The hot forging press stands at the forefront of modern manufacturing, delivering unparalleled strength and precision in metal components. At MAIKONG, we’ve perfected this technology through decades of innovation, creating forging solutions that combine superior performance with cost-effectiveness. Our comprehensive approach to metal forming ensures your components achieve optimal mechanical properties while maintaining efficient production cycles.Whether you’re seeking automotive components, aerospace parts, or industrial equipment elements, our hot forging press technology delivers the structural integrity and dimensional accuracy your applications demand. Contact our engineering team today to discover how our advanced forging capabilities can transform your manufacturing process.

Key Advantages of Hot Forging Press Technology

The hot forging press process offers significant advantages over alternative metal forming methods. By heating metal to temperatures above its recrystallization point before applying pressure, we achieve superior material flow and enhanced mechanical properties in the final product.

Enhanced Material Properties

- Improved grain structure alignment

- Superior strength-to-weight ratio

- Enhanced fatigue resistance

- Increased impact toughness

- Consistent mechanical properties

Production Advantages

- Reduced material waste

- Lower energy consumption

- Faster production cycles

- Near-net shape capabilities

- Minimal secondary machining

Our hot forging press machines are engineered to maximize these benefits while maintaining precise dimensional control. The result is consistently high-quality components that meet or exceed industry standards for structural integrity and performance.

Experience Superior Forging Quality

Discover how MAIKONG’s advanced hot forging technology can elevate your component quality while reducing overall production costs.

Request a Consultation

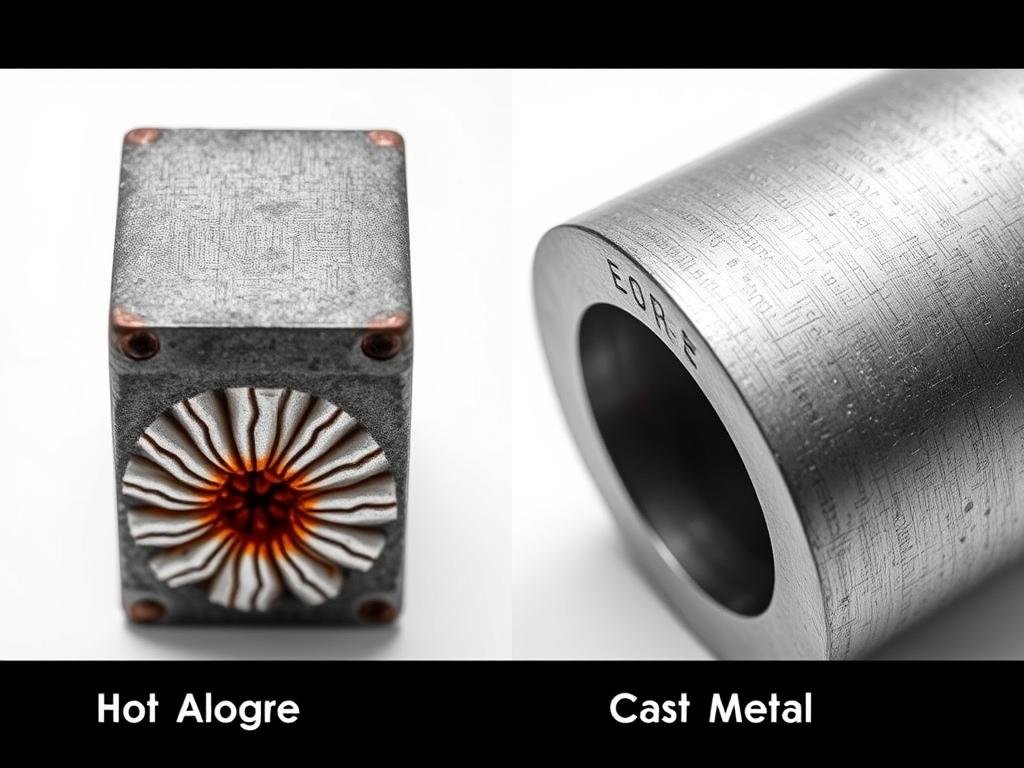

Hot Forging Press vs. Casting: A Comprehensive Comparison

When evaluating manufacturing methods for metal components, understanding the differences between hot forging press technology and casting is crucial. Each approach offers distinct advantages depending on your specific application requirements.

