2024 aluminum alloy forgings represent one of the most versatile and high-performance materials in modern manufacturing. With exceptional strength-to-weight ratios and superior mechanical properties, these forgings have become indispensable across aerospace, automotive, and precision engineering applications. At MAIKONG, we specialize in delivering premium-quality 2024 aluminum alloy forgings with comprehensive manufacturing capabilities that ensure optimal performance, reliability, and cost-effectiveness for your most demanding projects.

Essential Properties of 2024 Aluminum Alloy Forgings

2024 aluminum alloy forgings feature copper as their primary alloying element, typically containing 3.8-4.9% copper along with smaller amounts of magnesium and manganese. This composition creates a material with exceptional mechanical properties that can be further enhanced through proper heat treatment.

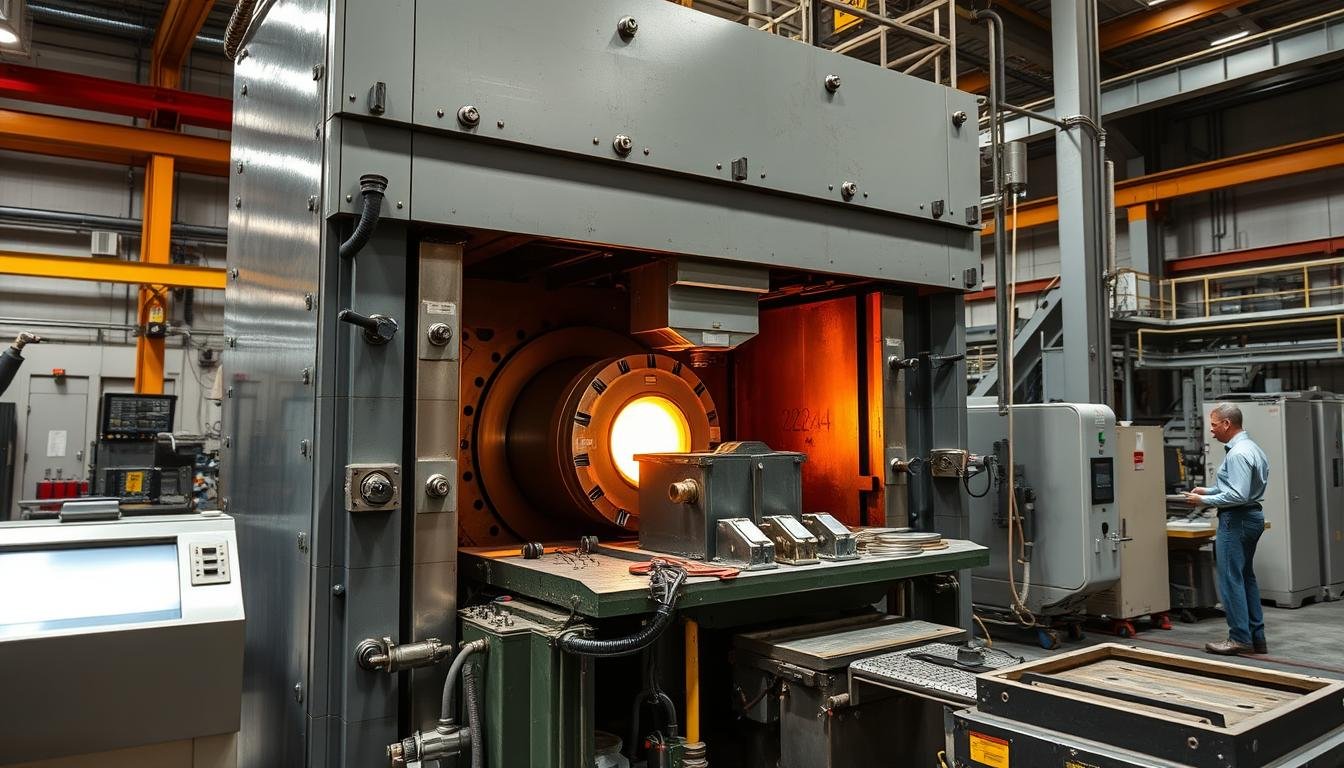

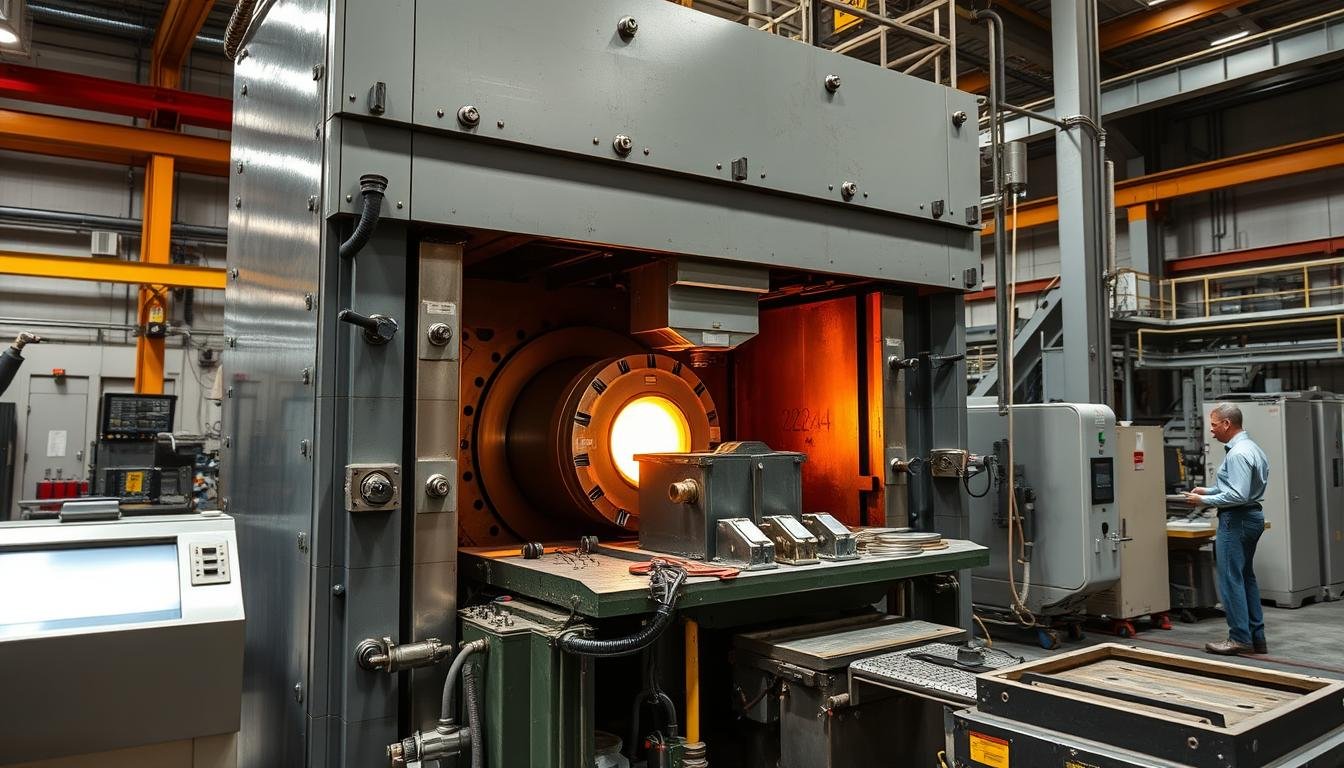

MAIKONG’s state-of-the-art facility specializing in 2024 aluminum alloy forgings

Key Mechanical Properties of 2024 Aluminum Alloy

| Property |

Value |

Condition |

| Density |

2.77 g/cm³ |

25°C |

| Tensile Strength |

470 MPa (68,000 psi) |

T3 Temper |

