Small Aluminum Forging Press: Precision Engineering for Metal Forming Excellence

»

Forging Press » Small Aluminum Forging Press: Precision Engineering for Metal Forming Excellence

The small aluminum forging press represents a cornerstone technology in modern metal fabrication. At MAIKONG, we specialize in designing and manufacturing compact, high-performance forging solutions that deliver exceptional results for aluminum processing. Our presses combine precision engineering with cost-effective operation, making them ideal for businesses seeking reliable metal forming equipment without compromising on quality or performance.

Small Aluminum Forging Press Technology

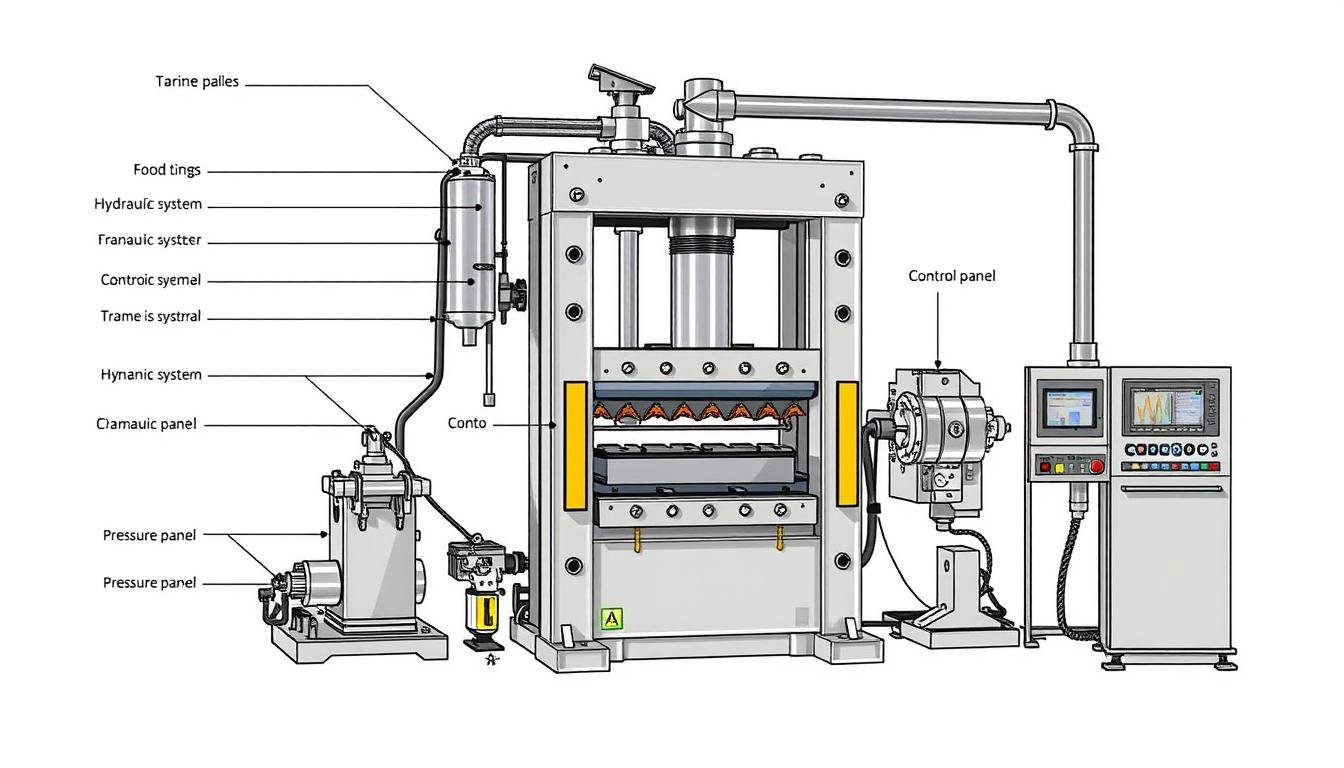

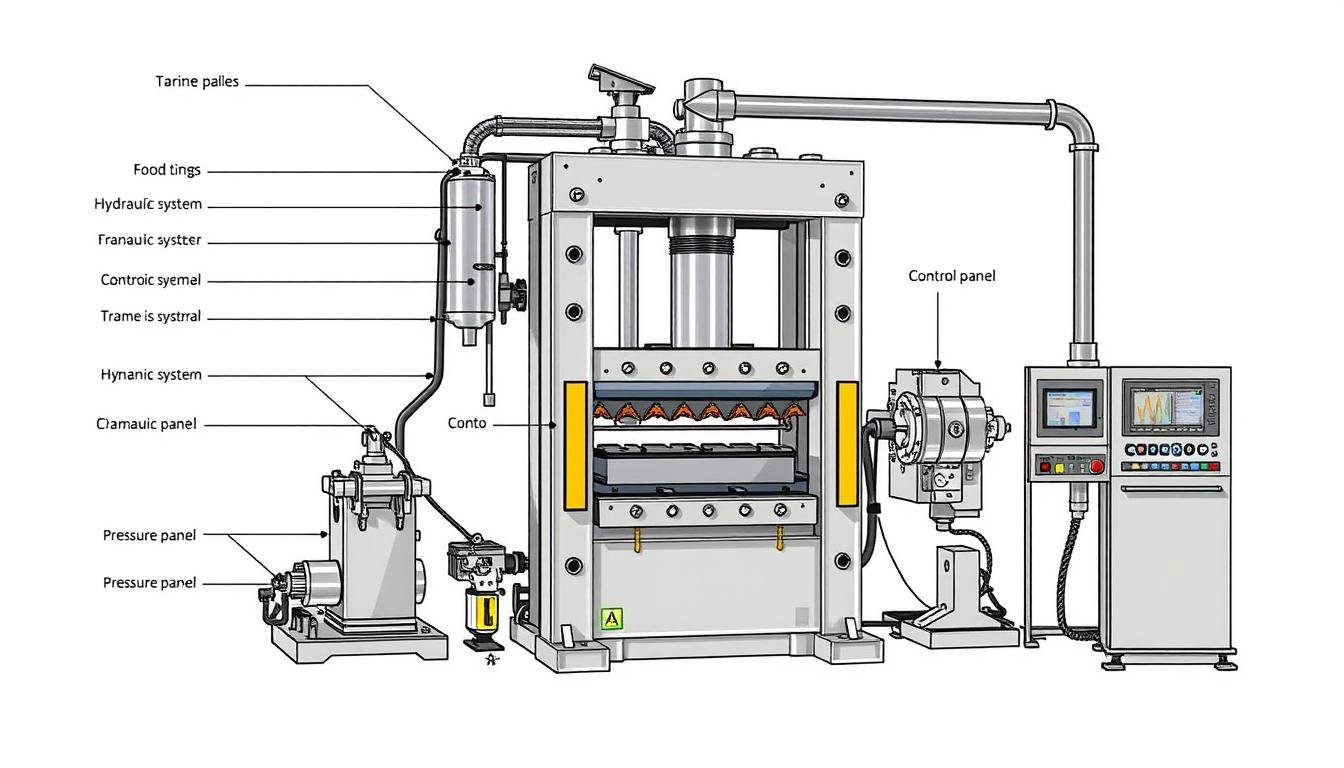

MAIKONG’s precision-engineered small aluminum forging press in operation

MAIKONG’s precision-engineered small aluminum forging press in operation

A small aluminum forging press utilizes controlled force to shape aluminum into precise forms through compressive pressure. Unlike larger industrial presses, these compact machines offer versatility for smaller production runs while maintaining excellent precision and material integrity.

Our hydraulic forging presses are designed specifically for aluminum applications, providing the optimal balance of pressure, control, and efficiency. With operating capacities typically ranging from 5 to 25 tons, these machines deliver impressive performance in a space-efficient footprint.

