Forged Aluminum 6061 Wheel Manufacturing: The MAIKONG Advantage

December 4, 2025

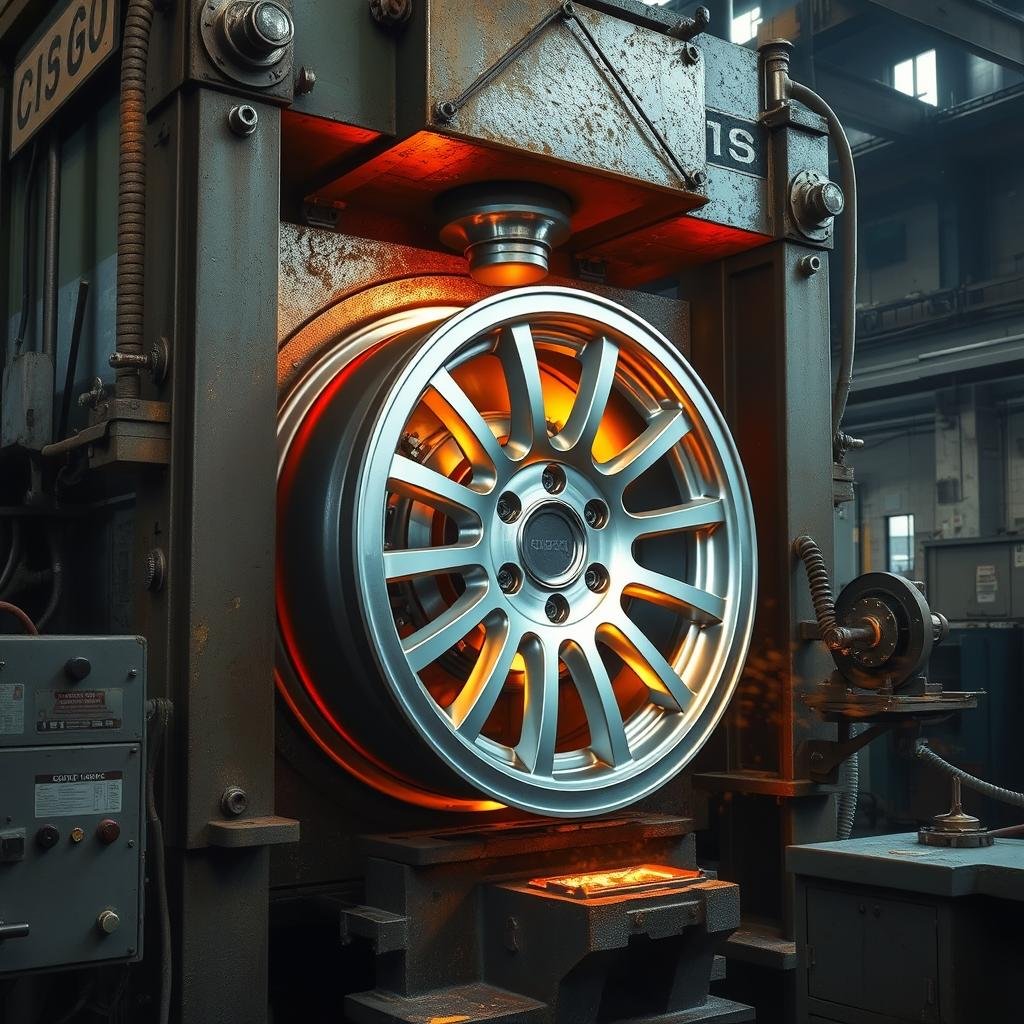

MAIKONG’s state-of-the-art forged aluminum 6061 wheel manufacturing facility in GD, SZ

MAIKONG’s state-of-the-art forged aluminum 6061 wheel manufacturing facility in GD, SZ

The Superior Benefits of Forged Aluminum 6061 Wheel Technology

The choice of material and manufacturing process for wheels significantly impacts vehicle performance, safety, and aesthetics. Forged aluminum 6061 wheels represent the premium choice for discerning customers who demand excellence without compromise.

Why Choose Forged Aluminum 6061 for Wheels?

- Exceptional strength-to-weight ratio – up to 30% lighter than cast alternatives

- Superior tensile strength (45,000 PSI) and yield strength (40,000 PSI)

- Enhanced fatigue resistance for longer service life

- Improved vehicle handling and acceleration due to reduced unsprung weight

- Better fuel efficiency through weight reduction

- Increased heat dissipation for improved brake performance

- Greater impact resistance against road hazards

- Precision manufacturing for perfect balance and fitment

Ready to Upgrade Your Wheel Performance?

Discover how MAIKONG’s forged aluminum 6061 wheels can transform your vehicle’s performance and appearance.