| Performance Factor |

Hot Forging Press |

Casting Process |

| Mechanical Strength |

Superior strength due to aligned grain structure |

Lower strength with potential internal voids |

| Material Density |

Consistent high density throughout |

Variable density with possible porosity |

| Fatigue Resistance |

Excellent resistance to cyclic loading |

Moderate to poor fatigue performance |

| Geometric Complexity |

Limited to moderate complexity |

High complexity possible |

| Surface Finish |

Excellent with minimal post-processing |

Requires significant finishing |

| Production Speed |

High-volume capability |

Typically slower process |

| Material Waste |

Minimal waste with near-net shapes |

Low waste but higher rejection rates |

MAIKONG’s hot forging press technology excels in applications where structural integrity and performance are paramount. Our engineering team can help determine whether forging or casting is optimal for your specific component requirements.

MAIKONG’s Advanced Hot Forging Press Capabilities

At MAIKONG, we’ve developed comprehensive hot forging press capabilities to meet diverse manufacturing requirements. Our state-of-the-art facility in GD, SZ combines advanced technology with skilled craftsmanship to deliver exceptional forged components.

Our Hot Forging Press Equipment

Our facility features multiple hot forging press machines with capacities ranging from 800 to 6,000 tons. This diverse equipment lineup allows us to handle components from small precision parts to large industrial elements with equal expertise.

Mechanical Forging Presses

- Tonnage: 800-4,000 tons

- High-speed production

- Precision control systems

- Energy-efficient operation

Hydraulic Forging Presses

- Tonnage: 1,000-6,000 tons

- Variable speed control

- Programmable pressure profiles

- Extended dwell capabilities

Specialized Forging Systems

- Automated material handling

- Integrated heating systems

- Robotic transfer mechanisms

- Advanced die management

Integrated Manufacturing Services

Beyond our core hot forging press operations, MAIKONG offers comprehensive manufacturing services to deliver complete component solutions:

CNC Machining Excellence

- Precision CNC milling services

- Advanced CNC turning capabilities

- Multi-axis machining centers

- High-tolerance finishing operations

- Comprehensive CNC prototyping

Quality Assurance Systems

- Advanced metrology equipment

- Material testing laboratory

- Non-destructive testing capabilities

- Statistical process control

- Comprehensive documentation

Explore Our Manufacturing Capabilities

MAIKONG offers end-to-end metal forming solutions from design assistance through final production. Our integrated approach ensures quality at every stage.

