2618 aluminum forging represents the pinnacle of high-strength, heat-resistant aluminum manufacturing. This specialized alloy, known for its exceptional mechanical properties at elevated temperatures, has become the material of choice for demanding aerospace, automotive, and high-performance applications. At MAIKONG, we’ve mastered the art and science of producing premium 2618 aluminum forgings that deliver superior strength, durability, and precision for the most challenging environments.

Key Properties of 2618 Aluminum Forging Alloy

The exceptional performance of 2618 aluminum forging stems from its unique chemical composition and mechanical properties. This high-strength alloy contains copper, magnesium, and iron as primary alloying elements, creating a material that maintains structural integrity even at elevated temperatures.

Chemical Composition of 2618 Aluminum

| Element |

Composition (%) |

| Aluminum (Al) |

93.0-95.0 |

| Copper (Cu) |

2.20-2.80 |

| Magnesium (Mg) |

1.50-2.50 |

| Iron (Fe) |

0.90-1.30 |

| Silicon (Si) |

0.50-0.90 |

| Nickel (Ni) |

0.90-1.20 |

| Titanium (Ti) |

0.04-0.10 |

| Zinc (Zn) |

0.20 max |

Mechanical Properties of 2618-T61 Forgings

| Property |

Metric |

Imperial |

| Tensile Strength |

440 MPa |

64,000 psi |

| Yield Strength |

370 MPa |

54,000 psi |

| Elongation |

10% |

10% |

| Density |

2.78 g/cm³ |

0.100 lb/in³ |

| Melting Point |

515-635°C |

960-1175°F |

Distinctive Advantages of 2618 Aluminum Forgings

- Superior High-Temperature Performance – Maintains strength at temperatures up to 250°C, making it ideal for engine components and aerospace applications.

- Excellent Strength-to-Weight Ratio – Provides exceptional structural integrity while keeping weight to a minimum, critical for fuel efficiency.

- Enhanced Fatigue Resistance – Withstands repeated loading and unloading cycles without premature failure.

- Good Machinability – Can be precisely machined to tight tolerances despite its high strength.

- Thermal Conductivity – Offers excellent heat dissipation properties (127 W/mK), ideal for components exposed to high temperatures.

- Corrosion Resistance – Provides good resistance to atmospheric corrosion when properly treated.

- Dimensional Stability – Maintains critical dimensions even under thermal stress.

- Improved Grain Structure – The forging process aligns the grain structure for enhanced mechanical properties.

Need Technical Specifications for Your Project?

Our engineering team can provide detailed material data sheets and consultation for your specific application requirements.

Request Technical Consultation

MAIKONG’s 2618 Aluminum Forging Process

At MAIKONG, we’ve perfected the 2618 aluminum forging process to deliver components with exceptional mechanical properties and precise dimensions. Our comprehensive manufacturing approach ensures superior quality from raw material selection through final inspection.

Our Comprehensive Forging Methodology

Material Selection

We source premium-grade 2618 aluminum billets with verified chemical composition to ensure consistent quality in every forging.

Precision Die Design

Our engineering team utilizes advanced CAD/CAM software to design optimal forging dies that maximize material flow and structural integrity.

Controlled Heating

Precise temperature control during preheating ensures optimal material plasticity for the forging process.

Hydraulic Forging

State-of-the-art hydraulic presses (up to 2500 tons) apply controlled pressure to form complex geometries while maintaining grain structure.

Heat Treatment

Specialized T6/T61 heat treatment processes optimize the mechanical properties of 2618 aluminum forgings for specific applications.

Precision Machining

Advanced CNC machining centers provide tight-tolerance finishing operations for complex components.

