MAIKONG: Leading Aluminum Forgings Manufacturers for Premium Quality Parts

As premier aluminum forgings manufacturers, MAIKONG delivers exceptional strength-to-weight ratio components with superior corrosion resistance and excellent machinability. With over 15 years of industry experience, we provide comprehensive aluminum forging solutions from design to delivery, serving aerospace, automotive, marine, and industrial sectors worldwide. Our state-of-the-art facility in GD, SZ combines advanced technology with metallurgical expertise to create precision-engineered aluminum components that exceed expectations.

Ready to Elevate Your Components with Premium Aluminum Forgings?

Our engineering team is ready to discuss your project requirements and provide competitive pricing.

Our engineering team is ready to discuss your project requirements and provide competitive pricing.

Get a Quick Quote

Contact via WhatsApp

Why Choose MAIKONG as Your Aluminum Forgings Manufacturers?

Superior Aluminum Forging Benefits

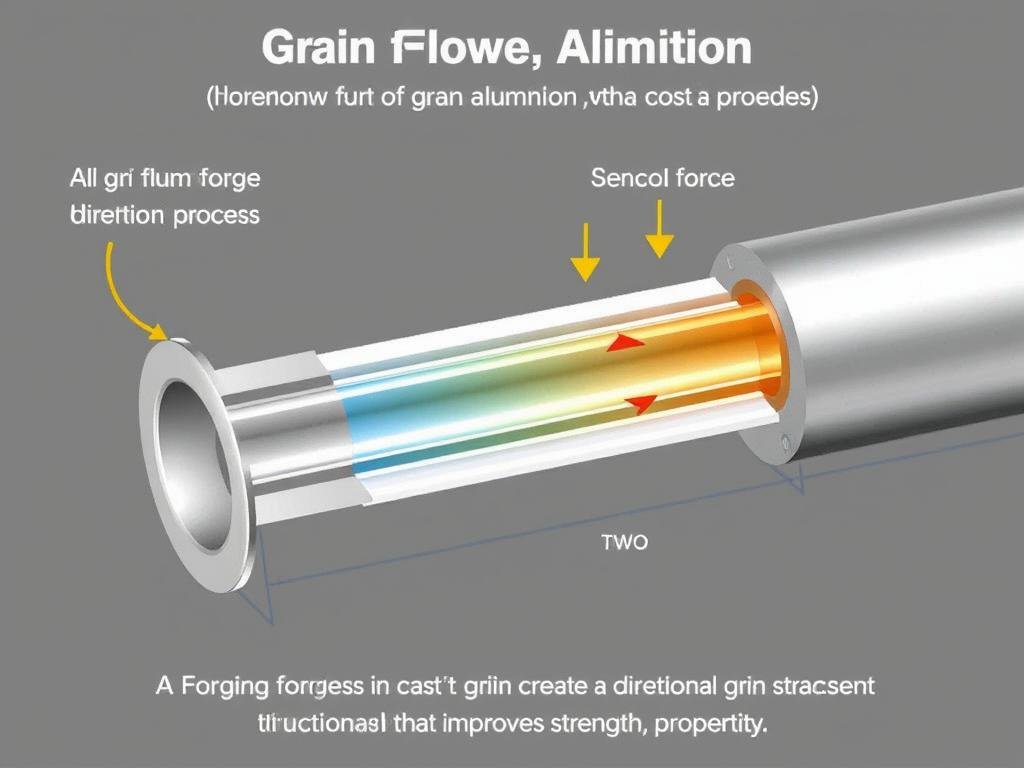

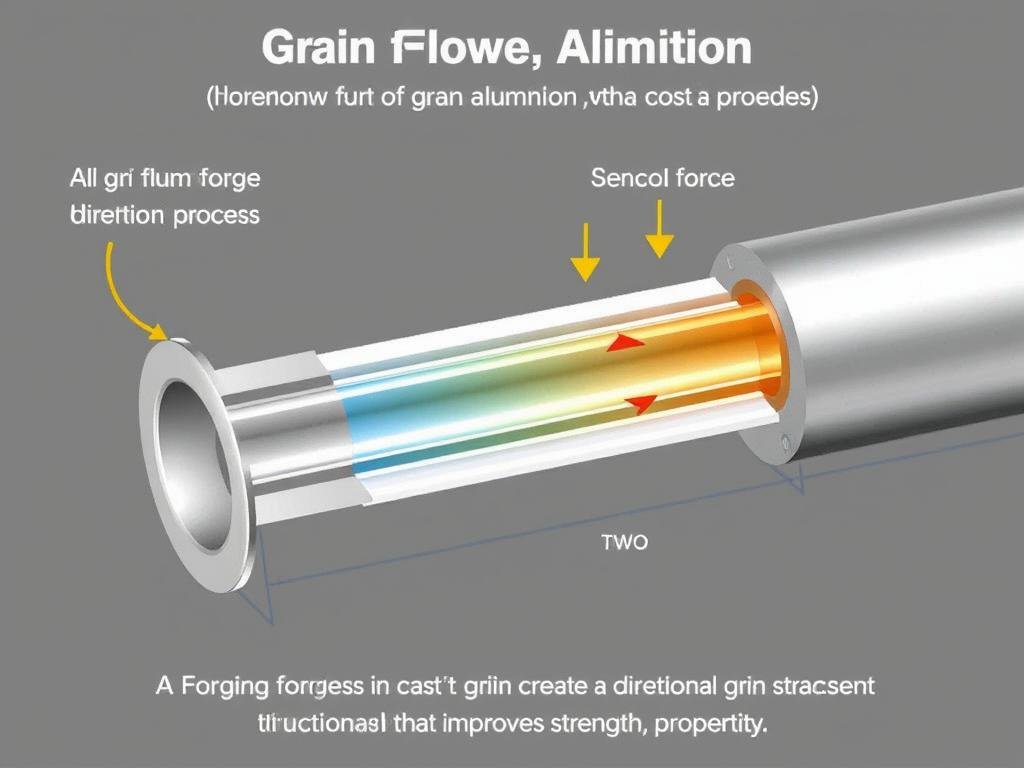

Aluminum forgings offer exceptional advantages for critical applications where performance, reliability, and weight savings are paramount. Our precision forging process aligns the grain structure of aluminum to maximize mechanical properties while maintaining lightweight characteristics.

- Exceptional strength-to-weight ratio

- Superior corrosion resistance

- Enhanced fatigue resistance

- Excellent thermal conductivity

- Improved dimensional stability

- 100% recyclable material

Through controlled deformation and precise grain flow, our forging process maximizes impact toughness, fracture resistance, and fatigue strength while ensuring consistent performance across all aluminum forgings.

Through controlled deformation and precise grain flow, our forging process maximizes impact toughness, fracture resistance, and fatigue strength while ensuring consistent performance across all aluminum forgings.

