Key Differences Between Billet vs Cast Manufacturing

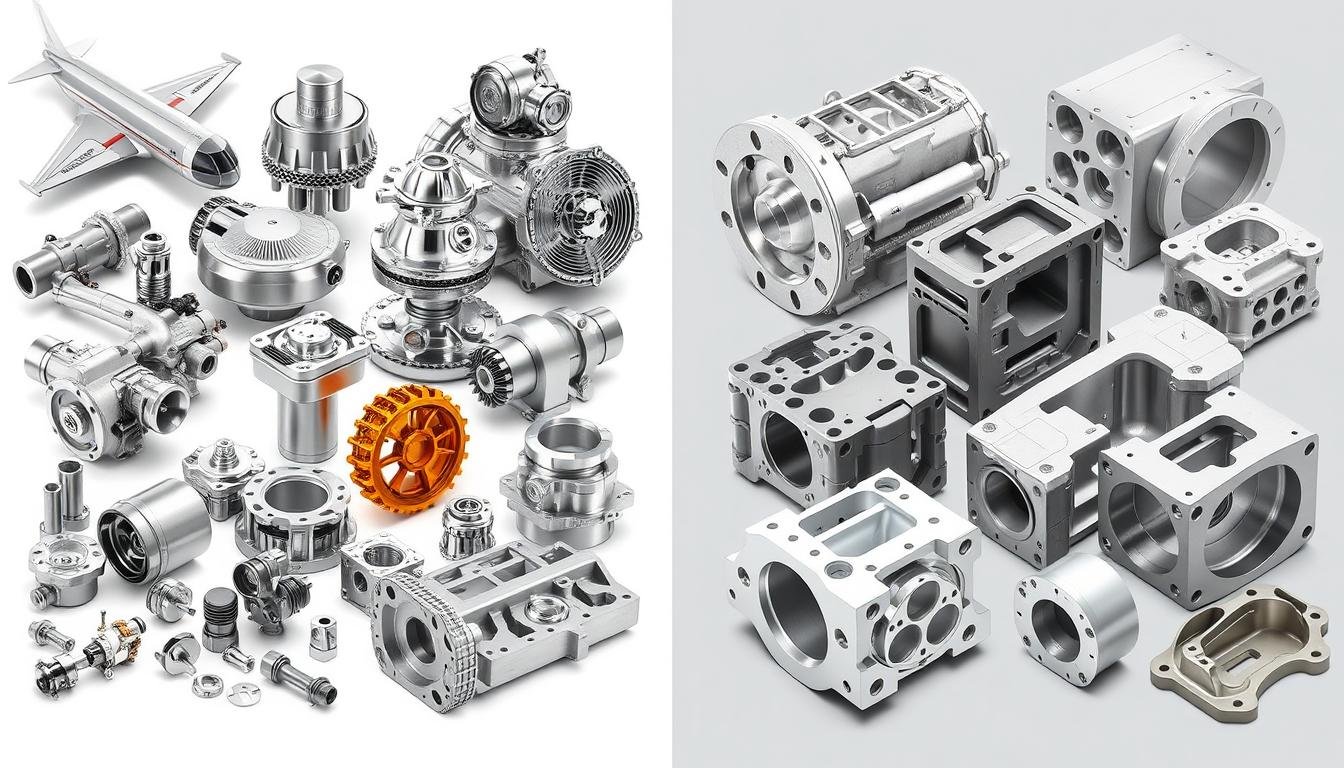

The most significant difference between billet and cast manufacturing lies in how the metal is processed. Billet parts are created through a subtractive process, while casting is an additive process. Let’s explore these differences in detail.

What is Billet Manufacturing?

Billet manufacturing refers to the process of machining parts from a solid block of metal. This subtractive process typically uses CNC (Computer Numerical Control) machines to precisely remove material until the desired shape is achieved. The term “billet” specifically refers to the solid metal stock used as the starting material.

At MAIKONG, our state-of-the-art CNC machining center features over 60 advanced CNC machines capable of producing the most intricate billet components with exceptional precision. Our facility provides over 100 tons of metal processing capacity monthly, ensuring we can handle projects of any scale.

What is Cast Manufacturing?

Casting is an additive manufacturing process where molten metal is poured into a mold cavity and allowed to solidify. The mold, which can be made from various materials such as sand, plaster, or metal, contains a hollow cavity shaped like the desired part. Once the metal cools and hardens, it’s removed from the mold.

MAIKONG specializes in various casting methods, including sand casting, die casting, and investment casting, allowing us to produce components with complex geometries that would be difficult or impossible to achieve through other manufacturing processes.

