Understanding the Basics: Billet vs Forged Manufacturing

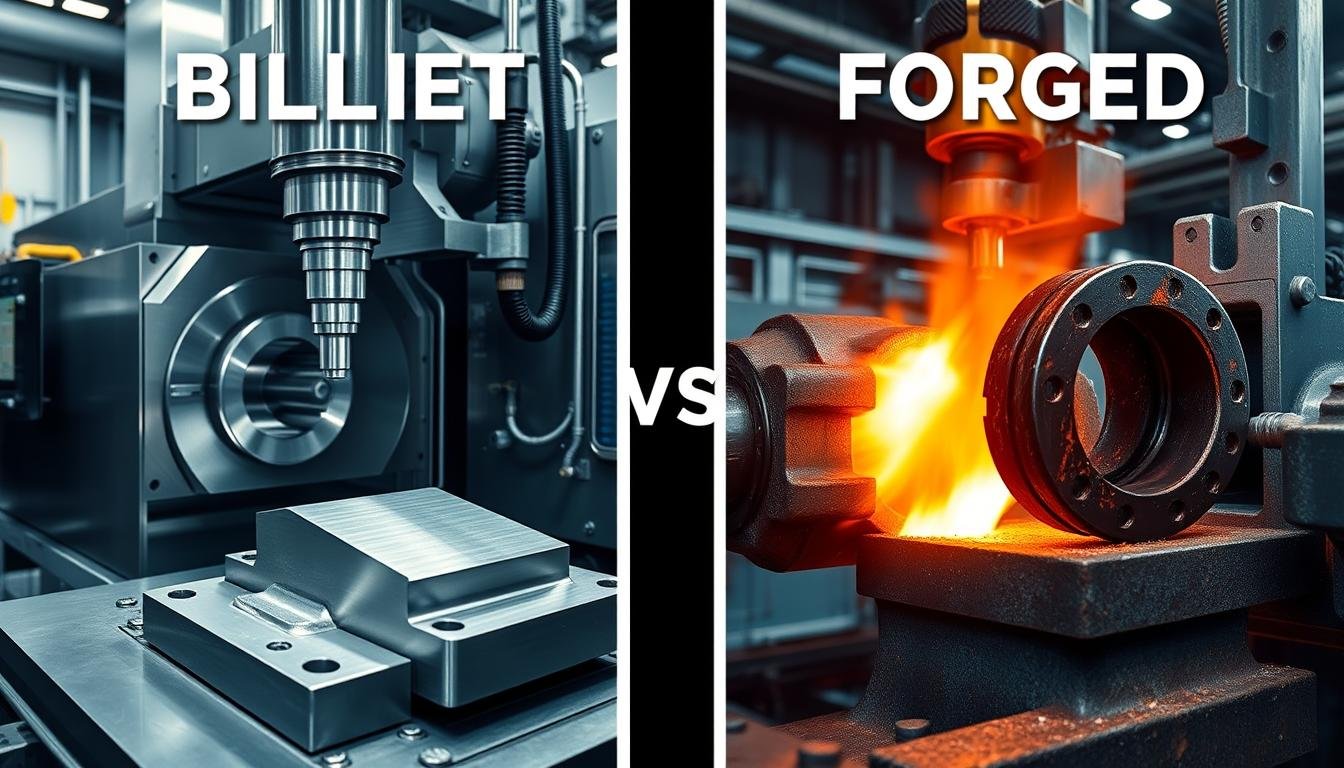

The fundamental difference between billet and forged manufacturing processes

The fundamental difference between billet and forged manufacturing processesBefore diving into the specifics, it’s essential to understand what billet vs forged actually means. These terms refer to two distinct manufacturing methods that create metal parts with different characteristics and properties.

What Is Billet Manufacturing?

Billet manufacturing starts with a solid block of metal (the billet) that has been pre-formed through casting or extrusion. Using precision CNC (Computer Numerical Control) machines, material is removed from this block until the desired shape emerges. This subtractive process allows for extremely tight tolerances and detailed geometries.

What Is Forged Manufacturing?

Forging is a forming process that uses compressive force to shape metal into the desired form. Metal is heated until pliable, then shaped using powerful hammers or presses. Unlike billet machining, which removes material, forging reshapes the original stock through pressure and force, aligning the internal grain structure along the contours of the part.