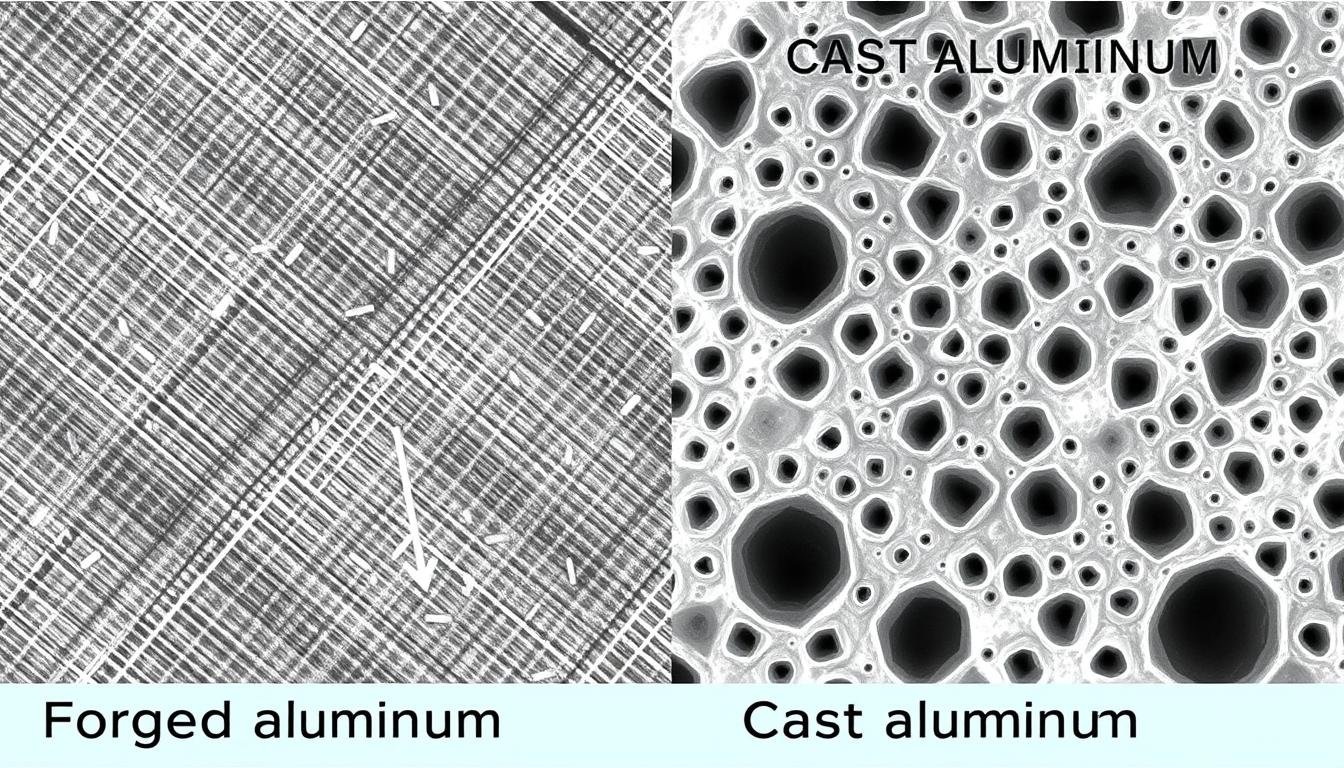

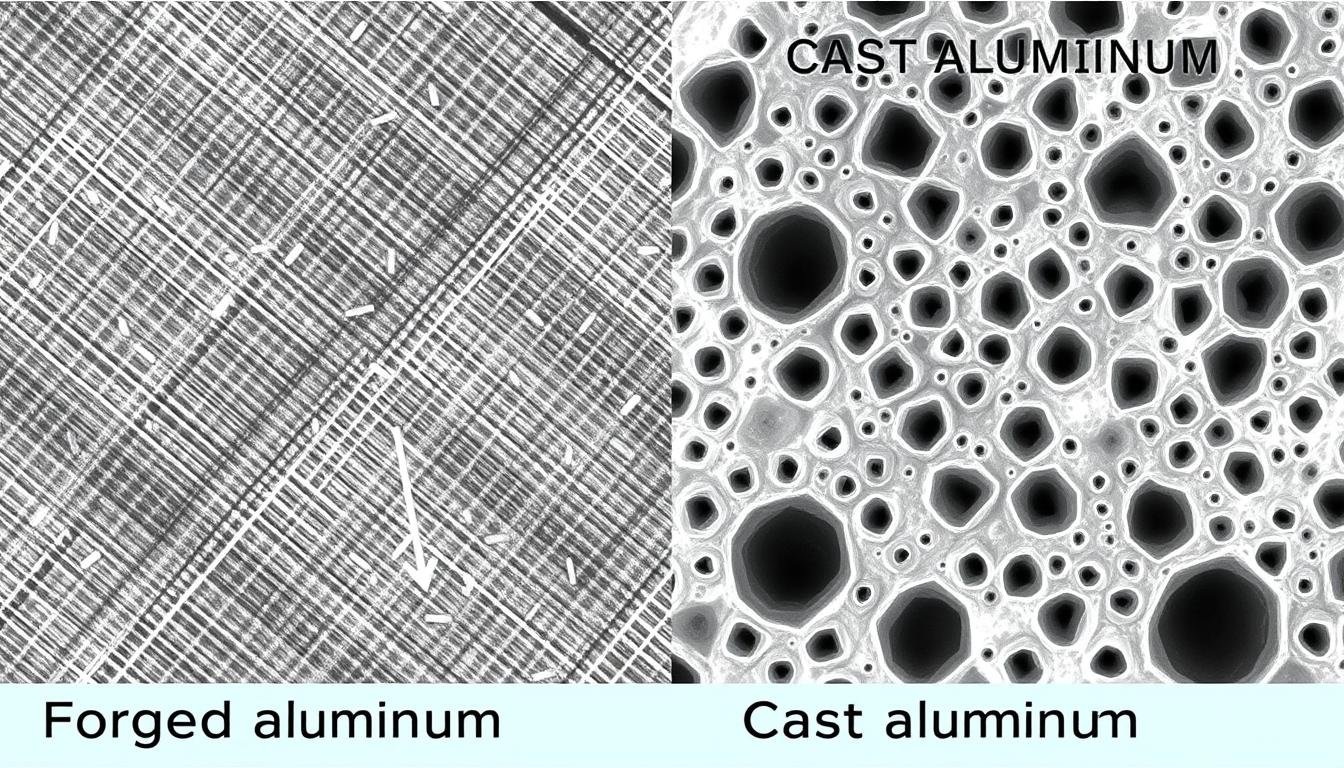

Aluminum Forging vs. Casting: The MAIKONG Advantage

Understanding the differences between forged and cast aluminum is crucial when selecting the optimal manufacturing process for your components. As experienced aluminum forgings manufacturers, we provide this comprehensive comparison to help you make informed decisions:

| Comparison Criteria |

Aluminum Forging |

Casting Aluminum |

| Strength & Durability |

Superior strength due to dense, uniform grain structure |

Lower strength with potential air pockets and inclusions |

| Tensile Properties |

Excellent tensile strength and resistance |

Reduced tensile properties |

| Fatigue Resistance |

Enhanced resistance against cyclic loading |

Lower fatigue resistance |

| Dimensional Accuracy |

Excellent accuracy with tight tolerances |

Potential inconsistencies and shrinkage |

| Surface Finish |

Smoother surfaces with minimal post-processing |

Requires more machining due to porosity |

| Weight-to-Strength Ratio |

Optimized strength-to-weight ratio |

Requires bulkier parts for equivalent strength |

| Ideal Applications |

Critical load-bearing components in aerospace, automotive, marine |

Less demanding applications, complex geometries |

Discover the MAIKONG Forging Advantage

Let our engineers help you determine the optimal manufacturing process for your specific application.

Email Our Engineering Team

Comprehensive Manufacturing Capabilities

As leading aluminum forgings manufacturers, MAIKONG offers a complete range of services from initial design to finished components. Our integrated manufacturing approach ensures quality control at every stage of production.

CAD/CAM Design

Our engineering team utilizes advanced simulation software for early-stage issue identification and optimization. We collaborate closely with clients to refine designs for optimal forging performance.

Precision Forging

Our forging workshop features hydraulic presses ranging from 800 to 3,000 tons, accommodating diverse aluminum forging specifications with exceptional precision and consistency.

Heat Treatment

In-house heat treatment facilities with comprehensive statistical analysis and documentation ensure optimal mechanical properties for every aluminum forging we produce.