| Yield Strength |

325 MPa (47,000 psi) |

T3 Temper |

| Elongation |

15% |

T3 Temper |

| Elastic Modulus |

73 GPa (10.6 × 10⁶ psi) |

25°C |

| Fatigue Strength |

140 MPa (20,000 psi) |

5 × 10⁸ cycles |

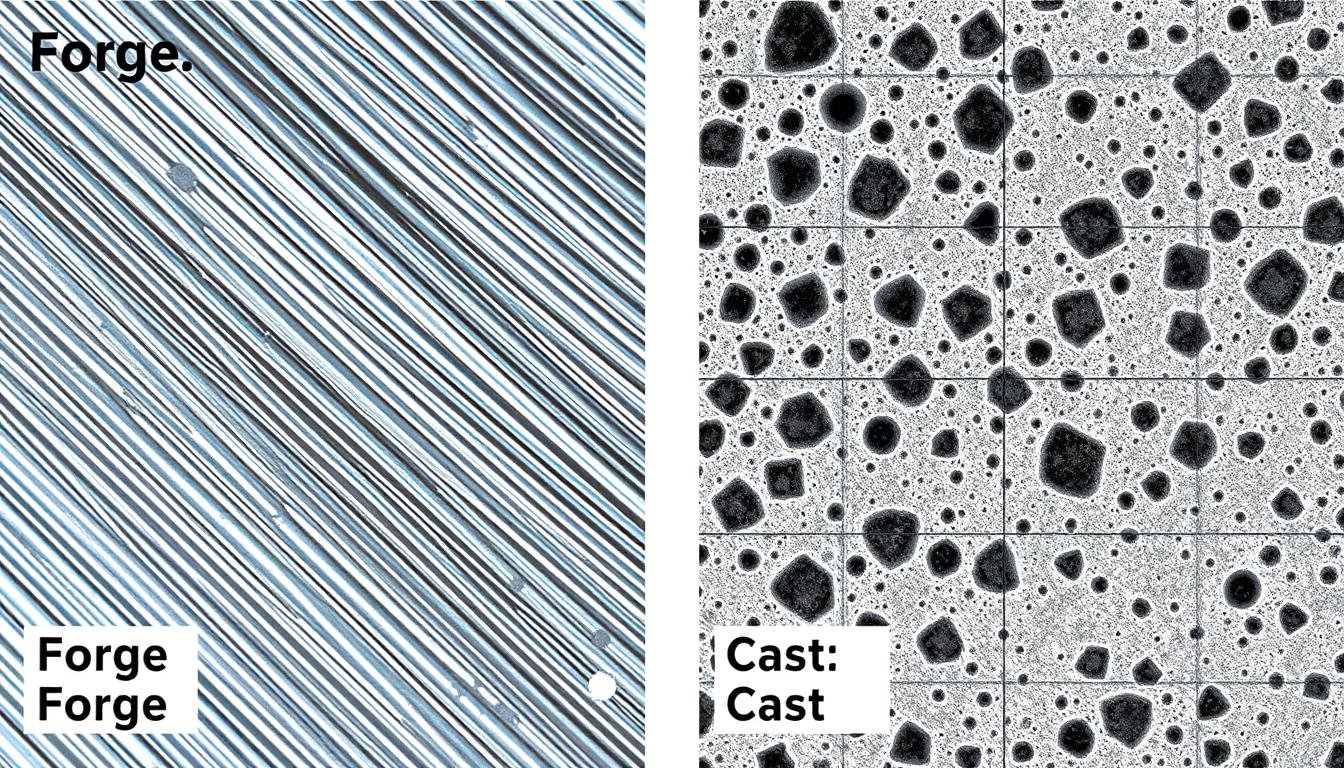

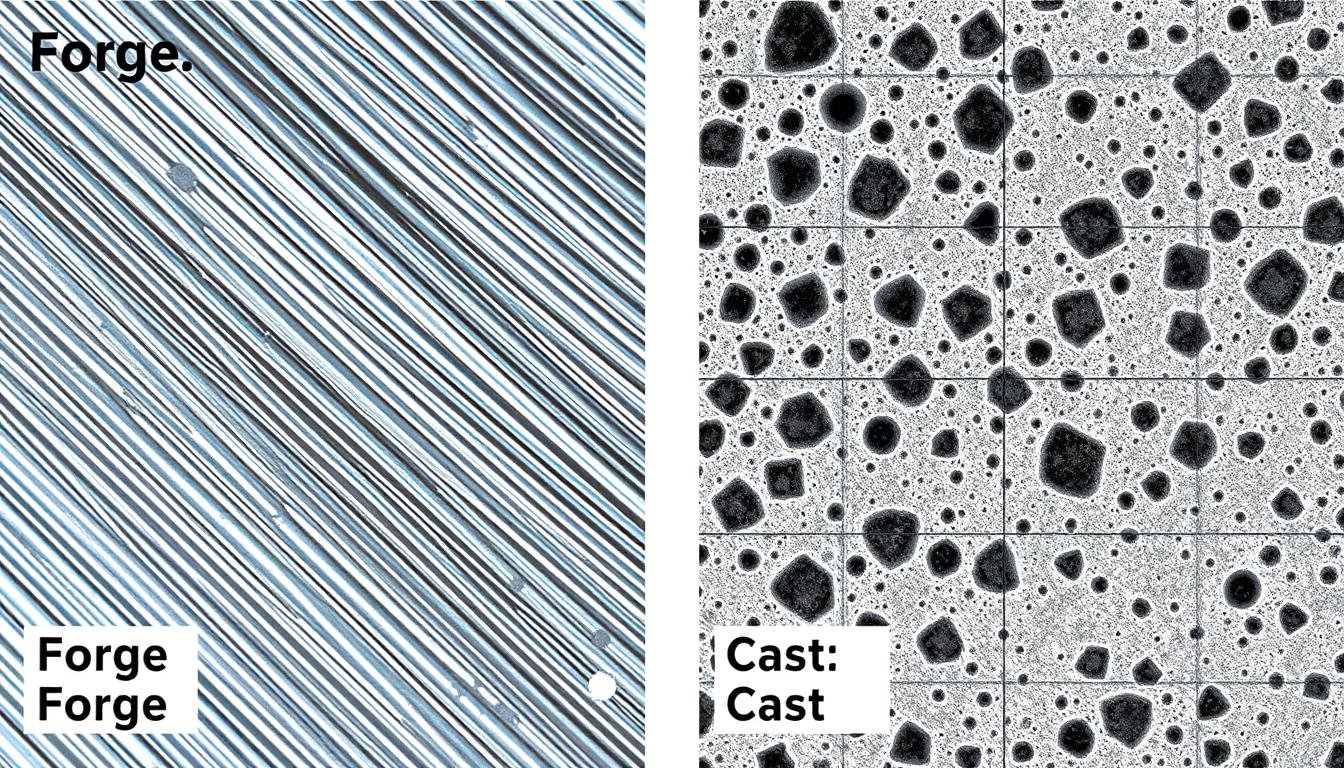

The exceptional mechanical properties of 2024 aluminum alloy forgings make them ideal for applications requiring high strength-to-weight ratios. The forging process further enhances these properties by aligning the grain structure and eliminating porosity, resulting in components with superior fatigue resistance and toughness compared to cast or machined parts.

Need Technical Specifications?

Our engineering team can provide detailed material data sheets and performance specifications for your specific application requirements.

Contact Our Engineers

MAIKONG’s Advanced Manufacturing Process for 2024 Aluminum Forgings

At MAIKONG, we’ve developed a comprehensive manufacturing process that ensures the highest quality 2024 aluminum alloy forgings with consistent mechanical properties and precise dimensional accuracy. Our integrated approach combines advanced design capabilities, precision forging techniques, and comprehensive quality control.