Get a Custom Quote

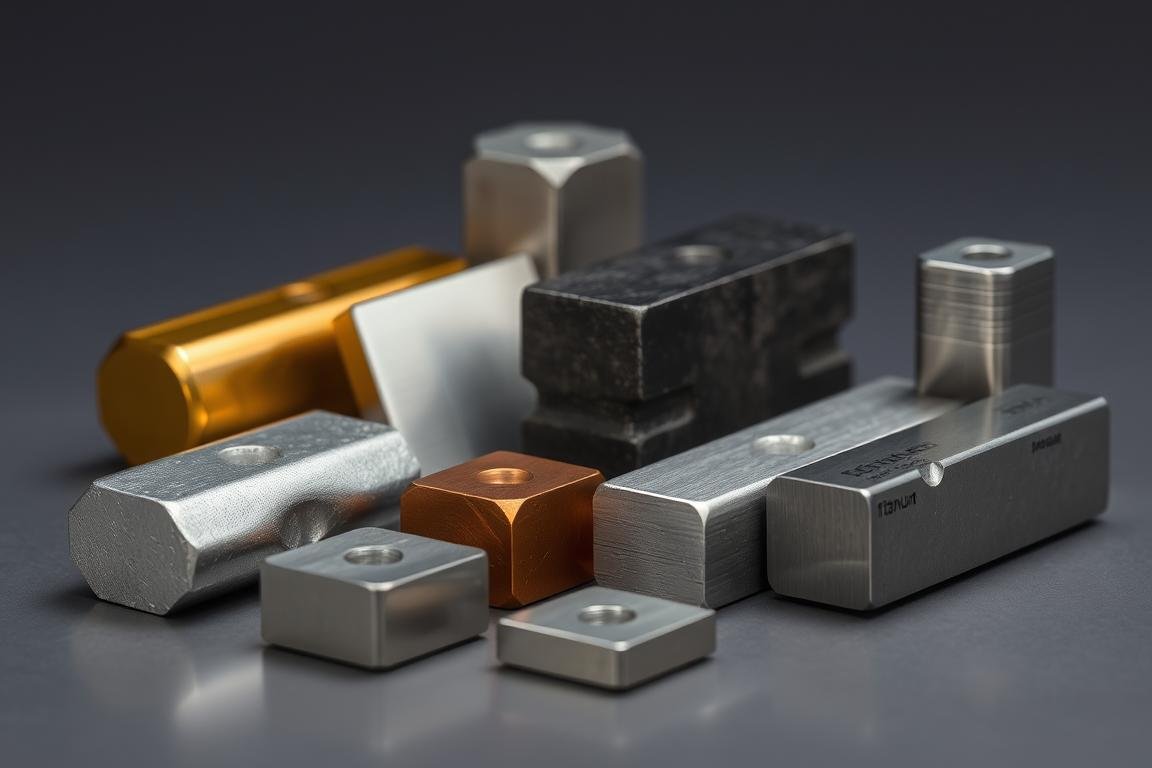

Materials and Applications for Hot Forging Press Technology

The versatility of hot forging press technology allows MAIKONG to work with a wide range of materials to serve diverse industry applications. Our expertise extends across multiple metal types and component categories.

Materials Expertise

Aluminum Alloys

- 2000 series (Al-Cu)

- 6000 series (Al-Mg-Si)

- 7000 series (Al-Zn)

- Custom aluminum formulations

Steel Varieties

- Carbon steels

- Alloy steels

- Tool steels

- Stainless steel grades

Specialty Metals

- Brass compositions

- Bronze alloys

- Titanium grades

- Nickel-based superalloys

Industry Applications

Our hot forging press technology serves critical applications across multiple industries where performance and reliability are essential:

Automotive Sector

- Connecting rods

- Crankshafts

- Steering components

- Transmission gears

- Suspension elements

Aerospace Industry

- Structural components

- Landing gear parts

- Engine mounts

- Turbine components

- Fastening systems

Industrial Equipment

- Heavy machinery parts

- Power transmission components

- Hydraulic system elements

- Mining equipment

- Construction hardware

MAIKONG’s hot forging press capabilities extend to custom applications beyond these standard categories. Our engineering team works closely with clients to develop specialized forging solutions for unique requirements.

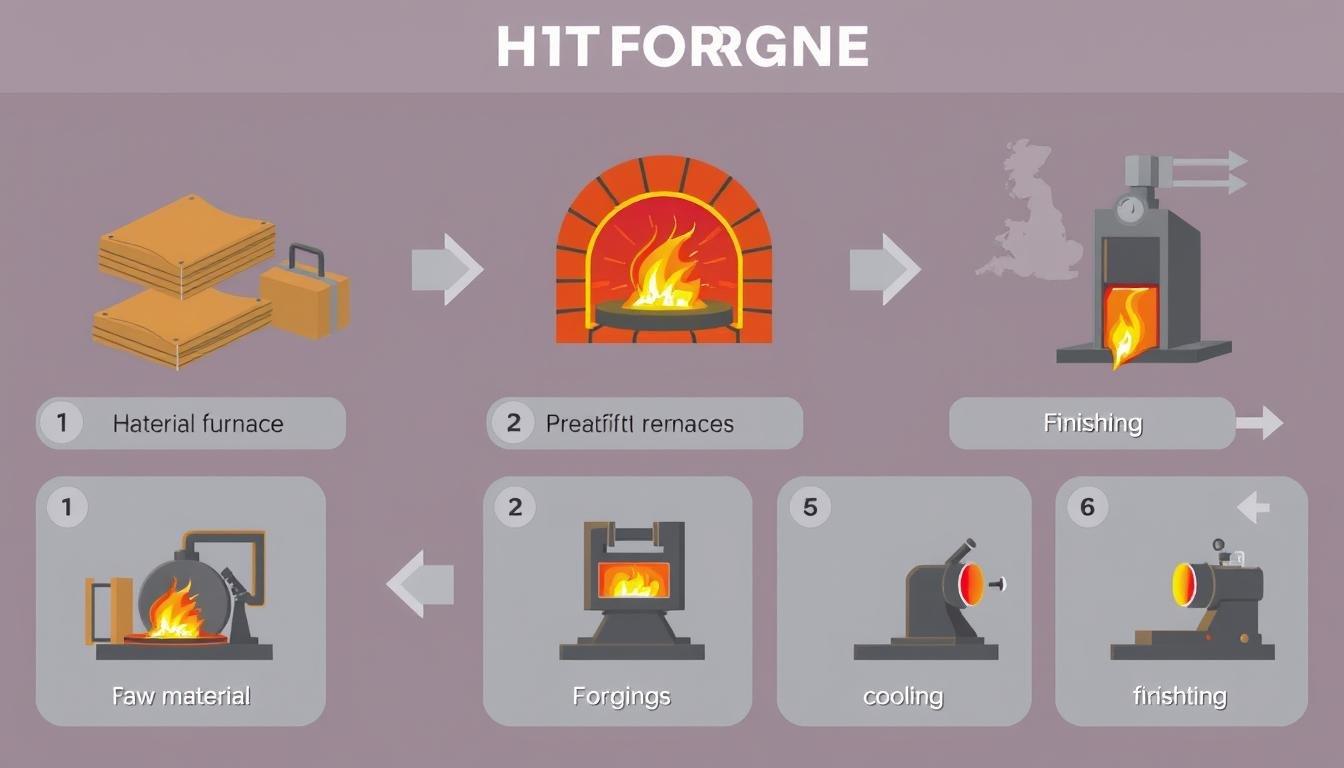

The MAIKONG Hot Forging Press Process

At MAIKONG, we’ve refined our hot forging press process to ensure consistent quality and optimal material properties. Our comprehensive approach integrates advanced technology with proven metallurgical principles.

Our Comprehensive Forging Methodology

Design & Engineering

- CAD/CAM integration for precise die design

- Finite element analysis for process optimization

- Material flow simulation

- Thermal analysis for optimal heating parameters

Material Preparation

- Rigorous material selection and testing

- Precision cutting to optimal billet dimensions

- Controlled heating to specific temperature ranges

- Temperature monitoring throughout process

Forging Operation

- Computer-controlled press operation

- Precise die alignment systems

- Optimized pressure application profiles

- Controlled cooling procedures

Advanced Heat Treatment

Our hot forging press process includes sophisticated heat treatment capabilities to optimize the mechanical properties of forged components:

Heat Treatment Capabilities

- Solution heat treatment

- Precipitation hardening

- Annealing processes

- Normalizing treatments

- Stress relief procedures

Quality Control Measures

- Hardness testing

- Microstructure analysis

- Tensile strength verification

- Dimensional stability checks

- Surface quality inspection

Partner with MAIKONG for Superior Forging Solutions

Our advanced hot forging press technology delivers exceptional quality at competitive prices. Contact us to discuss your specific requirements.

Quality Assurance in Hot Forging Press Manufacturing

At MAIKONG, quality is integrated into every aspect of our hot forging press operations. Our comprehensive quality assurance system ensures consistent performance and reliability in every component we produce.

Our Quality Control Infrastructure

MAIKONG’s quality assurance program for hot forging press manufacturing includes:

Material Verification

- Spectrographic analysis

- Mechanical property testing

- Batch certification

- Traceability systems

Process Monitoring

- Statistical process control

- Real-time temperature monitoring

- Press force verification

- Cycle time optimization

Final Inspection

- Dimensional verification

- Surface quality assessment

- Non-destructive testing

- Performance validation

Documentation and Certification

Our hot forging press manufacturing is supported by comprehensive documentation and certification processes:

- Material certifications for all raw materials

- Process parameter records for each production batch

- Inspection reports documenting all quality checks

- Traceability documentation linking components to raw materials

- Compliance certificates for industry-specific requirements

US Distribution Opportunities for MAIKONG Hot Forging Press Products

MAIKONG is actively seeking distribution partners across the United States for our premium hot forging press components and custom manufacturing services. Our cost-effective solutions offer significant opportunities for distributors serving industrial manufacturing sectors.

Partnership Benefits

For Distributors

- Competitive pricing structure

- Consistent high-quality products

- Comprehensive technical support

- Flexible minimum order quantities

- Custom branding options

For End Customers

- Superior component performance

- Cost-effective manufacturing solutions

- Reduced lead times

- Consistent quality standards

- Technical consultation services

Become a MAIKONG Distribution Partner

Join our growing network of US distributors and offer your customers premium hot forging press components at competitive prices.

Apply for Distribution Partnership

Frequently Asked Questions About Hot Forging Press Technology

Our clients often have questions about hot forging press technology and its applications. Here are answers to some common inquiries:

What temperature range is used in hot forging press operations?

Hot forging typically occurs at temperatures above the material’s recrystallization point. For steel, this is generally between 2100°F and 2300°F (1150°C to 1260°C). Aluminum alloys are typically forged at temperatures between 700°F and 950°F (370°C to 510°C). The specific temperature is determined by the alloy composition and desired mechanical properties.

How does hot forging press technology compare to cold forging?

Hot forging offers several advantages over cold forging, including lower force requirements, better material flow, and the ability to work with harder materials. Cold forging typically provides better dimensional accuracy and surface finish but is limited to less complex shapes and softer materials. At MAIKONG, we offer both processes and can recommend the optimal approach based on your specific component requirements.

What is the typical lead time for custom hot forged components?

Lead times vary based on component complexity, material availability, and current production schedules. For standard components, lead times typically range from 4-6 weeks. Custom designs requiring new tooling may require 8-12 weeks for initial production. MAIKONG offers expedited services for time-sensitive projects when possible.

What minimum order quantities does MAIKONG require for hot forged components?

Our minimum order quantities are flexible and depend on component size, complexity, and tooling requirements. For standard components, MOQs typically start at 500 pieces. For custom designs requiring new tooling, MOQs may start at 1,000 pieces to amortize tooling costs. We work with clients to find solutions that balance economic production with inventory management needs.

Partner with MAIKONG for Premium Hot Forging Press Solutions

MAIKONG combines advanced hot forging press technology with comprehensive manufacturing capabilities to deliver superior metal components at competitive prices. Our integrated approach—from design assistance through final production—ensures quality, consistency, and performance in every component we produce.

With our state-of-the-art facilities in GD, SZ and our commitment to excellence, we’re positioned to serve clients across diverse industries with precision-engineered forged components. Whether you need standard parts or custom solutions, our team is ready to exceed your expectations.

Ready to Elevate Your Manufacturing Capabilities?

Contact MAIKONG today to discuss your hot forging press requirements and discover our cost-effective solutions.