Strength and Durability: How Billet vs Forged Parts Compare

Forged Advantages

- Superior grain structure alignment following part contours

- Higher tensile strength, especially under load

- Excellent fatigue resistance for repetitive stress

- Superior impact resistance for demanding applications

- Better performance in high-stress environments

- Lower material waste during manufacturing

Billet Advantages

- Exceptional precision and dimensional accuracy

- Superior surface finish directly from machining

- Greater design flexibility for complex geometries

- Better for low-volume or prototype production

- More customization options for unique designs

- Lower tooling costs for small production runs

Grain Structure: The Key to Understanding Billet vs Forged Strength

The fundamental difference in strength between billet vs forged parts comes down to their internal grain structure. Forged parts have a directional grain flow that follows the contours of the part, providing superior strength along stress lines. Billet parts have a non-directional, uniform grain structure that offers consistent but generally lower strength.

| Property | Billet | Forged |

| Grain Structure | Non-directional (uniform) | Directional (follows part shape) |

| Tensile Strength | Good and consistent | Higher, especially under load |

| Fatigue Resistance | Moderate | Excellent |

| Impact Resistance | Lower | Superior |

| Weight-to-Strength Ratio | Good | Excellent |

Need Help Determining the Best Process for Your Application?

Our engineering team can analyze your specific requirements and recommend the optimal manufacturing approach.

Precision and Tolerances in Billet vs Forged Manufacturing

When precision matters, understanding the tolerance capabilities of billet vs forged manufacturing becomes crucial. Each process offers different advantages in terms of dimensional accuracy and surface finish.

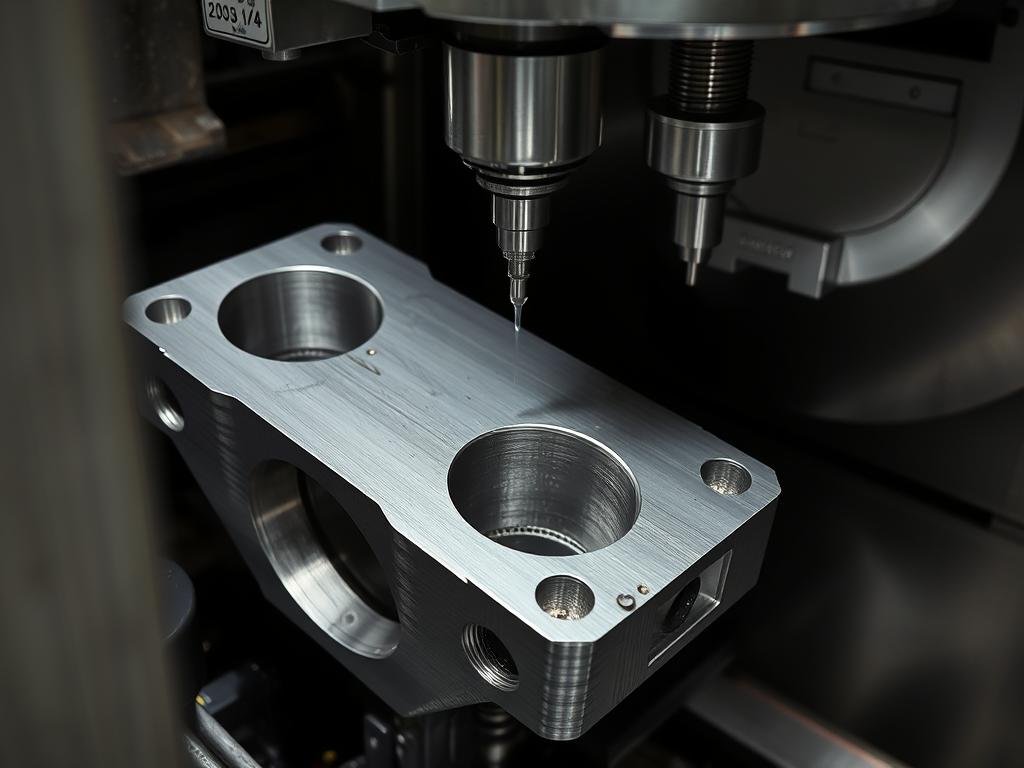

Billet Machining Precision

CNC machining of billet material offers exceptional precision, with tolerances as tight as ±0.0005 inches (0.0127mm) in some applications. This level of accuracy is possible because the material is cut to exact specifications using computer-controlled tools, without the dimensional variations that can occur during the heating and forming processes of forging.