Forging Specifications and Capabilities

| Forging Type |

Maximum Weight |

Maximum Dimensions |

| Open Die Forging – Cube |

≤9T |

Length≤7000mm, Width≤2000mm, Height≤500mm |

| Open Die Forging – Disk |

≤5T |

Diameter≤2500mm |

| Open Die Forging – Ring |

≤5T |

Outer diameter≤2500mm, Height≤500mm |

| Closed Die Forging |

– |

PVA≤3.0㎡ (Diameter≤1950mm) |

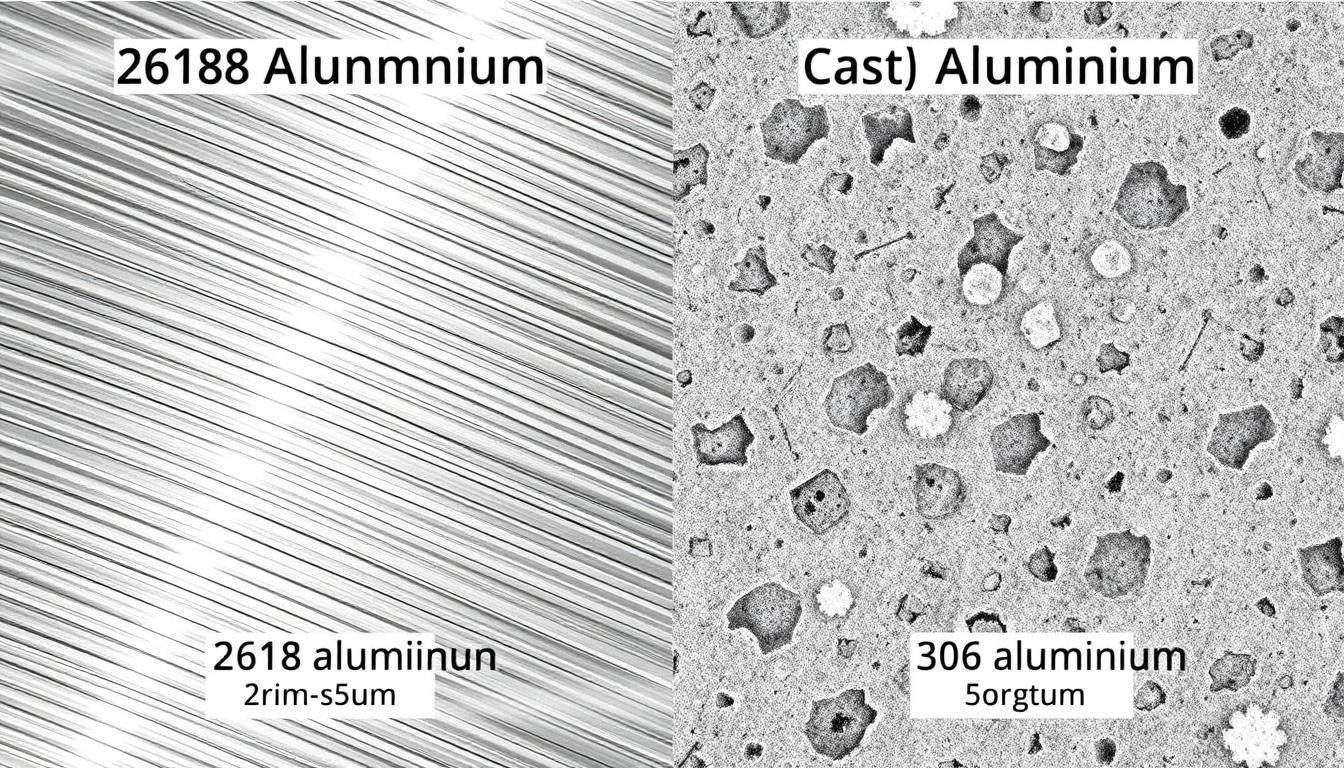

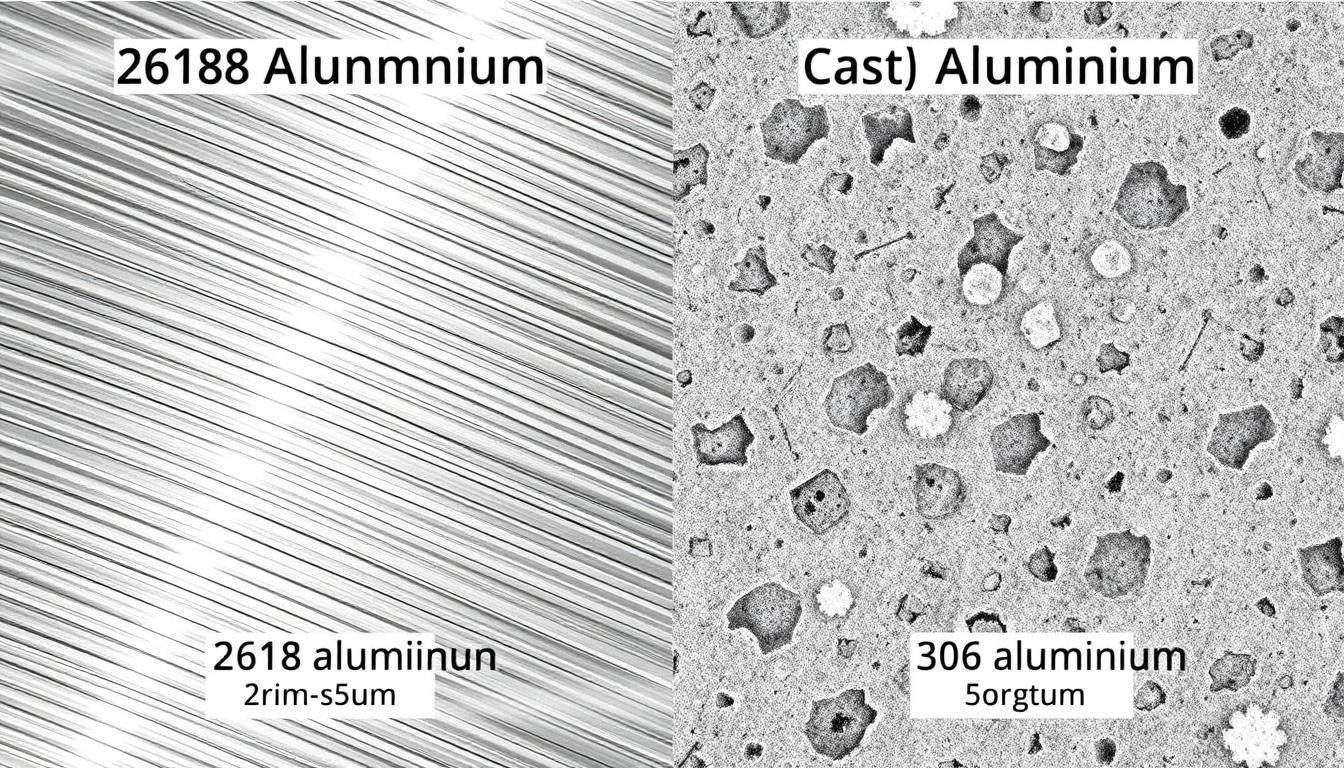

2618 Aluminum Forging vs. Casting: A Comprehensive Comparison

When considering manufacturing methods for aluminum components, understanding the differences between 2618 aluminum forging and casting is crucial for selecting the optimal process for your application.

| Comparison Criteria |

2618 Aluminum Forging |

Cast Aluminum |

| Strength and Durability |

Superior strength due to dense, uniform grain structure |

Lower strength due to potential porosity and inclusions |

| Tensile Properties |

Excellent tensile strength (440 MPa) and yield strength (370 MPa) |

Typically 20-30% lower tensile properties |

| Fatigue Resistance |

Enhanced resistance to cyclic loading and fatigue failure |

More susceptible to fatigue cracking |

| Grain Structure |

Directional grain flow for improved mechanical properties |

Random grain structure without directional strengthening |

| Complex Geometries |

May require additional machining for complex shapes |

Can achieve complex geometries in a single operation |

| Dimensional Accuracy |

Excellent dimensional stability and tighter tolerances |

Potential for dimensional inconsistencies |

| High-Temperature Performance |

Maintains properties at temperatures up to 250°C |

Significant property degradation at elevated temperatures |

Considering Aluminum Manufacturing Options?