Expert Forging Solutions for Your Business

Discover how MAIKONG’s small aluminum forging press technology can enhance your manufacturing capabilities.

Request a Quote Today

Key Advantages of MAIKONG Small Aluminum Forging Press Systems

Precision Engineering Excellence

Our small aluminum forging press machines are engineered to deliver exceptional precision and repeatability. With advanced hydraulic systems and precise control mechanisms, these presses ensure consistent results across production runs.

The compact design maximizes workspace efficiency without sacrificing performance, making them ideal for facilities with space constraints or specialized production needs.

Cost-Effective Production

MAIKONG’s small aluminum forging press systems are designed with efficiency in mind. Our machines minimize material waste while maximizing output quality, resulting in significant cost savings over traditional manufacturing methods.

With lower energy consumption and reduced maintenance requirements, our presses offer an excellent return on investment for businesses of all sizes.

Technical Specifications of MAIKONG Small Aluminum Forging Press

Detailed technical diagram of MAIKONG’s small aluminum forging press system

| Specification |

Standard Model |

Advanced Model |

Premium Model |

| Maximum Force |

12 Tons |

18 Tons |

23 Tons |

| Stroke Length |

6″ |

8″ |

11.65″ |

| Operating Speed |

3.5 IPS |

5.0 IPS |

13 mm/s |

| Reverse Speed |

5.0 IPS |

6.5 IPS |

75 mm/s |

| Power Requirement |

110V, 20A |

220V, 30A |

230/440V three-phase |

| Table Dimensions |

10″ x 10″ |

12″ x 12″ |

10″ x 10.2″ |

| Control System |

Manual |

Manual/Auto |

Manual/Auto with Limit Switches |

Find Your Ideal Forging Solution

Contact our technical team to determine which small aluminum forging press model best suits your specific manufacturing needs.

WhatsApp Our Experts

Applications of Small Aluminum Forging Press Technology

Automotive Components

Our small aluminum forging press systems excel at producing high-strength, lightweight automotive parts including brackets, connectors, and structural components.

Aerospace Applications

The precision and material integrity of our forging process make it ideal for critical aerospace components where performance and reliability are paramount.

Consumer Products

From bicycle components to electronic device housings, our small aluminum forging press technology delivers exceptional results for consumer-facing products.

“The MAIKONG small aluminum forging press has transformed our production capabilities. The precision and consistency of the parts produced have allowed us to expand into new markets while reducing our overall manufacturing costs.”

– Manufacturing Director, Precision Components Inc.

