What is Billet Material?

Cylindrical aluminum billets ready for processing

A billet is a solid metal rod or block that has been cast or formed from molten metal and prepared for further processing. Unlike ingots, which are larger and typically used for producing sheet metal, wire, and tubing, billets are smaller with a reduced cross-sectional area, making them ideal for manufacturing bars, rods, and other precision components.

Billets are commonly made from various metals and alloys including aluminum, steel, brass, and copper. The specific composition depends on the intended application and required mechanical properties. The quality of the internal structure of the billet is crucial as it directly affects the final mechanical properties of the manufactured product.

Key Characteristics of Billet Material

- Uniform composition throughout the material

- Consistent mechanical properties

- Refined grain structure for improved strength

- Higher density compared to cast materials

- Superior structural integrity for demanding applications

- Excellent machinability for precision manufacturing

Billet vs. Cast: Understanding the Differences

When comparing billet and cast materials, it’s important to understand their fundamental differences in manufacturing processes, properties, and applications. These differences directly impact the performance, cost, and suitability of the final product for specific uses.

Visual comparison of billet (left) and cast (right) material structures

Billet Manufacturing Process

Billet production is a subtractive manufacturing process. It begins with a solid block of metal that is machined using CNC equipment to create the desired shape. This process removes material to achieve the final form, resulting in a denser, stronger product with superior structural integrity.

- Starts with solid metal block

- Uses CNC machining (subtractive process)

- Results in higher density material

- Produces consistent internal structure

Casting Process

Casting is an additive manufacturing process where molten metal is poured into a mold cavity and allowed to solidify. The most common casting methods for low-volume production include no-bake sand castings and plaster mold castings. Once cooled, the casting is removed from the mold to reveal the finished product.

- Starts with molten metal

- Uses molds to form shapes (additive process)

- May contain air pockets or inclusions

- Allows for more complex geometries

Comparative Advantages and Limitations

| Comparison Factor | Billet Material | Cast Material |

| Strength | Superior strength due to dense structure | Lower strength with potential for porosity |

| Cost | Higher due to additional processing | More cost-effective for production |

| Weight | 30-60% heavier than cast equivalents | Lighter due to less dense structure |

| Design Flexibility | Limited by machining capabilities | Greater flexibility for complex shapes |

| Precision | Higher precision with CNC machining | Good precision but less consistent |

| Durability | Superior longevity in applications | Adequate for less demanding uses |

Need Expert Guidance on Billet Material Selection?

MAIKONG’s engineering team can help you determine the optimal material and manufacturing process for your specific application requirements.