Let our experts help you determine whether 2618 aluminum forging is the optimal solution for your specific application requirements.

Discuss Your Project on WhatsApp

Key Applications for 2618 Aluminum Forgings

The exceptional properties of 2618 aluminum forging make it the material of choice for demanding applications across multiple industries. At MAIKONG, we specialize in producing high-performance forgings for these critical applications.

Aerospace Applications

- Aircraft engine components

- Structural fuselage elements

- Wing skin frameworks

- Supersonic aircraft components

- Landing gear components

Automotive Applications

- High-performance pistons

- Racing engine components

- Connecting rods

- Suspension components

- Drivetrain components

Industrial Applications

- High-temperature industrial equipment

- Pressure vessels

- Structural components

- Military equipment

- Precision machinery parts

Why Choose 2618 Aluminum for Critical Applications

Advantages of 2618 Aluminum

- Exceptional high-temperature strength retention

- Superior fatigue resistance for cyclic loading

- Excellent thermal conductivity (127 W/mK)

- Good corrosion resistance with proper treatment

- Excellent machinability for precision components

- Optimal strength-to-weight ratio

Considerations

- Higher material cost than standard aluminum alloys

- Requires precise heat treatment for optimal properties

- More complex forging process than standard alloys

- May require additional machining for complex geometries

- Special handling needed during manufacturing

Need 2618 Aluminum Forgings for Your Industry?

Our engineering team specializes in developing custom solutions for demanding applications across aerospace, automotive, and industrial sectors.

Explore Our Aluminum Forging Services

MAIKONG’s Manufacturing Capabilities for 2618 Aluminum Forgings

At MAIKONG, we’ve developed comprehensive manufacturing capabilities to deliver premium 2618 aluminum forging solutions that meet the most demanding specifications. Our integrated approach ensures quality at every stage of production.

Our Comprehensive Manufacturing Process

Engineering & Design

Our engineering team utilizes advanced CAD/CAM software to optimize forging designs for manufacturability and performance. We conduct detailed FEA (Finite Element Analysis) to predict material behavior during forging.

Material Sourcing

We source premium 2618 aluminum from certified suppliers with full traceability. Each batch undergoes comprehensive chemical analysis to verify composition before entering production.

Tooling Development

Our in-house tooling specialists design and manufacture precision forging dies optimized for 2618 aluminum’s specific flow characteristics, ensuring consistent quality.

Forging Operations

Our forging workshop features hydraulic presses ranging from 800 to 2500 tons, capable of producing components from small precision parts to large structural elements.

Heat Treatment

We perform specialized T6/T61 heat treatment processes in-house with precise temperature control and comprehensive documentation to ensure optimal mechanical properties.

CNC Machining

Our advanced CNC machining centers provide precision finishing operations with tolerances as tight as ±0.005mm for complex components.

Quality Assurance for 2618 Aluminum Forgings

- Material Certification – Full chemical and mechanical property verification for all incoming material

- In-Process Inspection – Critical checkpoints throughout the manufacturing process

- Dimensional Verification – Coordinate Measuring Machine (CMM) inspection for critical dimensions

- Mechanical Testing – Tensile, hardness, and impact testing to verify material properties

- Non-Destructive Testing – Ultrasonic, dye penetrant, and other NDT methods as required

- Heat Treatment Verification – Comprehensive documentation and testing of heat treatment processes

- ISO 9001:2015 Certification – All processes conform to international quality standards

Advancing Performance Through Superior 2618 Aluminum Forgings

The exceptional properties of 2618 aluminum forging make it an invaluable material for applications where performance cannot be compromised. At MAIKONG, we combine technical expertise, advanced manufacturing capabilities, and rigorous quality control to deliver forgings that meet the most demanding specifications.

Whether you’re designing aerospace components, high-performance automotive parts, or industrial equipment, our team is ready to provide the premium 2618 aluminum forgings your application demands. Contact us today to discuss your project requirements and discover how MAIKONG can deliver the quality, precision, and reliability you need.