Forged Aluminum 6061 Wheel vs. Cast Aluminum: The Critical Differences

Understanding the fundamental differences between forging and casting processes is essential when selecting the right wheels for your application. The table below highlights why forged aluminum 6061 wheels consistently outperform cast alternatives in critical performance categories.

| Comparison Categories | Forged Aluminum 6061 Wheel | Cast Aluminum Wheel |

| Strength and Durability | ✅ Higher due to dense, uniform grain structure | Potentially lower due to air pockets and inclusions |

| Tensile Properties | ✅ Superior tensile strength and resistance | Lower tensile strength |

| Fatigue Resistance | ✅ Better resistance against fatigue failure | Potentially lower fatigue resistance |

| Dimensional Accuracy | ✅ Better accuracy and tighter tolerances | Potential inconsistencies |

| Surface Finish | ✅ Smoother surfaces, reduced post-processing | Might require more machining due to air pockets |

| Heat Treatment Response | ✅ Responsive for controlled material properties | Less predictable response |

| Weight-to-Strength Ratio | ✅ High strength-to-weight ratio | Bulkier parts may be needed for equivalent strength |

| Critical Applications | ✅ Ideal for structural members and load-bearing | Limited suitability for critical applications |

Cross-section comparison: Note the dense, uniform grain structure of forged aluminum 6061 wheel (left) versus the potential porosity in cast wheel (right)

MAIKONG’s Advanced Forged Aluminum 6061 Wheel Manufacturing Process

At MAIKONG, we’ve refined our manufacturing process to create the highest quality forged aluminum 6061 wheels available. Our comprehensive approach ensures superior performance, consistency, and reliability in every wheel we produce.

1. Design & Engineering

Our process begins with advanced CAD/CAM design, where our engineers create precision wheel specifications tailored to your exact requirements. We utilize finite element analysis to optimize strength, weight, and performance characteristics.

2. Material Selection

We source only premium 6061-T6 aluminum alloy, known for its excellent combination of strength, corrosion resistance, and machinability. Each billet is tested for composition and quality before entering production.

3. Tooling Development

Our proprietary tooling is designed for optimal grain flow and material distribution. We maintain rigorous tooling standards to ensure consistency across production runs and minimize variation.

4. Forging Process

Using hydraulic presses with up to 10,000 tons of force, we compress the aluminum billet, aligning the grain structure for maximum strength. This multi-stage process creates a dense, uniform material structure superior to cast alternatives.

5. Heat Treatment

Our precision-controlled heat treatment process optimizes the mechanical properties of the 6061 aluminum alloy, ensuring the perfect balance of strength, hardness, and ductility for automotive applications.

6. CNC Machining

Using state-of-the-art 5-axis CNC machines, we precisely shape each wheel to exact specifications. This process ensures perfect balance, accurate dimensions, and the desired aesthetic design features.

7. Surface Treatment

We offer various finishing options including anodizing, powder coating, and polishing to enhance both aesthetics and durability. Our surface treatments provide superior corrosion resistance and visual appeal.

8. Quality Control

Every wheel undergoes rigorous testing including dimensional verification, material analysis, and load testing to ensure it meets our exacting standards and your specific requirements.

9. Packaging & Shipping

We utilize specialized packaging designed to protect your wheels during transit. Our logistics team ensures timely delivery to your facility anywhere in the world.

Interested in Our Manufacturing Process?

Contact our engineering team to discuss your specific forged aluminum 6061 wheel requirements and discover how our manufacturing expertise can benefit your project.

Applications for MAIKONG Forged Aluminum 6061 Wheels

Our premium forged aluminum 6061 wheels are designed to excel in a wide range of applications where performance, weight reduction, and reliability are critical factors.

Automotive Applications

- High-performance sports cars and supercars

- Luxury vehicles requiring premium aesthetics

- Racing applications (track, drift, drag)

- Off-road and rally vehicles

- Custom automotive builds and restorations

- OEM replacement and upgrade programs

Motorsport Applications

- Formula and open-wheel racing

- Endurance racing where reliability is paramount

- Time attack and circuit racing

- Drift competition vehicles

- Rally and off-road racing

- Motorcycle racing and high-performance applications

Custom Applications

Beyond standard applications, MAIKONG specializes in developing custom forged aluminum 6061 wheel solutions for unique requirements. Our engineering team works closely with clients to design and manufacture wheels for specialized vehicles, prototype development, and other custom applications where off-the-shelf options won’t suffice.

Custom-engineered forged aluminum 6061 wheels designed for specialized applications

Need Custom Wheel Solutions?

Our engineering team specializes in developing custom forged aluminum 6061 wheel solutions tailored to your exact specifications and performance requirements.

Technical Specifications: MAIKONG Forged Aluminum 6061 Wheel Capabilities

Our manufacturing capabilities allow us to produce a wide range of forged aluminum 6061 wheels to meet diverse requirements. Below are the standard specifications and customization options available.

| Specification | Standard Range | Custom Options |

| Diameter | 15″ to 24″ | Custom sizes available upon request |

| Width | 6J to 14J | Custom widths for specialized applications |

| Offset (ET) | 0mm to 50mm | Custom offsets to match specific vehicle requirements |

| PCD (Bolt Pattern) | 4x100mm to 6×139.7mm | Custom PCDs available for specialized applications |

| Center Bore | 56.1mm to 74.1mm | Custom center bores to match vehicle specifications |

| Load Rating | Up to 1,000kg per wheel | Enhanced load ratings for commercial applications |

| Finish Options | Brushed, Polished, Anodized | Custom colors, powder coating, ceramic coating |

| Design Options | Multiple spoke designs | Fully custom designs, logo engraving, special features |