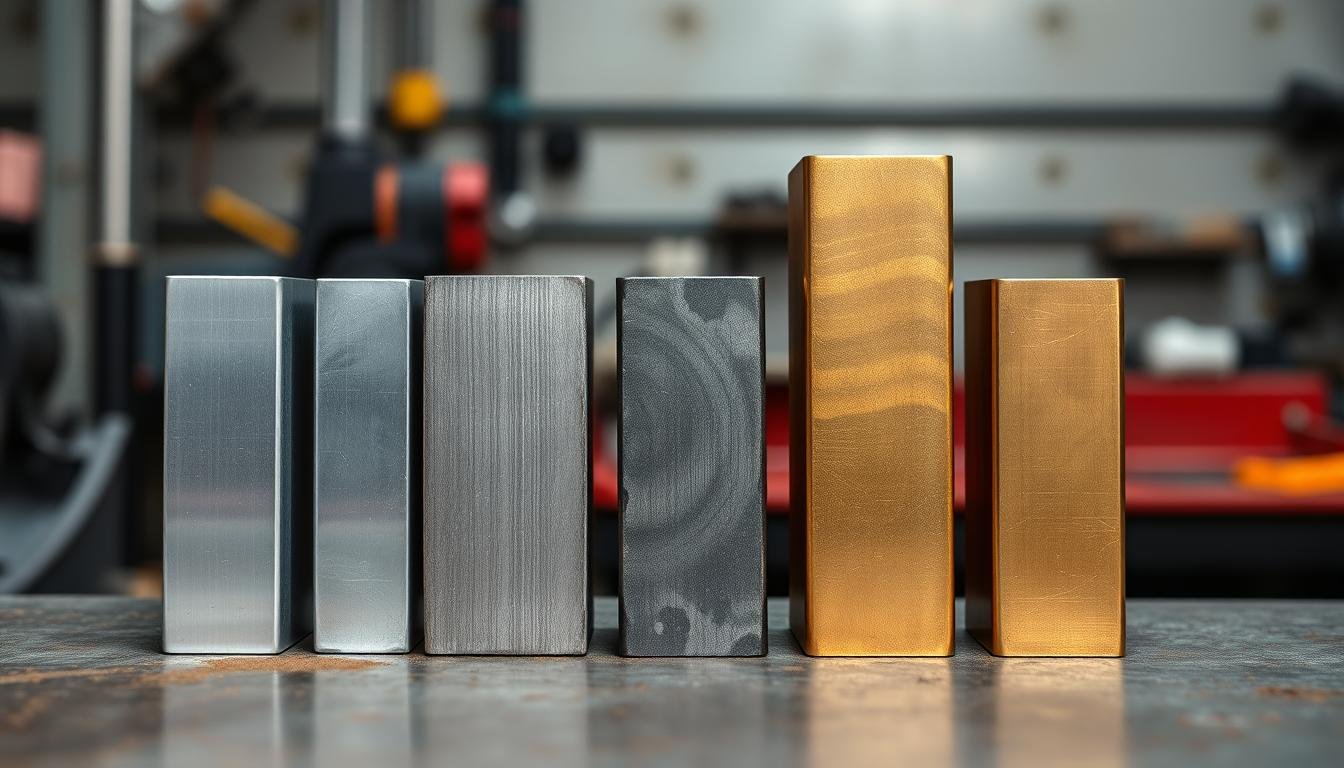

Common Types of Billet Material

Different industries require various types of billet materials based on specific application requirements. Each material offers unique properties that make it suitable for particular uses. Here are the most commonly used billet materials in manufacturing:

Various billet materials: aluminum, steel, and brass (left to right)

Aluminum Billet

Aluminum billets are among the most widely used in manufacturing due to their excellent combination of lightweight properties and strength. They’re particularly valuable in industries where weight reduction is critical.

- Key Properties: Lightweight, corrosion-resistant, excellent thermal and electrical conductivity

- Common Alloys: 6061, 6063, 7075, 2024

- Primary Applications: Aerospace components, automotive parts, construction profiles, electronics housings

Steel Billet

Steel billets provide exceptional strength and durability, making them ideal for structural applications and components that must withstand high stress and wear.

- Key Properties: High strength, excellent durability, good heat resistance

- Common Types: Carbon steel, alloy steel, stainless steel

- Primary Applications: Structural components, automotive parts, tools, machinery components

Brass Billet

Brass billets combine good machinability with attractive appearance, making them popular for both functional and decorative applications.

- Key Properties: Excellent machinability, corrosion resistance, attractive appearance

- Common Compositions: C360 (free-cutting brass), C385 (architectural bronze)

- Primary Applications: Plumbing fixtures, decorative hardware, electrical components

CNC machining of brass billet at MAIKONG’s facility

The Billet Material Manufacturing Process

The production of high-quality billet material involves several critical stages, each contributing to the final properties and performance of the material. Understanding this process helps in appreciating the value and capabilities of billets in various applications.

Molten metal preparation in billet manufacturing

Step-by-Step Billet Production

- Raw Material Selection: The process begins with selecting appropriate raw materials, which may include primary metal or high-quality scrap. The selection depends on the desired properties and cost considerations.

- Melting and Alloying: The selected materials are melted in a furnace at temperatures exceeding the metal’s melting point. For aluminum, this is typically above 660°C (1220°F). During this stage, alloying elements may be added to achieve specific properties.

- Casting: The molten metal is cast into cylindrical or rectangular shapes using specialized molds. This initial forming creates the basic billet shape.

- Cooling and Solidification: Controlled cooling allows for uniform solidification of the billet, which is critical for achieving consistent metallurgical properties throughout the material.

- Quality Testing: Billets undergo rigorous testing to ensure they meet required specifications. This may include chemical composition analysis, mechanical property testing, and inspection for defects.

Advanced Processing Techniques

After the initial billet formation, several additional processes may be employed to enhance properties or prepare the material for specific applications:

Extrusion

Extrusion involves forcing heated billet material through a die to create profiles with specific cross-sections. This process is particularly common with aluminum billets and creates products like tubes, rods, and complex structural shapes.