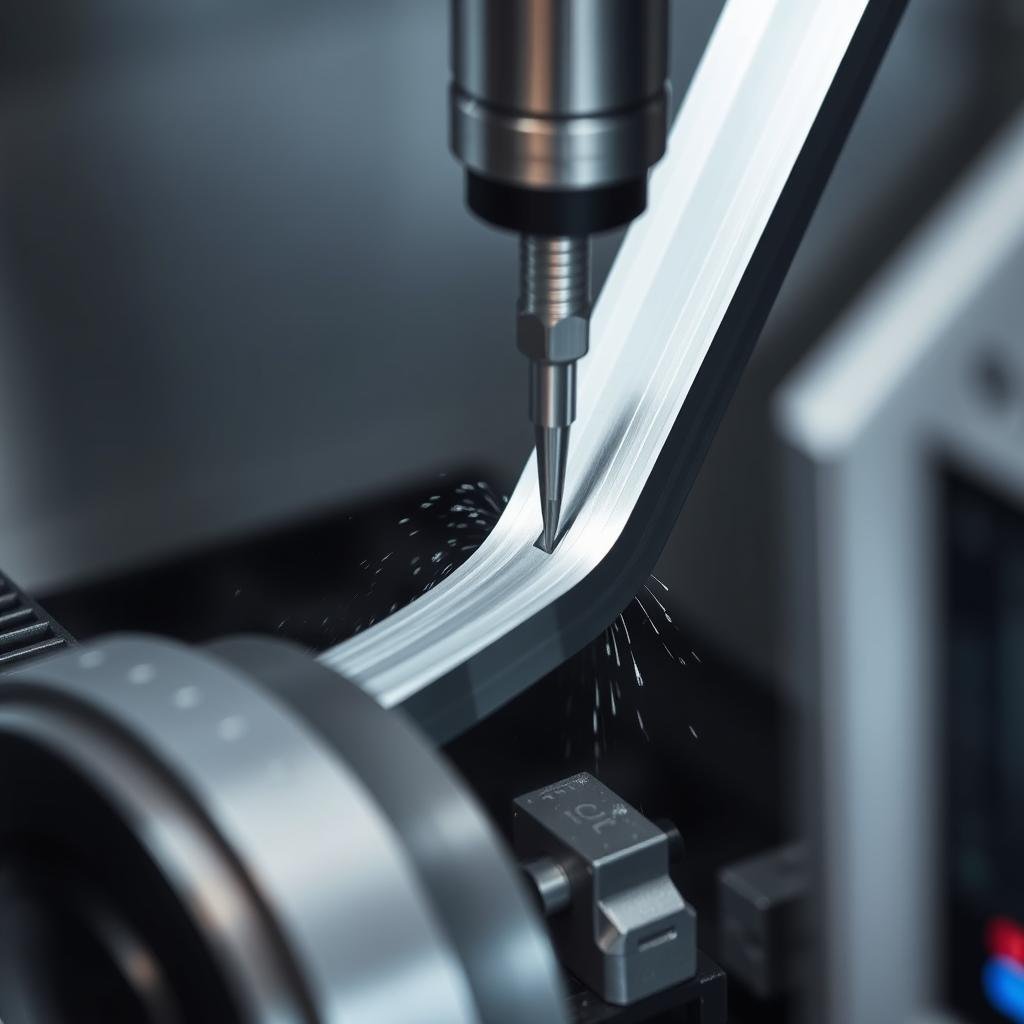

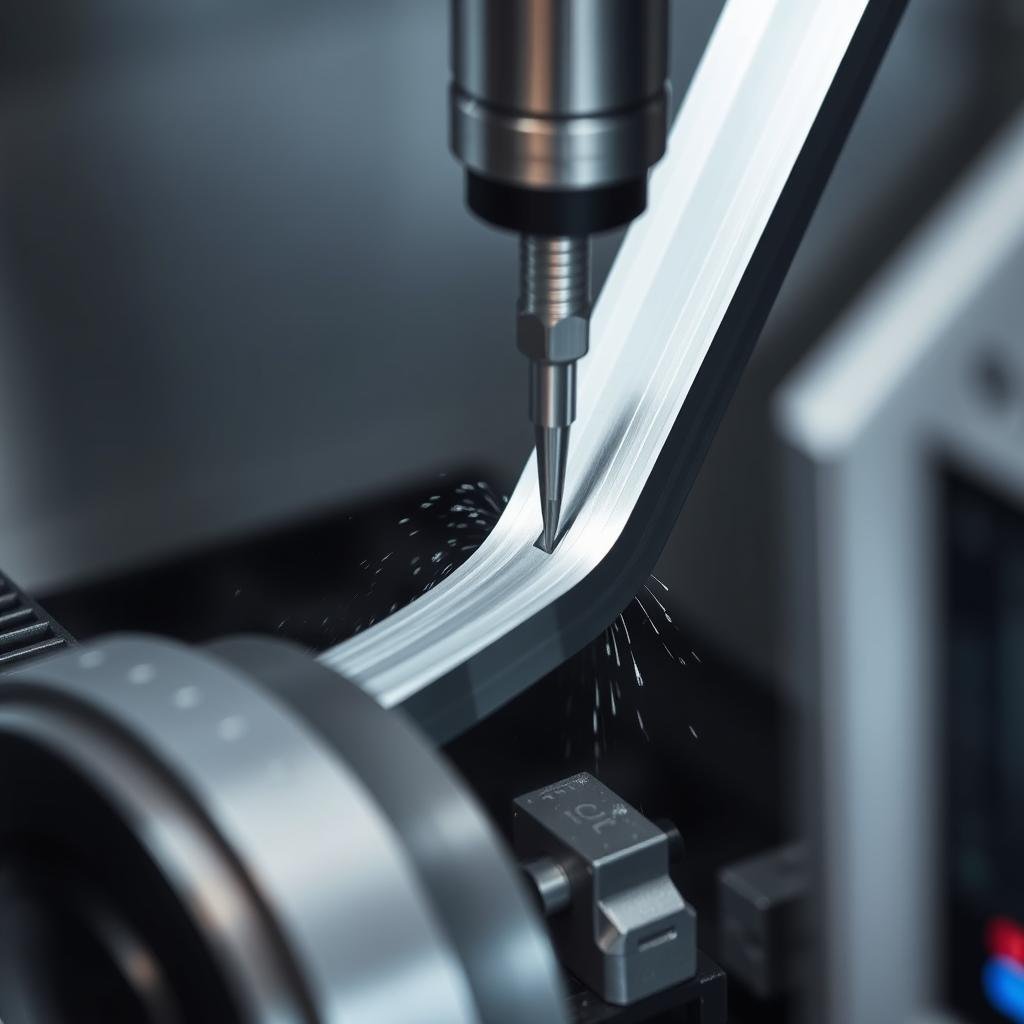

CNC Machining

Our state-of-the-art CNC machining center features 60+ machines providing 100+ tons of monthly processing capacity for precision turning, milling, and multi-axis machining.

Surface Treatment

Comprehensive surface finishing capabilities including anodizing, painting, laser engraving, and sand blasting with rigorous quality control for aesthetic and functional excellence.

Quality Assurance

Rigorous quality control procedures with advanced testing equipment ensure all forged components meet stringent standards and specifications for critical applications.

Aluminum Alloys for Superior Forgings

At MAIKONG, we work with a comprehensive range of aluminum alloys to meet diverse application requirements. Our metallurgical expertise ensures optimal material selection for your specific performance needs.

| Alloy |

Key Properties |

Ideal Applications |

| 2014 |

High strength, good machinability |

Aircraft structures, military components |

| 2024 |

Excellent fatigue resistance, high strength |

Aerospace structural components, aircraft fittings |

| 6061 |

Good corrosion resistance, weldability |

Marine hardware, automotive parts, structural components |

| 7050 |

Superior strength, stress corrosion resistance |

Aircraft bulkheads, aerospace structural parts |

| 7075 |

Highest strength-to-weight ratio |

Aircraft structures, defense applications |

Industry Applications for Aluminum Forgings

MAIKONG’s precision aluminum forgings deliver exceptional performance across multiple industries where reliability, weight savings, and durability are critical requirements.