Comprehensive Billet vs Cast Comparison

To help you make an informed decision, we’ve created this detailed comparison table highlighting the key differences between billet and cast manufacturing processes:

| Characteristic | Billet Manufacturing | Cast Manufacturing |

| Manufacturing Process | Subtractive (material removed from solid block) | Additive (molten metal poured into mold) |

| Strength | Higher yield strength (40,000 PSI for 6061-T6) | Lower yield strength (23,100 PSI for A380) |

| Grain Structure | Uniform, consistent throughout | Potential for porosity and inconsistencies |

| Design Complexity | Limited by machining capabilities | Excellent for complex internal geometries |

| Cost | Higher due to material waste and machining time | Lower, especially for complex parts and high volumes |

| Material Utilization | Lower (significant material waste) | Higher (minimal waste) |

| Surface Finish | Excellent, highly controllable | May require additional finishing |

| Dimensional Accuracy | ±0.0005″ possible with precision CNC | ±0.010″ typical for most casting methods |

| Production Volume | Ideal for low to medium volumes | Economical for medium to high volumes |

| Lead Time | Shorter for simple parts, longer for complex | Longer initial setup, faster for production runs |

Need help determining the best manufacturing process for your project?

Our engineering team can analyze your requirements and recommend the optimal approach based on your specific needs, timeline, and budget.

Advantages and Limitations of Billet Manufacturing

Billet manufacturing offers several distinct advantages that make it the preferred choice for certain applications. Understanding these benefits will help you determine if this process is right for your project.

Billet Manufacturing Advantages

- Superior strength and structural integrity due to consistent grain structure

- Exceptional dimensional accuracy and precision (±0.0005″ possible)

- Excellent surface finish requiring minimal post-processing

- Higher fatigue resistance and durability under stress

- Greater design flexibility for external features

- No risk of internal voids or porosity

- Easier to modify or adapt designs during development

- Better suited for low to medium production volumes

Billet Manufacturing Limitations

- Higher material costs due to significant waste

- Longer machining times for complex geometries

- Limited ability to create certain internal features

- Higher overall production costs, especially for large parts

- Less economical for high-volume production runs

- Heavier than cast parts (30-60% weight difference)

- More energy-intensive manufacturing process

- Limited by the capabilities of available machining equipment

MAIKONG’s Billet Manufacturing Capabilities

At MAIKONG, we’ve invested in the latest CNC machining technology to deliver exceptional billet components. Our capabilities include:

CNC Turning

Precision turning for cylindrical components with superior surface finishes, deep holes, and machined threads. Ideal for shafts, bushings, and precision cylindrical parts.

CNC Milling

Multi-axis milling for complex prismatic shapes and flat surfaces with exceptional accuracy. Perfect for structural components, brackets, and housings.

Swiss-Type Machining

Specialized machining for small precision parts and long shaft components with our dual-spindle, multi-axis equipment for one-stop manufacturing solutions.

Advantages and Limitations of Cast Manufacturing

Casting offers unique benefits that make it the optimal choice for many applications, particularly those requiring complex internal geometries or high-volume production.

Cast Manufacturing Advantages

- Lower cost for complex geometries and high volumes

- Ability to create intricate internal features

- Minimal material waste compared to machining

- More efficient for large parts production

- Lighter weight components possible

- Excellent for complex shapes difficult to machine

- More economical tooling for high-volume production

- Ability to incorporate multiple materials in some processes

Cast Manufacturing Limitations

- Lower mechanical properties due to potential porosity

- Reduced tensile strength compared to billet

- Less precise dimensional control (typically ±0.010″)

- Potential for internal defects and inconsistencies

- Often requires additional machining for critical surfaces

- Higher initial tooling costs for low volumes

- Longer lead times for initial production

- Limited surface finish quality without secondary operations

MAIKONG’s Casting Capabilities

Our foundry specializes in various casting methods to meet diverse project requirements:

Sand Casting

Versatile process for producing large components with complex geometries. Ideal for low to medium volume production with minimal tooling costs.

Die Casting

High-pressure casting for excellent dimensional accuracy and surface finish. Perfect for high-volume production of complex parts with thin walls.

Investment Casting

Precision casting method for intricate components with excellent surface finish and dimensional accuracy. Suitable for complex geometries in various alloys.

Industry Applications: When to Choose Billet vs Cast

Different industries have varying requirements that may favor either billet or cast manufacturing. Understanding these applications can help guide your decision-making process.

