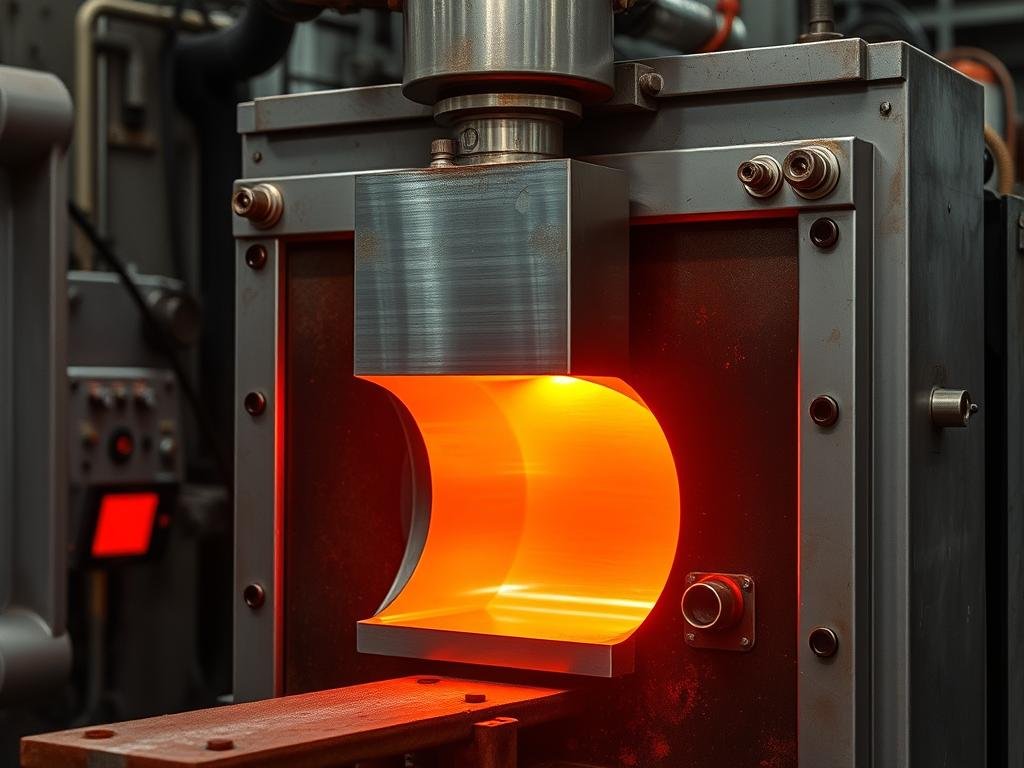

- Heat TreatmentIn-house heat treatment facilities provide precise control over the temper process, ensuring consistent mechanical properties throughout each batch of forgings.

- CNC MachiningAdvanced multi-axis CNC machining centers perform secondary operations with precision tolerances as tight as ±0.005mm for critical dimensions.

- Surface TreatmentWe offer comprehensive surface finishing options including anodizing, painting, powder coating, and various texturing processes to meet aesthetic and functional requirements.

- Quality InspectionEvery component undergoes rigorous inspection using coordinate measuring machines (CMM), ultrasonic testing, and other advanced inspection methods to verify dimensional accuracy and internal integrity.

Production Capabilities for 7075 Aluminum Forgings

| Forging Method |

Product Type |

Maximum Dimensions |

Maximum Weight |

| Open-Die Forging |

Blocks, Plates, Discs |

Length ≤ 2000mm, Width ≤ 1000mm |

≤ 500kg |

| Closed-Die Forging |

Complex Shaped Components |

≤ 800mm in any dimension |

≤ 100kg |

| Ring Rolling |

Seamless Rings, Flanges |

OD ≤ 1500mm, Height ≤ 300mm |

≤ 200kg |

| Precision Forging |

Near-Net Shape Components |

≤ 500mm in any dimension |

≤ 50kg |

Quality Certifications and Standards

MAIKONG maintains rigorous quality management systems to ensure consistent product quality and customer satisfaction:

- ISO 9001:2015 certified quality management system

- Compliance with aerospace standards including AMS 4126, AMS 4131, AMS 4141, and AMS 4147

- ASTM B247 compliance for aluminum alloy forgings

- 100% material traceability and batch certification

- Comprehensive documentation including material certificates, dimensional reports, and testing results

Ready to Start Your 7075 Aluminum Forging Project?

Contact our engineering team today to discuss your specific requirements and receive a customized quotation.

Get a Quote

WhatsApp: +86 13510907401

Why Choose MAIKONG for Your 7075 Aluminum Forgings

Engineering Expertise

Our team of experienced metallurgists and engineers specializes in optimizing designs for manufacturability, performance, and cost-efficiency.

Quality Assurance

Rigorous quality control procedures and advanced inspection equipment ensure every component meets or exceeds specification requirements.

Competitive Pricing

Our efficient manufacturing processes and strategic location in GD, SZ allow us to offer premium quality at competitive prices.

One-Stop Solution

From design to delivery, we handle every aspect of production including forging, heat treatment, machining, and surface finishing.

Global Delivery

Our logistics expertise ensures timely delivery to customers worldwide, with full support for international shipping documentation.

Customer Support

Dedicated account managers provide responsive communication and support throughout your project lifecycle.

MAIKONG is actively seeking distribution partners across the United States for our premium 7075 aluminum forgings. With our combination of quality, competitive pricing, and comprehensive capabilities, we offer an excellent opportunity for distributors serving the aerospace, automotive, defense, and industrial sectors.