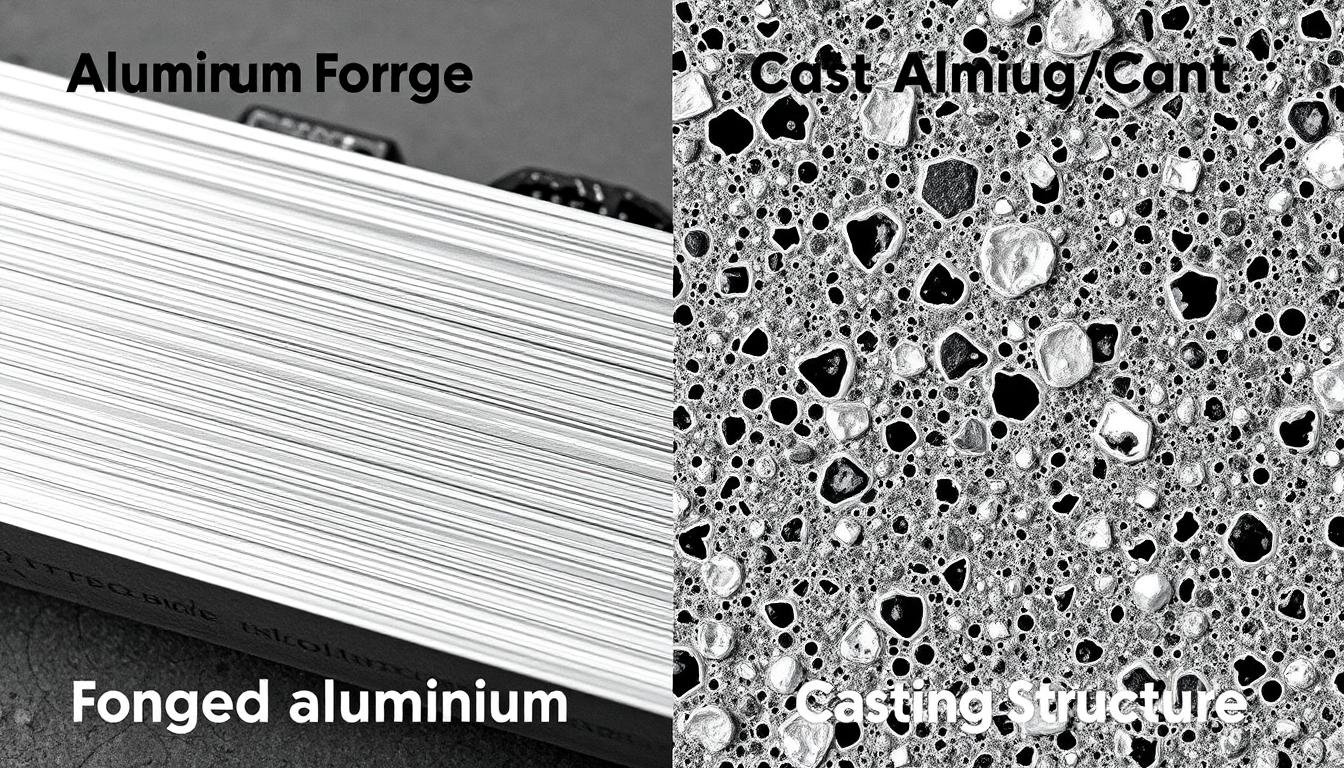

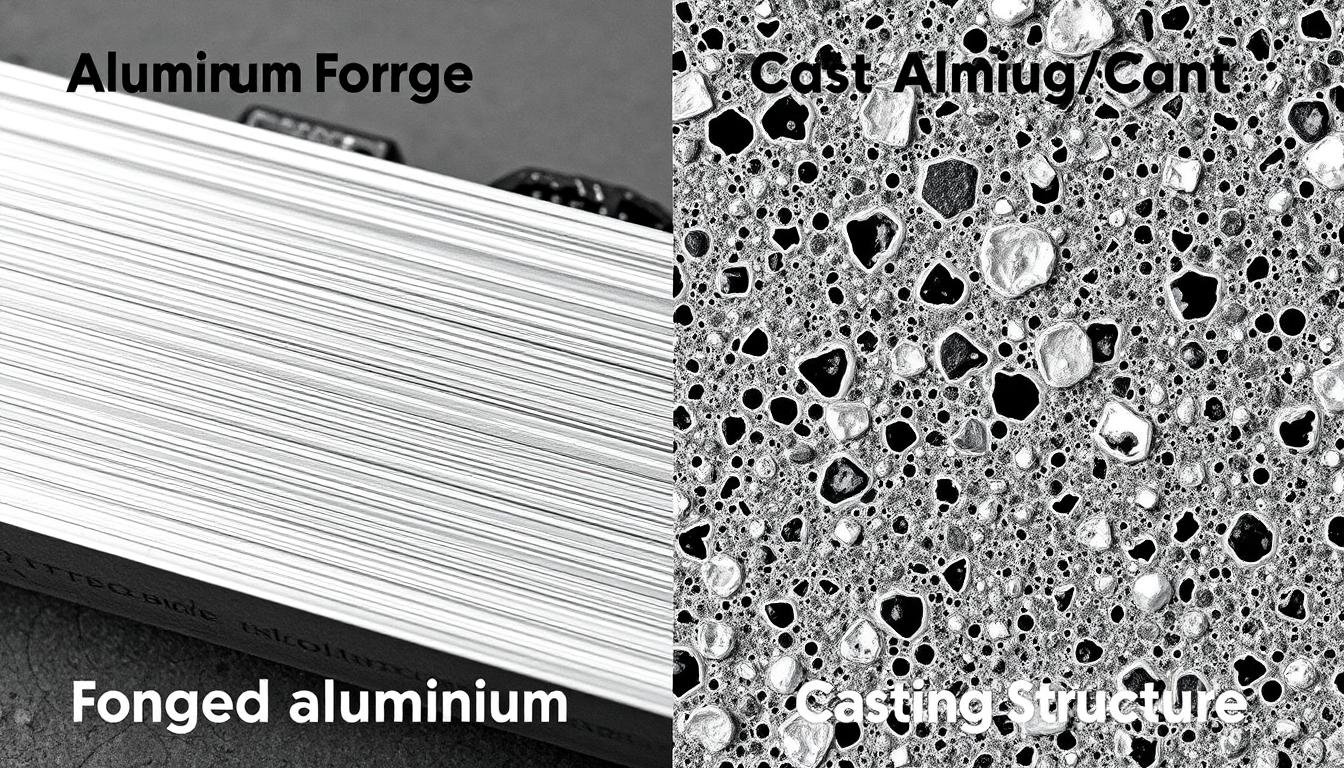

Aluminum Forging vs. Casting: Why Choose a Small Aluminum Forging Press

Microscopic comparison of forged vs. cast aluminum material structure

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Tensile Properties |

Superior tensile strength and resistance |

Lower tensile strength |

| Fatigue Resistance |

Better resistance against fatigue failure |

Potentially lower fatigue resistance |

| Dimensional Accuracy |

Better accuracy and tighter tolerances |

Potential inconsistencies |

| Surface Finish |

Smoother surfaces, reduced post-processing |

Might require more machining due to air pockets |

| Weight-to-Strength Ratio |

High strength-to-weight ratio |

Bulkier parts may be needed |

The small aluminum forging press process creates parts with superior mechanical properties by aligning the grain structure of the aluminum during deformation. This results in components with exceptional strength-to-weight ratios, ideal for applications where performance and reliability are critical.

Strength testing demonstrates superior performance of forged aluminum components

MAIKONG’s Comprehensive Small Aluminum Forging Press Services

Full-Service Manufacturing

- CAD/CAM design and optimization

- Material selection and testing

- Custom tooling design and fabrication

- Precision forging operations

- Heat treatment for optimal material properties

- CNC machining for final dimensions

- Surface treatment and finishing

- Comprehensive quality control

Our Quality Commitment