Aerospace & Defense

- Structural components for aircraft frames

- Landing gear components

- Engine mounts and brackets

- Missile components and defense systems

Automotive & Transportation

- Control arms and suspension components

- Steering knuckles and wheel hubs

- Transmission housings

- Brake calipers and pistons

Marine & Offshore

- Propeller components and shafts

- Marine hardware and fittings

- Offshore platform components

- Corrosion-resistant structural parts

Industrial & Energy

- Valve bodies and pressure vessels

- Turbine and compressor components

- Renewable energy system parts

- Heavy machinery components

Need Custom Aluminum Forgings for Your Industry?

Our engineering team specializes in developing application-specific solutions for challenging environments.

Discuss Your Requirements

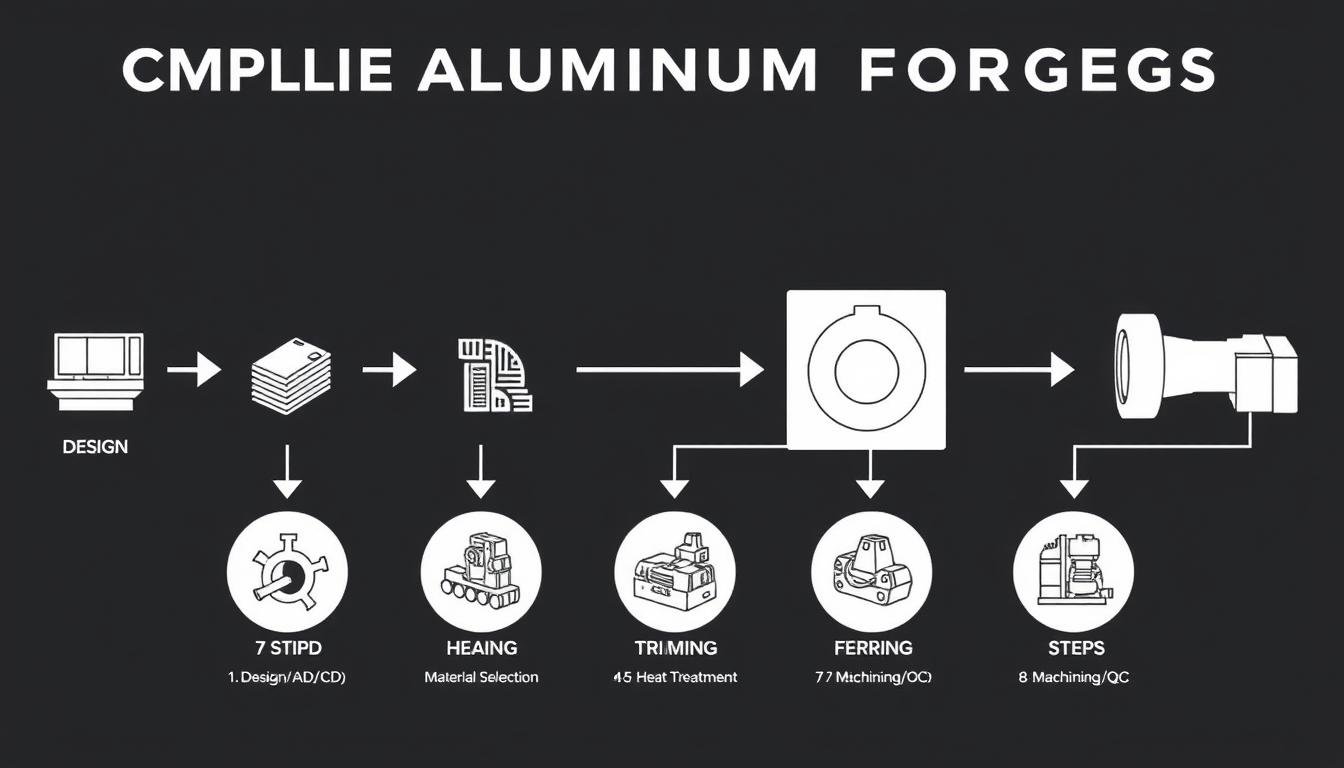

The MAIKONG Aluminum Forging Process

As experienced aluminum forgings manufacturers, we follow a rigorous process to ensure exceptional quality and consistency in every component we produce.