Forging

Forging applies compressive forces to shape the billet, improving its grain structure and mechanical properties. This process creates stronger components with superior structural integrity compared to cast parts.

Aluminum billet extrusion process at MAIKONG’s facility

Looking for Custom Billet Processing?

MAIKONG offers comprehensive billet processing services including CNC machining, forging, and extrusion to meet your exact specifications.

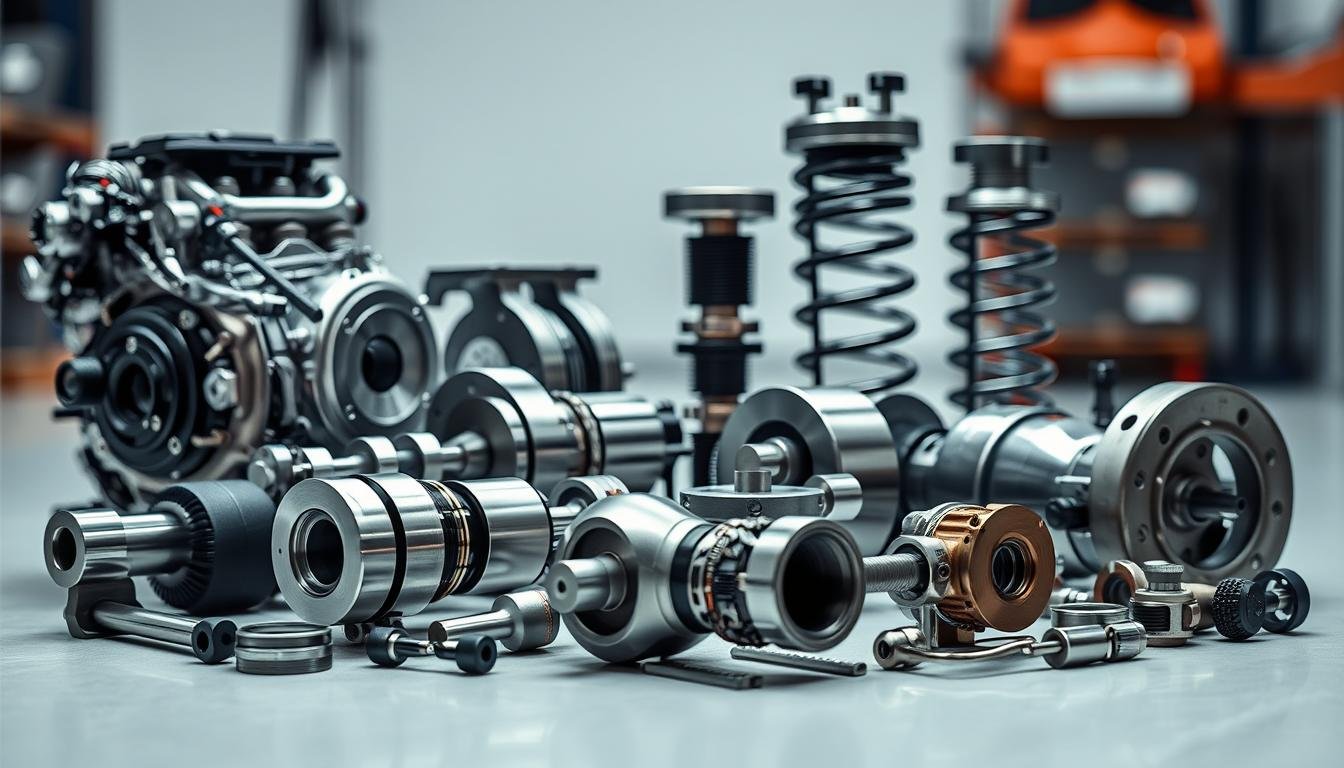

Industrial Applications of Billet Material

Billet materials find applications across numerous industries due to their versatility, strength, and precision manufacturing capabilities. Here’s how different sectors utilize billet materials in their products and components:

Precision automotive components manufactured from billet material

Automotive Industry

The automotive sector extensively uses billet materials for components requiring high strength, precision, and reliability. These parts often need to withstand significant stress while maintaining tight tolerances.