MAIKONG’s hydraulic forging press forming precision 2024 aluminum alloy forgings

Our Comprehensive Manufacturing Capabilities

Design & Engineering

Our engineering team utilizes advanced CAD/CAM systems to optimize part design for manufacturability, performance, and cost-effectiveness. We conduct finite element analysis (FEA) to simulate forging processes and predict material behavior.

Precision Forging

With over 60 CNC machines and 100+ tons of monthly processing capacity, we produce 2024 aluminum alloy forgings with exceptional dimensional accuracy and superior grain structure alignment for maximum strength.

Heat Treatment

Our in-house heat treatment facilities ensure precise control over material properties. For 2024 aluminum, we typically apply T3 or T4 tempers to achieve optimal strength, hardness, and corrosion resistance.

CNC Machining

Our advanced CNC turning, milling, and Swiss-type machining capabilities allow us to transform raw forgings into precision-finished components with complex geometries and tight tolerances.

Surface Treatments

We offer comprehensive surface finishing options including anodizing, painting, and laser engraving to enhance corrosion resistance, appearance, and functional properties of 2024 aluminum alloy forgings.

Quality Assurance

Our ISO 9001:2015 certified quality management system includes comprehensive testing for dimensional accuracy, mechanical properties, and material integrity using advanced inspection equipment.

Rigorous quality inspection ensures every 2024 aluminum alloy forging meets precise specifications

Ready to Start Your Project?

Our manufacturing experts are ready to discuss your 2024 aluminum alloy forgings requirements and provide a competitive quote.

Get A Quick Quote

Advantages of 2024 Aluminum Alloy Forgings vs. Casting

When comparing manufacturing methods for aluminum components, forging offers significant advantages over casting, particularly for applications requiring high strength, reliability, and consistent performance. Understanding these differences is crucial when selecting the optimal manufacturing process for your aluminum components.

Microstructure comparison: Forged 2024 aluminum (left) shows aligned grain structure vs. cast aluminum (right)

| Property |

2024 Aluminum Alloy Forgings |

Cast Aluminum |

Advantage |

| Mechanical Strength |

Superior strength due to dense, aligned grain structure |

Lower strength with potential porosity issues |

Forging |

| Fatigue Resistance |

Excellent resistance to cyclic loading |

Reduced fatigue life due to internal defects |

Forging |

| Dimensional Accuracy |

High precision with proper tooling |

Good for complex shapes but with potential shrinkage |

Forging |

| Material Integrity |

Consistent properties throughout |

Potential for inclusions and porosity |

Forging |

| Complex Geometries |

Limited by die design and forging process |

Excellent for intricate shapes |

Casting |

| Production Volume |

Economical for medium to high volumes |

Suitable for low to high volumes |

Depends on application |

Why Choose MAIKONG for Your 2024 Aluminum Alloy Forgings

MAIKONG Advantages

- Comprehensive manufacturing capabilities from design to finished product

- 60+ CNC machines with 100+ tons monthly processing capacity

- ISO 9001:2015 certified quality management system

- Advanced testing facilities for material verification

- Competitive pricing with excellent price-performance ratio

- Fast turnaround times and reliable delivery schedules

- Experienced engineering team for technical support

MAIKONG’s advanced CNC machining center processing 2024 aluminum alloy forgings

Applications of 2024 Aluminum Alloy Forgings

2024 aluminum alloy forgings find applications across numerous industries where high strength, excellent fatigue resistance, and good machinability are essential. At MAIKONG, we produce precision forgings for diverse applications, leveraging our comprehensive manufacturing capabilities to meet specific industry requirements.