- Design & Engineering – Collaborative design optimization using advanced CAD/CAM tools

- Material Selection – Choosing the optimal aluminum alloy based on application requirements

- Tooling Development – Precision die design and fabrication for consistent results

- Heating – Controlled heating of aluminum billets to optimal forging temperature

- Forging – Precision shaping using hydraulic presses with controlled pressure and speed

- Trimming – Removal of excess material and flash for dimensional accuracy

- Heat Treatment – Enhancing mechanical properties through controlled thermal processing

- Machining – Precision CNC operations to achieve final dimensions and features

- Surface Treatment – Application of protective and decorative finishes as required

- Quality Inspection – Comprehensive testing and verification of specifications

Quality Assurance & Certifications

At MAIKONG, quality is embedded in every aspect of our manufacturing process. Our commitment to excellence is backed by rigorous quality control procedures and international certifications.

Our Quality Commitments

- ISO 9001:2015 certified quality management system

- Comprehensive material testing and verification

- Advanced inspection equipment including CMM and spectrometry

- 100% traceability from raw material to finished product

- Detailed documentation and quality reporting

Our in-house testing capabilities include chemical composition analysis, mechanical property testing, non-destructive examination, and dimensional verification to ensure every component meets or exceeds specifications.

Our in-house testing capabilities include chemical composition analysis, mechanical property testing, non-destructive examination, and dimensional verification to ensure every component meets or exceeds specifications.

Why Choose MAIKONG as Your Aluminum Forging Partner?

The MAIKONG Advantage

- 15+ years of specialized experience in aluminum forging

- Comprehensive in-house capabilities from design to finishing

- State-of-the-art equipment and technology

- Rigorous quality control and international certifications

- Competitive pricing with exceptional value

- Responsive customer service and technical support

- Global shipping capabilities with logistics expertise

- Commitment to continuous improvement and innovation

“As both producers and consumers of our customers’ products, we recognize the crucial importance of consistency, strength, and weight in each forged part. Our dedicated focus on crafting superior aluminum forgings ensures we meet your exact requirements for heat treating, machining, and testing.”

– MAIKONG Engineering Team

Become a MAIKONG Distributor in the United States

MAIKONG is actively seeking distribution partners across the United States to represent our premium aluminum forging capabilities. As a MAIKONG distributor, you’ll gain access to competitive pricing, superior quality products, and comprehensive technical support.

Distributor Benefits

- Exclusive territory rights

- Competitive pricing structure

- Technical training and support

- Marketing materials and assistance

- Rapid response to inquiries

- Custom sample development

Interested in Distribution Opportunities?

Contact our partnership team to discuss how we can grow together in the US market.

Become a Distributor

Our engineering team is ready to discuss your project requirements and provide competitive pricing.

Our engineering team is ready to discuss your project requirements and provide competitive pricing. Through controlled deformation and precise grain flow, our forging process maximizes impact toughness, fracture resistance, and fatigue strength while ensuring consistent performance across all aluminum forgings.

Through controlled deformation and precise grain flow, our forging process maximizes impact toughness, fracture resistance, and fatigue strength while ensuring consistent performance across all aluminum forgings.

Our in-house testing capabilities include chemical composition analysis, mechanical property testing, non-destructive examination, and dimensional verification to ensure every component meets or exceeds specifications.

Our in-house testing capabilities include chemical composition analysis, mechanical property testing, non-destructive examination, and dimensional verification to ensure every component meets or exceeds specifications.