- Engine components (connecting rods, crankshafts)

- Suspension components (control arms, knuckles)

- Transmission parts

- Performance upgrades (intake manifolds, throttle bodies)

- Structural reinforcements

Aerospace Applications

The aerospace industry demands materials with exceptional strength-to-weight ratios and reliability. Billet materials, particularly aluminum alloys, meet these requirements for critical components.

- Structural airframe components

- Landing gear parts

- Engine mounts and brackets

- Interior fittings and supports

- Control system components

Construction and Architecture

Billet materials, especially aluminum, are widely used in construction for their combination of strength, light weight, and corrosion resistance.

- Structural profiles and framing

- Window and door systems

- Railings and balustrades

- Decorative elements and facades

- Curtain wall components

Precision CNC machined components from various billet materials

Electronics and Telecommunications

The electronics industry utilizes billet materials for components requiring excellent thermal management, electromagnetic shielding, and precise tolerances.

- Heat sinks and thermal management components

- Electronic enclosures and housings

- Base plates for circuit boards

- 5G infrastructure components

- Server and data center hardware

MAIKONG’s Billet Material Processing Capabilities

At MAIKONG, we specialize in comprehensive billet material processing services, offering end-to-end solutions from material selection to finished components. Our state-of-the-art facilities and experienced team ensure high-quality results for even the most demanding applications.

MAIKONG’s advanced CNC machining facility

Our Core Services

CNC Machining Services

Our facility houses over 60 CNC machines with a monthly processing capacity exceeding 100 tons. We specialize in precision fabrication of metal parts in any volume, offering turning, milling, multi-axis machining, and surface grinding.

Metal Forging Services

Our forging capabilities enhance the structural integrity of billet materials by aligning grain structures and increasing density. We offer aluminum, steel, and brass forging services for components requiring superior strength and durability.

Precision Finishing

We provide comprehensive finishing services including heat treatment, surface treatments, anodizing, painting, and laser engraving to enhance both the performance and appearance of your billet components.

Quality Assurance

Quality is at the core of everything we do at MAIKONG. Our comprehensive quality control procedures ensure that every component meets or exceeds the specified requirements:

- Advanced material testing laboratory for composition verification

- Precision measurement equipment for dimensional accuracy

- Comprehensive statistical analysis and documentation

- Rigorous inspection at every stage of production

- Full traceability from raw material to finished product

Quality control inspection of precision billet components

+86 13510907401Contact our technical team directly for specialized billet material inquiries

Why Choose MAIKONG for Your Billet Material Needs

MAIKONG stands out as a premier provider of billet material processing services, offering a unique combination of technical expertise, manufacturing capabilities, and customer-focused solutions. Here’s why leading companies choose to partner with us:

MAIKONG’s comprehensive manufacturing facility in GD, SZ

The MAIKONG Advantage

- Comprehensive in-house capabilities from design to finished product

- Superior quality control with advanced testing facilities

- Cost-effective solutions without compromising quality

- Extensive experience across multiple industries

- Flexible production capacity for both small and large orders

- Technical expertise in material selection and optimization

- Rapid prototyping and production capabilities

- Commitment to meeting exact specifications and deadlines

Industries We Serve

Our expertise in billet material processing spans numerous industries, allowing us to provide specialized solutions for diverse applications:

- Automotive manufacturing

- Aerospace and defense

- Construction and architecture

- Electronics and telecommunications

- Medical equipment

- Industrial machinery

- Consumer products

- Sports and recreation equipment

Become a US Distributor for MAIKONG

We’re actively seeking US distributors for our high-quality billet material components and services. Join our network and offer your customers superior manufacturing solutions at competitive prices.

Conclusion: Maximizing the Potential of Billet Material

Billet materials continue to be a cornerstone of modern manufacturing, offering superior strength, precision, and versatility across countless applications. By understanding the properties, manufacturing processes, and applications of billet materials, engineers and procurement specialists can make informed decisions to optimize their products and components.

At MAIKONG, we combine technical expertise with state-of-the-art manufacturing capabilities to help you maximize the potential of billet materials in your projects. Whether you need precision CNC machining, metal forging, or comprehensive manufacturing solutions, our team is ready to deliver exceptional results that meet your exact specifications.

Precision components manufactured from billet material by MAIKONG

Ready to Discuss Your Billet Material Project?

Contact MAIKONG today to speak with our engineering team about your specific requirements and discover how our billet material processing capabilities can benefit your next project.