Forged Part Tolerances

Forged parts typically have wider initial tolerances due to the nature of the forging process, which involves heat and deformation. While modern forging techniques have improved significantly, most forged parts require secondary machining operations to achieve precise dimensions in critical areas. However, this combination of forging strength with targeted machining often provides the best of both worlds.

Ideal Applications: When to Choose Billet vs Forged

When to Choose Billet

- Complex geometries with intricate details

- Low-volume production or prototyping

- Applications requiring exceptional surface finish

- Parts with internal features or cavities

- Components needing tight tolerances

- Custom, one-off parts

When to Choose Forged

- High-stress, load-bearing applications

- Parts subject to impact or fatigue

- Safety-critical components

- High-volume production

- Applications where weight-to-strength ratio is critical

- Parts with simple to moderate complexity

Industry-Specific Applications for Billet vs Forged Parts

| Industry | Typical Billet Applications | Typical Forged Applications |

| Automotive | Custom intake manifolds, valve covers, decorative components | Crankshafts, connecting rods, suspension components |

| Aerospace | Instrument housings, complex brackets, prototype parts | Structural components, landing gear parts, engine mounts |

| Medical | Surgical instruments, implant prototypes, custom devices | Orthopedic implants, surgical tools |

| Industrial | Custom fittings, specialized tooling, low-volume parts | Gears, shafts, structural components, high-wear parts |

Ready to Discuss Your Specific Application?

Contact our engineering team to evaluate which manufacturing process is best suited for your project requirements.

Cost Considerations: Billet vs Forged Manufacturing Economics

When evaluating billet vs forged manufacturing options, cost is inevitably a major consideration. However, looking only at the initial per-part price can be misleading. A comprehensive cost analysis should consider tooling, volume, material waste, secondary operations, and part longevity.

Initial Investment: Tooling and Setup

Billet Machining Costs

- Lower initial tooling investment

- Primarily requires programming and standard cutting tools

- Changes to design are relatively inexpensive

- Economical for low volumes and prototypes

Forging Costs

- Higher initial die and tooling costs

- Custom dies required for each unique part

- Design changes require new or modified tooling

- More economical at higher production volumes

Production Volume Break-Even Analysis

For most applications, there’s a break-even point where the higher initial tooling costs of forging are offset by the lower per-part production costs at higher volumes. MAIKONG can help you determine this point for your specific project to maximize cost-effectiveness.

Value-Added Perspective: Looking Beyond Initial Cost

When comparing billet vs forged manufacturing costs, consider these additional factors:

- Part longevity and performance in application

- Reduced maintenance and replacement costs

- Weight savings (especially important in automotive and aerospace)

- Material optimization and waste reduction

- Secondary operations and finishing requirements

Get a Customized Cost Analysis

Our team can provide a detailed cost comparison for your specific part, considering volume, complexity, and performance requirements.

Material Selection for Billet vs Forged Manufacturing

The choice between billet vs forged manufacturing is closely tied to material selection. Different alloys respond differently to each process, and the optimal manufacturing method often depends on the material properties required for your application.

Common Materials in Billet Machining

Aluminum Alloys

6061-T6, 7075-T6, and 2024 are commonly machined from billet. These alloys offer excellent machinability while providing good strength-to-weight ratios.

Stainless Steel

304, 316, and 17-4 PH stainless steels are frequently machined from billet for applications requiring corrosion resistance and moderate strength.

Specialty Metals

Titanium, brass, copper, and exotic alloys can be machined from billet when specific properties are required for specialized applications.

Common Materials in Forging

Aluminum Forging

2014, 6061, and 7075 aluminum alloys are commonly forged for applications requiring high strength-to-weight ratio and good fatigue resistance.

Steel Forging

Carbon steels, alloy steels, and tool steels are forged for applications requiring maximum strength, toughness, and wear resistance.

Specialty Forging

Titanium, nickel alloys, and other specialty metals can be forged for aerospace, medical, and other high-performance applications.