Ideal Applications for Billet Parts

- Aerospace: Critical structural components, landing gear parts, and control systems requiring maximum strength and reliability

- Automotive Racing: High-performance engine components, suspension parts, and drivetrain elements where weight and strength are crucial

- Medical Devices: Surgical instruments, implant components, and diagnostic equipment requiring precision and biocompatibility

- Defense: Weapon components, communication equipment housings, and tactical accessories needing durability and precision

- Precision Instruments: Measuring devices, scientific equipment, and calibration tools requiring extreme accuracy

Ideal Applications for Cast Parts

- Automotive: Engine blocks, transmission housings, and structural components for mass production vehicles

- Industrial Equipment: Pump housings, valve bodies, and machine bases with complex internal passages

- Consumer Products: Housings for electronics, appliance components, and decorative elements

- Construction: Structural connectors, decorative elements, and hardware components

- Energy Sector: Turbine components, pipe fittings, and housing elements for power generation equipment

“The choice between billet and cast manufacturing isn’t about which process is better overall, but rather which is better suited for your specific application, production volume, budget, and performance requirements.”

Key Factors in Choosing Between Billet vs Cast Manufacturing

When deciding between billet and cast manufacturing for your project, consider these critical factors:

1. Production Volume

For low to medium production volumes (1-1,000 units), billet manufacturing often provides better cost-efficiency due to lower tooling costs. For higher volumes, casting typically becomes more economical as the initial tooling investment is offset by lower per-unit costs and reduced material waste.

2. Geometric Complexity

If your design features complex internal geometries, undercuts, or hollow sections, casting may be the only viable option. Billet manufacturing excels at external features but is limited in creating certain internal structures without assembly of multiple components.

3. Mechanical Requirements

Applications requiring maximum strength, fatigue resistance, and consistent mechanical properties typically benefit from billet manufacturing. If your component needs to withstand high stress or safety-critical applications, the superior grain structure of billet parts often provides better performance.

4. Dimensional Precision

When tight tolerances are critical to your application, billet manufacturing offers superior dimensional control. While modern casting techniques have improved significantly, they typically cannot match the precision possible with CNC machining from billet stock.

5. Budget Constraints

Your budget will significantly influence the manufacturing choice. Billet parts typically cost more per unit due to material waste and machining time, while casting offers better material utilization but requires higher initial tooling investment.

Not sure which manufacturing process is right for your project?

MAIKONG’s engineering team can analyze your design, requirements, and production volume to recommend the optimal manufacturing approach.

Why Choose MAIKONG for Your Billet vs Cast Manufacturing Needs

MAIKONG offers comprehensive manufacturing capabilities in both billet and cast processes, providing you with the flexibility to choose the optimal approach for each component in your project.

Our Comprehensive Manufacturing Solutions

Advanced Equipment

With over 60 CNC machines and complete casting facilities, we offer 100+ tons of monthly metal processing capacity to handle projects of any scale with precision and efficiency.

Material Expertise

Our in-house material testing laboratory ensures optimal material selection and quality verification for every project, guaranteeing components that meet or exceed your specifications.

Quality Assurance

ISO 9001:2015 certified processes with comprehensive inspection protocols using advanced measurement equipment to ensure consistent quality across all manufacturing methods.

Our End-to-End Service Approach

Design Optimization

Our engineering team works with you to optimize designs for manufacturability, whether using billet or cast processes, potentially reducing costs while maintaining performance.

Secondary Operations

Comprehensive in-house capabilities for heat treatment, surface finishing, and assembly ensure your components are delivered ready for implementation.

Global Logistics

Efficient shipping and logistics solutions ensure timely delivery of your components anywhere in the world, with full tracking and documentation.

US Distributor Opportunities

MAIKONG is actively seeking distribution partners across the United States to represent our high-quality, cost-effective manufacturing services. If you’re interested in becoming a MAIKONG distributor, contact us to discuss partnership opportunities.

Contact MAIKONG for Your Billet vs Cast Manufacturing Requirements

Ready to discuss your project? Our team of manufacturing experts is available to help you determine whether billet or cast manufacturing is best suited for your specific application.

Get in Touch

Our engineering team is ready to analyze your requirements and provide expert recommendations on the optimal manufacturing approach for your project.

Connect with us on WhatsApp for quick responses:

Email us your project details:

Visit our website for more information:

Request a Quote

Making the Right Choice: Billet vs Cast for Your Project

The decision between billet and cast manufacturing ultimately depends on your specific project requirements, including performance needs, production volume, budget constraints, and design complexity. At MAIKONG, we excel in both manufacturing methods, allowing us to recommend and implement the optimal approach for your unique application.

Our team of experienced engineers and manufacturing specialists is ready to guide you through the decision-making process, providing expert advice based on decades of industry experience. Whether you need the superior strength and precision of billet components or the complex geometries and cost-effectiveness of cast parts, MAIKONG delivers exceptional quality and service.

Ready to start your next manufacturing project?

Contact MAIKONG today to discuss your requirements and discover how our comprehensive manufacturing capabilities can bring your designs to life with optimal quality, cost-efficiency, and performance.