Diverse industrial applications of 2024 aluminum alloy forgings manufactured by MAIKONG

Aerospace

- Aircraft structural components

- Landing gear components

- Bulkheads and fittings

- Engine mounts and brackets

Automotive

- Suspension components

- Chassis parts

- Drivetrain components

- Performance vehicle parts

Industrial Equipment

- High-stress mechanical components

- Hydraulic system parts

- Precision machinery components

- Tooling and fixtures

Custom 2024 Aluminum Alloy Forging Solutions

At MAIKONG, we specialize in developing custom 2024 aluminum alloy forgings tailored to your specific application requirements. Our engineering team works closely with clients to understand performance needs, operating environments, and cost considerations to deliver optimized solutions.

Custom-engineered 2024 aluminum alloy forgings designed for specific client applications

MAIKONG Quality Rating

4.9

Based on client feedback

Price Competitiveness

4.7

Become a US Distributor

MAIKONG is actively seeking US distributors and agents for our premium 2024 aluminum alloy forgings and other metal components. Join our growing network of partners.

Partner With Us

Technical Specifications for 2024 Aluminum Alloy Forgings

MAIKONG produces 2024 aluminum alloy forgings in accordance with international standards and specifications. Our manufacturing processes ensure consistent material properties and dimensional accuracy across all production runs.

Chemical Composition of 2024 Aluminum Alloy

| Element |

Percentage Range |

| Aluminum (Al) |

90.7-94.7% (Remainder) |

| Copper (Cu) |

3.8-4.9% |

| Magnesium (Mg) |

1.2-1.8% |

| Manganese (Mn) |

0.3-0.9% |

| Silicon (Si) |

0.5% max |

| Iron (Fe) |

0.5% max |

| Zinc (Zn) |

0.25% max |

| Titanium (Ti) |

0.15% max |

| Chromium (Cr) |

0.1% max |

Available Tempers for 2024 Aluminum Alloy Forgings

Standard Tempers

- O – Annealed, soft condition

- T3 – Solution heat treated, cold worked, naturally aged

- T4 – Solution heat treated, naturally aged

- T6 – Solution heat treated, artificially aged

- T8 – Solution heat treated, cold worked, artificially aged

Forging Capabilities

- Flat bar blocks: up to 27″ width

- Cylinders and sleeves: up to 50″ maximum O.D.

- Discs and hubs: up to 50″ diameter

- Rolled or hand forged rings: up to 84″ maximum O.D.

- Rounds and shafts: up to 144″ maximum length

Various forms of 2024 aluminum alloy forgings manufactured by MAIKONG

Quality Assurance for 2024 Aluminum Alloy Forgings

At MAIKONG, we implement comprehensive quality control procedures to ensure our 2024 aluminum alloy forgings meet or exceed industry standards. Our testing capabilities include:

Mechanical Testing

- Tensile strength testing

- Yield strength verification

- Elongation measurement

- Hardness testing

- Impact testing

Non-Destructive Testing

- Ultrasonic inspection

- Penetrant testing

- Visual inspection

- Dimensional verification

- Chemical composition analysis

Comprehensive quality testing of 2024 aluminum alloy forgings at MAIKONG’s laboratory

Request Custom Specifications

Need 2024 aluminum alloy forgings with specific requirements? Our engineering team can develop custom solutions tailored to your exact specifications.

Request Custom Quote

Why Choose MAIKONG for Your 2024 Aluminum Alloy Forgings

MAIKONG combines advanced manufacturing capabilities, technical expertise, and competitive pricing to deliver premium-quality 2024 aluminum alloy forgings for demanding applications. With our comprehensive services from design to finished product, we provide a one-stop solution for all your aluminum forging needs.

Our commitment to quality, reliability, and customer satisfaction has made us a trusted partner for clients worldwide. Whether you need standard components or custom-engineered solutions, MAIKONG has the capabilities and experience to meet your requirements.

Contact us today to discuss your 2024 aluminum alloy forgings project and discover how MAIKONG can help you achieve superior results with competitive pricing and reliable delivery.

Precision-finished 2024 aluminum alloy forgings ready for shipment to clients worldwide