Material Properties Comparison: Billet vs Forged

| Property | Billet Aluminum (7075-T6) | Forged Aluminum (7075-T6) | Improvement with Forging |

| Tensile Strength | 83 ksi (572 MPa) | 92 ksi (634 MPa) | ~11% |

| Yield Strength | 73 ksi (503 MPa) | 82 ksi (565 MPa) | ~12% |

| Fatigue Strength | 23 ksi (159 MPa) | 29 ksi (200 MPa) | ~26% |

| Impact Resistance | Moderate | High | Significant |

Call our materials experts to discuss your specific requirements

MAIKONG’s Capabilities in Billet vs Forged Manufacturing

At MAIKONG, we offer comprehensive capabilities in both billet vs forged manufacturing processes. Our state-of-the-art facility in GD, SZ is equipped with advanced machinery and staffed by experienced engineers and technicians who specialize in both methods.

Our Billet Machining Capabilities

- 60+ CNC machines with 100+ tons monthly processing capacity

- Multi-axis machining capabilities (3-axis, 4-axis, 5-axis)

- Precision tolerances to ±0.0005 inches (0.0127mm)

- Capability to machine aluminum, steel, stainless steel, brass, and specialty alloys

- Advanced CAD/CAM systems for complex geometries

- In-house material testing and verification laboratory

Our Forging Capabilities

- Hydraulic forging presses for precision forming

- Hot and cold forging capabilities

- Specialized in aluminum forging with superior grain structure

- Uniform heat treatment furnaces for optimal material properties

- In-house secondary machining operations

- Comprehensive quality control and testing

Integrated Manufacturing Solutions

What sets MAIKONG apart is our ability to offer integrated solutions that combine the advantages of both billet vs forged manufacturing. For many applications, the optimal approach involves:

- Initial forging to establish optimal grain structure and strength

- Precision CNC machining of critical features and tolerances

- Heat treatment to enhance material properties

- Surface treatments for appearance, corrosion resistance, or wear

- Comprehensive quality testing and verification

Partner with MAIKONG for Your Next Project

Whether you need billet machined parts, forged components, or a hybrid approach, our team is ready to deliver high-quality solutions with competitive pricing.

Quality Assurance in Billet vs Forged Manufacturing

Regardless of whether you choose billet vs forged manufacturing for your components, quality assurance is paramount. At MAIKONG, we implement rigorous quality control procedures throughout the entire manufacturing process.

Our Quality Control Process

Material Verification

Our in-house laboratory conducts comprehensive testing to verify material composition and properties before manufacturing begins.

In-Process Inspection

Regular checks during manufacturing ensure dimensions, tolerances, and surface finishes meet specifications at every stage.

Final Verification

Completed parts undergo comprehensive inspection using advanced measurement equipment and testing protocols.

Testing and Certification

MAIKONG provides comprehensive testing and certification for both billet and forged parts, including:

- Dimensional verification using coordinate measuring machines (CMM)

- Material composition analysis

- Mechanical property testing (tensile, yield, hardness)

- Non-destructive testing (NDT) for internal integrity

- Surface finish measurement

- Full documentation and certification packages

“Quality expresses a component’s capacity for fully satisfying the customer’s needs and expectations. At MAIKONG, we let the numbers speak for themselves.”

Our commitment to quality is reflected in our ISO 9001:2015 certification and our comprehensive quality management system that addresses all aspects of manufacturing: Man, Machine, Material, Measurement, Method, and Environment.

Conclusion: Making the Right Choice Between Billet vs Forged

The debate between billet vs forged manufacturing isn’t about which process is universally better, but rather which is most appropriate for your specific application. Both methods have distinct advantages that make them suitable for different scenarios.

Key Takeaways

- Forged parts offer superior strength, fatigue resistance, and grain structure for high-stress applications

- Billet machining provides exceptional precision, design flexibility, and surface finish for complex geometries

- Material selection plays a crucial role in determining the optimal manufacturing process

- Production volume significantly impacts the cost-effectiveness of each method

- For many applications, a hybrid approach combining both processes may yield optimal results

At MAIKONG, we specialize in both billet vs forged manufacturing processes, allowing us to recommend and implement the best solution for your specific requirements. Our engineering team works closely with clients to understand their application needs and provide expert guidance on material selection, design optimization, and manufacturing approach.

Ready to Start Your Next Manufacturing Project?

Contact MAIKONG today to discuss your requirements and discover how our expertise in both billet and forged manufacturing can deliver superior results for your application.

Or contact us directly:

Become a US Agent for MAIKONG

We’re currently recruiting agents throughout the United States to represent our high-quality, cost-effective manufacturing services. If you’re interested in becoming a MAIKONG representative, please contact us for more information.