Material Properties: 6061-T6 Aluminum Alloy

- Composition: Aluminum with magnesium and silicon as primary alloying elements

- Tensile Strength: 45,000 PSI (310 MPa)

- Yield Strength: 40,000 PSI (276 MPa)

- Elongation: 12% in 2 inches

- Hardness: Brinell 95

- Density: 2.7 g/cm³

- Melting Point: 1080-1205°F (582-652°C)

- Modulus of Elasticity: 10,000 ksi (68.9 GPa)

- Thermal Conductivity: 167 W/m·K

- Corrosion Resistance: Excellent with proper treatment

Sample of MAIKONG forged aluminum 6061 wheel designs with various finishes and configurations

Quality Assurance for MAIKONG Forged Aluminum 6061 Wheels

At MAIKONG, quality is not just a process—it’s our foundation. Our comprehensive quality control system ensures that every forged aluminum 6061 wheel we produce meets the highest standards for performance, safety, and reliability.

Our Quality Control Process

- Material Verification: Each aluminum billet is tested for composition and purity before entering production

- In-Process Inspection: Multiple quality checkpoints throughout the manufacturing process

- Dimensional Verification: Precision measurements to ensure exact specifications are met

- Structural Testing: Load testing and impact resistance verification

- Surface Quality Inspection: Detailed examination of finish quality and consistency

- Final Inspection: Comprehensive review before packaging and shipping

Certifications and Standards

MAIKONG maintains rigorous quality management systems and holds key industry certifications:

ISO 9001:2015

Our quality management system is certified to ISO 9001:2015 standards, ensuring consistent quality across all manufacturing processes.

IATF 16949

We maintain automotive industry quality standards, demonstrating our commitment to excellence in automotive component manufacturing.

Material Testing

Our in-house materials laboratory conducts comprehensive testing to verify material properties and performance characteristics.

“Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction and skillful execution. At MAIKONG, we embed this philosophy into every forged aluminum 6061 wheel we produce.”

About MAIKONG: Your Partner for Premium Forged Aluminum 6061 Wheels

MAIKONG is a leading manufacturer of high-performance forged aluminum components, specializing in premium forged aluminum 6061 wheel solutions for automotive and motorsport applications. With over two decades of experience, our state-of-the-art manufacturing facility in GD, SZ combines advanced technology with skilled craftsmanship to deliver exceptional products.

Our Capabilities

- 60+ CNC machines with 100+ tons monthly processing capacity

- Advanced forging presses up to 10,000 tons

- Precision CNC turning, milling, and multi-axis machining

- In-house heat treatment and surface finishing

- Comprehensive testing and quality control laboratory

- Custom design and engineering services

Our Services

CNC Machining Services

Precision fabrication of metal parts in any volume, specializing in turning, milling, swiss machining, and multi-axis machining.

Aluminum Forging Services

Comprehensive aluminum forging solutions with in-house secondary processing for optimal mechanical properties and dimensional tolerances.

Custom Metal Parts

Tailored manufacturing solutions for custom metal components across various industries, from prototype to high-volume production.

Become a MAIKONG Distributor in the USA

We’re seeking distributors across the United States for our premium forged aluminum 6061 wheel products. Join our network and offer your customers the highest quality forged wheels at competitive prices.

Contact MAIKONG for Your Forged Aluminum 6061 Wheel Needs

Ready to discuss your forged aluminum 6061 wheel requirements? Our team of experts is available to answer your questions, provide technical specifications, and develop custom solutions for your specific needs.

Get in Touch

- Phone/WhatsApp: 8613-51090-74-01

- Email: Lucy@maikongforge.us

- Website: https://maikongforge.us

- Location: GD, SZ

Request a Quote

Quick Response Guarantee: Our team will respond to your inquiry within 24 hours with detailed information and next steps for your forged aluminum 6061 wheel project.

Why Choose MAIKONG for Your Forged Aluminum 6061 Wheel Requirements

When you partner with MAIKONG for your forged aluminum 6061 wheel needs, you gain access to world-class manufacturing capabilities, engineering expertise, and dedicated customer service. Our commitment to quality, innovation, and competitive pricing makes us the ideal choice for automotive manufacturers, distributors, and performance enthusiasts seeking the best in forged wheel technology.

The MAIKONG Advantage

- Superior manufacturing capabilities with state-of-the-art equipment

- Comprehensive quality control and testing procedures

- Competitive pricing with excellent value-to-performance ratio

- Flexible customization options for unique requirements

- Experienced engineering team for technical support

- Global shipping and logistics expertise

- Dedicated customer service throughout the process

Ready to Elevate Your Wheel Performance?

Contact MAIKONG today to discuss your forged aluminum 6061 wheel requirements and discover how our premium forged wheels can enhance your vehicle’s performance, aesthetics, and value.

Or call us directly: 8613-51090-74-01

Contact us online by Whatsapp: