Welcome to MAIKONG’s comprehensive guide to aluminum tool forging pricelist information. As a leading manufacturer specializing in high-quality aluminum forging, we provide detailed pricing insights and competitive rates for all your custom metal fabrication needs. Our state-of-the-art facility in GD, SZ delivers precision-engineered aluminum components with superior strength-to-weight ratios and exceptional durability for various industrial applications.

Need Custom Aluminum Forging Pricing?

Get an immediate quote for your specific aluminum tool forging requirements. Our team provides fast, accurate pricing for any volume or complexity.

Get Your Custom Quote

Contact via WhatsApp

Understanding Aluminum Tool Forging Pricelist Factors

The cost of aluminum forging depends on several key factors that influence the final price. At MAIKONG, we maintain transparent pricing while delivering exceptional quality. Here’s what affects your aluminum forging costs:

| Pricing Factor |

Impact on Cost |

MAIKONG Advantage |

| Material Grade & Quality |

15-25% of total cost |

Premium aluminum alloys at competitive rates |

| Part Complexity |

20-40% of total cost |

Advanced tooling reduces costs for complex designs |

| Production Volume |

10-30% cost reduction at scale |

Flexible pricing for both small and large orders |

| Tolerance Requirements |

5-15% premium for tight tolerances |

Precision manufacturing with minimal cost impact |

| Surface Finish |

5-20% additional cost |

In-house finishing reduces overall costs |

| Secondary Operations |

10-30% additional cost |

One-stop service minimizes additional processing costs |

Aluminum Alloy Selection and Pricing Impact

The choice of aluminum alloy significantly affects both performance and price. MAIKONG offers competitive pricing across all major aluminum grades used in forging applications:

| Aluminum Alloy |

Typical Applications |

Relative Cost Index |

Strength Properties |

| 2014 |

Aircraft fittings, wheels, structural components |

110-120 |

High strength, good machinability |

| 2024 |

Aircraft structures, hardware, truck wheels |

115-125 |

High strength-to-weight ratio, fatigue resistance |

| 6061 |

General purpose structural, automotive parts |

90-100 |

Good corrosion resistance, medium strength |

| 6082 |

Heavy-duty structures, bridges, cranes |

95-105 |

Higher strength than 6061, excellent corrosion resistance |

| 7075 |

Aerospace applications, high-stress components |

130-145 |

Very high strength, good fatigue resistance |

Note: Relative Cost Index uses 6061 as the baseline (100). Actual prices vary based on market conditions and order volume.

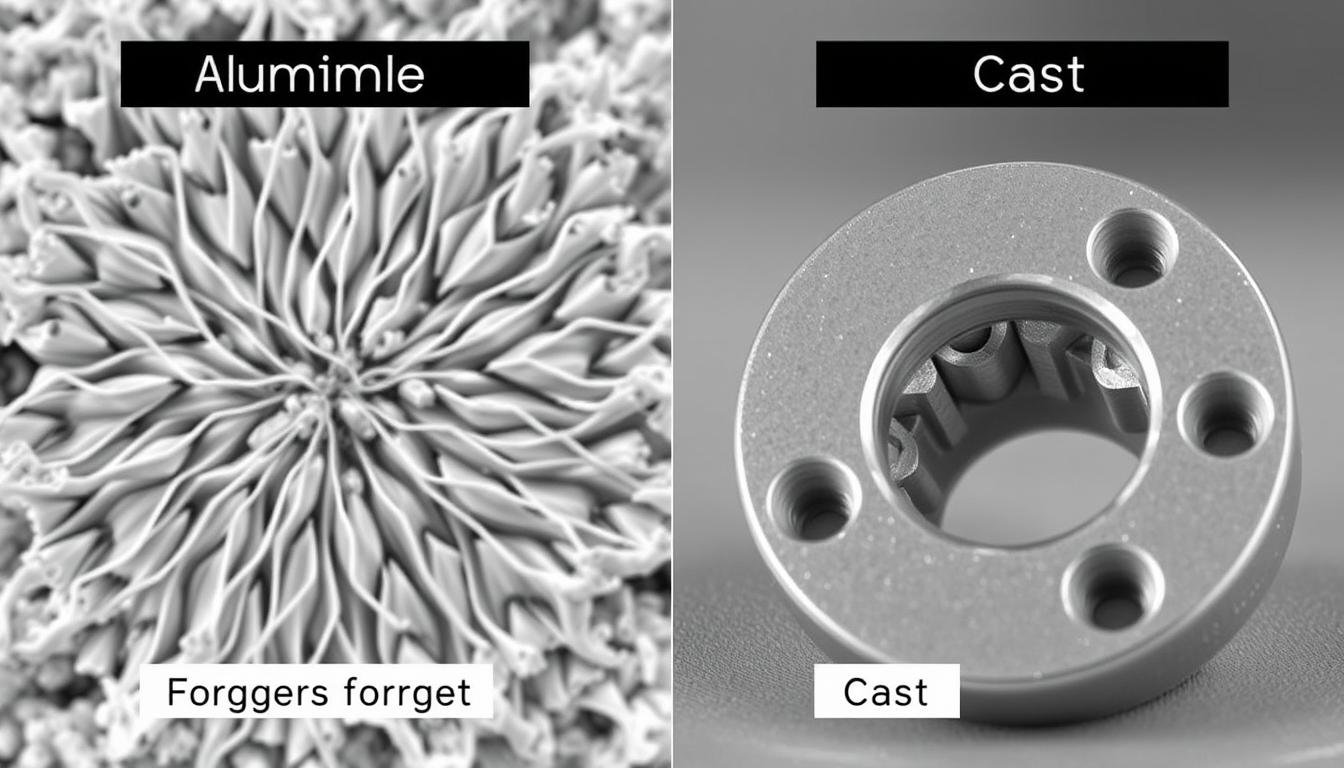

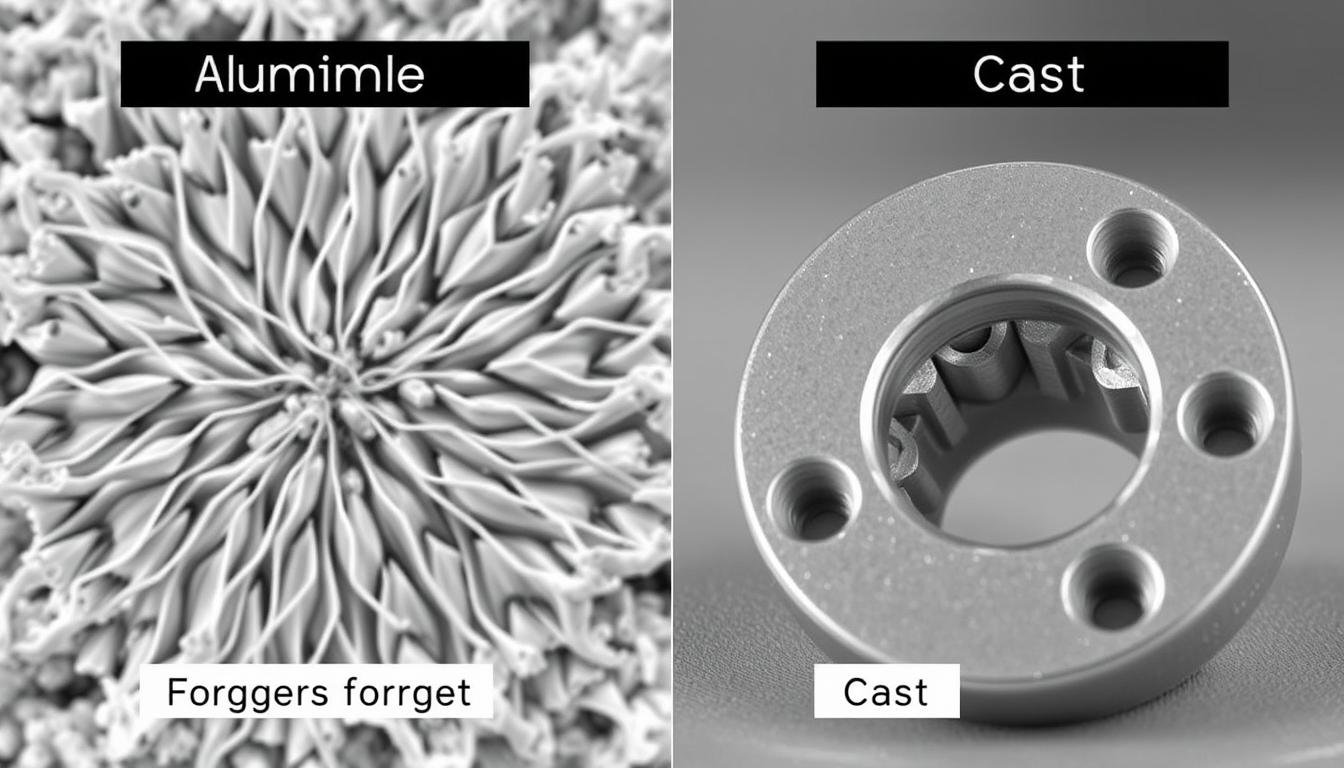

Aluminum Forging vs. Casting: Cost-Benefit Analysis

When considering manufacturing methods for aluminum components, understanding the cost-benefit relationship between forging and casting is crucial. MAIKONG specializes in aluminum forging, which offers superior mechanical properties for critical applications.

| Comparison Categories |

Aluminum Forging |

Casting Aluminum |

| Strength and Durability |

✅ Higher due to dense, uniform grain structure |

Potentially lower due to air pockets and inclusions |

| Initial Tooling Cost |

Higher investment in dies and tooling |

✅ Lower initial mold costs |

| Unit Cost at Volume |

✅ More economical for medium to high volumes |

More economical for low volumes or complex shapes |

| Dimensional Accuracy |

✅ Better accuracy and tighter tolerances |

Potential inconsistencies requiring machining |

| Material Waste |

✅ Less material waste in production |

Higher waste from gates, risers, and sprues |

| Long-term Value |

✅ Higher durability reduces replacement costs |

May require more frequent replacement |

| Weight-to-Strength Ratio |

✅ Superior strength-to-weight ratio |

Requires thicker sections for equivalent strength |

Need Help Choosing Between Forging and Casting?

Our engineering team can analyze your specific requirements and recommend the most cost-effective manufacturing approach for your aluminum components.

Email Our Engineering Team

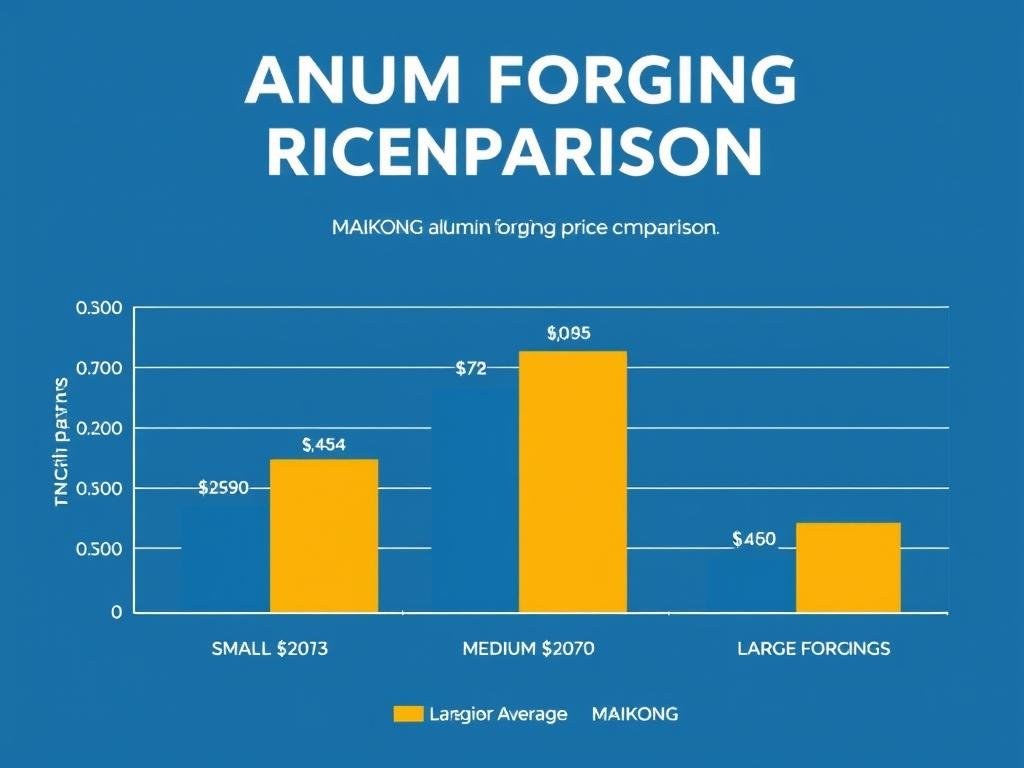

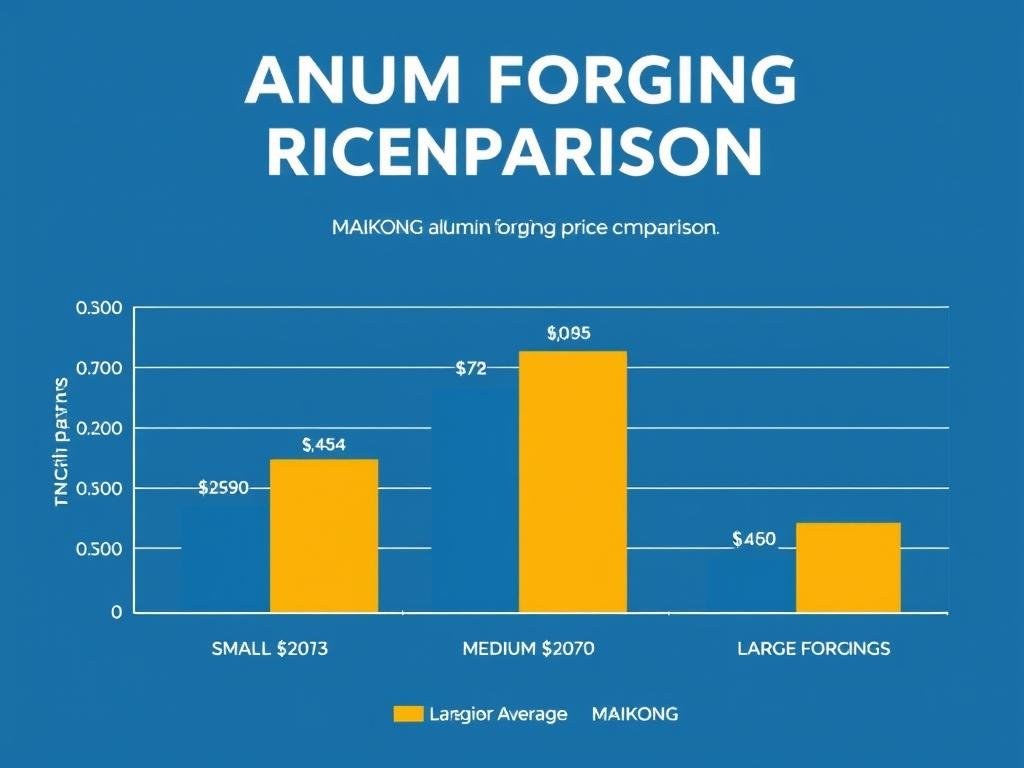

Volume-Based Aluminum Tool Forging Pricelist

MAIKONG offers competitive volume-based pricing for aluminum forged components. Our tiered pricing structure rewards larger orders while maintaining quality across all production volumes.

| Production Volume |

Small Parts

(<0.5 kg) |

Medium Parts

(0.5-2 kg) |

Large Parts

(>2 kg) |

| Prototype (1-10 pcs) |

$35-45 per piece |

$60-90 per piece |

$120-200+ per piece |

| Low Volume (11-100 pcs) |

$20-30 per piece |

$45-70 per piece |

$90-150 per piece |

| Medium Volume (101-500 pcs) |

$12-18 per piece |

$30-50 per piece |

$70-120 per piece |

| High Volume (501-1000 pcs) |

$8-15 per piece |

$25-40 per piece |

$60-100 per piece |

| Mass Production (1000+ pcs) |

$5-10 per piece |

$18-35 per piece |

$50-90 per piece |

Note: Prices are indicative and may vary based on specific design requirements, material selection, and secondary operations. Contact us for a precise quote tailored to your exact specifications.

Request Volume Pricing

Contact our sales team for detailed volume-based pricing tailored to your specific aluminum forging requirements.

Get Volume Quote

Call: +86 13510907401

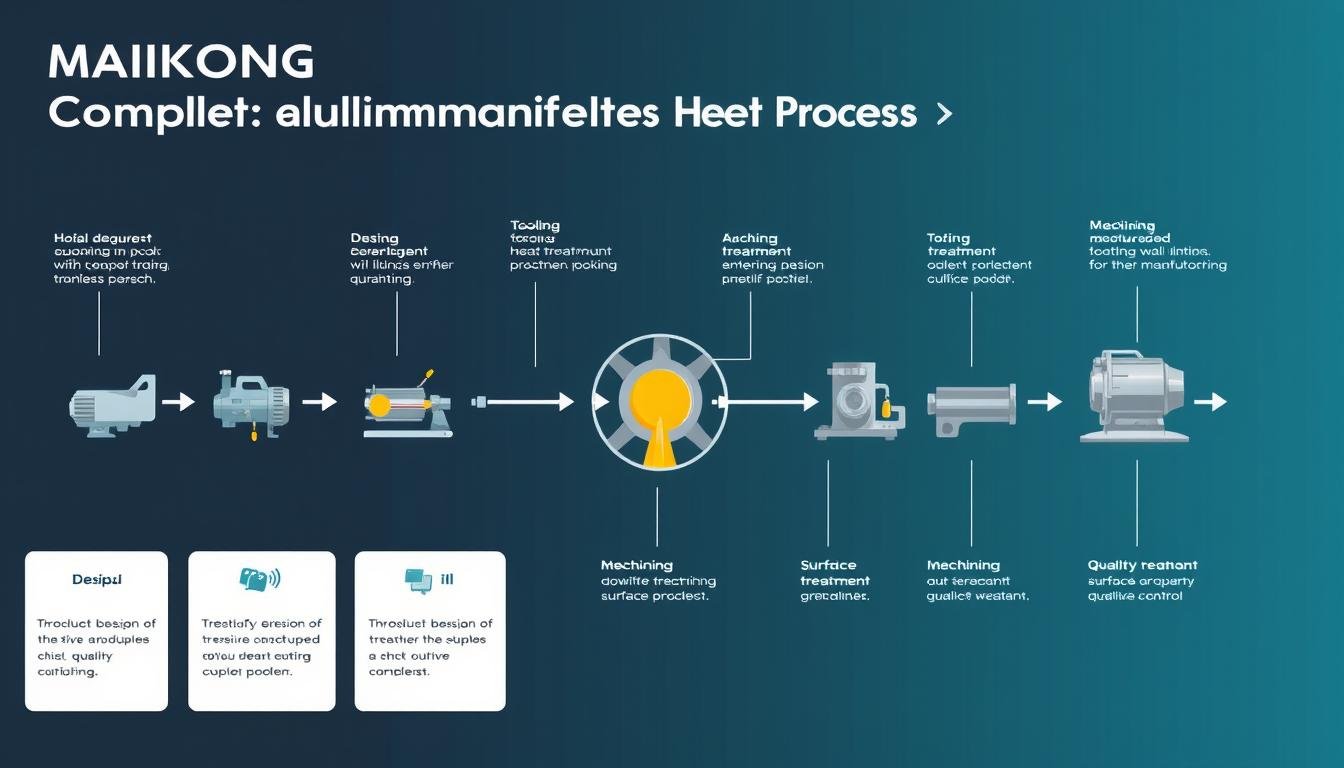

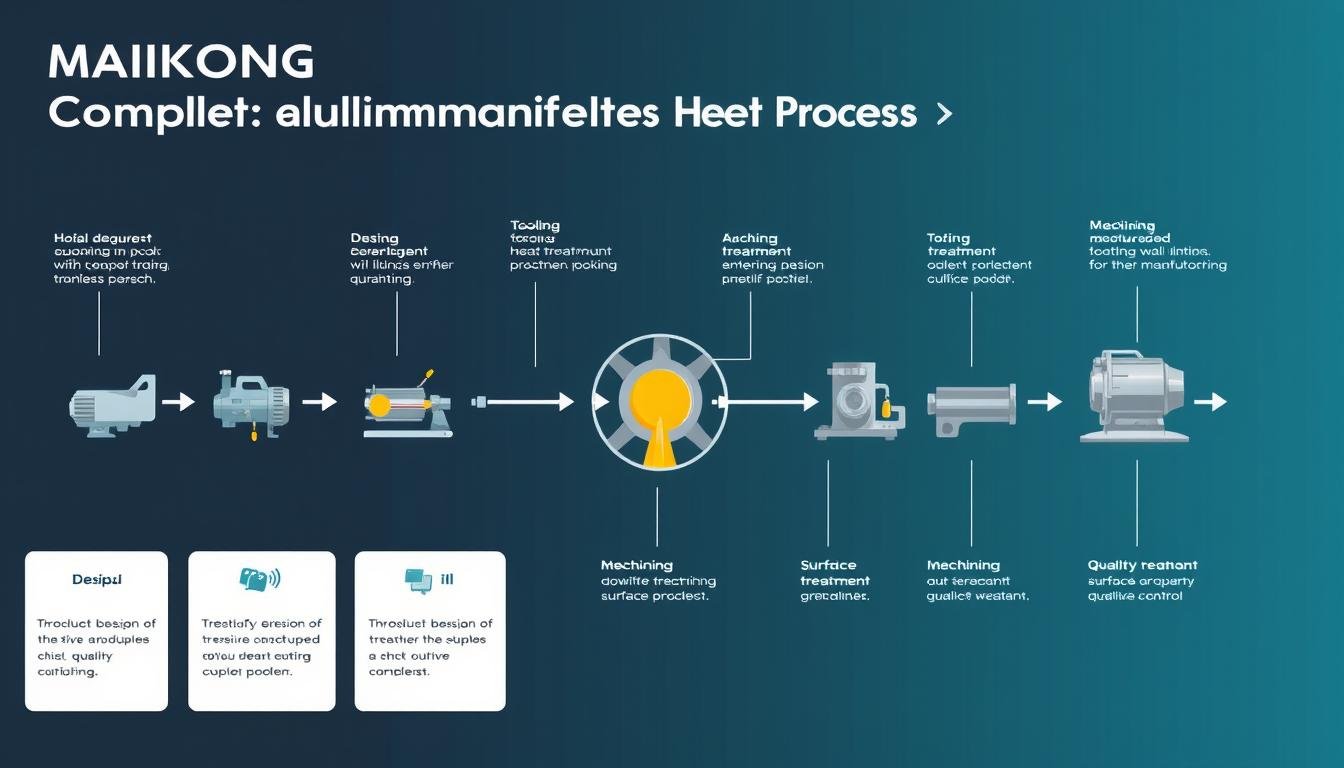

MAIKONG Manufacturing Capabilities

Our state-of-the-art facility in GD, SZ is equipped with over 60 CNC machines and provides 100+ tons of metal processing capacity per month. We deliver precision-engineered aluminum components with superior quality and competitive pricing.

CNC Machining

Our advanced CNC machining centers provide precision finishing for forged aluminum components with tolerances as tight as ±0.01mm.

Forging Presses

Our hydraulic and mechanical forging presses (400-2500 tons) enable us to produce aluminum forgings from small components to large structural parts.

Heat Treatment

In-house heat treatment facilities ensure optimal mechanical properties for all aluminum alloys, with precise temperature control and documentation.

Quality Control

Our comprehensive quality control system includes CMM inspection, material testing, and 100% visual inspection to ensure consistent quality.

Surface Treatment

We offer various surface treatments including anodizing, powder coating, painting, and polishing to enhance both aesthetics and performance.

Design & Engineering

Our experienced engineering team provides design optimization, material selection assistance, and DFM (Design for Manufacturing) support.

Tour Our Manufacturing Capabilities

Interested in learning more about our aluminum forging capabilities? Schedule a virtual tour of our facility or request detailed specifications.

Schedule Virtual Tour

Our Comprehensive Aluminum Forging Services

MAIKONG provides end-to-end aluminum forging solutions, from initial design consultation to finished components. Our services include:

- Design optimization for forgeability and cost reduction

- Tooling design and manufacturing

- Material selection and sourcing

- Prototype development and testing

- Production forging with strict quality control

- Heat treatment to achieve desired mechanical properties

- CNC machining and secondary operations

- Surface treatments and finishing

- Quality inspection and certification

- Packaging and global logistics

Industries Served with Aluminum Forged Components

MAIKONG’s aluminum forged components are used across various industries where strength, precision, and reliability are critical:

Automotive

Engine components, suspension parts, structural elements, and drivetrain components that require high strength-to-weight ratio.

Aerospace

Structural components, brackets, fittings, and control system parts that demand exceptional reliability and performance.

Industrial Machinery

Gears, connectors, structural elements, and high-stress components for manufacturing equipment.

Medical Equipment

Surgical instrument components, equipment frames, and precision mechanisms requiring sterility and reliability.

Defense

Tactical equipment components, vehicle parts, and specialized hardware requiring durability in extreme conditions.

Consumer Products

Sporting goods, high-end tools, recreational equipment, and premium consumer product components.