At MAIKONG, quality is built into every step of our process. Our ISO 9001:2015 certified facilities ensure consistent, reliable results for every component we produce. From material selection to final inspection, our comprehensive quality management system guarantees that each part meets or exceeds specifications.

Rigorous quality control ensures every component meets exact specifications

Partner with MAIKONG for Superior Results

Experience the difference that precision engineering and comprehensive service can make for your aluminum component needs.

Email Our Team

Why Choose MAIKONG for Your Small Aluminum Forging Press Needs

Our dedicated team of experts ensures excellence in every project

Unmatched Expertise

With years of specialized experience in aluminum forging technology, our team brings unparalleled knowledge to every project.

Superior Quality

Our commitment to excellence ensures that every component meets the highest standards for performance and reliability.

Competitive Pricing

We deliver exceptional value through efficient processes and optimized manufacturing techniques.

Partner with MAIKONG for your small aluminum forging press needs and experience the difference that precision engineering, comprehensive service, and unwavering commitment to quality can make for your business.

Ready to Elevate Your Manufacturing Capabilities?

Contact MAIKONG today to discuss your specific requirements and discover how our small aluminum forging press solutions can transform your production process.

Get Started Today

MAIKONG’s precision-engineered small aluminum forging press in operation

MAIKONG’s precision-engineered small aluminum forging press in operation