Quality Assurance for Aluminum Forged Components

At MAIKONG, quality is built into every step of our manufacturing process. Our comprehensive quality management system ensures consistent, reliable performance of all aluminum forged components.

Quality Certifications

- ISO 9001:2015 certified quality management system

- IATF 16949 automotive quality standards

- Material certifications and traceability

- Dimensional inspection reports

- Mechanical property verification

Testing Capabilities

- Material composition analysis

- Mechanical property testing (tensile, yield, elongation)

- Hardness testing (Brinell, Rockwell, Vickers)

- Non-destructive testing

- Dimensional verification with CMM

Custom Aluminum Forging Solutions

MAIKONG specializes in developing custom aluminum forging solutions tailored to your specific requirements. Our engineering team works closely with clients to optimize designs for manufacturability, performance, and cost-effectiveness.

4.8

Customer Satisfaction

Price Competitiveness

4.6/5

Start Your Custom Aluminum Forging Project

Ready to discuss your specific aluminum forging requirements? Our engineering team is available to provide expert guidance and competitive pricing.

Start Your Project

Email Us

US Distribution Opportunities

MAIKONG is actively seeking distribution partners across the United States for our premium aluminum forged components. We offer competitive pricing, reliable quality, and comprehensive support for distributors.

Distributor Benefits

- Exclusive territorial rights

- Competitive pricing structure

- Technical training and support

- Marketing materials and assistance

- Reliable supply chain and inventory management

- Custom packaging and branding options

Ideal Partner Profile

- Established presence in industrial markets

- Technical sales capabilities

- Experience with metal components

- Strong customer relationships

- Commitment to quality and service

- Growth-oriented business approach

Become a US Distributor

Interested in distributing MAIKONG’s premium aluminum forged components? Contact our distribution team to discuss partnership opportunities.

Distribution Inquiry

Call: +86 13510907401

Frequently Asked Questions About Aluminum Tool Forging Pricelist

What factors most significantly impact aluminum forging prices?

The most significant factors affecting aluminum forging prices include material grade selection, part complexity, production volume, required tolerances, and any secondary operations needed. At MAIKONG, we optimize each of these factors to provide the most competitive pricing without compromising quality.

How does MAIKONG ensure competitive pricing for aluminum forgings?

MAIKONG maintains competitive pricing through several strategies: vertical integration of our manufacturing processes, efficient tooling design, optimized production workflows, strategic material sourcing, and economies of scale. Our facility in GD, SZ combines advanced technology with cost-effective manufacturing practices to deliver exceptional value.

What is the minimum order quantity for custom aluminum forgings?

While our production is most cost-effective at higher volumes, MAIKONG accommodates various order sizes, including small prototype runs. Minimum order quantities typically start at 10-25 pieces for custom forgings, though this can vary based on part complexity and size. We’re happy to discuss your specific requirements and find the most economical solution.

How long does it take to receive a quote for aluminum forged components?

MAIKONG typically provides initial pricing estimates within 24-48 hours for standard components. For complex custom designs, a detailed quote may take 3-5 business days as our engineering team analyzes manufacturability and optimizes the production approach. Expedited quotes are available upon request for urgent projects.

Does MAIKONG offer price breaks for higher volume orders?

Yes, MAIKONG offers tiered pricing with significant discounts for higher volume orders. Our volume-based pricing structure typically includes breakpoints at 100, 500, 1,000, and 5,000+ pieces. The per-unit cost decreases substantially at each tier due to more efficient production runs and amortized tooling costs.

Why Choose MAIKONG for Your Aluminum Forging Needs

MAIKONG combines advanced manufacturing capabilities, competitive pricing, and exceptional quality to deliver superior aluminum forged components for demanding applications. With our comprehensive services from design to delivery, we provide a seamless experience for clients worldwide.

- State-of-the-art manufacturing facility with 60+ CNC machines

- 100+ tons monthly metal processing capacity

- ISO 9001:2015 certified quality management system

- Competitive pricing with volume discounts

- Comprehensive capabilities from design to finished components

- Global shipping and logistics support

- Dedicated customer service and technical support

Partner with MAIKONG for your aluminum tool forging needs and experience the perfect balance of quality, price, and service. Contact us today to discuss your specific requirements and receive a customized quote.

Ready to Get Started?

Take the first step toward high-quality, cost-effective aluminum forged components for your application.

Contact Us Now

WhatsApp Inquiry